Phrozen Ceramic White Resin Series

Phrozen | Product Model:

アドオンを選択

Couldn't load pickup availability

Phrozen Engineering Rigid Ceramic White Pro Resin (1kg)

Complete Guide to Ceramic White Pro Resin Printing

Wash and air dry

1. Remove any residual resin from the holes.

2. Place the model in a cleaning machine filled with 99% IPA and clean for 30-60 seconds (do not soak in the solvent for more than 60 seconds, as this may damage the surface of the object).

3. After cleaning, the model can be dried with an air gun or by using the fan function of the Prosen curing machine for 10-30 minutes.

*When printing thin parts on the bottom, please carefully remove them, as this may deform the model.

*Please make sure to clean the inside of hollow, thin parts thoroughly.

Light curing <br /> Place the model in the post-curing machine for 120 minutes of post-curing (60 minutes on each side) to ensure the best results.

Thermosetting <br>After photocuring, the model is placed in an oven with precise temperature control and gradient temperature rise (temperature error ±2°C) for thermosetting to improve mechanical properties. Please refer to the following settings:

| Time setting | Temperature setting | |

|---|---|---|

| Initial heating conditions | 2 hours | 30°C – 150°C |

| maintain | 3 hours | 150°C |

| Cooling conditions | 2 hours | 150°C – 30°C |

Phrozen Ceramic White Resin

Phrozen has partnered with BASF Forward AM, a world-leading chemical materials company, to launch the first high-ceramic-content composite resin. This resin achieves ceramic-like wear resistance, appearance, and feel without the need for complex ceramic sintering. It boasts high strength and resistance to deformation; furthermore, its precise detail allows for rapid evaluation of shape and function, optimizing the manufacturing process. It is the ideal choice for prototyping industrial assemblies and creating exquisite handicrafts.

With up to 50% ceramic content, no heat treatment required*; it creates a hard, smooth, matte surface, just like the texture of real ceramic.

Tensile modulus up to 5800 MPa

It exhibits excellent wear resistance and high precision, performing exceptionally well even under external pressure.

Excellent liquidity

With an extremely low viscosity of only 120 mPas, it is easy to print quickly and is also easy to cure afterward.

*It can be heated at 80°C for 24 hours to achieve higher heat resistance.

3D printed samples

.png)

Click to see:

Phrozen Slicing Tutorial

Enjoy the UV curing printing experience offered by Phrozen's various resins now . Customize your selection based on your needs and characteristics to provide the best finished product results, or contact us now for more information.

