Ultimaker | Product Model:

UM202254D

Ultimaker S5 Pro Bundle Full-Featured 3D Printer

Regular price

¥2,152,200 JPY

Unit price

/

Unavailable

Subtotal

—

Ultimaker S5 Pro Bundle Full-Featured 3D Printer is backordered and will ship as soon as it is back in stock.

Choose add-on

Couldn't load pickup availability

Ultimaker S5 Pro Bundle Full-Featured 3D Printer

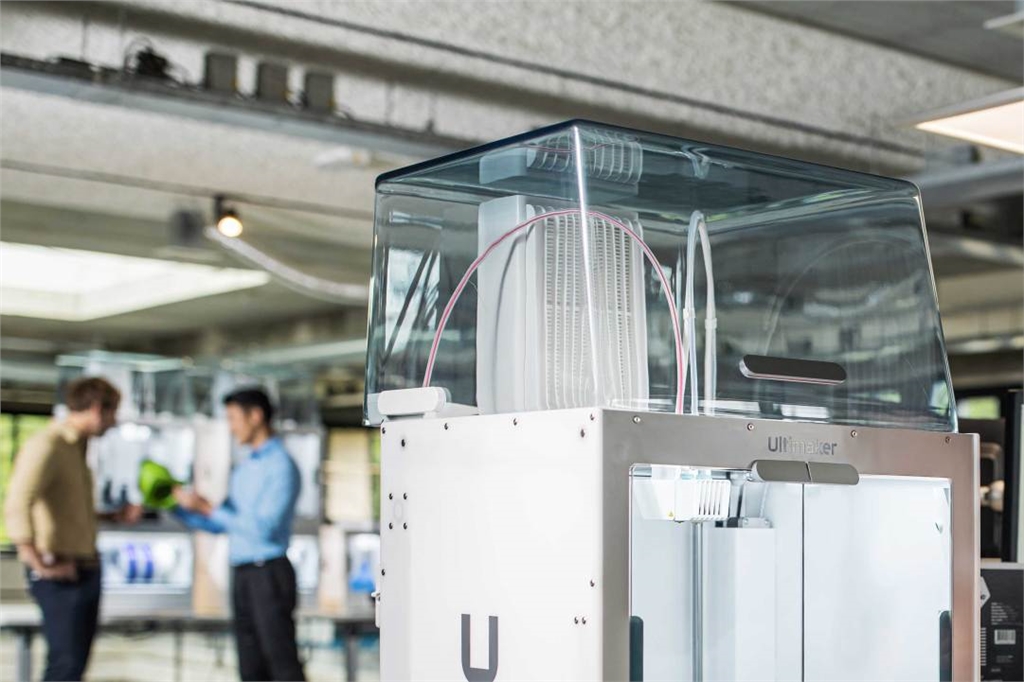

The Ultimaker S5 Pro Bundle will fully integrate three separate devices:

