Bambu Lab X1E 3D Printer

Bambu Lab X1E 3D Printer is backordered and will ship as soon as it is back in stock.

Choose add-on

Couldn't load pickup availability

For Bambu Lab equipment purchases, Santima offers a one-year standard warranty or enhanced warranty option . For any operational inquiries, please contact Santima via email.

• We cannot accept additional orders for the "Enhanced Warranty Plan" after shipment . Please confirm the selected warranty plan that meets your needs when placing your order.

• If there is any problem with the machine, please fill out the technical support form .

• Be sure to use the original complete packaging (outer box, protective foam, etc.) and include all original accessories (e.g., power supply, SD card, cable, printing materials used at the time, etc.) to avoid any omissions in the repair process.

• The engineer assessed the damage as caused by human error or unauthorized modification . For non-human-caused damage, original manufacturer repair and warranty services are available. Consumables (such as spray nozzles) and spare parts are not covered by the warranty.

• All operation training is quoted separately by a Sandima specialist. You can fill out the contact form to inquire.

Topzhu Bambu Lab X1E 3D Printer (including AMS automatic feeding system)

*Packaging has been reinforced.

Bambu Lab has launched a new product – the X1E, which inherits all the advantages of the X1 Carbon and improves upon them, adding powerful new features! Click here to see all the features included in the X1 Carbon. The main features of the X1E are introduced below:

Overall Functionality

• Enables WPA2 enterprise authentication and LAN communication

• Maximum hot end temperature: 320°C (608°F)

• Active body heating function (maximum temperature 60°C)

• Includes air filtration

• Features vibration and compression compensation as well as AI fault detection capabilities.

• Multi-material printing and management are supported through AMS .

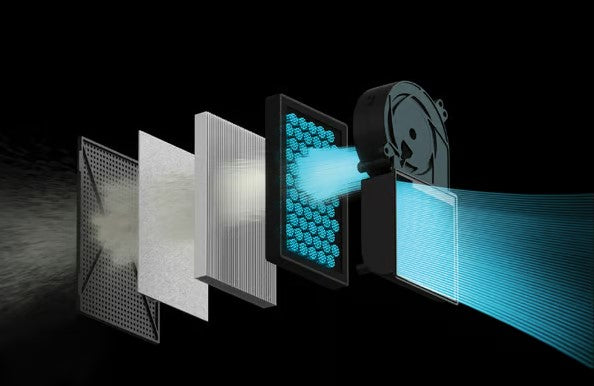

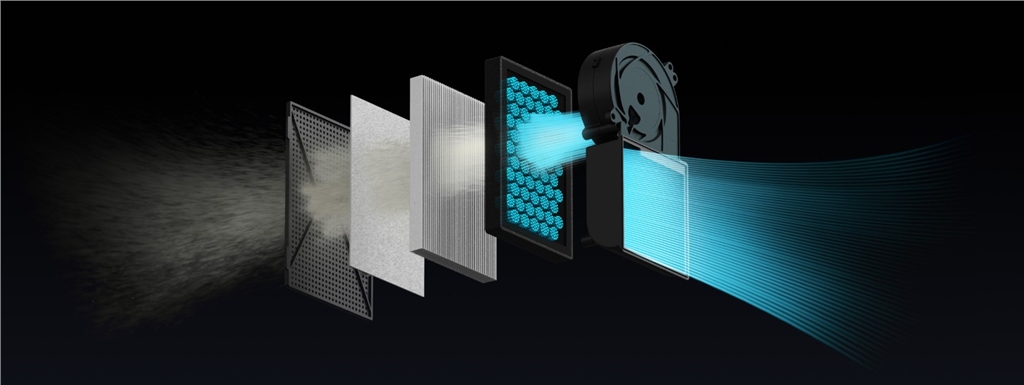

High-performance air filtration device

The X1E effectively filters particulates and volatile organic compounds generated during 3D printing, providing optimal air filtration. When printing in poorly ventilated environments, the improved filtration effectively reduces excessive odors and particles.

