Roland | Product Model:

RL0002

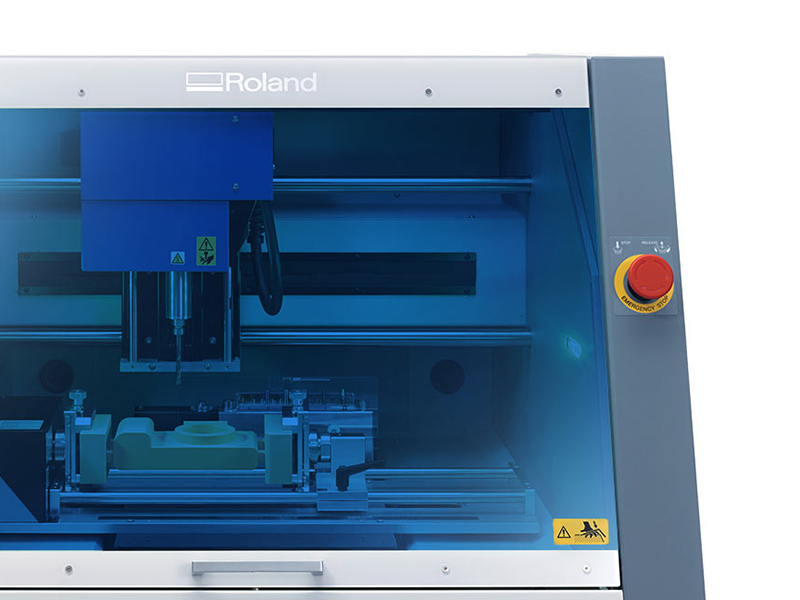

Benchtop CNC milling machine MDX-50

Regular price

¥2,570,300 JPY

Unit price

/

Unavailable

Subtotal

—

Benchtop CNC milling machine MDX-50 is backordered and will ship as soon as it is back in stock.

Choose add-on

Couldn't load pickup availability

Benchtop CNC milling machine MDX-50

Includes complete instructions and on-site installation.

The MDX-50 combines precise automatic cutting capabilities with ease of use, making it an ideal solution for short-cycle and prototyping applications. The MDX-50 reduces operation time and simplifies production processes, allowing users to easily create CNC functional parts from a variety of materials.

MDX-50 Main Features

• Desktop CNC rapid prototyping machine. • Standard ATC automatic tool changer – continuous operation without downtime for tool changes. • Expanded working area: 15.8" (X) x 12" (Y) x 5.3" (Z)

• Optimized drive system supports three-dimensional stability of the equipment. • Includes user-friendly CAM software. • Optional rotary axis, self-centering spindle box, and tailstock workpiece clamping device.

