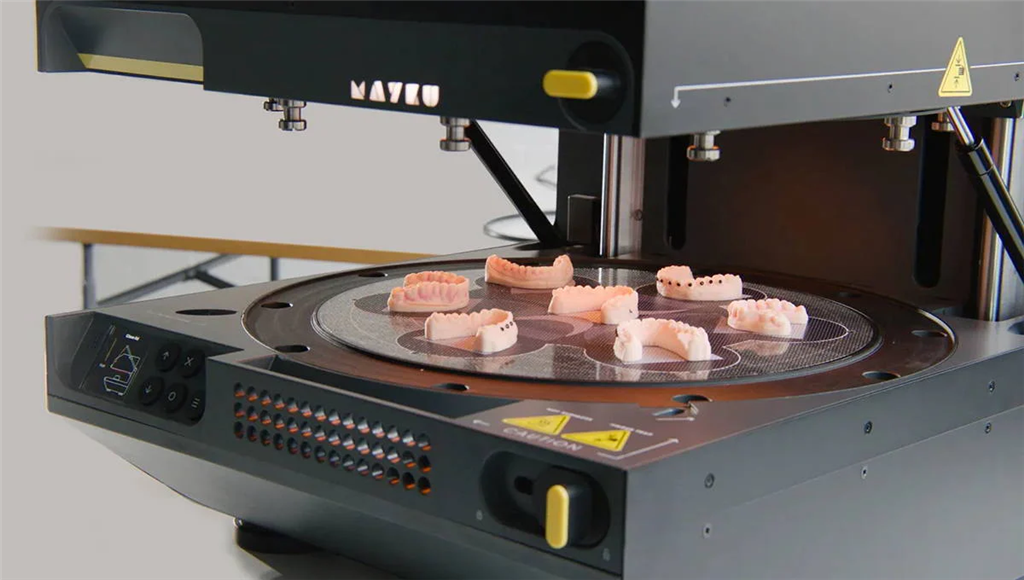

[Pressure Molding] Why do you need a Mayku Multiplier if you work in the dental field? Speed up your workflow!

With the continuous advancement of modern technology, the dental industry is also developing rapidly. You, the reader of this article, are probably wondering what a pressure molding machine is, what it can do, and so on. This article will explain the principles of pressure molding: vacuum molding vs. pressure molding, and what the differences are! We'll tell you all at once! This article will also introduce how this machine accelerates the production of dental molds and yields high-quality molds! The Mayku Multiplier is a benchtop large-scale pressure molding machine that can significantly improve the productivity and product quality of dental clinics . Below, we will explore why dental professionals should own a Mayku Multiplier !

|

|

|

||

| Save time | Consistent effect | Your favorite materials | ||

| Multipliers have a large molding area, which increases production capacity, freeing up time to focus on new revenue streams and business expansion. | The built-in automatic leveling system ensures uniform heating of materials, thereby improving the consistency and accuracy of each batch of products. | Mayku's modular reducing plates and customizable material profiles allow you to use any thermoforming material you prefer. | ||

|

|

|

||

| Flexible scalability | Easy to operate | Super reliable | ||

| Modular reducing plates, a variety of materials, and rock-solid long-term performance enable you to adapt to growing customer needs without worrying about machine downtime. | Multiplier is designed and tested to be usable by virtually anyone, allowing technicians of any skill level to achieve high-quality results while minimizing training requirements and human error. | The Multiplier is designed to meet the requirements of continuous industrial use, ensuring that the laboratory can keep up with demand without worrying about the risk of machine downtime. |

👉Related Article: Creating a Custom Precision Model! A Complete Unboxing Guide to the Mayku Multiplier!

