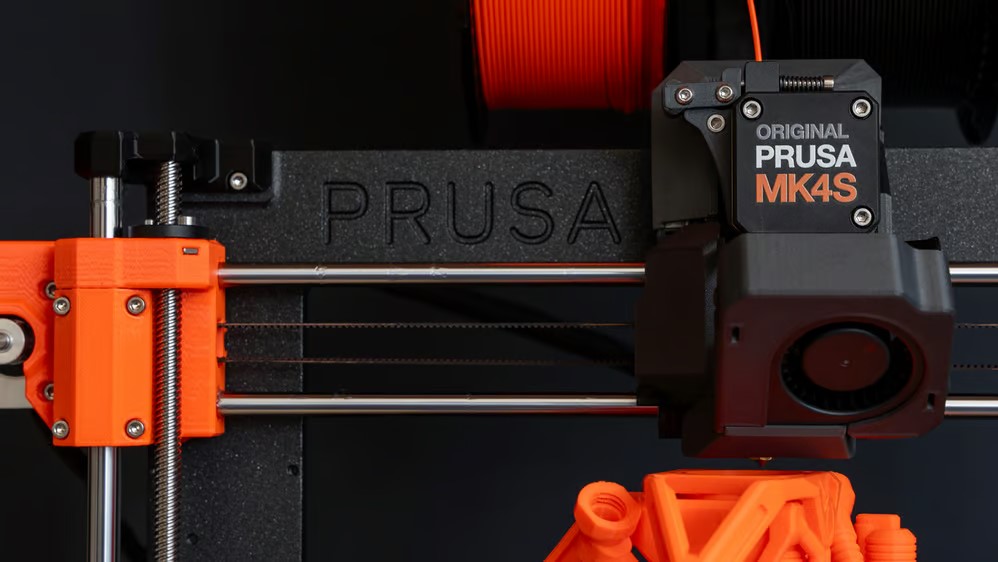

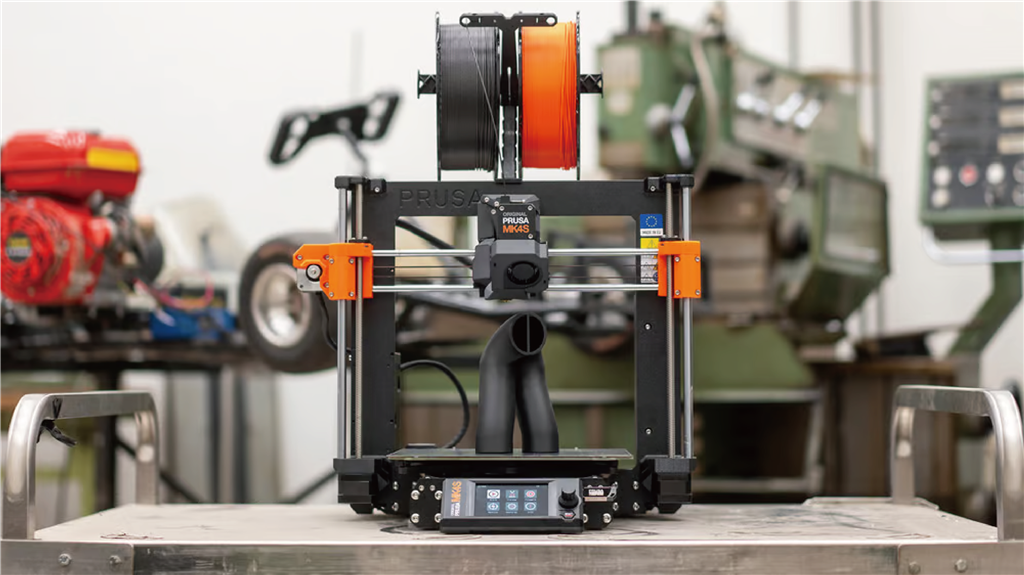

Original Prusa MK4S 3D Printer

Original Prusa MK4S 3D Printer is backordered and will ship as soon as it is back in stock.

