Drywise | Product Model:

Drywise Vertical Smart Wire Dryer - 1.75 / 2.85 mm

Regular price

¥493,600 JPY

Unit price

/

Unavailable

Subtotal

—

Drywise Vertical Smart Wire Dryer - 1.75 / 2.85 mm - is backordered and will ship as soon as it is back in stock.

Choose add-on

Couldn't load pickup availability

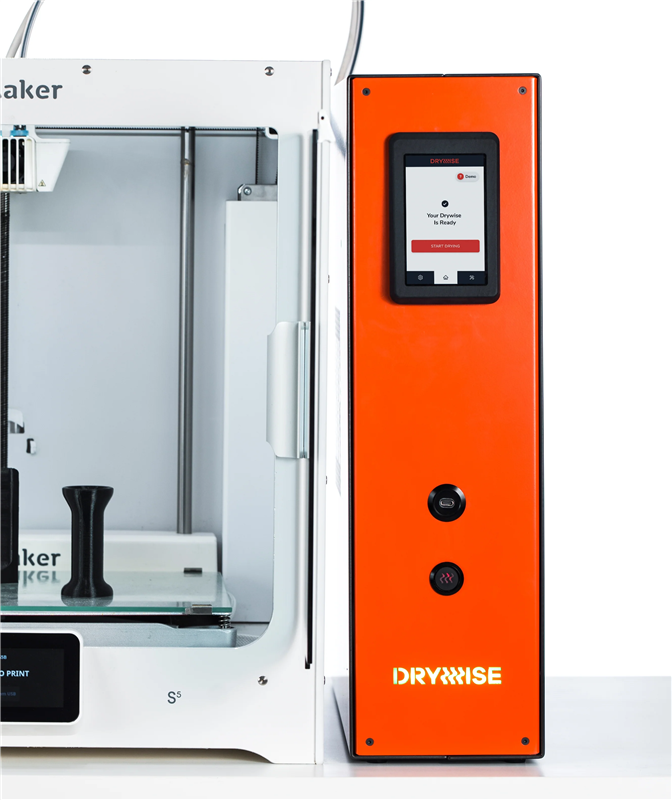

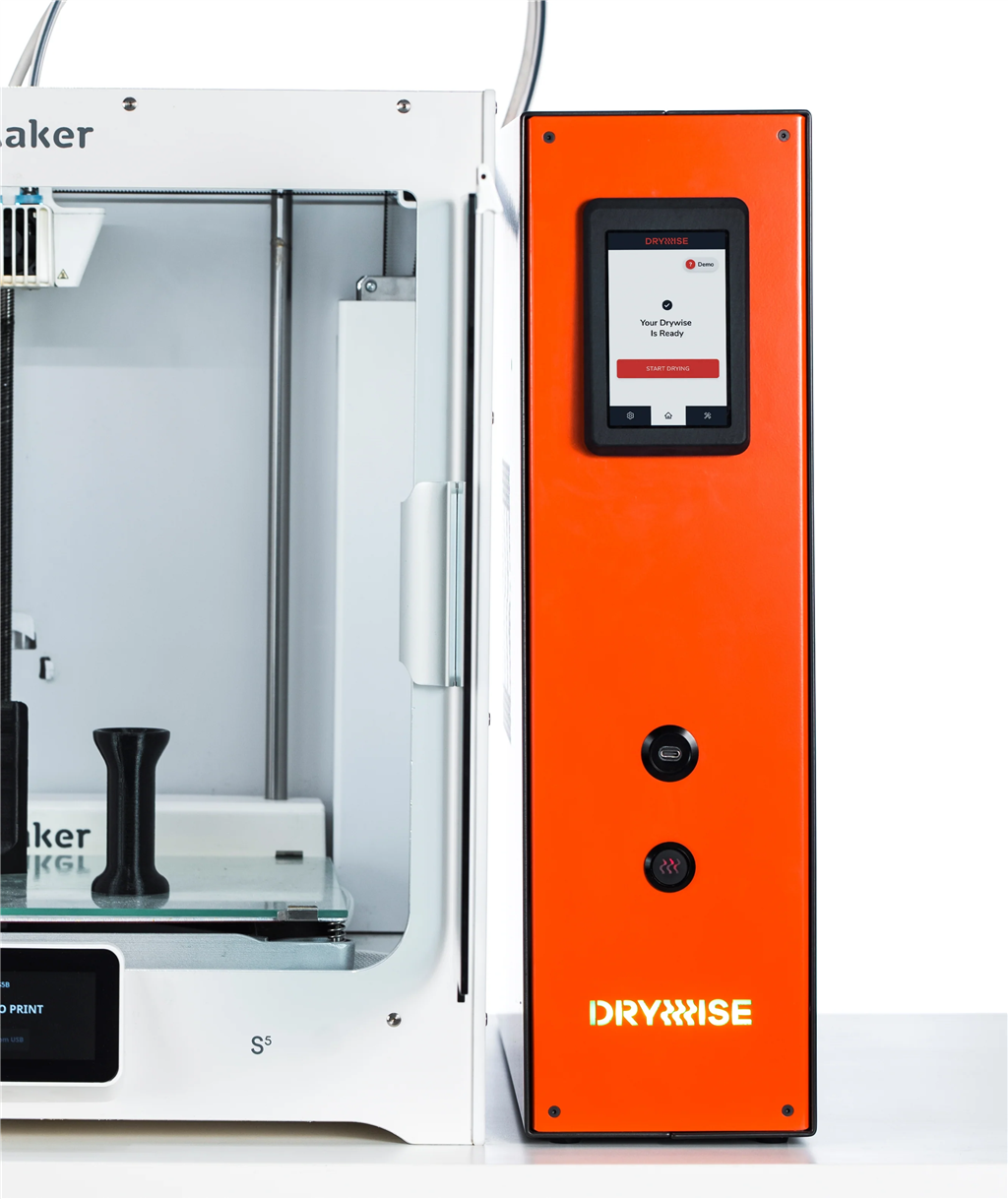

Drywise Vertical Smart Wire Dryer

Once opened, FDM filaments absorb a significant amount of moisture from the environment. If your 3D printing exhibits severe abnormalities such as filament pulling, clumping, or seepage, it's highly likely due to moisture absorption by the filaments. Therefore, dry filaments should be stored in a humidity-controlled environment. To address this issue, most 3D printing users dry the filaments in an oven and use material stations to reduce additional moisture absorption, or create temporary boxes with desiccants. This is not only cumbersome, but the non-standardized processing methods do not achieve ideal drying results. Furthermore, multiple pre-treatments of the filament spools can degrade the material quality.