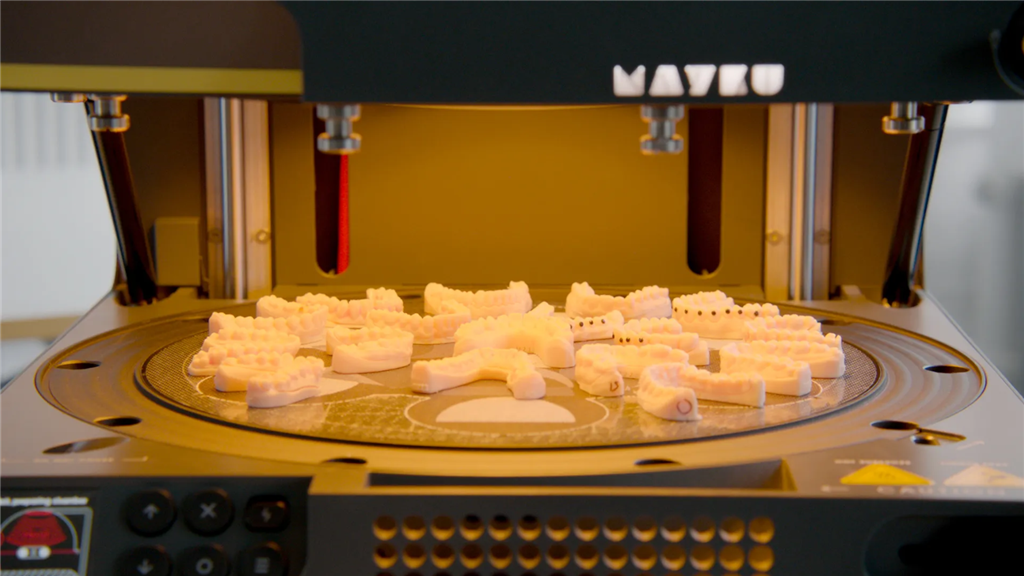

High output ? No speed restrictions!

Traditional dental device manufacturing often requires outsourcing, which is time-consuming and costly. The Mayku Multiplier, however, allows for rapid in-clinic fabrication of necessary equipment, reducing waiting time and outsourcing expenses . Its large molding area and high throughput allow for the production of up to 19 instruments per cycle using 428 mm round blanks, and up to 7 instruments per cycle using 7-cycle thinning plates and 120 mm or 125 mm round blanks, significantly accelerating production speed.

Avoid sagging

Built-in automatic leveling system and temperature sensors ensure precise and uniform heating of raw materials every time. This eliminates sagging, thereby reducing thinning, ensuring material stability during heating, preventing deformation or stretching , and improving component definition and quality.

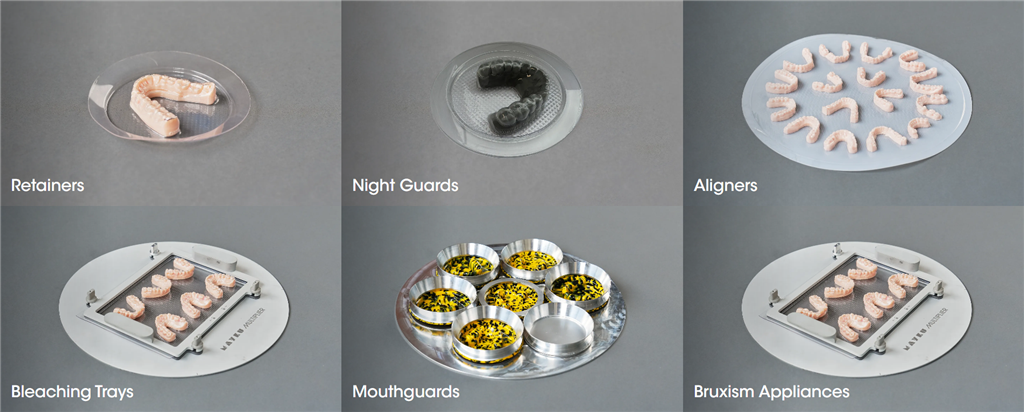

This is a world of materials!

The Mayku Multiplier supports a variety of industry-standard materials and, when used with reducing plate fittings, can handle thermoformed materials of all standard sizes. It can easily handle 120mm, 125mm, and 428mm round blanks, as well as A4 dental thermoformed blanks, with thicknesses ranging from 0.1mm to 5mm, suitable for a wide range of dental applications such as orthodontics, prosthodontics, and surgical models .

Unique configuration files with unlimited customization

Pre-installed material settings, along with the ability to add, edit, and customize materials to meet your needs—once the profile is set up, you can replay with a single click for consistent, reliable results every batch. The Mayku Multiplier features a user-friendly interface designed for ease of use, with on-screen instructions guiding you through each step, making the machine suitable for users of all skill levels.

Updatable firmware

Connecting the machine to Wi-Fi allows for wireless firmware updates, access to the latest material profiles and new machine features, keeping you at your best at all times.

Internal compressor

No external air supply is required; the Multiplier comes with a built-in compressor (and outlet) to ensure completely clean air is available anywhere.

Make your workspace more effective!

Multipliers offer a large molding area and achieve micron-level precision, ensuring that every manufactured component meets your specifications. This is especially important for the fabrication of dental devices such as temporary crowns, models, and orthodontic appliances, enabling robust, isotropic components without layers or hierarchies .

— Finished dental mold —

In summary, the Mayku Multiplier is a significant innovation in the dental industry, improving clinic productivity, reducing costs, and enhancing the patient experience. Owning such a device will give your clinic a competitive edge in a highly competitive market, making it a worthwhile investment.

👉Related Article: How Oertli, a medical device company, created medical packaging prototypes using pressure molding in 24 hours

Want to learn more about Mayku products? Click "Contact Us" below!

-Contact Us-

SanDiMa offers more than just pressure molding ; we provide three major OEM services: " 3D Printing ," " 3D Scanning ," and " Spatial 3D Scanning ."

Follow our fan page and stay up-to-date with the latest news:

Facebook | Instagram | LinkedIn

References