Choose add-on

Couldn't load pickup availability

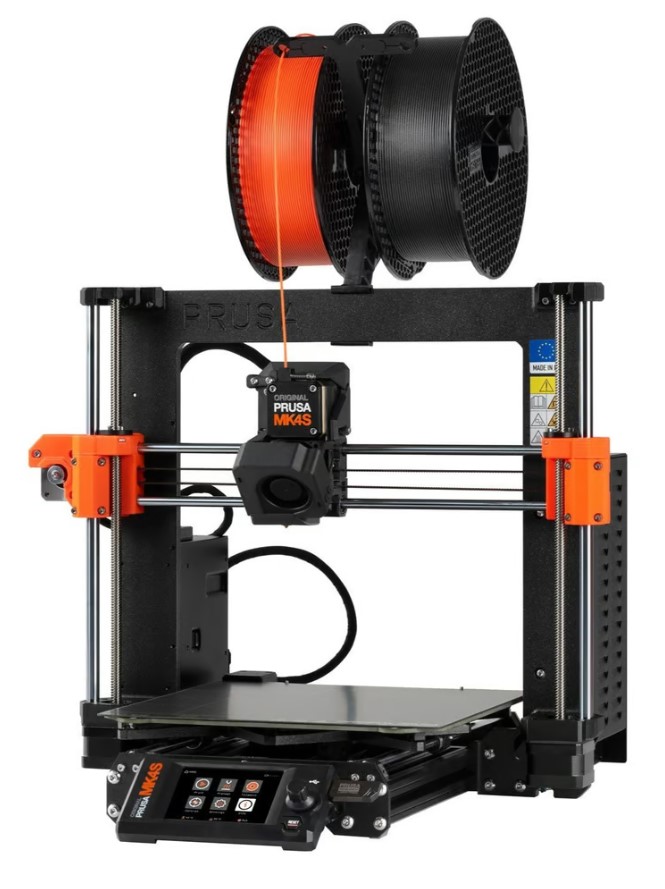

The MK4S offers the convenience of high-speed 3D printing and is as reliable as all Original Prusa 3D printers. It boasts all the best features of the MK4—easy maintenance, advanced security features, and more!

Original Prusa MK4 and MK4S

Every Original Prusa 3D printer comes with years of long-term support after its release. This includes not only minor bug fixes but also major firmware and hardware upgrades that bring useful new features, and the MK4 is no exception.

Compared to the original Prusa MK4, the MK4S brings the following innovations:

• New high-performance 360° cooling system

• Standard configuration includes high-quality, high-flow nozzles*

• The native iOS/Android Prusa app for iOS and Android allows for easy Wi-Fi setup via a simple NFC tap.

• Improve printing speed

• Improve print quality

• New parts printed or injection molded from Prusament PC mixed with carbon fiber

• Optional accessory: GPIO hacking board

• Optional Accessories: Accelerometer for Printer Modifiers

* For the MK4S/MMU3 kit, you will receive two nozzles in the package - a standard nozzle and a high-flow nozzle. The MK4S and MMU3 are bundled together, and the printer comes pre-loaded with the standard nozzle.

feature

Building area

250×210×220 mm (width×depth×height)

floor height

0.05 - 0.30 mm

1.75mm wire

Unlocked suppliers

0.4mm nozzle

Easy to replace

Detachable

Print pages

open source

Community friendly

• Fast and quiet 3D printing with minimal effort. Watch Benchy videos in under 20 minutes!

• With Load Cell sensors, fully automated first-layer calibration

• Ready to print right out of the box; no need to print single-page documents, no need for repairs, and no need for real-time Z-axis adjustments.

• Nextruder – A new extruder with a custom splitter and intelligent features

• Safety features, such as wire sensors and power failure detection and recovery, will not disappoint you.

• Easy to maintain, quick nozzle replacement, and removable print platform

• Supports a variety of materials, including PLA, PETG, Flex, Nylon, ASA, PVA, PC, PP, and composite materials.

• A color LCD screen with a simple navigation user interface for quick access to all important functions.

• Open source code

Plug and print!

Superior print quality and reliability

Speed is meaningless without quality and reliability. Chasing speed records is pointless when the quality of the printed product is subpar. While the MK4S is twice as fast as its predecessor, we've focused on further improving print quality. With its newly designed 360° cooling, high-quality, high-flow nozzles, robust components, and finely tuned print profiles, the MK4S delivers exceptional performance through precise directional cooling and an extreme 75° overhang, easily handling flexible materials. The MK4S offers excellent dimensional accuracy, allowing you to reliably print parts.

