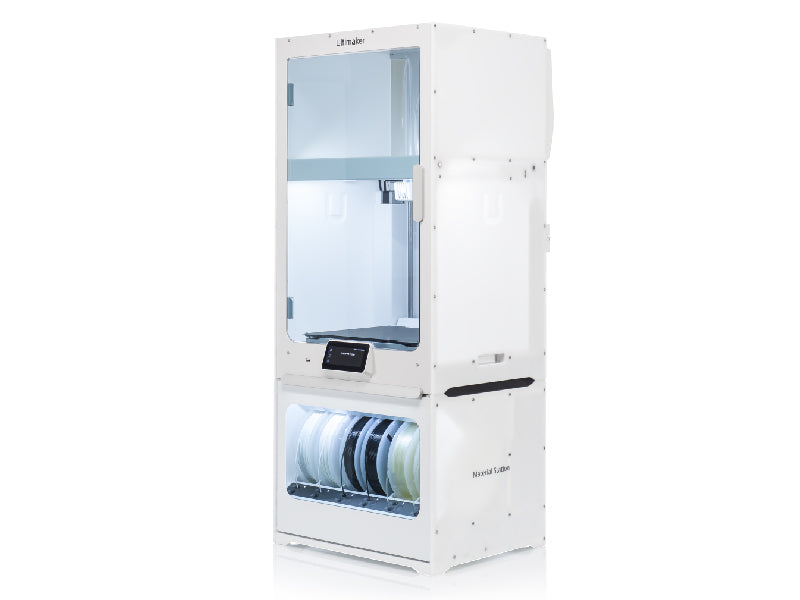

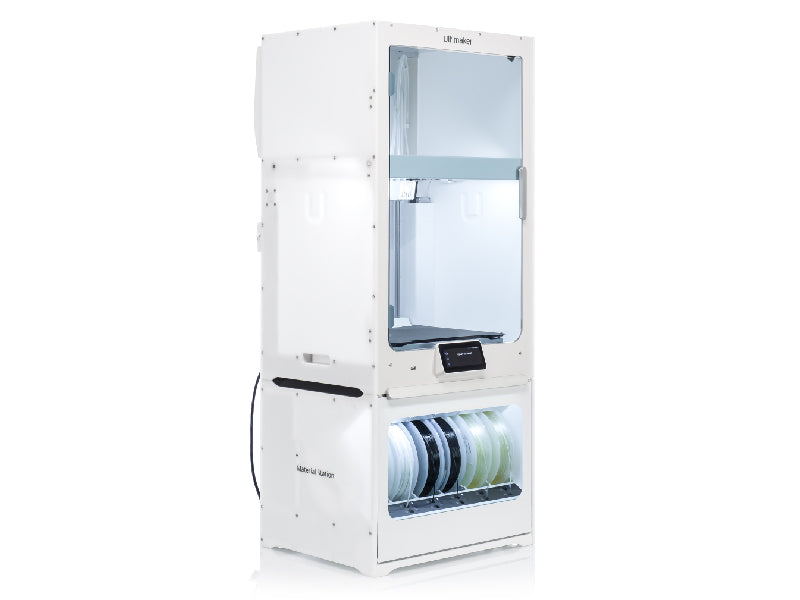

UltiMaker S7 Pro Bundle Full-Featured 3D Printer

Ultimaker | Product Model:

UM234154PB0

アドオンを選択

Couldn't load pickup availability

UltiMaker S7 Pro Bundle Full-Featured 3D Printer

The S7 incorporates everything customers love about the award-winning UltiMaker S5, and improves upon it. The S7 is packed with our latest technology, making it easier than ever to 3D print high-quality parts.

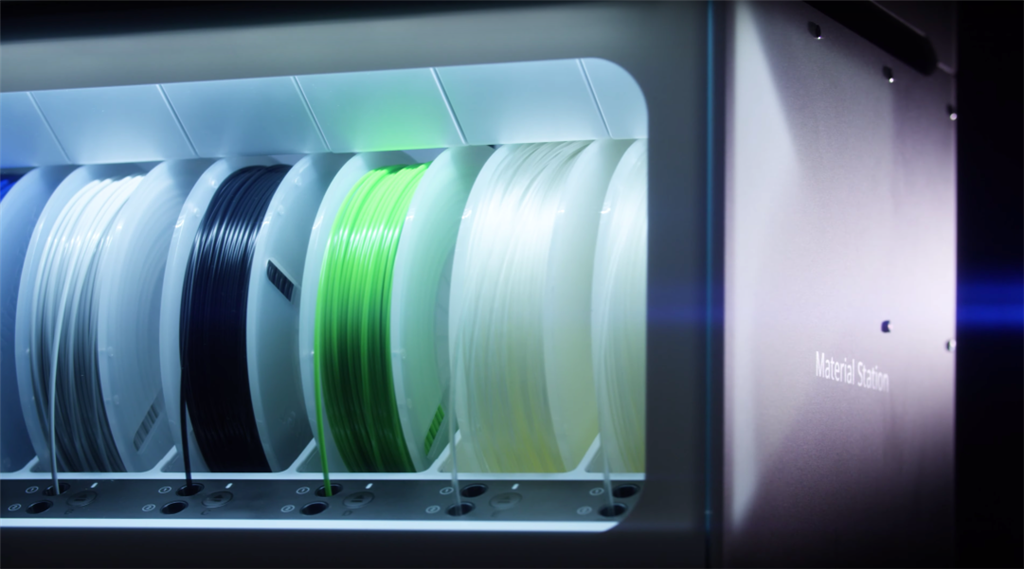

Material Station (Intelligent Material Feeding Station)

