Ultimaker | Product Model:

UM218053

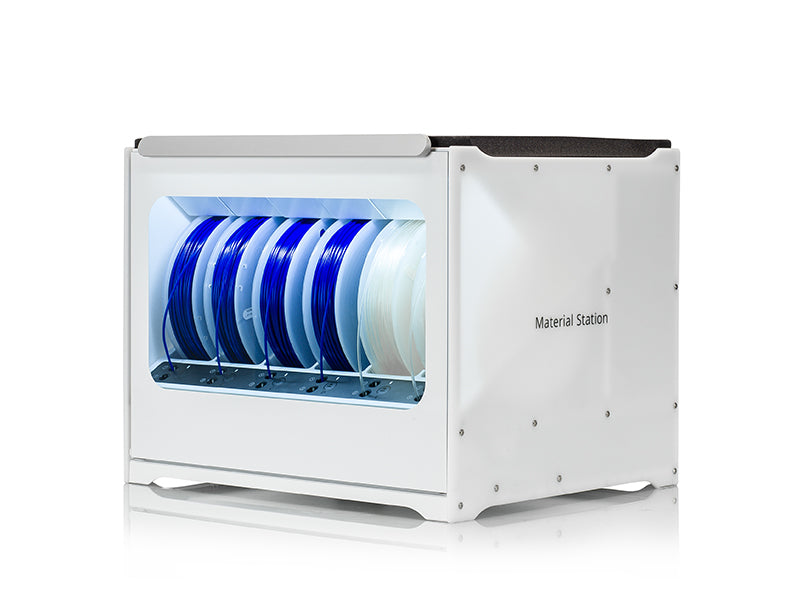

Material Station (Suitable for S5 and S7)

Regular price

¥694,400 JPY

Unit price

/

Unavailable

Subtotal

—

Material Station (Suitable for S5 and S7) is backordered and will ship as soon as it is back in stock.