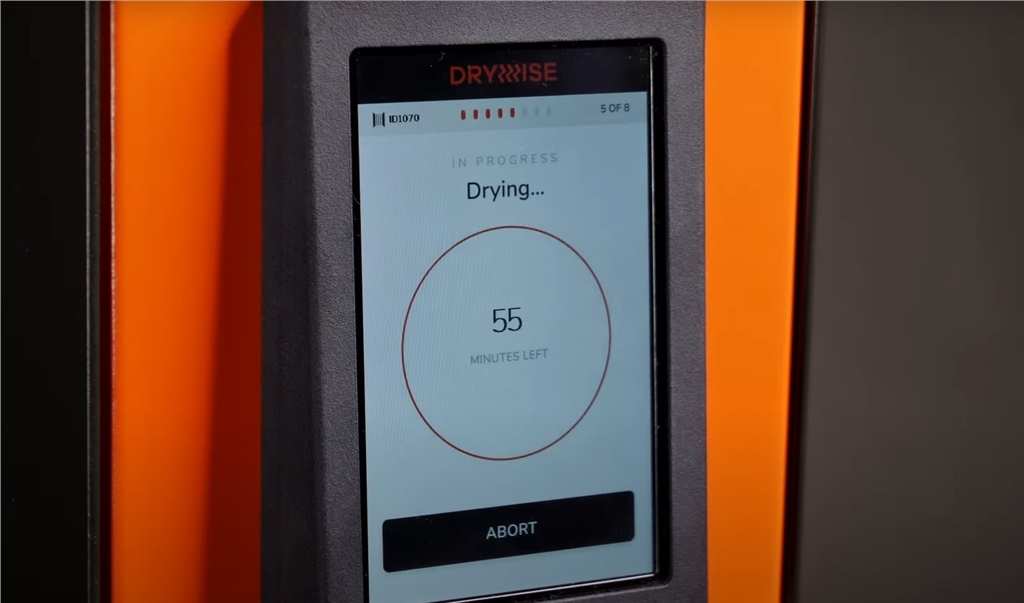

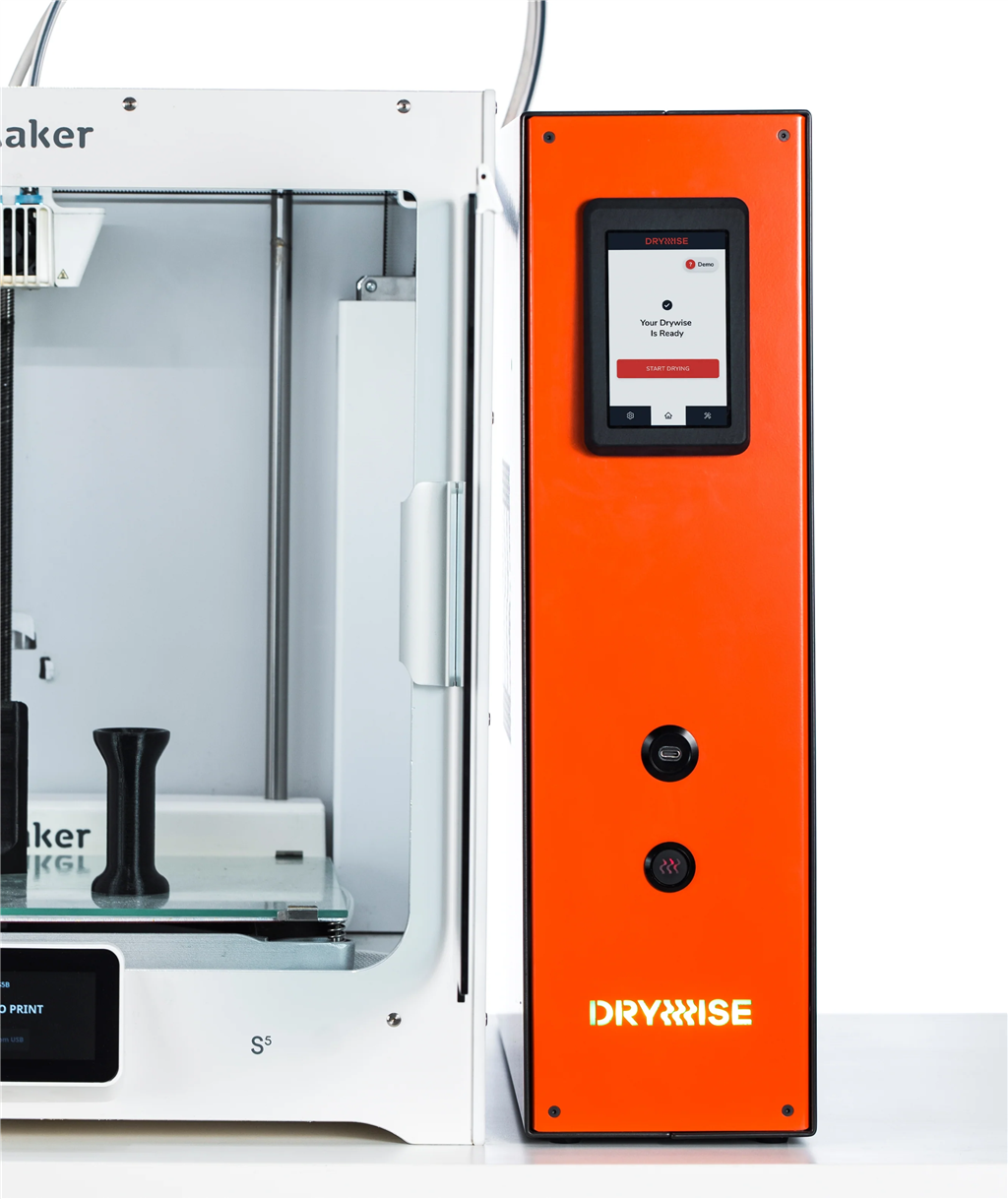

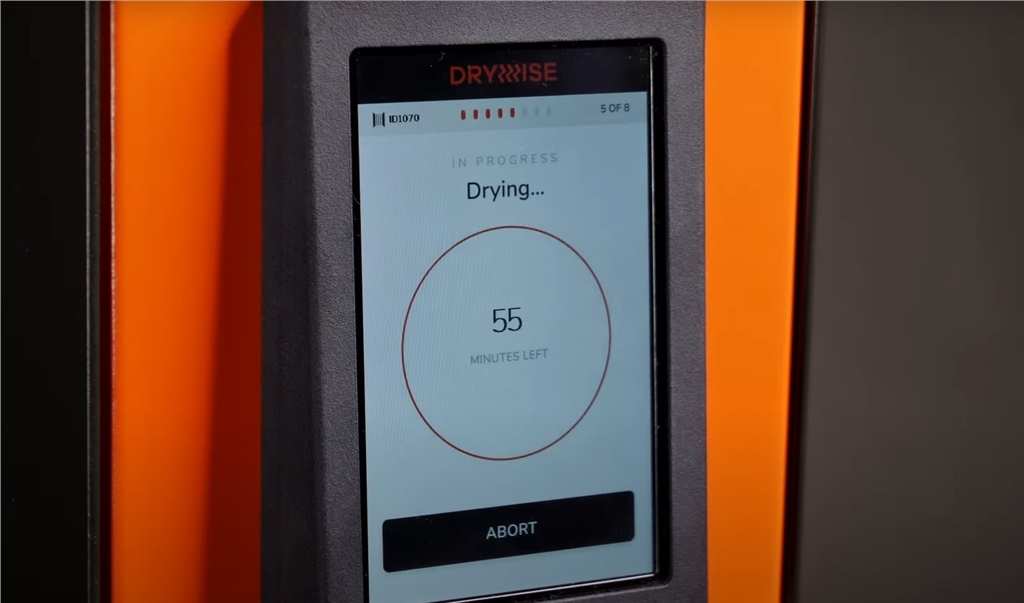

The Drywise filament dryer is a state-of-the-art device designed specifically for 3D printing, significantly improving printing efficiency and reducing filament stringing and clumping. Utilizing its intelligent drying technology, it pre-treats a small batch of filament in just 40-90 minutes, placing it in optimal printing conditions before starting 3D printing and maintaining consistency throughout the printing job, saving valuable time and reducing energy costs.

Drywise wire drying features

Once opened, FDM filaments absorb a significant amount of moisture from the environment. If your 3D printing exhibits severe abnormalities such as filament pulling, clumping, or seepage, it's highly likely due to moisture absorption by the filaments. Therefore, dry filaments should be stored in a humidity-controlled environment. To address this issue, most 3D printing users dry the filaments in an oven and use material stations to reduce additional moisture absorption, or create temporary boxes with desiccants. This is not only cumbersome, but the non-standardized processing methods do not achieve ideal drying results. Furthermore, multiple pre-treatments of the filament spools can degrade the material quality.

The Drywise filament dryer is a state-of-the-art device designed specifically for 3D printing, significantly improving printing efficiency and reducing filament stringing and clumping. Utilizing its intelligent drying technology, it pre-treats a small batch of filament in just 40-90 minutes, placing it in optimal printing conditions before starting 3D printing and maintaining consistency throughout the printing job, saving valuable time and reducing energy costs.