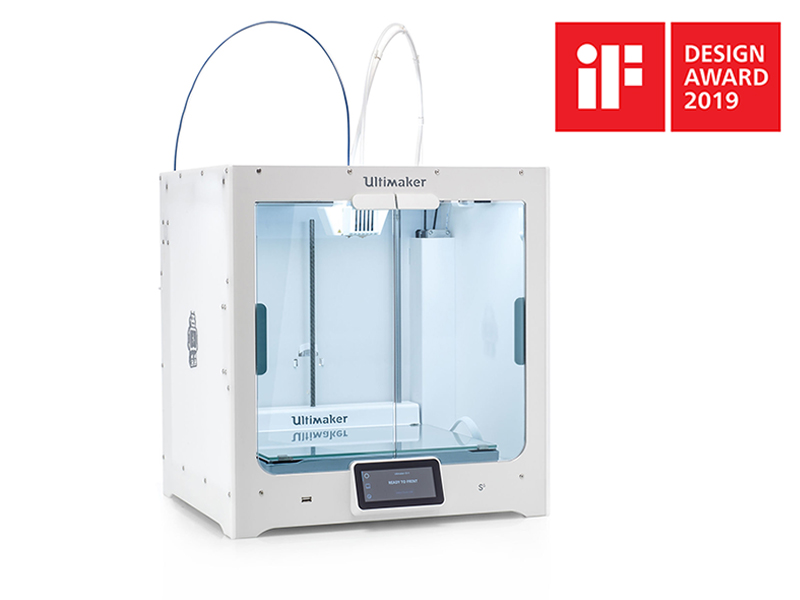

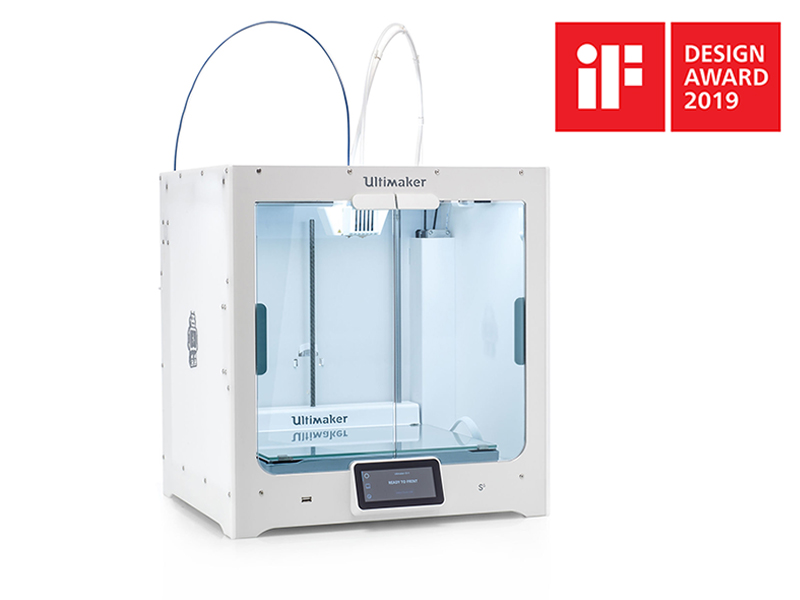

The Ultimaker S5 3D printer is an award-winning desktop industrial-grade 3D printer .

Material Station Intelligent Feeding Station – a multi-functional system with moisture-proof and dehumidification capabilities, a capacity of 6 rolls of wire, material shortage detection, and automatic material changing.

Air Manager – an outer-mounted air filter that detects materials and automatically adjusts the EPA filtration system.

The three devices each perform their respective functions and are fully compatible, completely simplifying the 3D printing process; they solve the common problems of filament replacement and storage in FFF technology in one go— providing a complete system for demanding industrial and commercial 3D printing applications.

Features of the Ultimaker S5 3D Printer

Print larger objects: With larger print volumes, the Ultimaker S5 delivers a reliable 3D printing experience. For large, technically demanding prints, Tough PLA offers the toughness of ABS with the simplicity of PLA.

• Optimized Materials: Ultimaker materials have been extensively tested, and you can get the best results on Ultimaker S5. Ultimaker Cura software comes with pre-set configuration profiles, so you don't need to spend too much time on complex slicing settings.

• Limitless Possibilities: 3D printing ranges from rapid prototyping to complex technical parts, utilizing Ultimaker's extensive range of building and support materials. You can also opt for customized material solutions using the open filament system.

Increased reliability: Active platform calibration ensures a perfect first layer, a closed front panel stabilizes airflow, a dual-nozzle system with automatic lifting, and a line flow sensor that notifies you before the material runs out. You can trust the S5 to help you get the job done perfectly.

Larger print volume: With a volume of 330 x 240 x 300 mm, combined with Ultimaker's reliable double extrusion and water-soluble support, you can realize your designs more freely or print multiple parts at once, thus meeting your needs with maximum efficiency and comfortably mounted on your desk.

• Quick setup, long run time: Ultimaker’s unique print nozzle design allows for nozzle swapping in seconds, switching between print and support materials, with selectable 0.8, 0.4, or 0.25mm nozzles to suit both fast and fine detail printing.

