Bambu Lab | Product Model:

BL00018

PEI Printing Platform

PEI Printing Platform - Smoothing PEI - H2D is backordered and will ship as soon as it is back in stock.

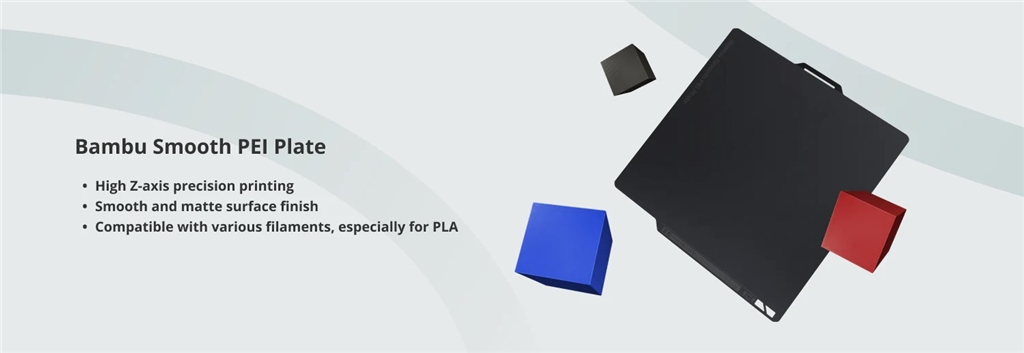

Bambu Lab Smooth PEI Printing Platform

High Z-axis precision printing

During the printing process, using a smooth PEI printing platform helps improve Z-axis accuracy, ensuring higher precision and consistency in vertical dimensions. These characteristics make smooth PEI plates an excellent choice for printing parts with high precision requirements, where accurate alignment and tight tolerances are crucial.

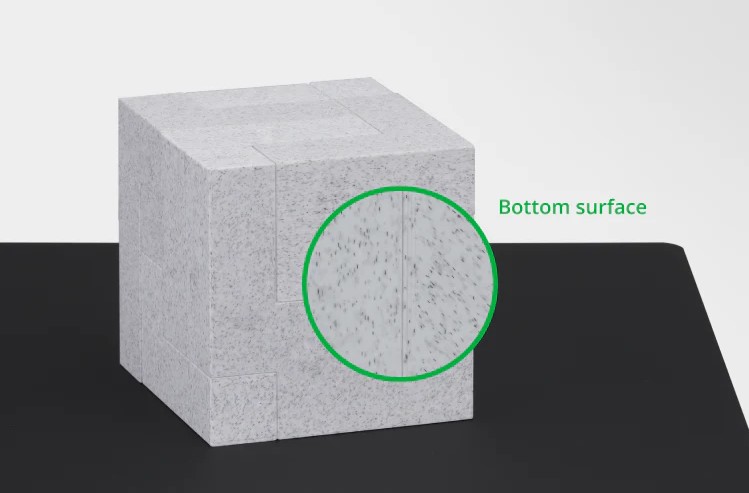

Smooth matte surface treatment

Using specially selected matte PEI sheets can give the bottom surface of prints a smooth matte texture, thereby enhancing their overall appearance.

Compatible with a variety of cables

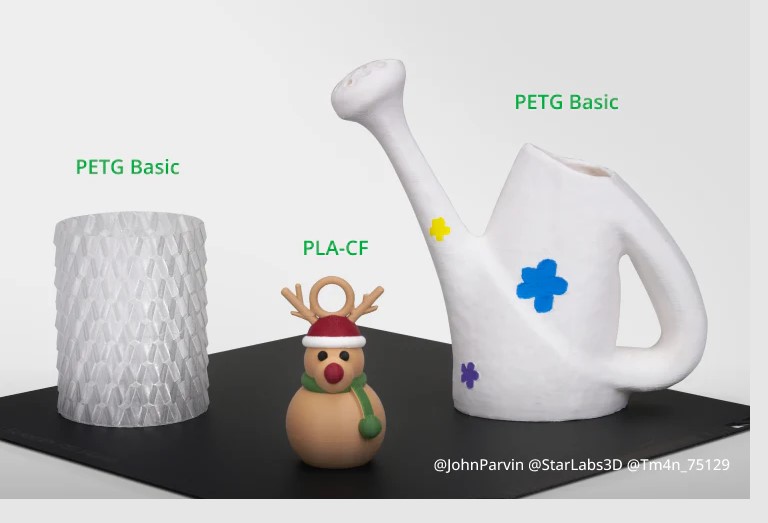

PEI can print not only on common materials such as PLA , TPU , and PETG , but also on materials that require high temperatures, such as ABS and nylon .

Note: If printing with cables other than PLA, apply glue to prevent the board from tearing.