Choose add-on

Couldn't load pickup availability

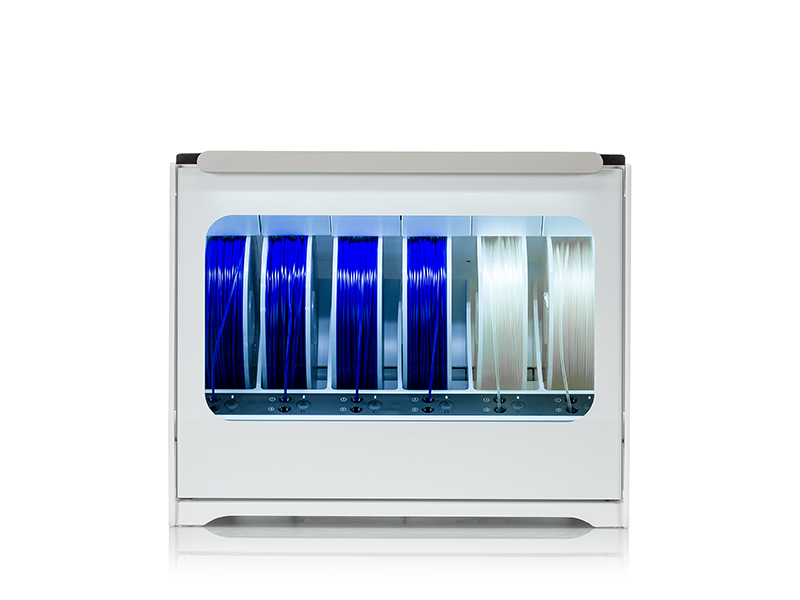

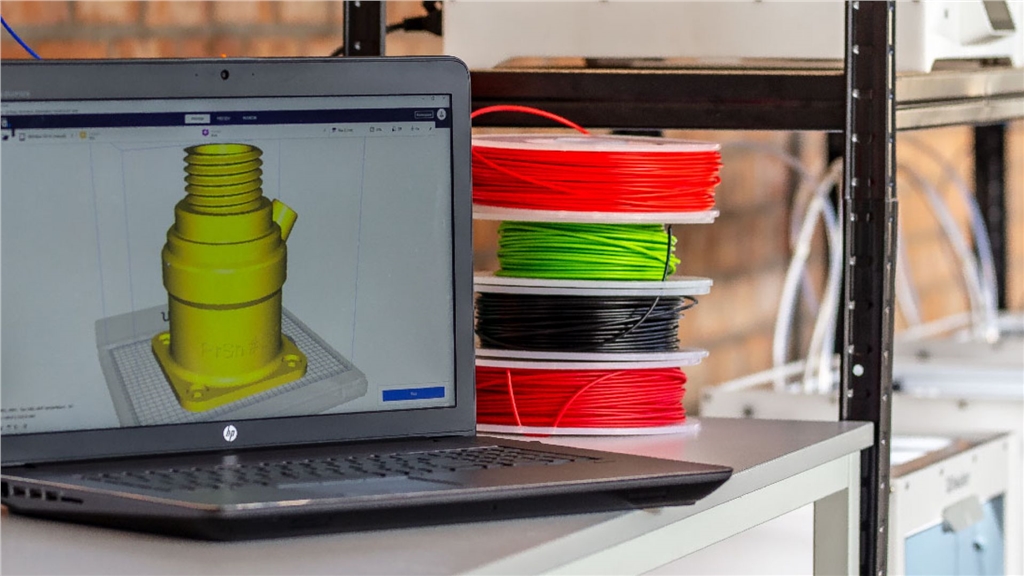

Material Station (Intelligent Material Feeding Station)

Improve productivity and accelerate product delivery.

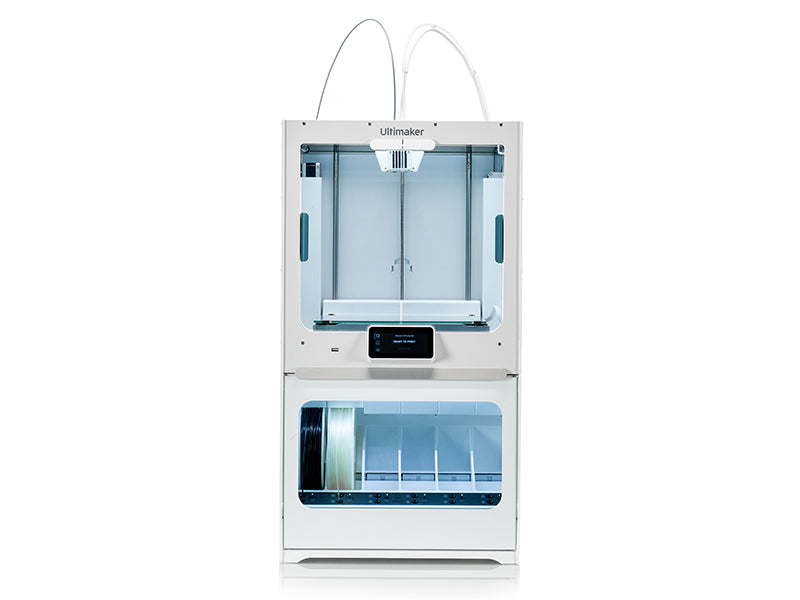

The Material Station intelligent feeder is perfectly compatible with the Ultimaker S5 and UltiMaker S7 , ushering in a new era from material handling to 3D printing . The Material Station intelligent feeder can hold up to six filaments, allowing automation to handle the preparation process. Equipped with features such as feed gears supporting composite materials, filament sensors, material breakage detection, and automatic filament changing, it enables users to simultaneously improve both output and quality.

· Simplify 3D printing workflow

Since 2011, Ultimaker has been dedicated to making 3D printing simpler, and this latest system represents a major breakthrough. Material can be placed face-up in just seconds, and there's no need to worry about material getting damp during long 3D printing sessions . The Material Station intelligent feeder is compatible with both Ultimaker S5 and UltiMaker S7. It is fully compatible with the operating system, allowing users to keep track of their workflow at all times.

