Phrozen | Product Model:

PH0240

Phrozen EL400 elastic resin (1KG)

Regular price

¥19,700 JPY

Unit price

/

Unavailable

Subtotal

—

Phrozen EL400 elastic resin (1KG) is backordered and will ship as soon as it is back in stock.

Choose add-on

Couldn't load pickup availability

Phrozen EL400 Elastic Resin (1KG)

3 times more tear-resistant, upgraded toughness

Ideal soft material that combines elasticity and toughness with high tear resistance

The test model can easily withstand up to 60,000 repeated bends*, with a tear strength of 39.1 kN/m. Its rubber-like flexibility makes it resistant to damage even after long-term use, allowing you to easily create endless possibilities.

* Bending fatigue test (23℃, 60° bending, 100 cycles/minute).

Features

Extreme elasticity, high extensibility

With 4 times the tensile strength (elongation at break: 391%*), EL400 resin offers rubber-like flexibility and hardness, providing long-lasting stability beyond limits.

With 4 times the tensile strength (elongation at break: 391%*), EL400 resin offers rubber-like flexibility and hardness, providing long-lasting stability beyond limits.

Exceptional resilience, stable and without deformation

With a 50-55% resilience, it quickly returns to its original shape after deformation, making it suitable for product development processes involving long-term testing and repeated verification, ensuring the durability of printed objects.

Application Examples

EL400 features repeated bending and high tear resistance, making it particularly suitable for high-intensity use without easily being damaged or broken, such as bicycle saddles and athletic shoe soles.

Ideal material for wide application

It possesses high elasticity and tear resistance, meeting stringent industrial manufacturing standards. Its superior properties make it an ideal alternative to foam and TPU, suitable for a wide range of applications.

*The following data shows the performance of the materials after post-processing. Please refer to the tutorial below for post-processing methods.

User Guide

| Settings | Recommended setting value |

| Printing thickness | 100 micrometers |

| Model wall thickness | ≥ 1.5 mm |

| Return speed | 120 - 150 mm/min |

| Support thickness | 1.0 mm or ≥ 1.2 mm |

* hint:

1. When printing, it is recommended to print with the bottom facing down to reduce deformation. If the model requires support, please refer to point 2.

2. If the space between the model support or the shape is too small, the resin may solidify in the gaps, affecting the printing process.

3. When printing, it is recommended to slow down the lift and return speeds and increase the dwell time. The return speed should be adjusted according to the model type.

4. Thermosetting mainly helps improve the mechanical properties of materials, especially tensile and tear strength, but it will also reduce ductility. Laboratory test data can be found in the TDS content on the first page. It is recommended to choose the appropriate curing method according to the application requirements of the printed model.

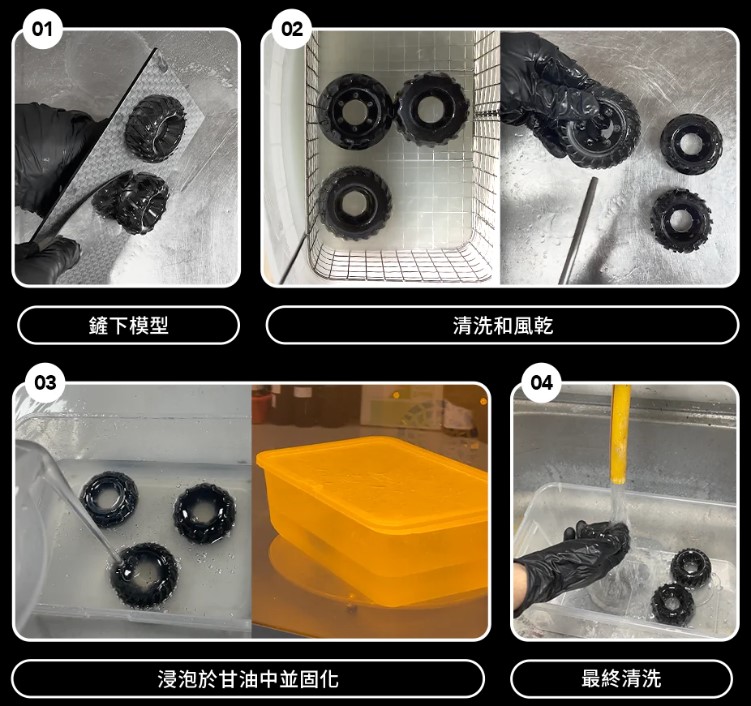

Post-processing methods

1. Clean with Phrozen Wash in 95% ethanol.

2. Please make sure to clean the inside of the model thoroughly.

3. After cleaning, let it stand for at least 30 minutes to ensure the object is dry before curing.

Post-curing

1. Use Phrozen Curing Station .

2. Immerse the model in glycerin for approximately 60 minutes to cure. Remove it as soon as possible after curing. (Immersion in glycerin improves model integrity and reduces surface stickiness.)

*Note: When soaking in glycerin, maintain spacing between parts to prevent the model from hardening and sticking together. Do not soak in ethanol/glycerin/water for extended periods, as this may cause the resin to absorb the solvent and swell and deform.

Model cleaning

1. Rinse the cured model with clean water. 2. After cleaning, place it in a cool, well-ventilated indoor environment to air dry. 3. If further tear resistance and resilience are required, bake at 80°C for 2 hours. (Please refer to the specifications above).

*Reminder: After cleaning or post-curing, the object must be cleaned immediately. Do not soak it in water or glycerin for extended periods, as this may cause the resin to absorb the solvent and swell or deform.

Click to see: Phrozen Slicing Tutorial

Phrozen resin should be shaken well before use and stored in a dry, well-ventilated place at room temperature (15-35°C).

Phrozen resin should be shaken well before use and stored in a dry, well-ventilated place at room temperature (15-35°C).

Enjoy the UV curing printing experience offered by Phrozen's various resins now. Customize your selection based on your needs and characteristics to provide the best finished product results, orcontact us now for more information.

| color | grey |

| weight | 1KG |

| Recommended cleaning method | Clean with alcohol spray and dry with an air gun (do not soak in alcohol for more than 30 seconds). |

| Applicable models | Phrozen 3D Printer Series |