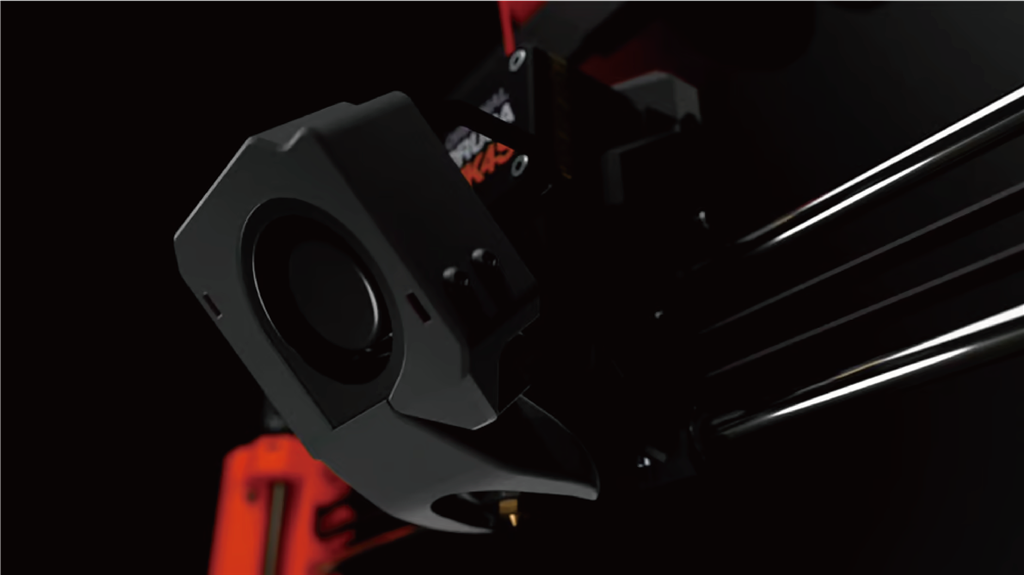

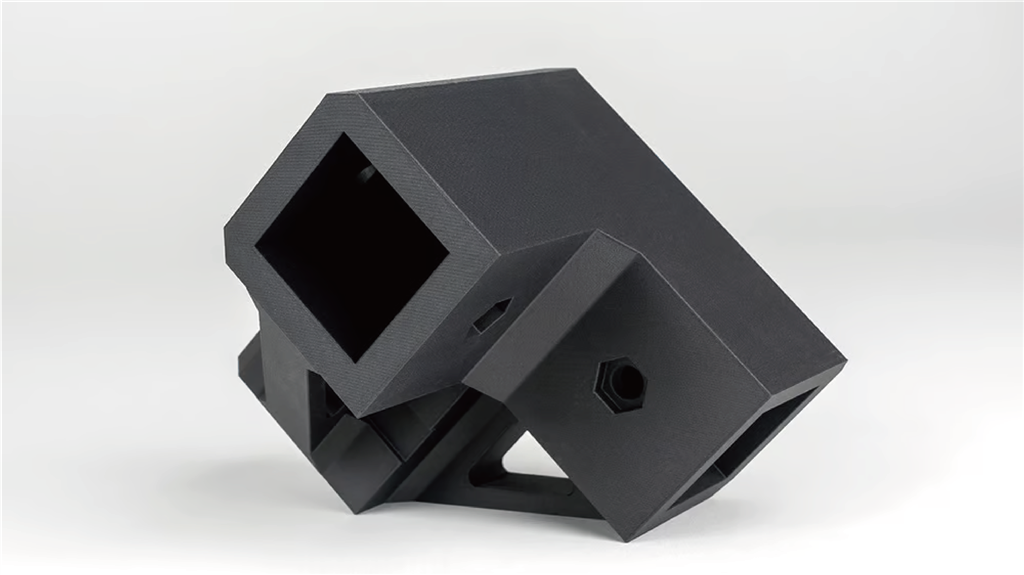

High-performance 360° cooling

The MK4S features a brand-new 360° cooling system, comprised of a high-performance motor and a redesigned fan shroud, ensuring that cool air is precisely directed onto the printhead. This solution is more efficient than traditional fans because airflow is not obstructed by the printhead itself. The Nextruder maintains almost the same weight but delivers significantly better performance.

Even with a large motor, the printer remains remarkably quiet and can produce prints with extreme 75° overhangs. The MK4S also effortlessly delivers aesthetically pleasing prints. Less support results in shorter printing times and less material waste.

