[New Product Launch] UltiMaker introduces its new flagship S7, featuring integrated filtration management, a flexible build platform, and other new functions!

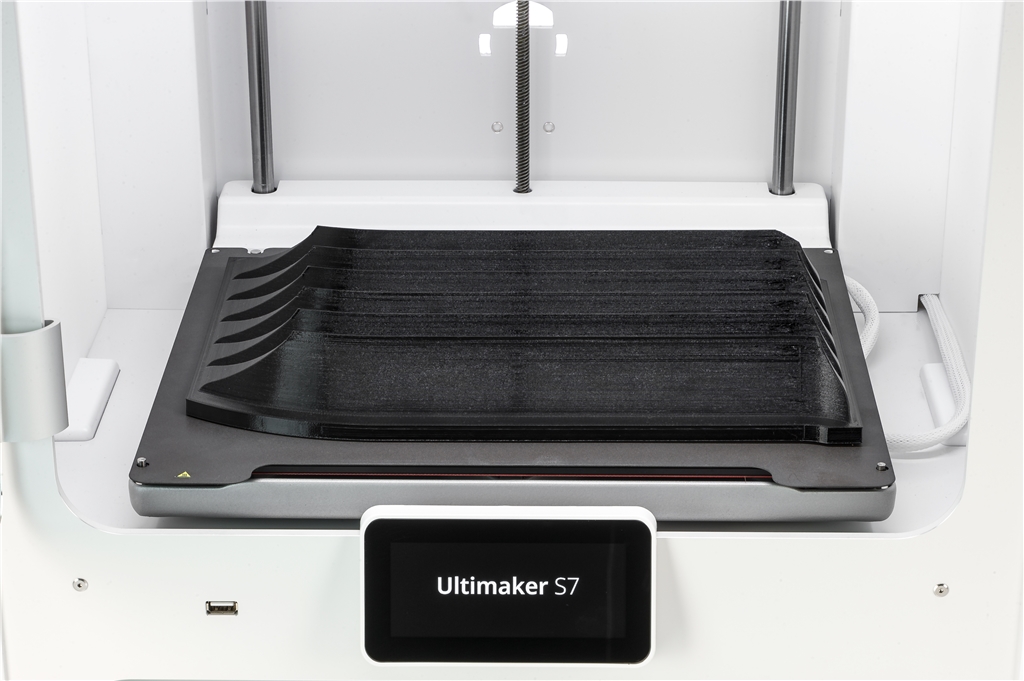

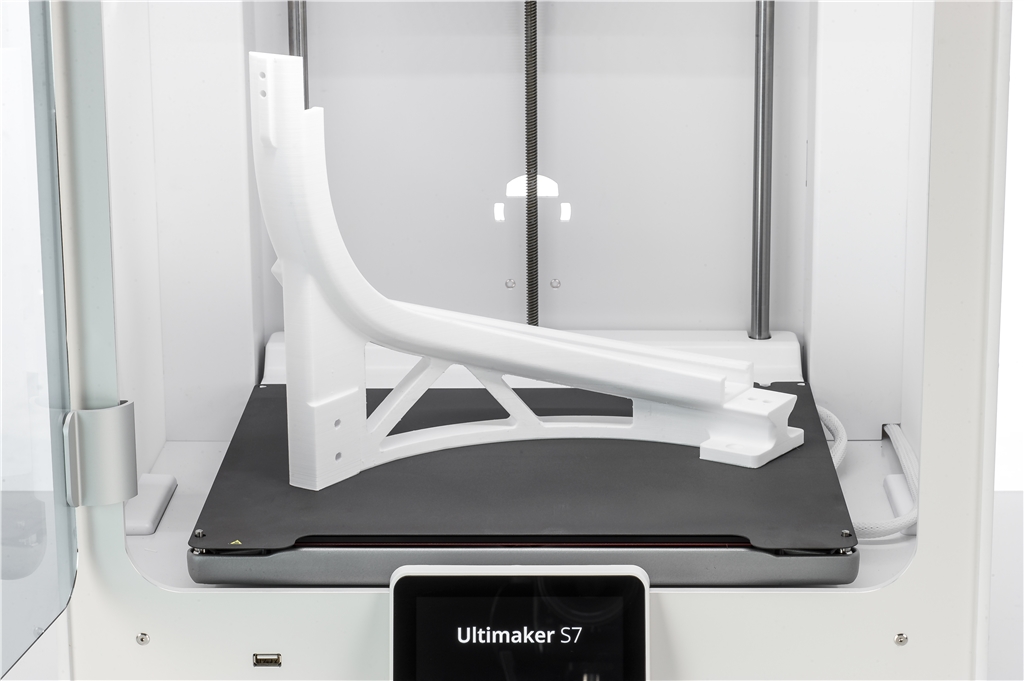

Since the merger of Ultimaker and MakerBot , UltiMaker's first new S-Series features several new functions, including an integrated filter manager and flexible build boards, raising ease of use and reliability to a new level, and offering greater accuracy than its predecessor. A new automatic leveling heated bed function improves first-layer adhesion and allows printing on 330x240x300mm build boards.

"More than 25,000 customers use the UltiMaker S5 for innovation every day, making it one of the most widely used professional 3D printers on the market and an award-winning product," said Nadav Goshen, CEO of UltiMaker. "And the S7 inherits all the features of the S5 , making it even better!"

UltiMaker thermal fusion manufacturing

Prior to its merger with MakerBot, a former Stratasys subsidiary, in 2022, Ultimaker had already established a strong reputation for developing versatile desktop 3D printers. In 2018, Ultimaker launched the Ultimaker S5 , which remained its flagship 3D printer until the release of the S7 . While the S5 was initially designed for twin-extrusion composites, it has since undergone several upgrades, including a metal extension kit that allows customers to print with 17-4 PH stainless steel.

Over the past five years, the versatility of the S5 has been adopted by various leading brands, including Ford, Siemens, L'Oréal, Volkswagen, Zeiss, and Decathlon. In terms of applications, Materialise has also successfully used the S5 in medical 3D printing applications, and ERIKS has developed a workflow that meets food safety standards using the S5 .

Of course, MakerBot is also known in the desktop 3D printing field. Before merging with Ultimaker, the company was known for its METHOD products. As revealed in the METHOD-X review of 3D Printing Industry, these machines are capable of producing parts durable enough for end use, and companies like Arash Motor Company now use them to 3D print custom supercar components.

UltiMaker's latest flagship S7 3D printer

UltiMaker introduces a new system with a built-in board sensor that detects the built-in area with reduced noise and higher accuracy. The system's automatic tilt compensation eliminates the need for users to calibrate the S7 printing platform with wing screws, making leveling tasks much easier!