The Material Station intelligent feeder has six spool racks, providing greater 3D printing capacity and flexible configuration options. For example, 3D printed items that will be printed for more than three days no longer require manual spool changing or individual configuration. Each spool rack is equipped with an NFC sensor, compatible with Ultimaker filaments (excluding the 350g special specification) and " Ultimaker Material Consortium" filaments available from Cura Marketplace, enabling a wide range of industrial applications, such as glass fiber, carbon fiber composites, or other similar 2.85 mm third-party spools.

Automatic line changing

The Material Station intelligent feed station of Ultimaker S5 & Ultimaker S7 has been tested and can perform line changing before, after, and even during 3D printing operations. Each spool is equipped with a line detection function, which automatically switches to the next matching material when a spool of wire runs out, and the internal branching feed tubes can automatically prevent the wire from tangling.

Moisture-proof wire

The Ultimaker S5 and Ultimaker S7 intelligent feeding stations simultaneously solve common problems related to moisture and dust. Through their internal dehumidification system, even in environments with 70% humidity, the relative humidity inside the dehumidification cabinet can be reduced to 40%. By eliminating the problem of moisture, the filament molecules will no longer degrade or swell due to absorbing moisture, thus extending the 3D printing time and shelf life.

Product Features

• Quick installation: It only takes a few seconds to insert the cable into the front tray and it is ready to use. Up to six rolls of cable can be inserted at a time.

• Continuous printing: The thread runout detection system automatically replaces other reels when the thread runs out, allowing printing to continue and saving valuable time.

Humidity control: The intelligent system will maintain the humidity inside the box at approximately 40% or less.

• Easy setup: Featuring an NFC material recognition system that is perfectly compatible with Ultimaker , it can be operated synchronously using the Ultimaker S5 touchscreen.

Composite materials: Dual wear-resistant feed gears can be 3D printed with high-strength and special-property wires (such as carbon fiber composites).

• Flexible application: Supports both original and external 3D printing cables.

The S7 incorporates everything customers love about the award-winning UltiMaker S5, and improves upon it. The S7 is packed with our latest technology, making it easier than ever to 3D print high-quality parts.

Print easily, breathe comfortably

The integrated air manager is independently tested and removes up to 95% of ultrafine particles* from every print. Not only does it improve air quality for your peace of mind... but the fully enclosed compartment and single glass door also enhance print quality.

*Tested by Fraunhofer WKI. Includes only UltiMaker materials.

The integrated air manager is independently tested and removes up to 95% of ultrafine particles* from every print. Not only does it improve air quality for your peace of mind... but the fully enclosed compartment and single glass door also enhance print quality.

*Tested by Fraunhofer WKI. Includes only UltiMaker materials.

Flexible printing base plate

The PEI-coated flexible printing plate allows for easy removal of parts without the need for glue. 25 magnets and 4 locating pins can be easily replaced, reducing the time spent using the UltiMaker S7 and increasing productivity.

The PEI-coated flexible printing plate allows for easy removal of parts without the need for glue. 25 magnets and 4 locating pins can be easily replaced, reducing the time spent using the UltiMaker S7 and increasing productivity.

Induction base plate sensor

The new inductive printhead sensor detects the substrate with lower noise and higher accuracy. Automatic tilt compensation eliminates the need for finger screw bed calibration.

The new inductive printhead sensor detects the substrate with lower noise and higher accuracy. Automatic tilt compensation eliminates the need for finger screw bed calibration.