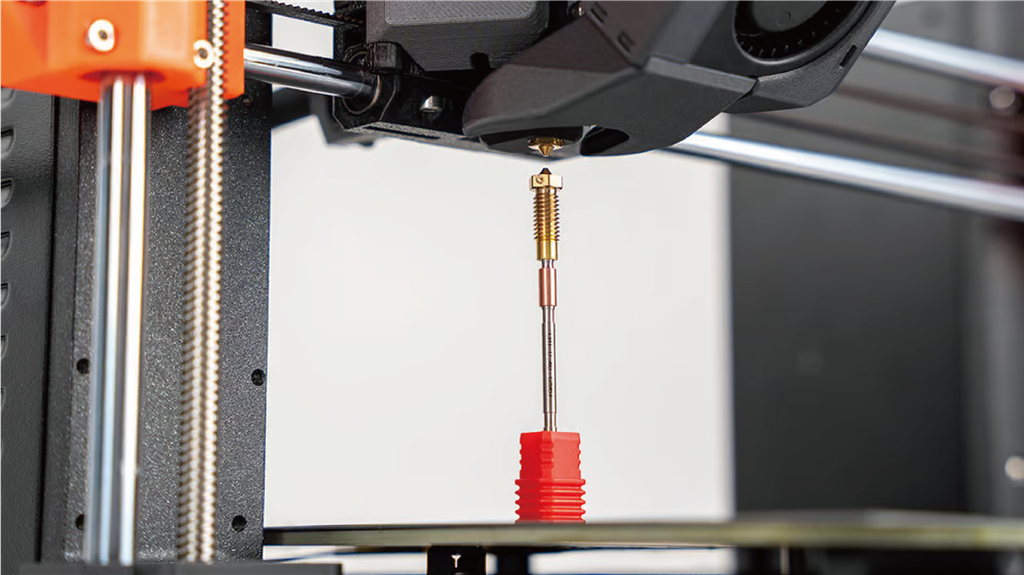

Original factory high-flow nozzle

The MK4S comes standard with a high-flow nozzle based on CHT technology. This high-flow nozzle not only enables faster printing speeds but also produces more durable prints. Furthermore, you can fully utilize your familiar and preferred supplies without needing to search for any dedicated high-flow supplies. Compared to the standard nozzle in the MK4, the new high-flow nozzle can increase flow rate by 50% to 114%, depending on the material and nozzle diameter.

Handling any type of cable

Whether your artwork requires PLA and PETG, or even ASA and carbon fiber, the MK4S can handle them appropriately. Printing flexible materials with the MK4S is easier than ever before, allowing you to easily create amazing and fun pieces.

Precisely measure offset

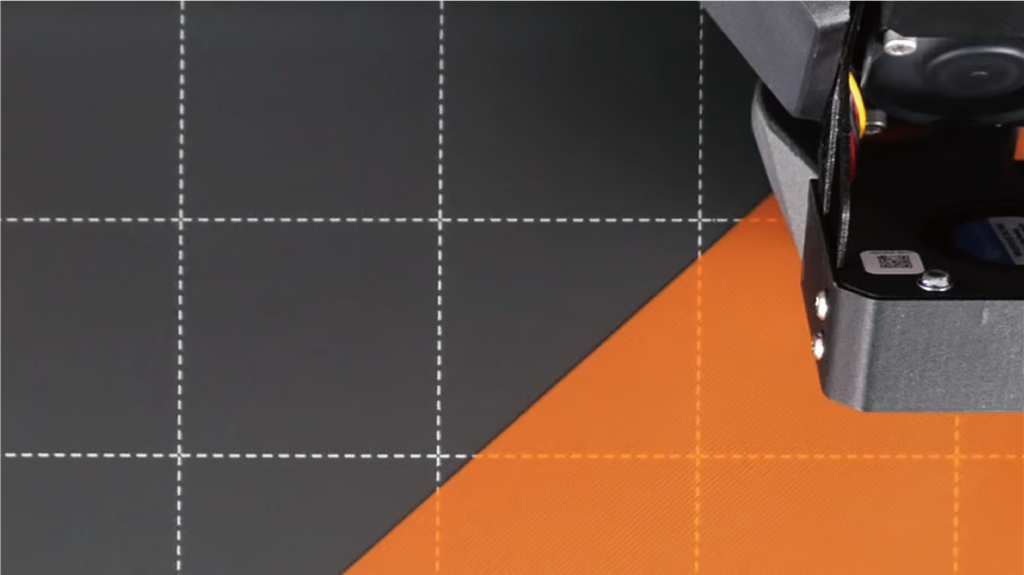

You don't need to painstakingly adjust the Z-axis or perform frequent manual calibrations. Regardless of the printing platform you use, the MK4S Loadcell sensor will accurately measure offsets without interference from reflective or textured surfaces. This sensor provides excellent accuracy for a wide range of printed products!

Incredible dimensional accuracy

When your designed parts need to fit with existing objects, or when you want to ensure screw hole matching, you need dimensionally accurate 3D prints. The MK4S has been tuned in terms of firmware and print settings for excellent print quality, thus delivering satisfactory dimensional accuracy.

WIFI and Prusa Connect

The genuine Prusa MK4S comes equipped with a Wi-Fi module and a LAN port, allowing you to control your printer from anywhere using the secure and encrypted Prusa Connect system. Prusa Connect offers powerful features, letting you schedule print jobs or monitor remotely via a network camera. With the Prusa app, the MK4S also allows you to quickly set up Wi-Fi using simple NFC sensing.