Product Features

Product Features

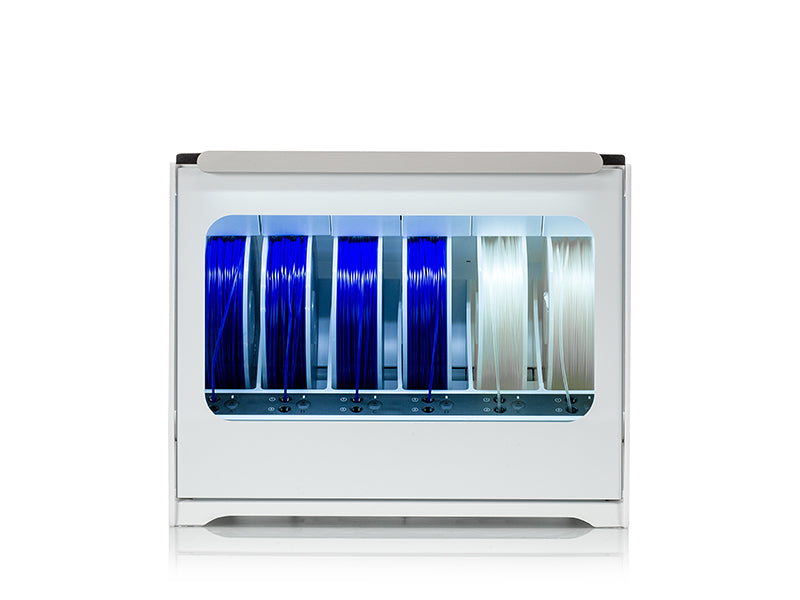

• Quick installation: It only takes a few seconds to insert the cable into the front tray and it is ready to use. Up to six rolls of cable can be inserted at a time.

• Continuous printing: The thread runout detection system automatically replaces other reels when the thread runs out, allowing printing to continue and saving valuable time.

Humidity control: The intelligent system will maintain the humidity inside the box at approximately 40% or less.

• Easy setup: Featuring an NFC material recognition system that is perfectly compatible with Ultimaker , it can be operated synchronously using the Ultimaker S5 touchscreen.

Composite materials: Dual wear-resistant feed gears can be 3D printed with high-strength and special-property wires (such as carbon fiber composites).

• Flexible application: Supports both original and external 3D printing cables.