• G3 pre- filter

• H12 HEPA filter

• High-quality activated carbon filter

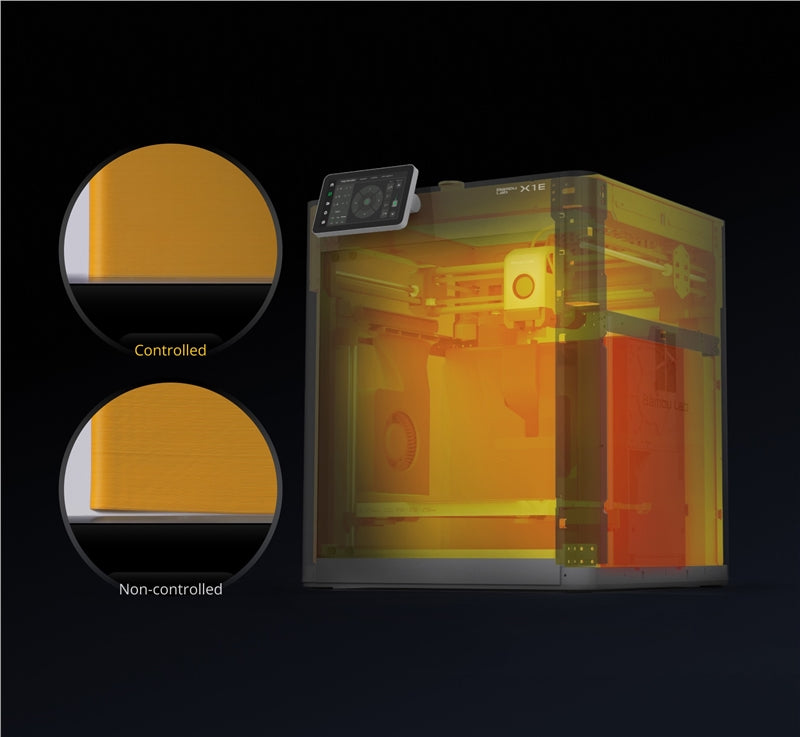

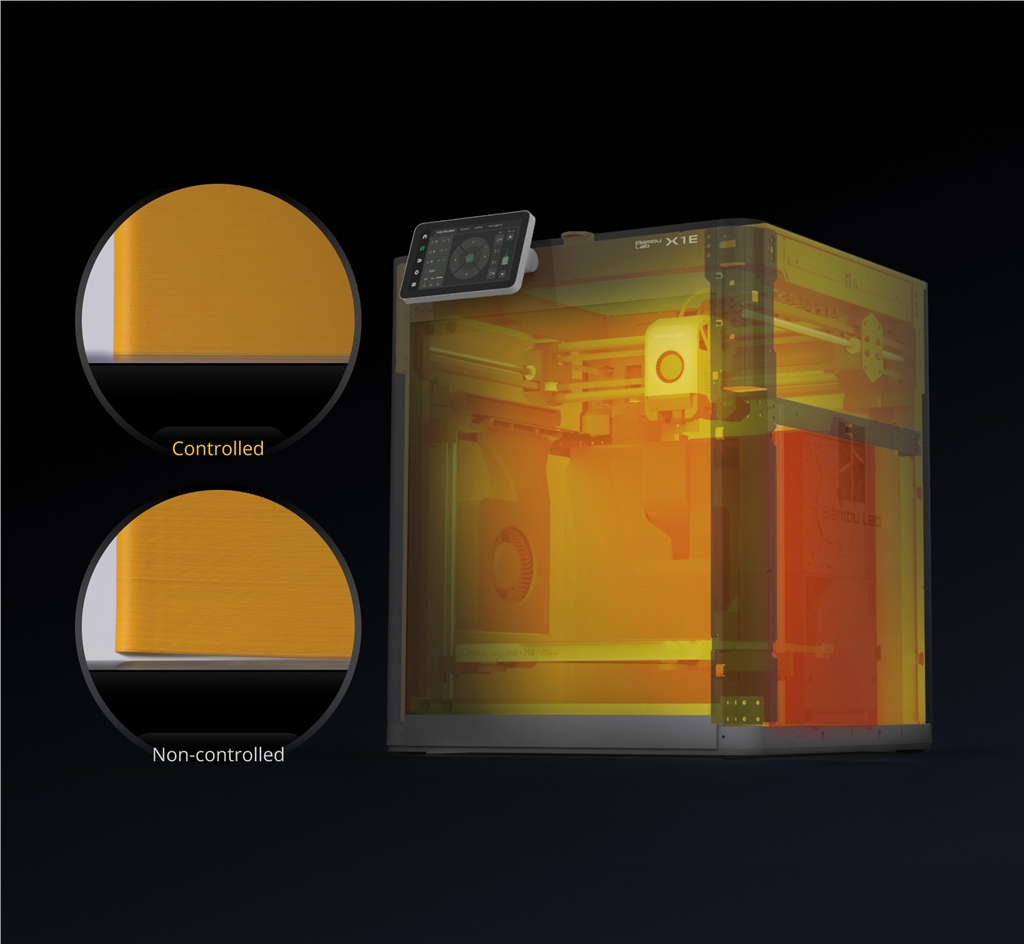

Reliable functionality delivers superior print quality.