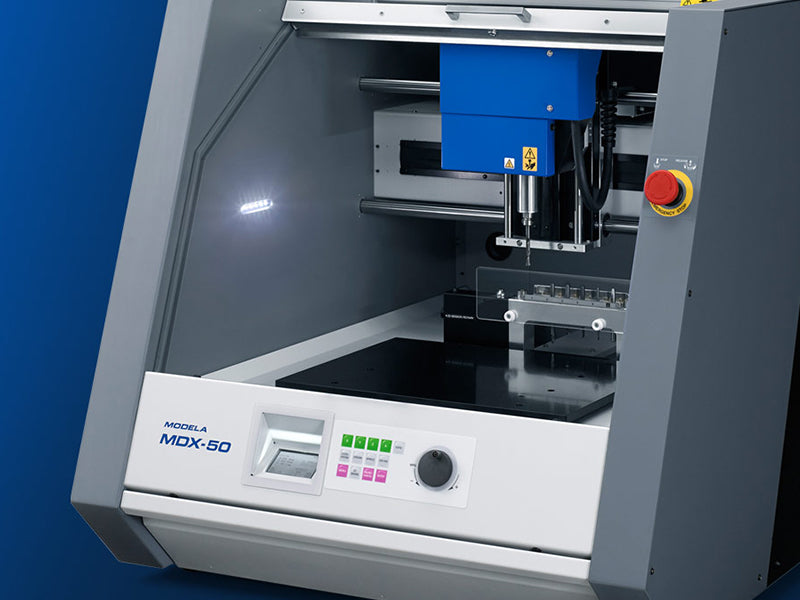

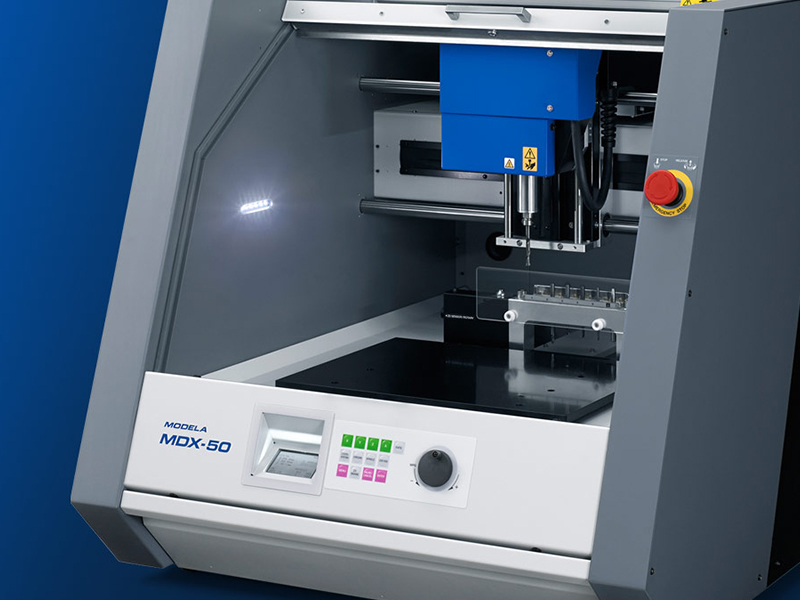

Easy-to-use control panel and software

The MDX-50 features a simple yet powerful built-in control panel and virtual control panel (VPanel), along with the included SRP Player CAM software, simplifying operation and making the device easy to use, helping you instantly become a CNC cutting expert. The control panel can manage almost all operations, eliminating the need to switch between the computer and the device. The VPanel interface seamlessly integrates with the MDX-50, allowing users to easily adjust spindle speeds and rates.

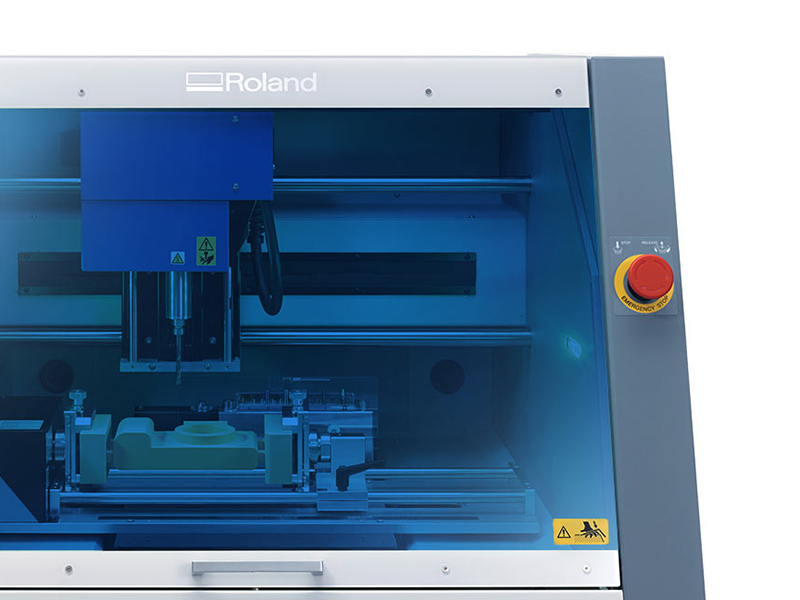

Automatic tool changer

The expanded processing area of the MDX-50 CNC rapid prototyping machine enhances equipment performance and reduces production time, effectively accelerating product processing. Additionally, five automatic tool changers allow for uninterrupted tool changes without downtime. Common materials used in the MDX-50 desktop CNC rapid prototyping machine include: ABS, POM, nylon foam, wax molds, PVC plywood, hardwood, and acetal plastics.