• Easy touch control: The 11.9 cm touch display screen allows you to easily operate the 3D printer. The on-screen guide explains setting changes and maintenance, as well as the print preview.

• Connectivity Design: The Ultimaker S5 automatically detects material and printhead settings, while direct firmware upgrades via the internet make adding the latest features simpler. Print via Wi-Fi, network, or USB, and monitor the printing progress using the built-in camera.

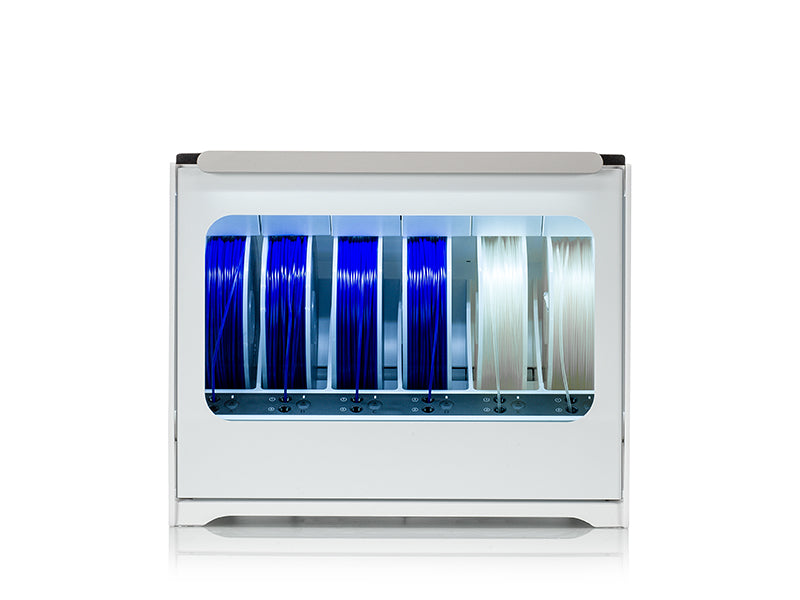

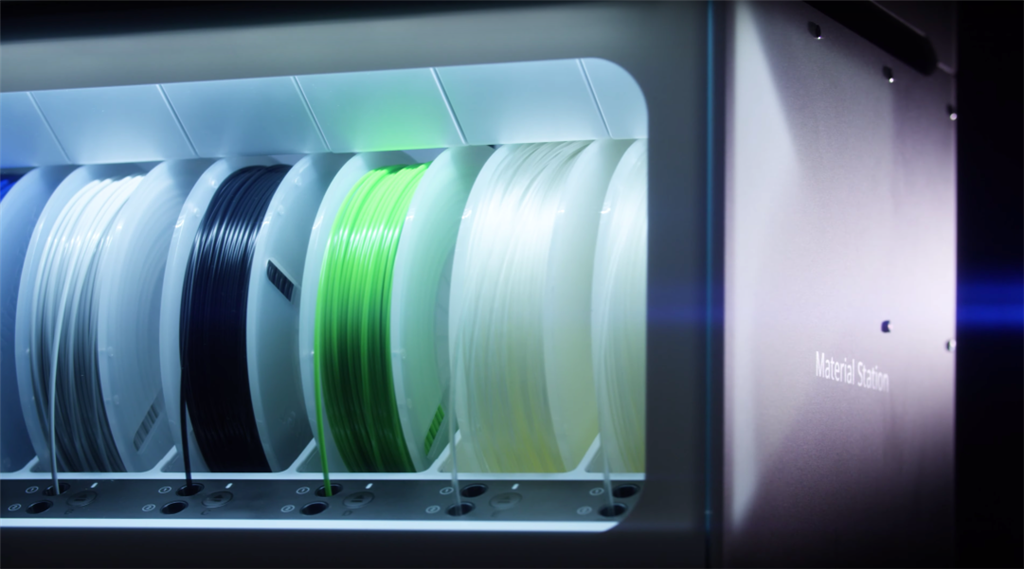

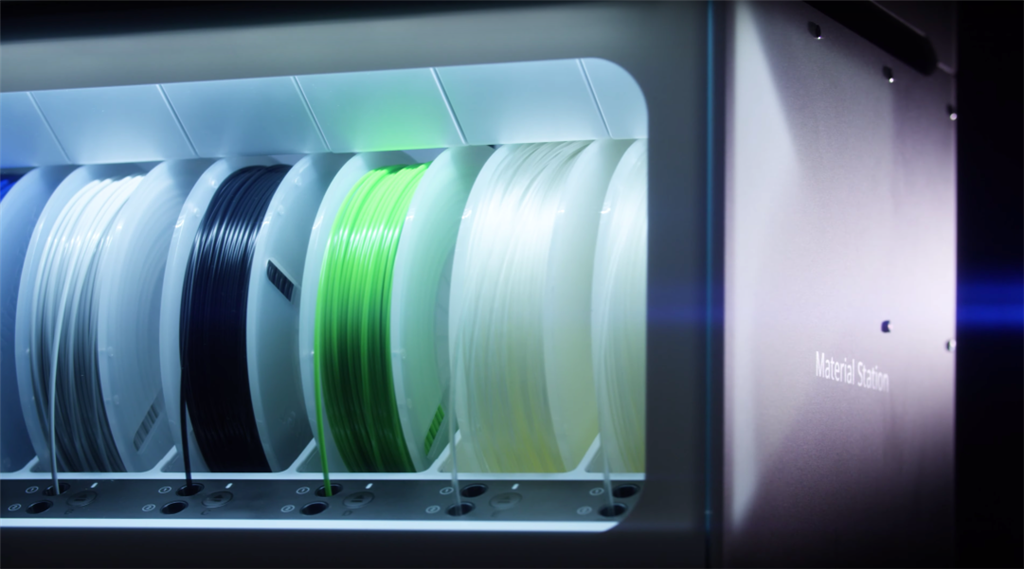

Material Station (Intelligent Material Feeding Station)

The Material Station intelligent feeder has six spool racks, providing greater 3D printing capacity and flexible configuration options. For example, 3D printed items that will be printed for more than three days no longer require manual spool changing or individual configuration. Each spool rack is equipped with an NFC sensor, compatible with Ultimaker filaments (excluding the 350g special specification) and " Ultimaker Material Consortium" filaments available from Cura Marketplace, enabling a wide range of industrial applications, such as glass fiber, carbon fiber composites, or other similar 2.85 mm third-party spools.

Automatic line changing

The Ultimaker S5 's Material Station intelligent feeder has been tested and can perform line changes before, after, and even during 3D printing operations. Each spool is equipped with a line detection function, automatically switching to the next matching material when a spool of wire runs out, and the internal branching feed tubes automatically prevent wire from tangling.

Moisture-proof wire

The Ultimaker S5 intelligent feeding station solves common problems related to moisture and dust. Through its internal dehumidification system, even in an environment with 70% humidity, the relative humidity inside the dehumidification box can be reduced to 40%. By eliminating the problem of moisture, the filament molecules will no longer degrade or swell due to absorbing moisture, thus extending the 3D printing time and shelf life.

Product Features

• Quick installation: It only takes a few seconds to insert the cable into the front tray and it is ready to use. Up to six rolls of cable can be inserted at a time.

• Continuous printing: The thread runout detection system automatically replaces other reels when the thread runs out, allowing printing to continue and saving valuable time.

Humidity control: The intelligent system will maintain the humidity inside the box at approximately 40% or less.

• Easy setup: Featuring an NFC material recognition system that is perfectly compatible with Ultimaker , it can be operated synchronously using the Ultimaker S5 touchscreen.

Composite materials: Dual wear-resistant feed gears can be 3D printed with high-strength and special-property wires (such as carbon fiber composites).

• Flexible application: Supports both original and external 3D printing cables.