The Bambu Lab X1E 3D printer incorporates many advanced technologies designed to improve print quality, some of which are listed below:

• The addition of an active heating function reduces the possibility of warping in the finished product.

• Chamber temperature control system (up to 60°C or 140°F)

• Improve print quality - especially suitable for filaments prone to warping, such as ABS and PC.

Designed specifically for high-temperature materials

The higher the nozzle temperature, the better the printed material properties.

• Maximum hot end temperature : Up to 320°C (608°F)

• A wider range of compatible advanced cables are available, including PPA-CF/GF PPS and PPS-CF.

• Utilize advanced materials to improve stability, heat resistance, and mechanical properties.

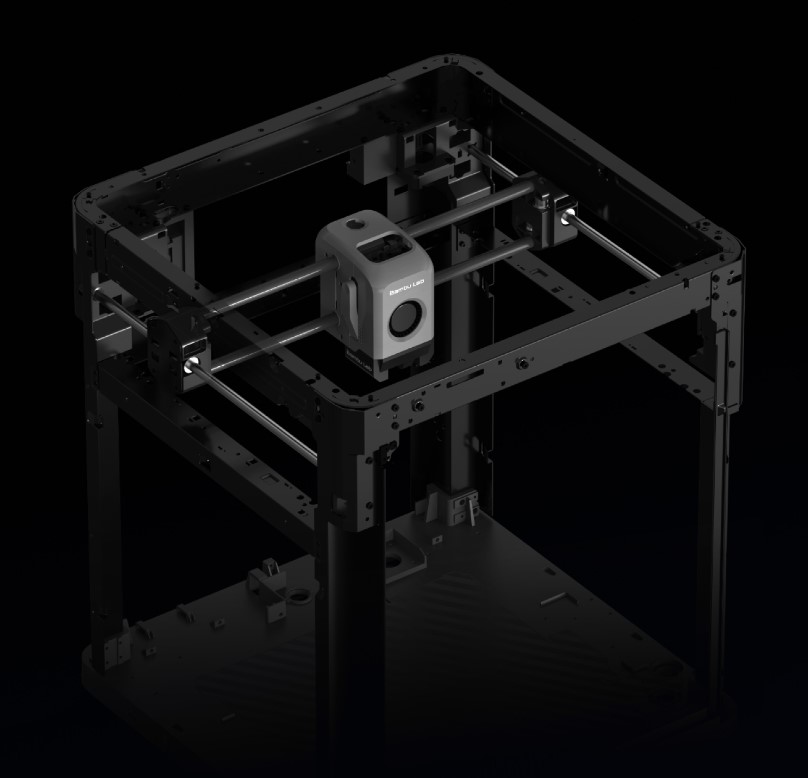

Ultra-high speed and rigid structure

The robust and durable high-speed CoreXY moving parts utilize premium carbon fiber rods, reducing the weight of moving components and significantly shortening overall printing time.

• Utilizing a high-quality carbon fiber shaft, the tool head achieves an acceleration of 20,000 mm/s².