Polishing details and smooth surface finish

With its drive system, machine rigidity, and enhanced drive mechanism, the MDX-50 milling machine enables very smooth and precise prototyping, suitable for testing structures, functions, and assembly with other parts. Its 400 x 305 x 135mm machining area allows for the production of large objects or the mass production of smaller parts.

Other outstanding features

• Advanced drive system maintains equipment stability. Large machining area, increased equipment robustness, and upgraded drive unit. Optional easy-to-use tools and automatic equipment calibration. No special electrical settings or additional air compressor required. User is alerted to equipment status via color LED status indicators and email. Built-in debris collection trough with rail-mounted safety door ensures safe and clean production. Suitable for workshops and educational environments.

Automatic tool changer and optional spindle

The automatic sensing function adjusts the tool length to ensure precision for every cutting task, and the optional rotary axis can easily complete complex surface cutting. The material can rotate automatically within the range of 0-360 degrees, enabling 2-sided, 4-sided, and custom angle indexing.

Simplified settings

The MDX-50's working area and built-in lighting improve visibility and enable quick setup. Additionally, the included tool adapter helps with the rapid installation of ATC tools—no wrenches or other tools are needed.

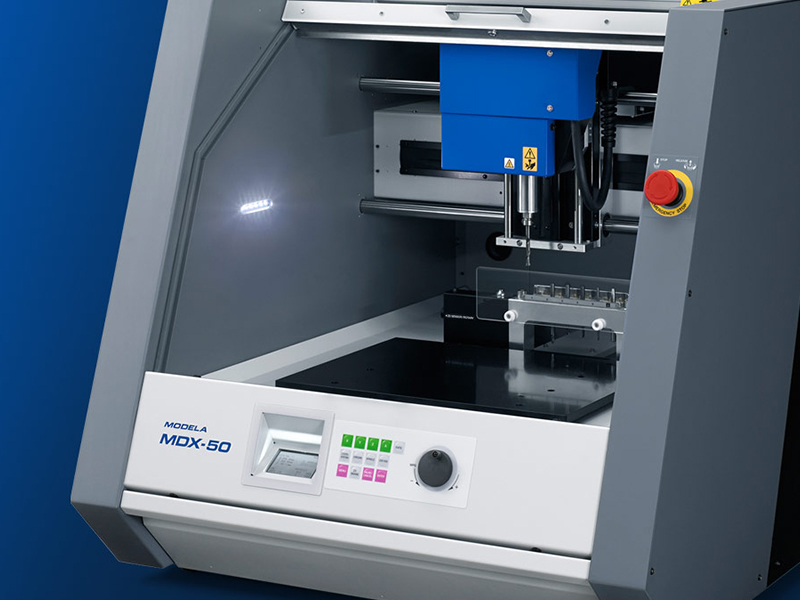

Clean, tidy, and convenient

The MDX-50 is suitable for use in studio and teaching environments. Built-in rail safety doors ensure safe operation, and built-in drawers collect debris for easy cleaning.