Drywise wire drying features

A more efficient 3D printing experience

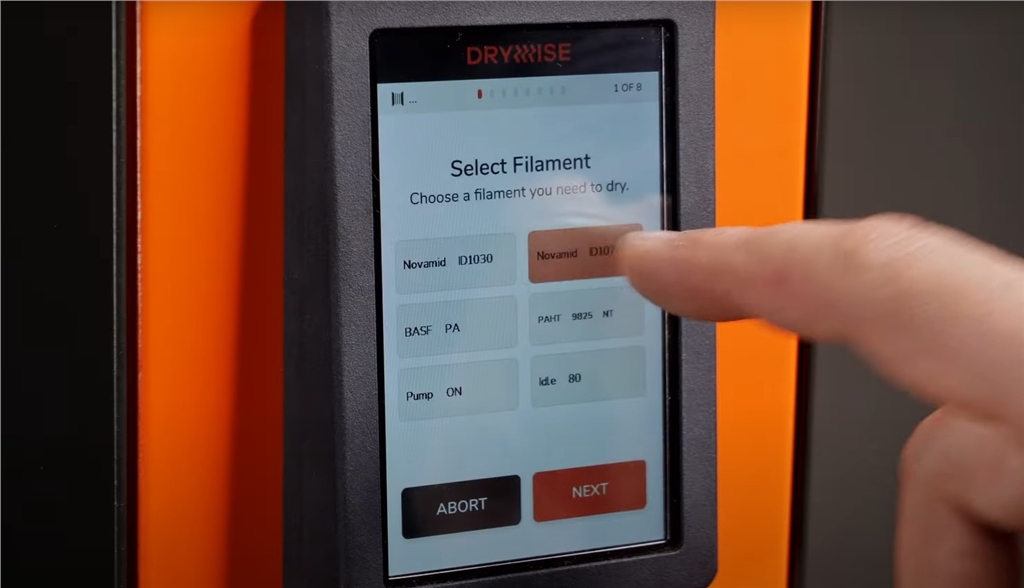

The built-in drying structure and instant drying function save valuable time. Furthermore, pre-calibrated certified material settings eliminate tedious testing and save the trouble of researching setup steps.

Shorter part completion time

Direct-connection drying is more efficient and eliminates the problem of excessively long drying times because it dries directly during the printing process.

Longer machine runtime

No prior planning is required, and it is now easier to fully utilize the machines.

Reduce energy costs

Due to its high drying efficiency, no auxiliary equipment is needed to maintain the wire in good condition.

Minimize material waste

Ensure excellent material quality control before and during printing.

The process is more streamlined and reliable.

Drywise eliminates uncertainties in material quality control, enabling flexible material usage to provide parts with optimal performance.

• fast

• fast

The linear design dries only the portion to be 3D printed, reducing the amount of work required.

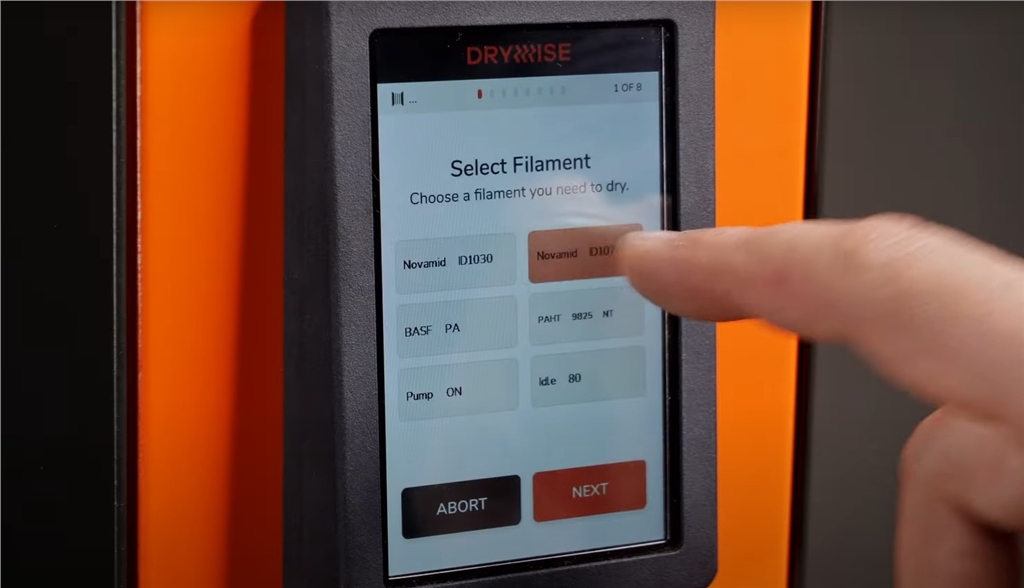

• Supported by intelligent systems

Use smart sensors to dry to optimal 3D printing conditions, avoiding overheating and over-drying.

• User-friendly

Use replaceable and rechargeable desiccant boxes to reduce downtime.

• Safe and reliable

A smart sensor system detects idle periods and shuts off the heater to ensure safety.

• Upgradeable

The list of certified consumables can be continuously expanded.

• Multifunctional

Thanks to its built-in architecture, Drywise can use any cable format or size. Drywise is available in 1.75mm or 2.85mm versions.

The built-in drying structure and instant drying function save valuable time. Furthermore, pre-calibrated certified material settings eliminate tedious testing and save the trouble of researching setup steps.

Shorter part completion time

Direct-connection drying is more efficient and eliminates the problem of excessively long drying times because it dries directly during the printing process.