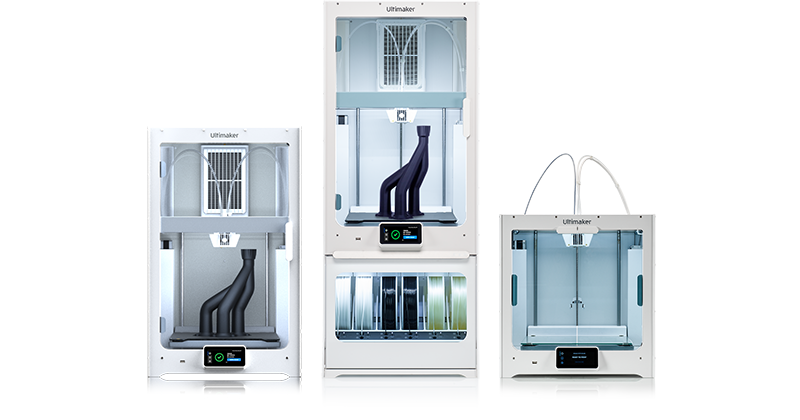

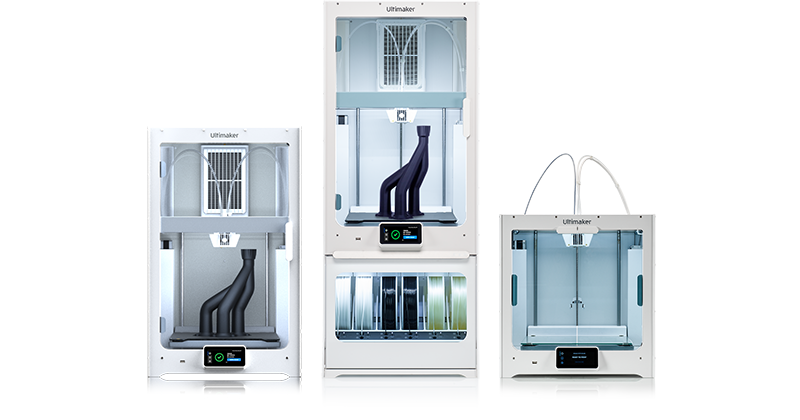

Ultimaker All-round 3D Printing System

A leading global brand of award-winning 3D printers , stable, reliable, and easy to use; capable of continuously printing high-quality parts around the clock, allowing you to obtain the products you need faster and easier; when used with Air Manager, it achieves the best results, making your workflow smoother in a safe and efficient environment.

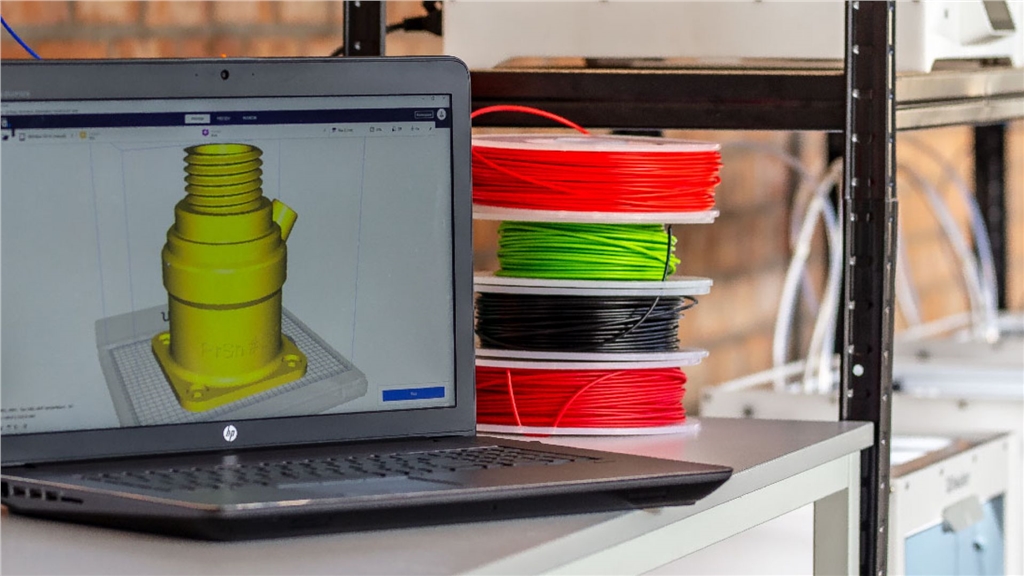

Official slice software

Ultimaker Cura's official slicing software supports 14 languages, is trusted by millions of users worldwide, and allows for the addition of add-ons through the Marketplace. Combined with the Ultimaker Cloud system, it enables digital manufacturing globally.

Global Materials Alliance

Ultimaker users have access to the widest selection of materials on the market, collaborating with global material suppliers to meet your diverse product development needs, from acid and alkali resistant materials to carbon fiber composite wires.

Professional Services <br> As the exclusive distributor of Ultimaker in Taiwan, 3DMart provides you with the most comprehensive introduction, professional services, teaching resources , and user training. Contact us now to keep up with the pace of digital manufacturing!

Ultimaker 3D printer enterprise application cases

Three key aspects of smart production lines: how major computer manufacturers are doing it!

Heinegan Beer: 3D printing is all about Ultimaker!

Ford Motor Company: How to win the war on the production line?

