[Vacuum Forming Application] Create your own custom chocolate iceberg mold! A chocolate master teaches you how!

Paul A. Young is an award-winning chocolatier who advocates for craftsmanship and unique creativity in producing distinctive chocolate products. He and his team use fresh ingredients and custom molds to handcraft small-batch productions. They collaborated with the Mayku Multiplier vacuum forming machine to create a unique iceberg-shaped dessert. Let's see how it was made!

Unique global design, locally manufactured

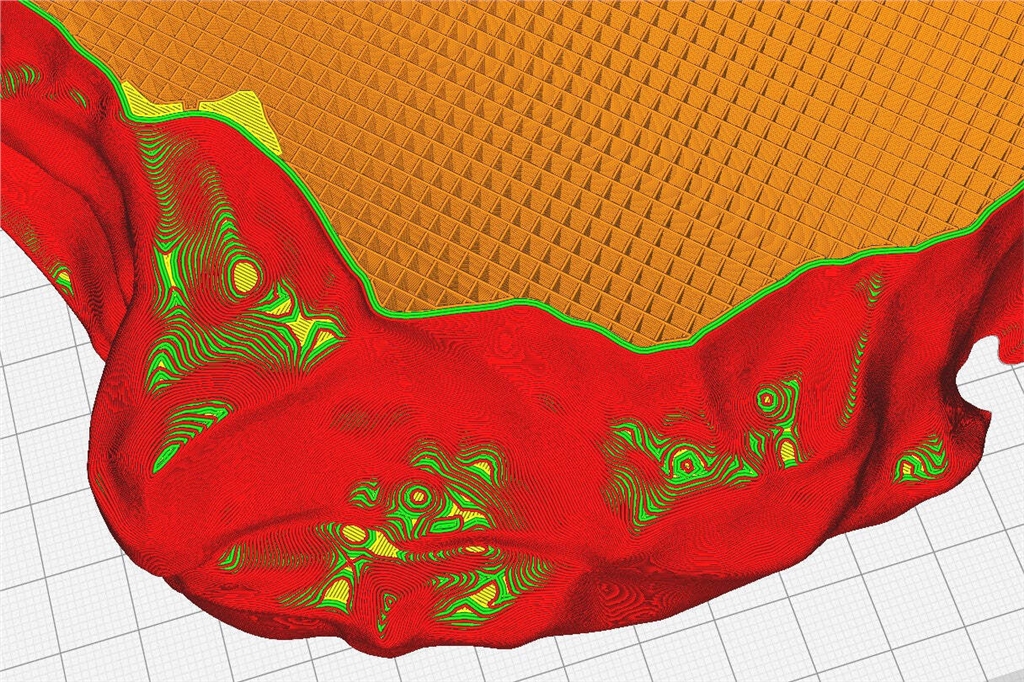

The unique creative ideas and cross-industry collaboration were very challenging, and traditional clay manufacturing testing processes were not feasible because all design processes had to be conducted remotely. Sending handmade images via email was not very efficient. Therefore, a digital manufacturing approach was ultimately adopted to accelerate the production process. 3D modeling software was used to design models of icebergs and igloos. This process allowed for rapid testing and immediate feedback. Different forms of icebergs were designed during the process, and changes in shape, surface texture, size, and so on were tested.

Creating chocolate art using the latest manufacturing technology

Each digital manufacturing method offers a different surface finish. While a smooth finish is typically required when making chocolate molds, Paul decided to go against the grain and opt for a textured final look. The iceberg model was created using an Ultimaker FDM 3D printer . This technology allows for rapid prototyping, but FDM-printed objects have a unique layered texture.

While creating the prototype, Paul noticed how well the texture produced by the mold matched the model, so he decided to use an FDM 3D printer to create the final template. The main changes from the prototype template to the final version were increasing the wall thickness and infill density to make its structure more complete and ensure that it could be used to make several molds.

The iceberg model was created using FDM 3D printing , but the igloo template was made using a different technique. Due to the reduced size of the objects and the need to obtain more surface detail, SLA photopolymerization 3D printing was used.

Use 3D printing and vacuum forming machines to press and create molds.

After several tests, a satisfactory template was finally obtained and ready for final production. A high-quality template was created, and multiple molds were used in the production of icebergs and igloos.

Use 3D printing and vacuum forming machines to press and create molds.

After several tests, a satisfactory template was finally obtained and ready for final production. A high-quality template was created, and multiple molds were used in the production of icebergs and igloos.

Both designs feature vertical walls and bottom cuts, characteristics that typically conflict with vacuum forming principles. However, Mayku's new Flexible Sheets allow you to create high-quality, reusable molds using this material. When making molds with the Mayku Multiplier vacuum compression forming machine , you only need to produce the required number of molds. There's no need to worry about minimum order quantities or over-purchasing specialty sheets.

How to make custom chocolates using the Mayku Multiplier vacuum compression molding machine

Once the template is made, it's ready to use immediately! Unlike outsourced production or silicone mold making, which takes time. Paul filled the igloo template with chocolate, creating a candy-like effect, and placed it on top of the iceberg.

Once the template is made, it's ready to use immediately! Unlike outsourced production or silicone mold making, which takes time. Paul filled the igloo template with chocolate, creating a candy-like effect, and placed it on top of the iceberg.

On the other hand, the iceberg design is incredibly ambitious. Paul filled the mold with tempered chocolate, removed the excess, creating a fillable iceberg shell, and then filled it with different layers of sorbet, sponge cake, and more chocolate. Once all the components were assembled, the iceberg was ready to be unmolded! The properly tempered chocolate shrinks as it solidifies, meaning that using Mayku 's elastic material sheets makes unmolding even easier and faster.

How to customize templates and save time and costs using a vacuum forming machine

Custom-made chocolates typically require significant time and resources from customers. Traditional mold development is slow and costly, increasing expenses and reducing profits. Traditional chocolate molds can take weeks to create, but the Mayku Multiplier vacuum pressure molding machine allows you to complete the process in just a few days, unleashing your creativity and enabling rapid adjustments!

We often underestimate the costs of communicating back and forth with mold manufacturers. The Mayku Multiplier vacuum compression molding machine allows you to create your own molds without minimum order quantities! Creativity is no longer limited!

Did you enjoy this sharing session? Use the Mayku Multiplier vacuum forming machine in your work and life to create a unique style! Breaking away from traditional manufacturing concepts, 3D printing offers more than just 3D printing . Contact us today to learn more about vacuum forming applications.

Follow our fan page to stay up-to-date with the latest news: https://www.facebook.com/3dmart.com.tw/

https://www.instagram.com/3dmart/

References