Dedicated Prusa application

Quickly browse all printers and running print jobs, and start, pause, and stop printing from anywhere with an intuitive and simple interface. You can also access printable files directly from the app; if your project contains printable files, simply tap the print button to start printing instantly, without needing slicing software. This app is available for iOS and Android and requires no additional printer setup.

Actively update

Even years after its release, Prusa continues to update its products, bringing more complete and practical features that change the way you print. The MK3S+ has received continuous firmware updates over the years. The original Prusa MINI received a major update four years after its release, doubling its printing speed. And the MK4S is the latest version of Prusa's proven MK4 platform.

Designed for offline use

The MK4S is designed for offline use, so you can use it without an internet connection. The printer can be fully configured without network access, and there are no drawbacks or limitations. For use cases requiring the highest level of information security, it will not affect printing progress or functionality.

Comparison of MK4S, MK3S+, and MINI+

Original Prusa MK4S

|

Original Prusa i3 MK3S+

|

Original Prusa MINI+

|

|

| Construction volume |

250 x 210 x 220 mm | 9.84 x 8.3 x 8.6 inches | 250 x 210 x 210 mm | 9.84 x 8.3 x 8.3 inches | 180 x 180 x 180 mm | 7 x 7 x 7 inches |

Maximum hot end/heated bed temperature |

290°C/120°C (554°F/248°F) |

290°C/120°C (554°F/248°F) |

280°C/100°C (536°F/212°F) |

| motherboard | Customized 32-bit xBuddy electronic products using STM32 | Einsy RAMBo 8-bit board |

Customized 32-bit Buddy Electronics using STM32 |

| Stepper driver | Sanhe2130 | Sanhe2130 | Sanlian 2209 |

| Stepper motor | Precise 0.9° X, Y stepper motors (prevent VFA) | Standard 1.8° X, Y stepper motor | Standard 1.8° X, Y stepper motor |

| MMU3 Support | Yes |

Yes |

No |

| Extruder electronic equipment | Customized breakout boards for connecting fans, thermistors, and other components. | No |

No |

| Filament path | Aluminum radiator, all-metal heating element |

Aluminum radiator, all-metal heating element |

Aluminum radiator, all-metal heating element |

| drive system | Nextruder planetary gear system, 10:1 gear ratio | direct drive |

Bowden system with a 3:1 gear ratio |

| First layer calibration | Fully automatic (thanks to the weighing sensor) | Manually adjust Z | Manually adjust Z |

| Quick-change nozzle system | Yes |

| Build volume | 250 x 210 x 220 mm | 9.84 x 8.3 x 8.6 in |

| wire diameter | 1.75 |

| floor height | 0.05-0.30mm |

| motherboard | Custom 32-bit xBuddy electronics with STM32 |

| Stepper driver | Trinamic 2130 |

| Stepper motor | Precision 0.9° X, Y stepper motors (to prevent VFA) |

| Extruder | Nextruder extruder, direct drive, compatible with E3D V6 (with adapter) |

| Extruder electronic components | Custom-designed junction boards for connecting fans, thermistors, and other components. |

| Wire path | Aluminum radiator, all-metal heatsink |

| drive system | Nextruder planetary gear system, 10:1 gearbox ratio |

| Nozzle diameter | Nozzle diameter 0.4mm (preset) / Other nozzle diameters supported |

| Nozzle maximum temperature | 290 °C |

| Maximum heated bed temperature | 120 °C |

| LCD screen | 3.5-inch 65k color graphics screen |

| Connection method | Optional ESP Wi-Fi module (included with device). |

| File transfer | USB / LAN / Internet access via Prusa Connect |

| Advanced Sensors | Wire sensor, Loadcell sensor, Power panic, 4 high-precision thermistors (genuine Semitec) + fan motor RPM monitoring |

| Printing Platform | Magnetic heated bed with removable PEI spring steel sheets. |

| Printing platform bed calibration | Automatic wire bed leveling (only in the printing area) |

| Support cable | PLA, PETG, ABS, ASA, Flex, HIPS, PA, PVA, PC, PP, CPE, PVB, NGEN composite materials, etc. |

| Equipment dimensions (excluding spools) | 7 kg, 500×550×400 mm; 19.6×21.6×15.7 inches (X×Y×Z). |

| power supply | 240W, custom-made by Delta, equipped with Power Panic HW |

| Power consumption | PLA settings: 80W ABS setting: 120W |