[Waterjet Cutting] WAZER combines with DIWire to design metal prototypes, pioneering diverse applications!

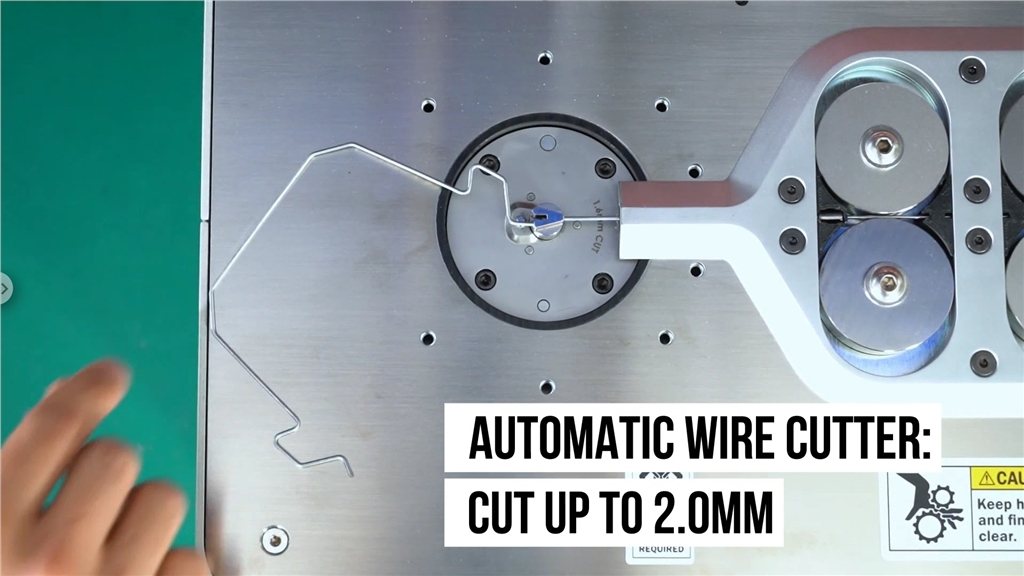

Pensa Labs has partnered with WAZER to demonstrate the combination of two metalworking tools. Through DIWire Pro wire bending and WAZER waterjet sheet metal cutting, high-quality and practical 3D metal designs can be quickly achieved.

Both the DIWire Pro and WAZER waterjet cutting machines utilize CNC technology , enabling users to create parts durable enough for functional prototyping or final production. Both machines can handle a wide variety of materials and are simple, quick, and provide a good user experience.

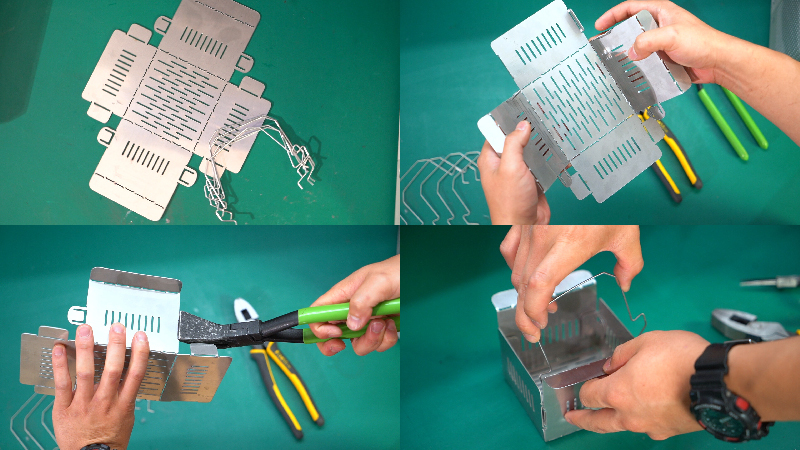

Outsourcing metal prototyping is expensive and time-consuming. By integrating DIWire Pro and WAZER internally, part developers can repeatedly test and design prototypes using the final materials, and continue to use the equipment for small-batch production. This shortens development time and brings prototype parts to market faster.

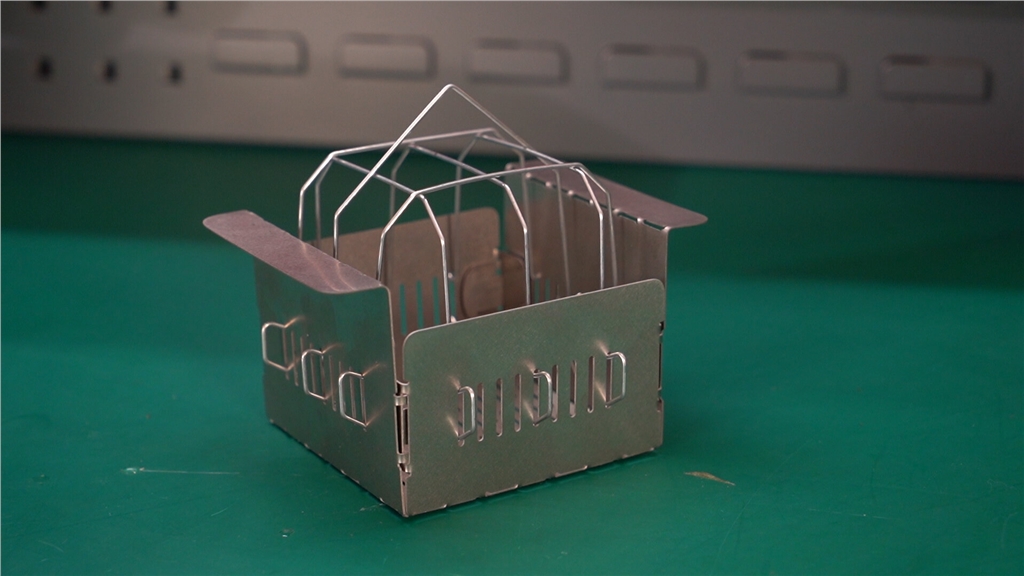

WAZER uses metal wire and sheet metal to design a movable cage that can accommodate the components of an ultrasonic cleaner. The main body is made of stainless steel, which is resilient to most chemicals placed in the tank, so there is no need to worry about corrosion or oxidation over time. This allows for rapid design and manufacturing, providing laboratories with stable development technology and saving time.

Did you enjoy this sharing? 3D printers offer more than just 3D printing . Contact us now to learn more about our 3D printers and 3D scanners .

Follow our fan page to stay up-to-date with the latest news: https://www.facebook.com/3dmart.com.tw/

https://www.instagram.com/3dmart/

References

Follow our fan page to stay up-to-date with the latest news: https://www.facebook.com/3dmart.com.tw/

https://www.instagram.com/3dmart/

References