Royal Netherlands Air Force: 3D printing technology takes off!

Taiwanese innovative design is making its way into the European market!

Improve productivity and accelerate product delivery.

The Material Station intelligent feeder is perfectly compatible with the Ultimaker S5 and UltiMaker S7 , ushering in a new era from material handling to 3D printing . The Material Station intelligent feeder can hold up to six filaments, allowing automation to handle the preparation process. Equipped with features such as feed gears supporting composite materials, filament sensors, material breakage detection, and automatic filament changing, it enables users to simultaneously improve both output and quality.

· Simplify 3D printing workflow

Since 2011, Ultimaker has been dedicated to making 3D printing simpler, and this latest system represents a major breakthrough. Material can be placed face-up in just seconds, and there's no need to worry about material getting damp during long 3D printing sessions . The Material Station intelligent feeder is compatible with both Ultimaker S5 and UltiMaker S7. It is fully compatible with the operating system, allowing users to keep track of their workflow at all times.

• Quick installation: It only takes a few seconds to insert the cable into the front tray and it is ready to use. Up to six rolls of cable can be inserted at a time.

• Continuous printing: The thread runout detection system automatically replaces other reels when the thread runs out, allowing printing to continue and saving valuable time.

Humidity control: The intelligent system will maintain the humidity inside the box at approximately 40% or less.

• Easy setup: Featuring an NFC material recognition system that is perfectly compatible with Ultimaker , it can be operated synchronously using the Ultimaker S5 touchscreen.

Composite materials: Dual wear-resistant feed gears can be 3D printed with high-strength and special-property wires (such as carbon fiber composites).

• Flexible application: Supports both original and external 3D printing cables.

Ultimaker All-round 3D Printing System

A leading global brand of award-winning 3D printers , stable, reliable, and easy to use; capable of continuously printing high-quality parts around the clock, allowing you to obtain the products you need faster and easier; when used with Air Manager, it achieves the best results, making your workflow smoother in a safe and efficient environment.

Official slice software

Ultimaker Cura's official slicing software supports 14 languages, is trusted by millions of users worldwide, and allows for the addition of add-ons through the Marketplace. Combined with the Ultimaker Cloud system, it enables digital manufacturing globally.

Global Materials Alliance

Ultimaker users have access to the widest selection of materials on the market, collaborating with global material suppliers to meet your diverse product development needs, from acid and alkali resistant materials to carbon fiber composite wires.

Professional Services <br> As the exclusive distributor of Ultimaker in Taiwan, 3DMart provides you with the most comprehensive introduction, professional services, teaching resources , and user training. Contact us now to keep up with the pace of digital manufacturing!

Ultimaker 3D printer enterprise application cases

Three key aspects of smart production lines: how major computer manufacturers are doing it!

Heinegan Beer: 3D printing is all about Ultimaker!

Ford Motor Company: How to win the war on the production line?

Royal Netherlands Air Force: 3D printing technology takes off!

Taiwanese innovative design is making its way into the European market!

| Consumable diameter | 2.85mm |

| Material roll size | Width: 50-70mm Diameter: 197-203mm Central aperture: >98mm |

| Material capacity | 6 volumes |

| Material Identification | NFC Automatic Identification System |

| Feeder type | Wear-resistant dual-feed gears |

| Data connection | UMB connection |

| Power input | 85-264V AC, maximum 125W |

| Power output | Maximum 10A (for Ultimaker S5) |

| Compatible 3D printers | Ultimaker S5 |

| Compatible materials | Ultimaker PLA, Tough PLA, ABS, Nylon, CPE, CPE+, PC, PP, TPU 95A, PVA, Breakaway, and third-party materials. |

| size | 491 x 438 x 400 mm |

| net weight | 17.7KG |

| Support software (free online download) | Ultimaker Cura Slicing Software, Ultimaker Connect Printer System, Ultimaker Cloud Remote Printing |

| Warranty | twelve months |