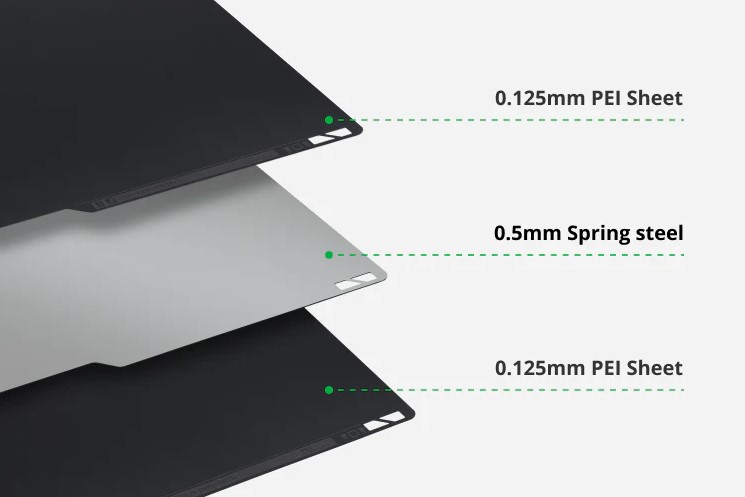

Reliable magnetic adhesion prevents warping

The Bambu smooth PEI printing platform features a 0.5 mm thick spring steel plate to enhance magnetic adhesion, which helps prevent warping and ensures optimal print quality during 3D printing . It is also helpful when printing large models using easily warped materials such as ABS, PC, and nylon.

Precautions

• Please note that when using a smooth PEI printing platform on A1 , there is a higher risk of platform edge curling or the print pattern detaching from the plate. This is because a thicker layer of smooth PEI is used on the plate, increasing the distance from the bed magnet and reducing magnetic attraction.

• If air bubbles appear at the bottom of the printing platform, heating it on a heated bed at a temperature of at least 80 degrees Celsius for several hours can help eliminate the air bubbles.

• Dust and grease deposited on the build board can reduce adhesion. It is recommended to clean the surface regularly with detergent and water to maintain optimal adhesion.

• Never use acetone to clean smooth PEI, as acetone will damage the PEI surface.

• Before removing the printed mold, please wait a few minutes to allow the printing plate to cool down before removing the print. This prevents damage to the plate and ensures the product's lifespan.

• Carefully sanding the surface with fine sandpaper (600 grit recommended) can help restore adhesion.

• Smooth PEI sheets are considered consumable parts and will degrade over time. The warranty covers only manufacturing defects and does not include cosmetic damage such as scratches, dents, or cracks. Only sheets arriving with defects are covered under warranty.

Recommended settings

Please note that other slicing software settings may need to be adjusted based on the printing model and filament requirements.

| Material | heated bed temperature | Do you need glue sticks? |

| PLA/PLA-CF/PLA-GF | 45~60℃ | No |

| PETG/PETG-CF | 60~80℃ | Glue sticks/liquid glue |

| ABS (not applicable to A1 mini) | 90~100℃ | Glue sticks/liquid glue |

| ASA (not applicable to A1 mini) | 90~100℃ | Glue sticks/liquid glue |

| TPU | 35~45℃ | Glue sticks/liquid glue |

| PVA | 45~60℃ | Glue sticks/liquid glue |

| PC/PC-CF (Not compatible with A1 mini) | 90~110℃ | glue stick |

| PA/PA-CF/PAHT-CF (Not applicable to A1 mini) | 90~110℃ | glue stick |

| PET-CF (Not applicable to A1 mini) | 80~100℃ | Glue sticks/liquid glue |

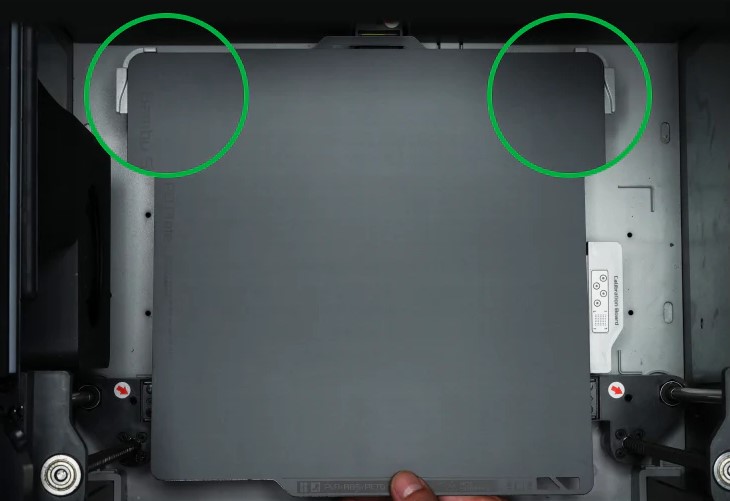

X1 Series/P1 Series/A1 Installation Steps

Step 1: Align the printing plate with the mounting points on the platform, with the plate's name facing you.

Step 2: Lower the plate and fix it to the magnetic platform.

A1 Mini Installation Steps

Step 1: Align the printing plate with the mounting points on the platform, with the plate's name facing you.

Step 2: Lower the plate and fix it to the magnetic platform.

カスタム製品仕様