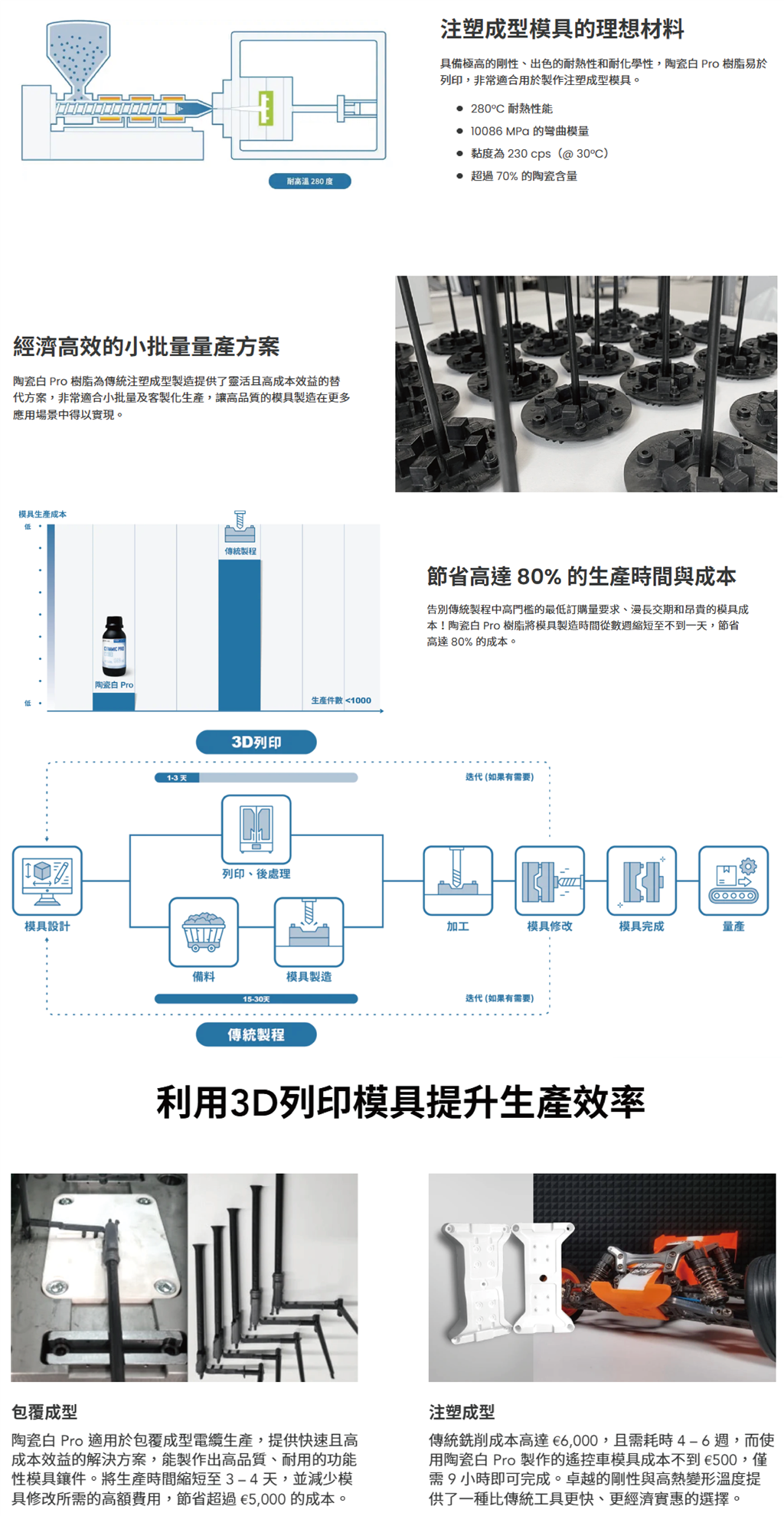

Phrozen Engineering Rigid Ceramic White Pro Resin

| capacity | 500ml/1 L |

| density | 1.65 g/cm³ |

| viscosity | 230 cP |

| hardness | 96 D |

| Tensile strength at break | 83.8 MPa |

| Tensile modulus at break | 8380 MPa |

| Elongation at break | 1.00% |

| Bending strength | 129.8 MPa |

| Flexural modulus | 10860 MPa |

| Impact strength of cantilever beam (notch) | 18.1 J/m |

| Heat distortion temperature (0.45 MPa) | 280 °C (thermosetting) |

Phrozen Ceramic White Resin (500ml)

| density | 1.45 g/cm3 |

| viscosity | 120 cP |

| Surface hardness | >90 Shore D |

| Tensile modulus | 5800MPa |

| Tensile strength at break | 62 MPa |

| Elongation at break | 2% |

| Bending Modulus | 5400 MPa |

| Bending strength | 90 MPa |

| Impact strength of cantilever beam (notch) | 26.00 J/m |

| Izod unnotched impact strength | 90 J/m |

| Heat distortion temperature (0.45 MPa) | 67 °C |

| Heat distortion temperature (1.82 MPa) | 58 °C |

Precautions <br /> Please use and store this resin in a cool, dark, and well-ventilated place.

Shake the resin well before use.

Recommended cleaning method: Clean with alcohol spray and dry with an air gun. If soaking in alcohol, do not soak for more than 30 seconds. Store used resin in an opaque bottle or jar and avoid mixing with new material.

Please keep this material out of reach of infants and young children and avoid direct sunlight.

Wear gloves and a mask when handling. If the resin comes into contact with skin or eyes, rinse immediately with plenty of water.

Do not dump this material arbitrarily. If you need to discard it, please solidify the material completely and recycle the solids as "general resources".

Once opened, the resin has a shelf life of one year; please use it up as soon as possible.