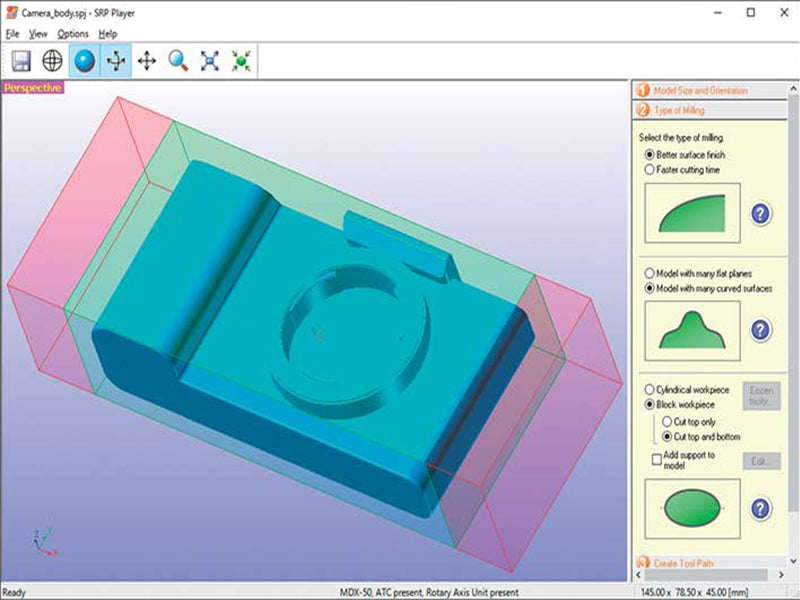

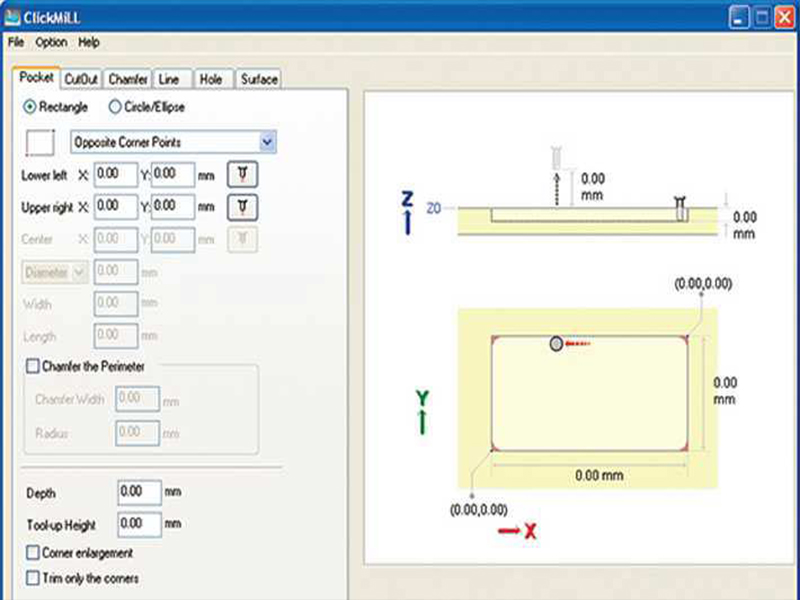

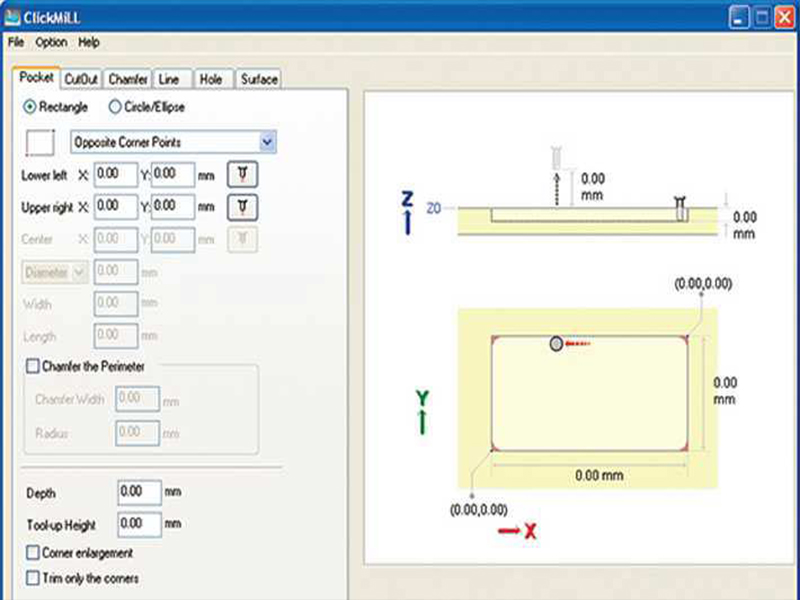

SRP Player CAM

This popular software, widely used in both industrial and educational fields, has been upgraded based on the advanced features of the MDX-50. Cutting setup can be completed in just five simple steps, making it easy for even beginners to master the operation. ClickMill software directly controls the MDX-50's milling of planes, drilling, slotting, and other machining processes without the need for CAD or CAM software. The MDX-50 also supports G-Code NC encoding, making it suitable for professional applications as well.

