Mayku | Product Model:

MK0011

Mayku Multiplier Tabletop Compression Molding Machine

Subtotal

—

Mayku Multiplier Tabletop Compression Molding Machine is backordered and will ship as soon as it is back in stock.

Choose add-on

Couldn't load pickup availability

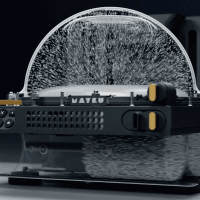

Mayku Multiplier Benchtop Compression Molding Machine

Compression forming is an industrial-grade mold-making technology used for the rapid production of molds and parts. The Mayku Multiplier benchtop compression forming machine is the world's first desktop compression forming machine, using high pressure to heat, soften, and shape a sheet of material . Compression forming can create molds finer than a human hair, and the entire process takes only one minute. Just place and press—realizing your ideas is that simple! Vacuum forming VS Compression forming: What's the difference? We'll tell you all at once!

Create high-resolution molds/parts in 1 minute:

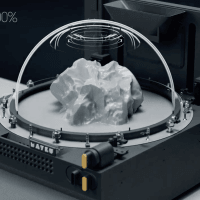

Step 1: First, place a sheet of molding material into the Multiplier compression molding machine, and then place the item to be processed on the molding platform below the sheet of material .

Step 2: Pull the handle down and the machine will heat the material sheet to soften it. At the same time, it will apply 4 atmospheres of pressure to the material sheet , making the material sheet adhere tightly to the object and capture the shape of the object with a precision of 3 micrometers.

Step 3: Once the formed material sheet is removed from the Multiplier compression molding machine and cooled, it can be used as a mold to create the next batch of product prototypes. The whole process takes only about 1 minute. This mold can be filled with castable materials such as concrete, resin , or even chocolate.

Product Features:

• High precision quality: The Multiplier benchtop compression molding machine can produce ultra-precise mold edges, even capturing objects with 90-degree sharp corners !

• High level of detail : Capable of capturing textures finer than human hair.

Larger size: It has a circular molding area of 400mm wide x 400mm long x 160mm high, which is twice the size of the FormBox desktop compression molding machine !

Easy to operate : You can learn to operate the machine in 1 hour and start making a molding mold in 5 minutes.

• Portable : The Multiplier benchtop compression molding machine can be used on a table without external support.

• LED Touch Screen : Features a high-contrast LED touch screen, making machine operation more convenient and clearer.

Compared to traditional FormBox vacuum forming machines , the newly designed Multiplier benchtop pressure forming machine is more powerful and precise, making it the top choice for creating large molds!

Click here to see more Mayku Multiplier case studies and unboxing tutorials

[Pressure Molding Tutorial] Creating Custom Precision Models! Mayku Multiplier Unboxing and Complete Guide!

[Vacuum & Pressure Forming Applications] Vacuum Forming VS Pressure Forming: What's the Difference? We'll Tell You All About It!

[Pressure Molding Applications] Home Furnishing Accessory Mold Making – Used by Top Designers!

[Pressure Molding Application] Silicone flip-flops: Self-contained production line, no outsourcing required!

Contact us now to learn more about pressure molding machines !

| Forming bed size | 400mm x 400mm x 160mm |

| Maximum material sheet thickness | PETG, Flex sheets, and other materials with a thickness of 0.5mm - 8mm are acceptable. |

| Minimum material sheet thickness | 0.5mm |

| Detail resolution | 0.0004mm |

| External pump | unnecessary |

| size | 585mm x 515mm x 420mm |

| weight | 57 kg (including packaging) |