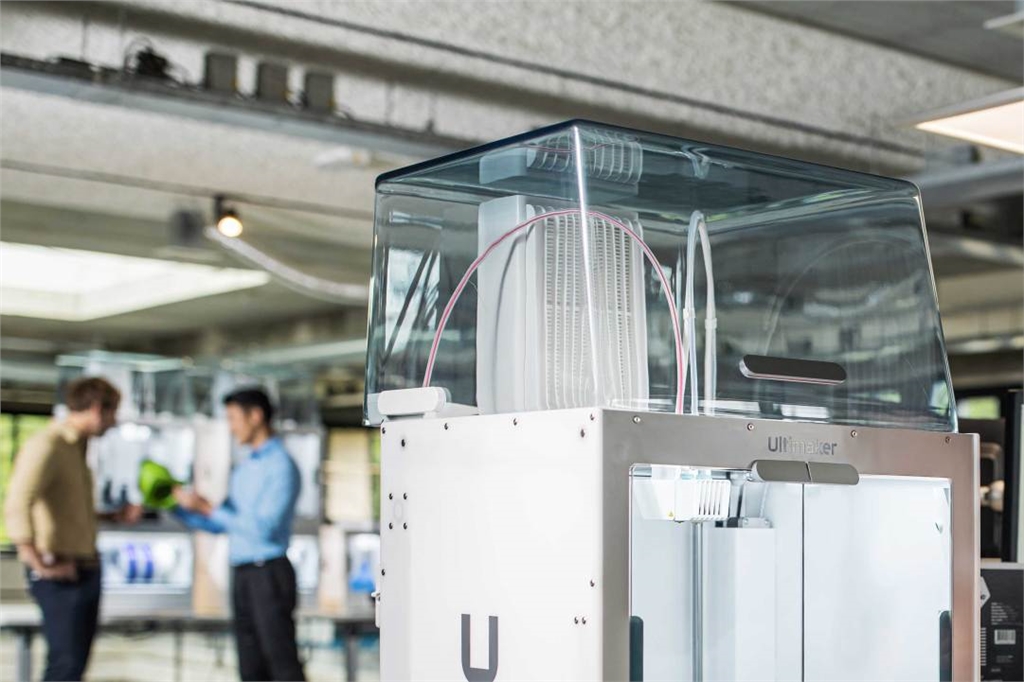

Air Manager

Air Manager features a quiet 140mm (5.5-inch) fan that generates airflow from the inside out, effectively and continuously filtering particulate matter from the air through a high-efficiency filter. It also provides a notification via Ultimaker Connect when the filter's lifespan is depleted. Furthermore, Air Manager adjusts its fan speed according to different materials and includes this information in the Ultimaker Cura printing parameters, ensuring the fan and filter operate at optimal efficiency during printing. It's easy to install, requires no tools, and all functions and control systems are interoperable with Ultimaker S5 firmware and Ultimaker Cura software and are regularly updated.

Click to see: Ultimaker S5 Pro Bundle unboxing tutorial

Click to see: Complete tutorial on the all-new Cura 4 series

Enjoy the streamlined workflow of the Ultimaker S5 Pro Bundle , freeing up valuable time for design and development, and rapidly reducing product lead times to boost sales. It's the world's most complete 3D printing system: from automated feeding and changing systems to air filtration and filament moisture protection and storage, it delivers a worry-free 3D printing process, putting the power of digital manufacturing in everyone's hands.

The Ultimaker S5 Pro Bundle will fully integrate three separate devices:

The Ultimaker S5 3D printer is an award-winning desktop industrial-grade 3D printer .

Material Station Intelligent Feeding Station – a multi-functional system with moisture-proof and dehumidification capabilities, a capacity of 6 rolls of wire, material shortage detection, and automatic material changing.

Air Manager – an outer-mounted air filter that detects materials and automatically adjusts the EPA filtration system.

The three devices each perform their respective functions and are fully compatible, completely simplifying the 3D printing process; they solve the common problems of filament replacement and storage in FFF technology in one go— providing a complete system for demanding industrial and commercial 3D printing applications.