Adopting the latest technology of S7

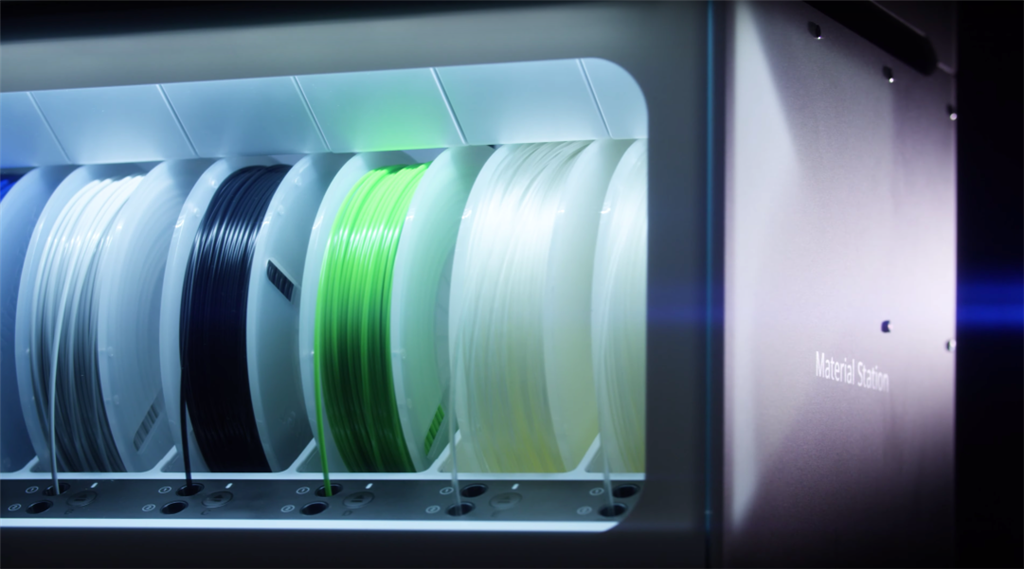

Material Station (Intelligent Material Feeding Station)

The Material Station intelligent feeder has six spool racks, providing greater 3D printing capacity and flexible configuration options. For example, 3D printed items that will be printed for more than three days no longer require manual spool changing or individual configuration. Each spool rack is equipped with an NFC sensor, compatible with Ultimaker filaments (excluding the 350g special specification) and " Ultimaker Material Consortium" filaments available from Cura Marketplace, enabling a wide range of industrial applications, such as glass fiber, carbon fiber composites, or other similar 2.85 mm third-party spools.

Automatic line changing

The Material Station intelligent feed station of Ultimaker S5 & Ultimaker S7 has been tested and can perform line changing before, after, and even during 3D printing operations. Each spool is equipped with a line detection function, which automatically switches to the next matching material when a spool of wire runs out, and the internal branching feed tubes can automatically prevent the wire from tangling.

Moisture-proof wire

The Ultimaker S5 and Ultimaker S7 intelligent feeding stations simultaneously solve common problems related to moisture and dust. Through their internal dehumidification system, even in environments with 70% humidity, the relative humidity inside the dehumidification cabinet can be reduced to 40%. By eliminating the problem of moisture, the filament molecules will no longer degrade or swell due to absorbing moisture, thus extending the 3D printing time and shelf life.

Product Features

• Quick installation: It only takes a few seconds to insert the cable into the front tray and it is ready to use. Up to six rolls of cable can be inserted at a time.

• Continuous printing: The thread runout detection system automatically replaces other reels when the thread runs out, allowing printing to continue and saving valuable time.

Humidity control: The intelligent system will maintain the humidity inside the box at approximately 40% or less.

• Easy setup: Featuring an NFC material recognition system that is perfectly compatible with Ultimaker , it can be operated synchronously using the Ultimaker S5 touchscreen.

Composite materials: Dual wear-resistant feed gears can be 3D printed with high-strength and special-property wires (such as carbon fiber composites).

• Flexible application: Supports both original and external 3D printing cables.

| Printing technology | Thermal fusion lamination (FFF) |

| Print volume | 330 x 240 x 300 mm |

| Machine size | 495 x 585 x 800mm |

| Incoming line method | Twin gear extrusion |

| touchscreen | 4.7-inch (11.9mm) color touchscreen |

| Print core replacement | Replaceable PrintCore |

| Nozzle head | Dual extrusion printheads with an automatic nozzle lifting system, replaceable print core, and overlay printhead malfunction detection. |

| Applicable wire diameter | 2.85 mm |

| Layer resolution | 0.25 mm nozzle: 150 - 60 microns 0.4 mm nozzle: 200 - 20 microns 0.6 mm nozzle: 300 - 20 microns 0.8 mm nozzle: 600 - 20 microns |

| XYZ resolution | 6.9, 6.9, 2.5 micrometers |

| Nozzle diameter | 0.25 mm, 0.4 mm, 0.6 mm, 0.8 mm |

| Filtration technology | Replaceable EPA filter |

| extraction rate | 1 - 50 m³/h (most materials have a nominal flow rate of 35 m³/h at 23 °C) |

| Nozzle temperature | 180 - 280 °C |

| Nozzle heating time | < 2 minutes |

| Operation sound | < 51 decibels |

| Build board leveling | Advanced active leveling with a more accurate inductance sensor |

| base plate | PEI coated flexible steel base plate (20 - 140 °C) |

| Build board heating time | < 5 minutes (from 20 to 60 °C) |

| Operating ambient temperature | 15 - 32 °C |

| Non-operating temperature | 0 - 32 °C |

| Free software to use | UltiMaker Cura – Printing Software UltiMaker Digital Factory – Printer Management Software |

| operating system | MacOS, Windows, and Linux |

| Plugin integration | SolidWorks, Siemens NX, Autodesk Inventor |

| File support types | UltiMaker Cura: STL, OBJ, X3D, 3MF, BMP, GIF, JPG, PNG Printable formats: G, GCODE, GCODE.gz, UFP |

| weight | 29.1 kg |

| Maximum power output | 500W |

| File transmission method | Wi-Fi (2.4 and 5 GHz), Ethernet, USB |