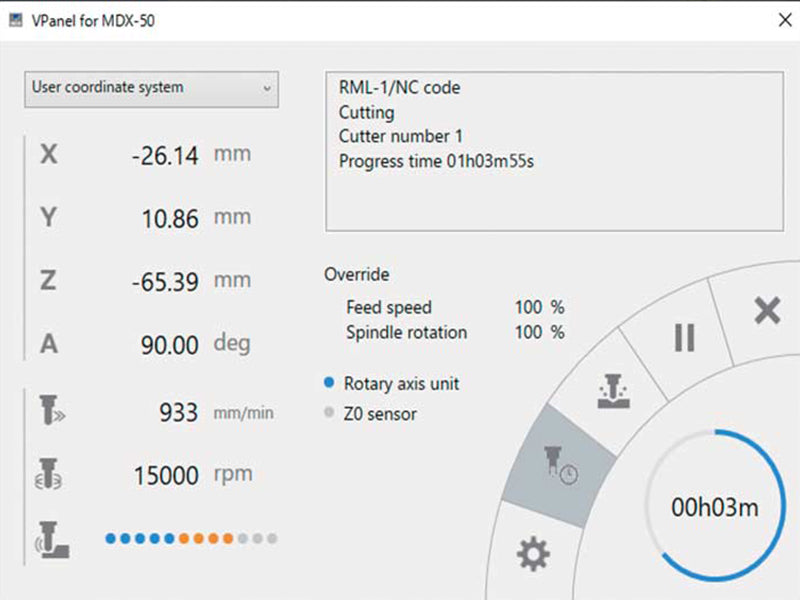

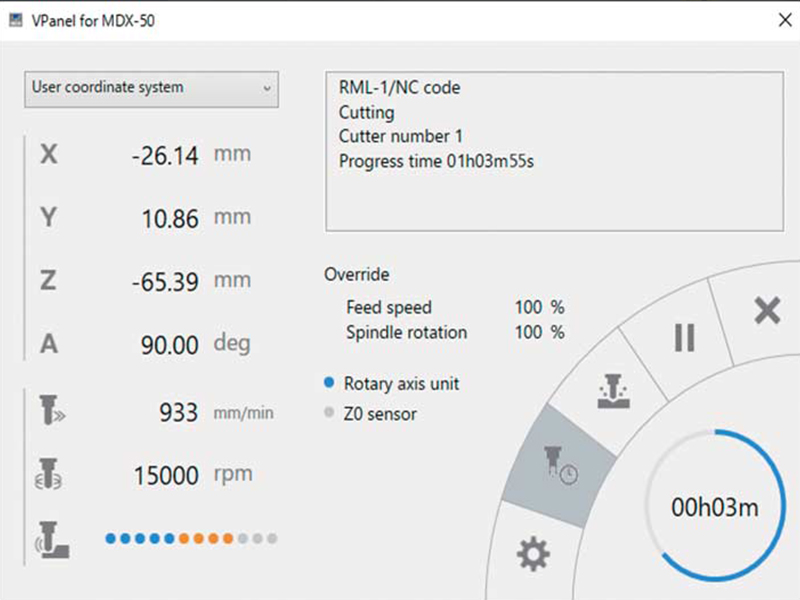

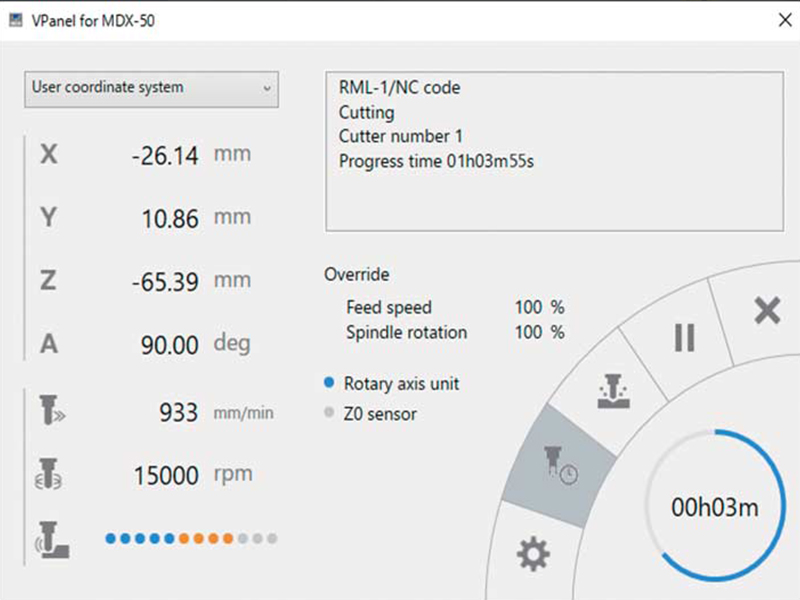

Virtual Control Panel (VPanel)

Vpanel is a virtual control panel that has all the functions of a regular control panel, plus tool usage management and email notification features.

Roland's international ISO certification is an acknowledgment of its high-quality products and excellent service, and the product comes with a one-year warranty.

Includes complete instructions and on-site installation.

The MDX-50 combines precise automatic cutting capabilities with ease of use, making it an ideal solution for short-cycle and prototyping applications. The MDX-50 reduces operation time and simplifies production processes, allowing users to easily create CNC functional parts from a variety of materials.

MDX-50 Main Features

• Desktop CNC rapid prototyping machine. • Standard ATC automatic tool changer – continuous operation without downtime for tool changes. • Expanded working area: 15.8" (X) x 12" (Y) x 5.3" (Z)

• Optimized drive system supports three-dimensional stability of the equipment. • Includes user-friendly CAM software. • Optional rotary axis, self-centering spindle box, and tailstock workpiece clamping device.

Easy-to-use control panel and software

The MDX-50 features a simple yet powerful built-in control panel and virtual control panel (VPanel), along with the included SRP Player CAM software, simplifying operation and making the device easy to use, helping you instantly become a CNC cutting expert. The control panel can manage almost all operations, eliminating the need to switch between the computer and the device. The VPanel interface seamlessly integrates with the MDX-50, allowing users to easily adjust spindle speeds and rates.

Automatic tool changer

The expanded processing area of the MDX-50 CNC rapid prototyping machine enhances equipment performance and reduces production time, effectively accelerating product processing. Additionally, five automatic tool changers allow for uninterrupted tool changes without downtime. Common materials used in the MDX-50 desktop CNC rapid prototyping machine include: ABS, POM, nylon foam, wax molds, PVC plywood, hardwood, and acetal plastics.

Polishing details and smooth surface finish

With its drive system, machine rigidity, and enhanced drive mechanism, the MDX-50 milling machine enables very smooth and precise prototyping, suitable for testing structures, functions, and assembly with other parts. Its 400 x 305 x 135mm machining area allows for the production of large objects or the mass production of smaller parts.

Other outstanding features

• Advanced drive system maintains equipment stability. Large machining area, increased equipment robustness, and upgraded drive unit. Optional easy-to-use tools and automatic equipment calibration. No special electrical settings or additional air compressor required. User is alerted to equipment status via color LED status indicators and email. Built-in debris collection trough with rail-mounted safety door ensures safe and clean production. Suitable for workshops and educational environments.