Features of the Ultimaker S5 3D Printer

Print larger objects: With larger print volumes, the Ultimaker S5 delivers a reliable 3D printing experience. For large, technically demanding prints, Tough PLA offers the toughness of ABS with the simplicity of PLA.

• Optimized Materials: Ultimaker materials have been extensively tested, and you can get the best results on Ultimaker S5. Ultimaker Cura software comes with pre-set configuration profiles, so you don't need to spend too much time on complex slicing settings.

• Limitless Possibilities: 3D printing ranges from rapid prototyping to complex technical parts, utilizing Ultimaker's extensive range of building and support materials. You can also opt for customized material solutions using the open filament system.

Increased reliability: Active platform calibration ensures a perfect first layer, a closed front panel stabilizes airflow, a dual-nozzle system with automatic lifting, and a line flow sensor that notifies you before the material runs out. You can trust the S5 to help you get the job done perfectly.

Larger print volume: With a volume of 330 x 240 x 300 mm, combined with Ultimaker's reliable double extrusion and water-soluble support, you can realize your designs more freely or print multiple parts at once, thus meeting your needs with maximum efficiency and comfortably mounted on your desk.

• Quick setup, long run time: Ultimaker’s unique print nozzle design allows for nozzle swapping in seconds, switching between print and support materials, with selectable 0.8, 0.4, or 0.25mm nozzles to suit both fast and fine detail printing.

• Easy touch control: The 11.9 cm touch display screen allows you to easily operate the 3D printer. The on-screen guide explains setting changes and maintenance, as well as the print preview.

• Connectivity Design: The Ultimaker S5 automatically detects material and printhead settings, while direct firmware upgrades via the internet make adding the latest features simpler. Print via Wi-Fi, network, or USB, and monitor the printing progress using the built-in camera.

Material Station (Intelligent Material Feeding Station)

The Material Station intelligent feeder has six spool racks, providing greater 3D printing capacity and flexible configuration options. For example, 3D printed items that will be printed for more than three days no longer require manual spool changing or individual configuration. Each spool rack is equipped with an NFC sensor, compatible with Ultimaker filaments (excluding the 350g special specification) and " Ultimaker Material Consortium" filaments available from Cura Marketplace, enabling a wide range of industrial applications, such as glass fiber, carbon fiber composites, or other similar 2.85 mm third-party spools.

Automatic line changing

The Ultimaker S5 's Material Station intelligent feeder has been tested and can perform line changes before, after, and even during 3D printing operations. Each spool is equipped with a line detection function, automatically switching to the next matching material when a spool of wire runs out, and the internal branching feed tubes automatically prevent wire from tangling.

Moisture-proof wire

The Ultimaker S5 intelligent feeding station solves common problems related to moisture and dust. Through its internal dehumidification system, even in an environment with 70% humidity, the relative humidity inside the dehumidification box can be reduced to 40%. By eliminating the problem of moisture, the filament molecules will no longer degrade or swell due to absorbing moisture, thus extending the 3D printing time and shelf life.

Product Features

• Quick installation: It only takes a few seconds to insert the cable into the front tray and it is ready to use. Up to six rolls of cable can be inserted at a time.

• Continuous printing: The thread runout detection system automatically replaces other reels when the thread runs out, allowing printing to continue and saving valuable time.

Humidity control: The intelligent system will maintain the humidity inside the box at approximately 40% or less.

• Easy setup: Featuring an NFC material recognition system that is perfectly compatible with Ultimaker , it can be operated synchronously using the Ultimaker S5 touchscreen.

Composite materials: Dual wear-resistant feed gears can be 3D printed with high-strength and special-property wires (such as carbon fiber composites).

• Flexible application: Supports both original and external 3D printing cables.

Air Manager

Air Manager features a quiet 140mm (5.5-inch) fan that generates airflow from the inside out, effectively and continuously filtering particulate matter from the air through a high-efficiency filter. It also provides a notification via Ultimaker Connect when the filter's lifespan is depleted. Furthermore, Air Manager adjusts its fan speed according to different materials and includes this information in the Ultimaker Cura printing parameters, ensuring the fan and filter operate at optimal efficiency during printing. It's easy to install, requires no tools, and all functions and control systems are interoperable with Ultimaker S5 firmware and Ultimaker Cura software and are regularly updated.