• Achieve high-speed continuous printing

• Maximum moving speed: 500 mm/s

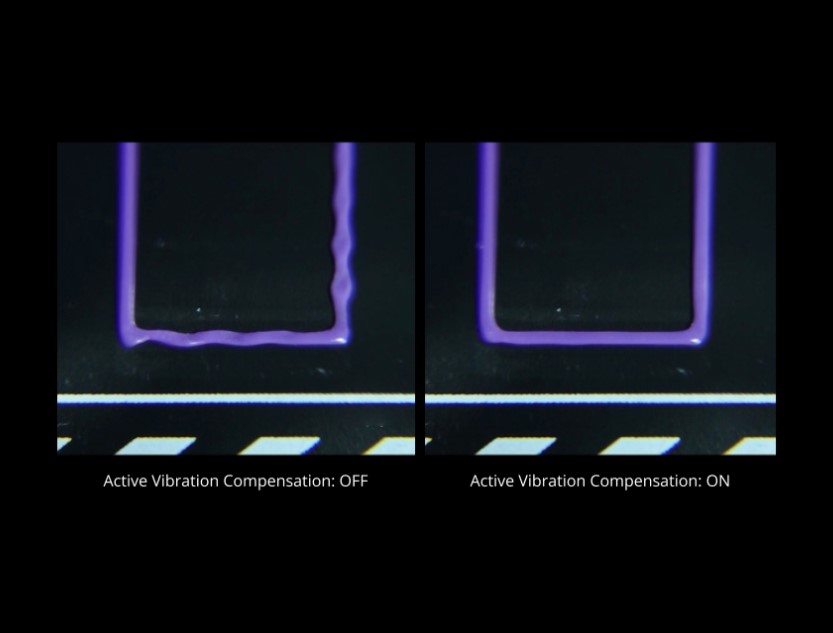

Unprecedented high-speed and stable printing

To ensure exceptionally smooth printing quality, the X1E can actively compensate for vibration and extrusion issues along the X and Y axes.

• Achieve stable, high-quality printing even at high speeds

• Fully automatic measurement

• No manual adjustment required

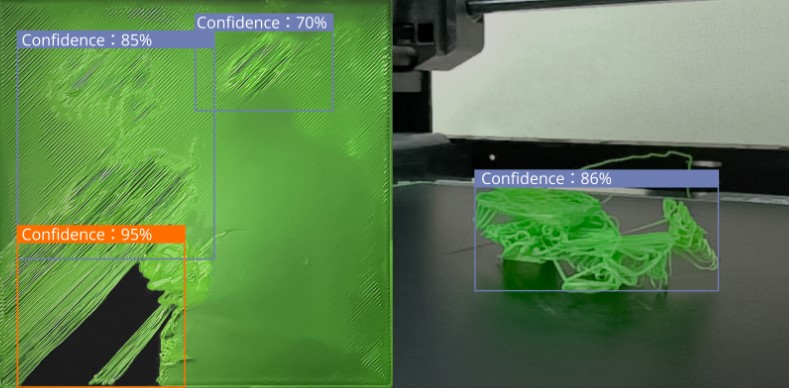

Secure printing using artificial intelligence technology

The X1E's AI algorithm uses LiDAR and computer vision to detect defects and errors in the first layer.

• Features AI-powered fault detection to ensure successful printing.

• Prevent catastrophic failures by automatically pausing printing .

• Reduce wire waste and downtime

Multi-material printing using AMS

The X1E features AMS intelligent cable management. It can connect to four Bambu AMS systems in parallel and print using up to 16 cable reels.

• Supports automatic cable reloading

• Enables multi-material printing through supporting materials

• Achieve seamless surface and multi-color printing

For a comparison of the X1E and X1 Carbon, please refer to the product specifications . -

Contact us for more information about the Bambu Lab 3D printer !

| body | X1E | X1-Carbon | |

| technology | Fused deposition modeling | ||

| Print size (length × width × height) | 256×256×256 mm | ||

| External dimensions | 389×389×457mm | ||

| net weight | 16kg | 14.13kg | |

| fuselage frame | steel | ||

| shell | Aluminum & Glass | ||

| tool head | |||

| hot end | All Metal | ||

| Extruder teeth | Hardened steel | ||

| nozzle | Hardened steel | ||

| Nozzle maximum temperature | 320℃ | 300℃ | |

| Nozzle diameter (default setting) | 0.4mm | ||

| Nozzle diameter (optional) | 0.2mm, 0.6mm, 0.8mm | ||

| Tool head cutter | built-in | ||

| wire diameter | 1.75 mm | ||

| Supported cables | |||

| PLA, PETG, TPU, PVA, BVOH | optimal | ||

| ABS, ASA, PC, PA, PET | excellence | ideal | |

| Carbon/ Glass Fiber Reinforced PLA, PETG, PA, PET, PC, ABS, ASA | excellence | ideal | |

| PPA-CF/ GF, PPS, PPS-CF/ GF | ideal | No | |

| heating | |||

| Active cavity heating | have | No | |

| Maximum control temperature of the machine body | 60℃ | not applicable | |

| Air purification | |||

| Pre-filtering level | G3 | No | |

| HEPA high-efficiency air filter rating | H12 | No | |

| Activated carbon filter type | Coconut shell pellets | Coal particles | |

| VOC (volatile organic compound) filtration | optimal | can | |

| Particulate matter filtration | have | No | |

| Network control | |||

| Ethernet | have | No | |

| Automatic disconnection | Ethernet | No | |

| Detachable network module | have | No | |

| 802.1X Network Access Control | have | No | |

| heated bed | |||

| Printing plate | Flexible steel structure panel | ||

| Printing plate surface (included) | Bambu double-sided texture PEI printing platform | Bambu double-sided texture PEI printing platform | |