Longer machine runtime

No prior planning is required, and it is now easier to fully utilize the machines.

Reduce energy costs

Due to its high drying efficiency, no auxiliary equipment is needed to maintain the wire in good condition.

Minimize material waste

Ensure excellent material quality control before and during printing.

The process is more streamlined and reliable.

Drywise eliminates uncertainties in material quality control, enabling flexible material usage to provide parts with optimal performance.

The linear design dries only the portion to be 3D printed, reducing the amount of work required.

• Supported by intelligent systems

Use smart sensors to dry to optimal 3D printing conditions, avoiding overheating and over-drying.

• User-friendly

Use replaceable and rechargeable desiccant boxes to reduce downtime.

• Safe and reliable

A smart sensor system detects idle periods and shuts off the heater to ensure safety.

• Upgradeable

The list of certified consumables can be continuously expanded.

• Multifunctional

Thanks to its built-in architecture, Drywise can use any cable format or size. Drywise is available in 1.75mm or 2.85mm versions.

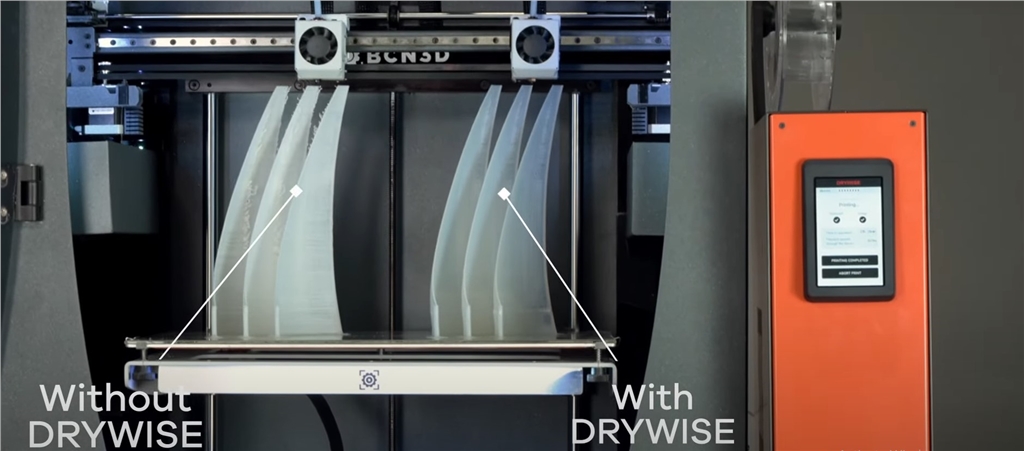

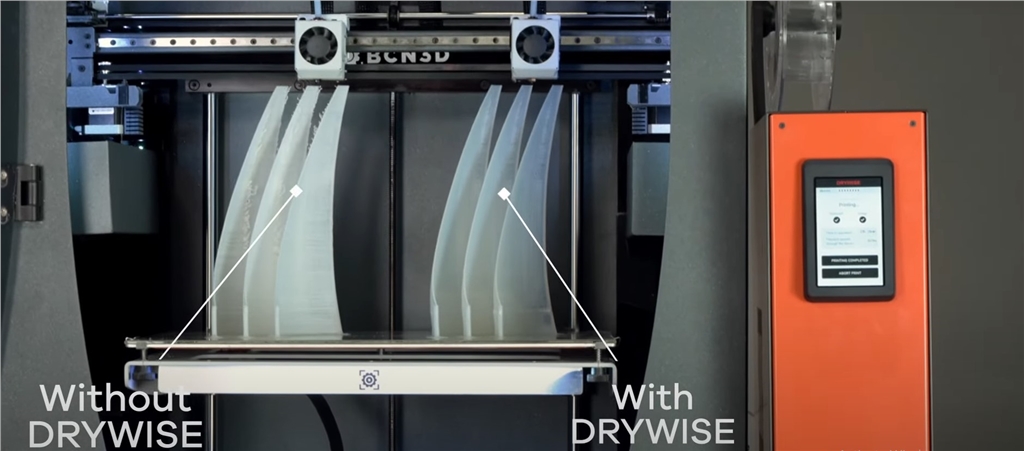

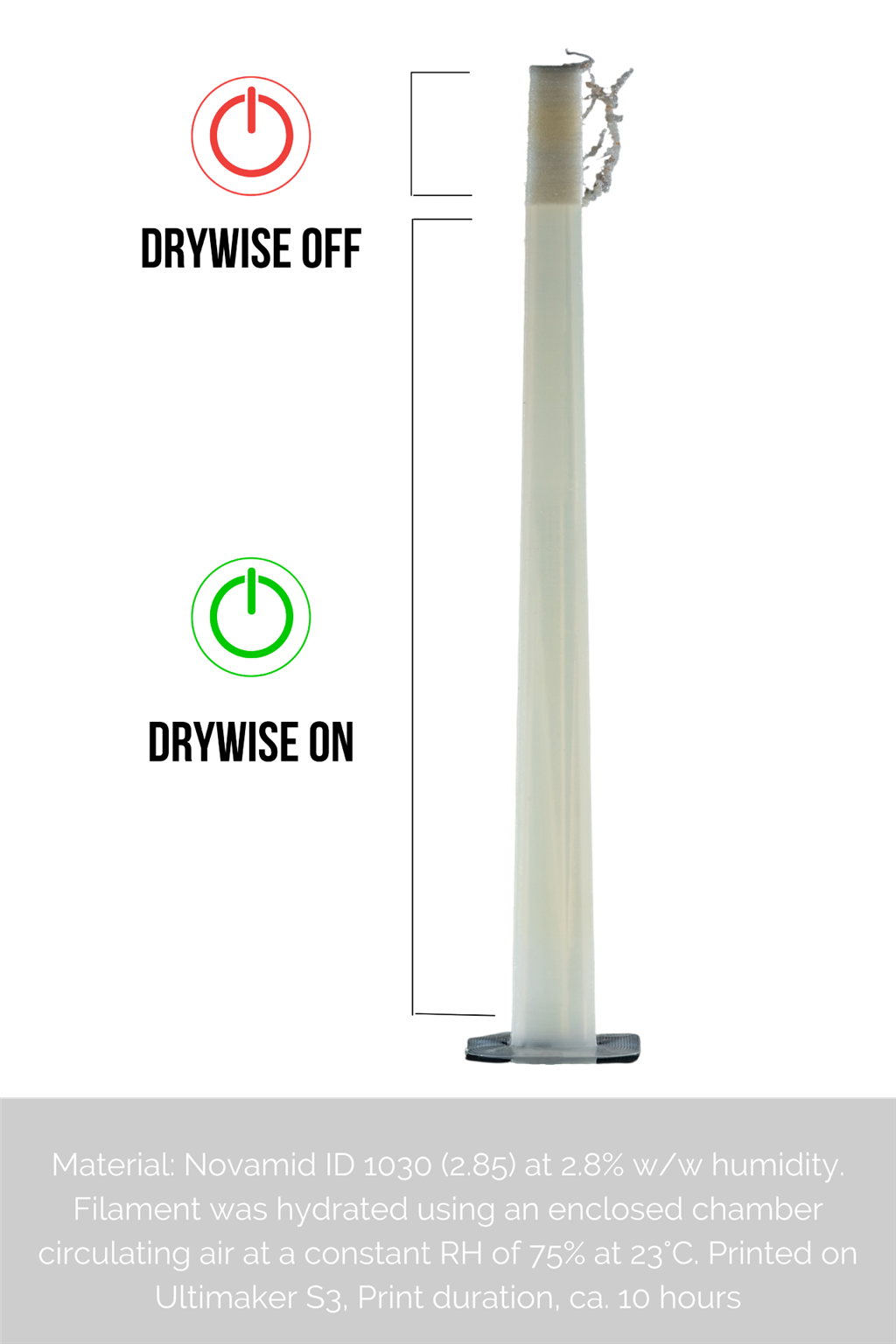

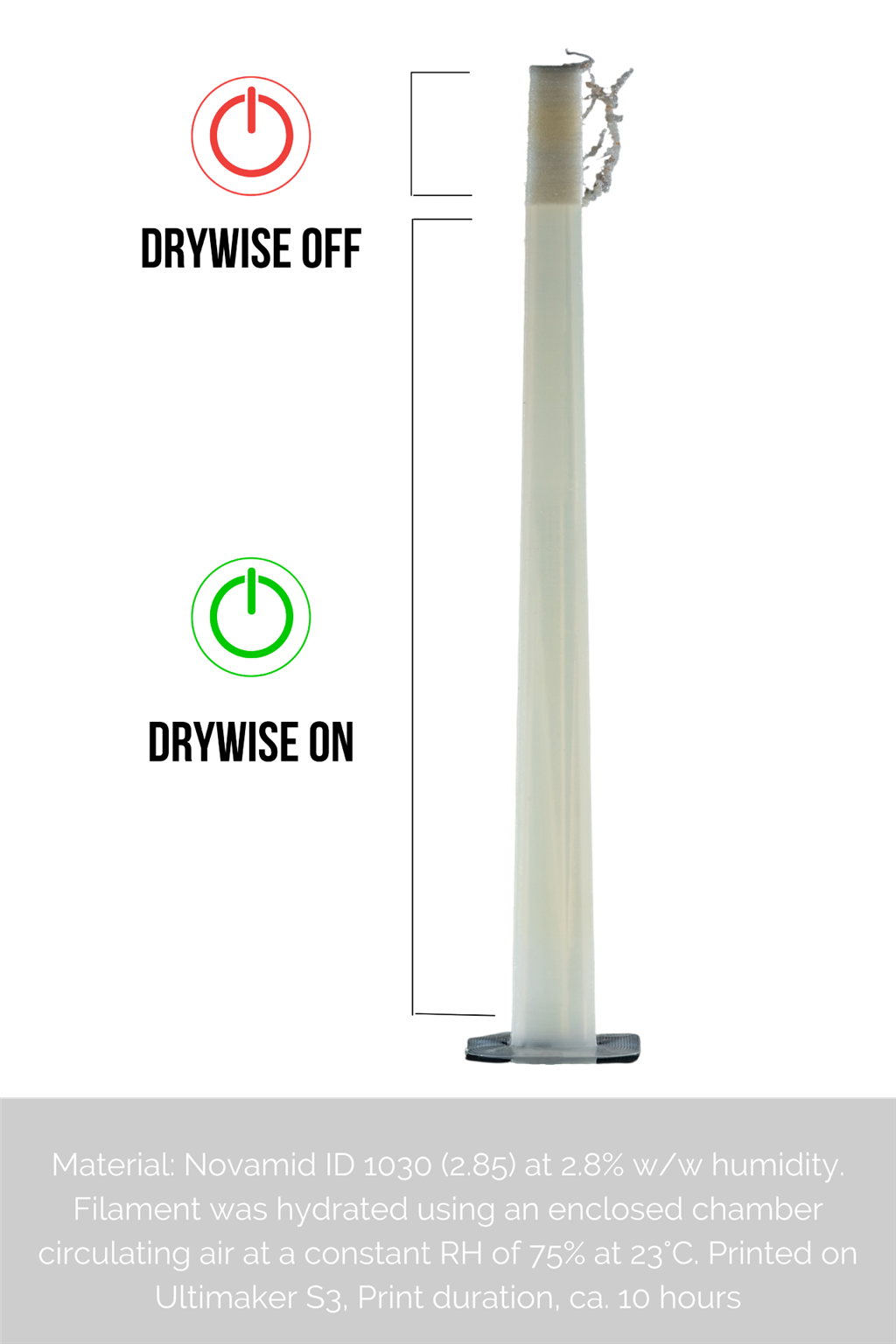

Drywise On/Off Test

| Basic Information | |

| device | Built-in wire dryer |

| technology | Fused Wire Fabrication (FFF) Pretreatment |

| interface | - 4.3-inch capacitive touch panel - Guide LED lights |

| Wire Channel | Guided input and output cable ports |

| wire diameter | 2.85mm/1.75mm |

| Compatible materials | - For a list of updated nylon materials and materials from major wire brands, please see https://drywise.co/materials * Reinforced nylon material requires additional accessories (sold separately). This is necessary for the Drywise machine to process the data smoothly. |

| Operation sound | <50dBA |

| Connection method | USB-C port |

| Physical dimensions | |

| size | 520*500*145mm (Including desiccant container 590*500*145mm) |

| net weight | 12 kg (including a 12.5 kg desiccant container) |

| Transport weight | Approximately 13 kilograms |

| Power requirements | |

| Voltage | 100 - 240 VAC |

| frequency | 50 - 60 Hz |

| power | Maximum 350W |