Click to see: Ultimaker S5 Pro Bundle unboxing tutorial

Click to see: Complete tutorial on the all-new Cura 4 series

Enjoy the streamlined workflow of the Ultimaker S5 Pro Bundle , freeing up valuable time for design and development, and rapidly reducing product lead times to boost sales. It's the world's most complete 3D printing system: from automated feeding and changing systems to air filtration and filament moisture protection and storage, it delivers a worry-free 3D printing process, putting the power of digital manufacturing in everyone's hands.

Ultimaker S5 3D printer

Intelligent Material Station

Ultimaker S5 Air Manager

| Print volume | 330 x 240 x 300 mm |

| Printing Platform | Glass heating platform |

| Support cables | PLA /Tough PLA / ABS / CPE / CPE+/ Nylon / TPE / PC / PP/ PVA / Breakaway |

| Printing speed | <24mm³/s |

| Minimum print layer thickness | 20 micron |

| Nozzle configuration | Dual nozzles, automatic lifting system |

| Nozzle temperature | 180-280 °C |

| Nozzle size | 0.4mm (Quickly replaceable with 0.25mm/0.8mm nozzles) |

| Consumable diameter | 2.85 mm |

| Transmission method | USB port, Wi-Fi, LAN |

| Positioning accuracy | 6.9, 6.9, 2.5 microns |

| Slicing software | Cura official slicing software |

| File type | STL / UPF |

| AC input | 100-240V, 6A, 50-60Hz, maximum 500W |

| Average operating noise | 50 dBA |

| External dimensions | 495 x 457 x 520 mm |

| External dimensions (including feed tube and spool holder) | 495 x 585 x 780 mm |

| Weight/Shipping weight | 18 kg / 25 kg |

| shipping container | 650 x 600 x 700 mm |

Intelligent Material Station

| Consumable diameter | 2.85mm |

| Material roll size | Width: 50-70mm Diameter: 197-203mm Central aperture: >98mm |

| Material capacity | 6 volumes |

| Material Identification | NFC Automatic Identification System |

| Feeder type | Wear-resistant dual-feed gears |

| Data connection | UMB connection |

| Power input | 85-264V AC, maximum 125W |

| Power output | Maximum 10A (for Ultimaker S5) |

| Compatible 3D printers | Ultimaker S5 |

| Compatible materials | Ultimaker PLA, Tough PLA, ABS, Nylon, CPE, CPE+, PC, PP, TPU 95A, PVA, Breakaway, and third-party materials. |

| size | 491 x 438 x 400 mm |

| net weight | 17.7KG |

| Support software (free online download) | Ultimaker Cura Slicing Software, Ultimaker Connect Printer System, Ultimaker Cloud Remote Printing |

| Warranty | twelve months |

Ultimaker S5 Air Manager

| Filtration technology | EPA filter |

| Fan technology | Low-noise brushless fan exhaust |

| air exchange rate | 1-50 cubic meters per hour (the standard rate for most materials at 23°C is 35 cubic meters per hour). |

| Filtration efficiency | Up to 95% |

| Filter replacement | It can filter approximately 1500 hours of print time (about 1 year). |

| Operating noise | <51dBA |

| Connection methods (data and power) | UMB connection |

| Compatible 3D printers | Ultimaker S5 |

| Compatible materials | Ultimaker PLA, Tough PLA, ABS, Nylon, CPE, CPE+, PC, PP, TPU 95A, PVA, Breakaway, and third-party materials. |

| size | Single unit: 490x503x350mm Assembly dimensions: 490x503x967mm (including Ultimaker S5) |

| net weight | 3.6KG |

| Support software (free online download) | Ultimaker Cura Slicing Software, Ultimaker Connect Printer System, Ultimaker Cloud Remote Printing |

| Warranty | twelve months |