Automatic tool changer and optional spindle

The automatic sensing function adjusts the tool length to ensure precision for every cutting task, and the optional rotary axis can easily complete complex surface cutting. The material can rotate automatically within the range of 0-360 degrees, enabling 2-sided, 4-sided, and custom angle indexing.

Simplified settings

The MDX-50's working area and built-in lighting improve visibility and enable quick setup. Additionally, the included tool adapter helps with the rapid installation of ATC tools—no wrenches or other tools are needed.

Clean, tidy, and convenient

The MDX-50 is suitable for use in studio and teaching environments. Built-in rail safety doors ensure safe operation, and built-in drawers collect debris for easy cleaning.

SRP Player CAM

This popular software, widely used in both industrial and educational fields, has been upgraded based on the advanced features of the MDX-50. Cutting setup can be completed in just five simple steps, making it easy for even beginners to master the operation. ClickMill software directly controls the MDX-50's milling of planes, drilling, slotting, and other machining processes without the need for CAD or CAM software. The MDX-50 also supports G-Code NC encoding, making it suitable for professional applications as well.

Virtual Control Panel (VPanel)

Vpanel is a virtual control panel that has all the functions of a regular control panel, plus tool usage management and email notification features.

Roland's international ISO certification is an acknowledgment of its high-quality products and excellent service, and the product comes with a one-year warranty.

| Brand - Model | Roland- MDX-50 | |

|---|---|---|

| Acceptable materials* | Resins, such as chemical wood and model wax (metals are not supported) | |

| Operating range | X: 15.80 in (400 mm) Y: 12.00in (305 mm) Z: 5.315in (135 mm) |

|

| Workbench size | W: 15.80in (400 mm) D: 12.00in (305 mm) |

|

| Loadable workpiece size | X: 15.80 in (400 mm) Y: 12.00in (305 mm) Z: 3.90in (100 mm) |

|

| Axis drive | Stepper motor | |

| feed rate | XY: 0.3 to 141.7 inches/minute (7 to 3600 millimeters/minute) Z: 0.3 to 118.1 inches/minute (7 to 3600 mm/minute) |

|

| Software resolution | RML-1: 0.001 mm/step NC code 0.001 mm/step | |

| Mechanical resolution | 0.01 mm/step (0.39 mils/step; half step) | |

| spindle motor | DC brushless motor | |

| Spindle speed | 4500~15000 RPM | |

| knife clip | sleeve | |

| Tool changing method | Automatic tool changer (ATC) | |

| ATC clip capacity | 5 cutting tools + 1 probe (6-bit capacity) | |

| Handle diameter | 0.250 inches, 0.125 inches (6.35, 3.175 mm) | |

| Operating noise | run | |

| Dust collection box size | 23.62 x 27.65 x 3.74 inches (600 x 700 x 95 mm) | |

| interface | USB | |

| Power requirements (VAC / A) | AC 100 to 240V ±10%, 50/60Hz, 1.2A (Voltage category: II, IEC 60664-1) |

|

| Power consumption (W) | ≒95W | |

| (Decibel) Noise Level | No-load operation: | Not exceeding 60 decibels (A) |

| Standby: | Not exceeding 45 decibels (A) | |

| External dimensions | Width x Depth x Height: | 29.92×35.43×28.82 inches (760×900×732 mm) |

| weight | 269 pounds (122 kilograms) | |

| Installation Environment | Use indoor height | Not exceeding 6500 inches (2000 meters) |

| temperature | 41 to 104°F (5 to 40°C) | |

| humidity | 35 to 80% RH (non-condensing) | |

| Environmental pollution level | 2 (as specified by IEC 60664-1) | |

| Short-term temporary voltage | 1440 V | |

| Long-term temporary voltage | 490 volts | |

| Included accessories | Power cord, USB cable, manual, Roland software package CD, probes, hex screwdriver, hex wrench, wrench, tool holder, tool positioner, Z0 sensor | |