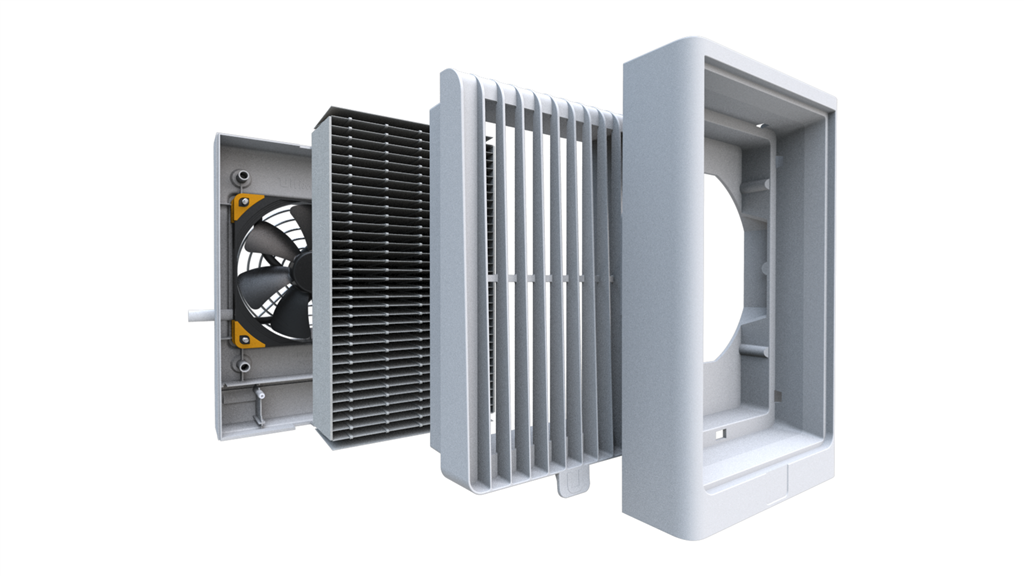

In addition, the S7 features a new air collection manager, which has been independently tested and proven to remove up to 95% of ultrafine particles in every print job. This not only gives users peace of mind about the air quality around the machine, but the fully enclosed chamber and single-pane glass door also improve overall print quality.

UltiMaker thermal fusion manufacturing

Prior to its merger with MakerBot, a former Stratasys subsidiary, in 2022, Ultimaker had already established a strong reputation for developing versatile desktop 3D printers. In 2018, Ultimaker launched the Ultimaker S5 , which remained its flagship 3D printer until the release of the S7 . While the S5 was initially designed for twin-extrusion composites, it has since undergone several upgrades, including a metal extension kit that allows customers to print with 17-4 PH stainless steel.

Over the past five years, the versatility of the S5 has been adopted by various leading brands, including Ford, Siemens, L'Oréal, Volkswagen, Zeiss, and Decathlon. In terms of applications, Materialise has also successfully used the S5 in medical 3D printing applications, and ERIKS has developed a workflow that meets food safety standards using the S5 .

Of course, MakerBot is also known in the desktop 3D printing field. Before merging with Ultimaker, the company was known for its METHOD products. As revealed in the METHOD-X review of 3D Printing Industry, these machines are capable of producing parts durable enough for end use, and companies like Arash Motor Company now use them to 3D print custom supercar components.

UltiMaker's latest flagship S7 3D printer

UltiMaker introduces a new system with a built-in board sensor that detects the built-in area with reduced noise and higher accuracy. The system's automatic tilt compensation eliminates the need for users to calibrate the S7 printing platform with wing screws, making leveling tasks much easier!

In addition, the S7 features a new air collection manager, which has been independently tested and proven to remove up to 95% of ultrafine particles in every print job. This not only gives users peace of mind about the air quality around the machine, but the fully enclosed chamber and single-pane glass door also improve overall print quality.

What are the advantages of the S7 compared to the S5 ? Ultimaker retains the best features of the S5 in the S7 , not only being compatible with the previous generation of machines, but also being able to print using the same library of more than 280 materials as before. The upgraded capabilities of the S7 have been internally tested by Polymaker and igus , and the results are excellent.

"As more and more customers use 3D printing to grow and innovate their businesses, our goal is to provide them with a complete solution for success! With the new S7 , customers can get set up and up and running in minutes: manage printers, users, and designs with our Digital Factory software, improve their 3D printing knowledge with e-learning courses from the UltiMaker Academy, and choose from hundreds of materials and add-ons in the UltiMaker Cura Marketplace," said Nadav Goshen, CEO of UltiMaker.

_(1).png)

The following are the technical specifications for the UltiMaker S7 3D printer.

_(1).png)

The following are the technical specifications for the UltiMaker S7 3D printer.

| Printing technology | Thermal fusion lamination (FFF) |

| Print volume | 330 x 240 x 300 mm |

| Incoming line method | Twin gear extrusion |

| wire diameter | 2.85 mm |

| XYZ resolution | 6.9, 6.9, 2.5 micrometers |

| Nozzle diameter | 180~280 °C |

| aspect | 495 x 585 x 800mm |

| weight | 29.1 kg |

| Maximum power output | 500W |

| File transfer | Wi-Fi (2.4 and 5 GHz), Ethernet, USB |

Did you enjoy this sharing? We offer more than just 3D printing . Contact us now to learn more about the Ultimaker S7 3D printer.

Follow our fan page to stay up-to-date with the latest news: https://www.facebook.com/3dmart.com.tw/

https://www.instagram.com/3dmart/

Source of information