| Printing plate surface (optional) | Bambu cooling panel, high-temperature printing panel | High-temperature printing panel | |

| Maximum temperature of printing plate | 110℃@220V, 120℃@110V | ||

| speed | |||

| Maximum speed of tool head | 500 mm/s | ||

| Maximum acceleration of tool head | 20000 mm/s² | ||

| Maximum hot end flow | 32 mm/s @ABS (Model: 150 × 150 mm Single wall material: Bambu ABS; Temperature: 280°C) | ||

| sensor | |||

| Bambu Miniature LiDAR | Yes | ||

| Aircraft monitoring camera | 1920*1080 (inclusive) | ||

| Door opening detection | support | ||

| Material breakage detection | support | ||

| Thread fineness measurement | Supports when used with AMS | ||

| Power outage resume printing | support | ||

| Electricity demand | |||

| Voltage | 100-240 VAC, 50/60 Hz | ||

| Maximum power | 1400W@220V, 750W@110V | 1000 W @ 220 V, 350 W @ 110 V | |

| electronic devices | |||

| Display screen | 5-inch 1280×720 touchscreen | ||

| capacity | 4GB eMMC and support for external microSD cards | ||

| User interface | Touchscreen, mobile app, desktop application | ||

| motion controller | Dual-core Cortex-M4 processor | ||

| Application processor | Quad-core 1.2GHz ARM-A7 processor | ||

| Neural Network Processing Unit | 2 Tops | ||

| software | |||

| Slicing software | It supports other vendor slicers that can export standard G-code, such as Superslicer, Prusaslicer, and Cura, but some smart features may not be supported. | ||

| The slicing software supports operating systems. | MacOS, Windows | ||

| cool down | |||

| Component cooling fan | Closed-loop control | ||

| Hot end fan | Closed-loop control | ||

| Main control board fan | Closed-loop control | ||

| Cooling main unit casing temperature control fan | Closed-loop control | ||

| Auxiliary component cooling fan | Closed-loop control | ||

| other | |||

| Micro laser radar | built-in | ||

| Wire material usage and residual material detection | Supports when used with AMS | ||

| Printing interrupted | support | ||

| Product contents | |||

| Bambu Lab X1E 3D Printer | Bambu Lab X1E 3D printer x1 Bambu Lab AMS (cable not included, for display only) x1 Bambu Dual-Texture PEI Panel x1 Hot end wipe nozzle x2 heated bed solid glue x1 Nozzle cleaning needle x1 Hardened steel nozzle assembly 0.4mm x 1 Wire cutter x2 Bambu heated bed scraper blade x1 250g Bambu cable x3 (color/type random) |

||

Authorized and certified by the National Communications Commission (NCC)※

For Bambu Lab equipment purchases, Santima offers a one-year standard warranty or enhanced warranty option . For any operational inquiries, please contact Santima via email.

🔧【Standard Warranty Service Plan 】

| Free gift with purchase |

We provide free parts and repair training methods, and ship the parts to a designated location → Customers assemble the product themselves using the parts.

👨💻【Enhanced Warranty Service Plan】

Free shipping | Free testing |Free repair

San Di Ma will send someone to collect repair equipment free of charge. → Santima engineer performs repair → After completion, Santima dispatches a vehicle to return it.

• If there is any problem with the machine, please fill out the technical support form .

• Be sure to use the original complete packaging (outer box, protective foam, etc.) and include all original accessories (e.g., power supply, SD card, cable, printing materials used at the time, etc.) to avoid any omissions in the repair process.

• The engineer assessed the damage as caused by human error or unauthorized modification . For non-human-caused damage, original manufacturer repair and warranty services are available. Consumables (such as spray nozzles) and spare parts are not covered by the warranty.

• All operation training is quoted separately by a Sandima specialist. You can fill out the contact form to inquire.

• Be sure to use the original complete packaging (outer box, protective foam, etc.) and include all original accessories (e.g., power supply, SD card, cable, printing materials used at the time, etc.) to avoid any omissions in the repair process.

• The engineer assessed the damage as caused by human error or unauthorized modification . For non-human-caused damage, original manufacturer repair and warranty services are available. Consumables (such as spray nozzles) and spare parts are not covered by the warranty.

• All operation training is quoted separately by a Sandima specialist. You can fill out the contact form to inquire.