Bambu Lab | Product Model:

BLFAP031

Bambu H2 Series Visual Encoding Board

Regular price

¥17,000 JPY

Unit price

/

Unavailable

小計

—

Bambu H2 Series Visual Encoding Board is backordered and will ship as soon as it is back in stock.

アドオンを選択

Couldn't load pickup availability

Topzhu Bambu Lab H2D Visual Encoding Board

Bambu Lab Visual Encoding Palette – A New Level of Accuracy

Take your 3D printing precision to a new level with Bambu Lab Vision Encoder.

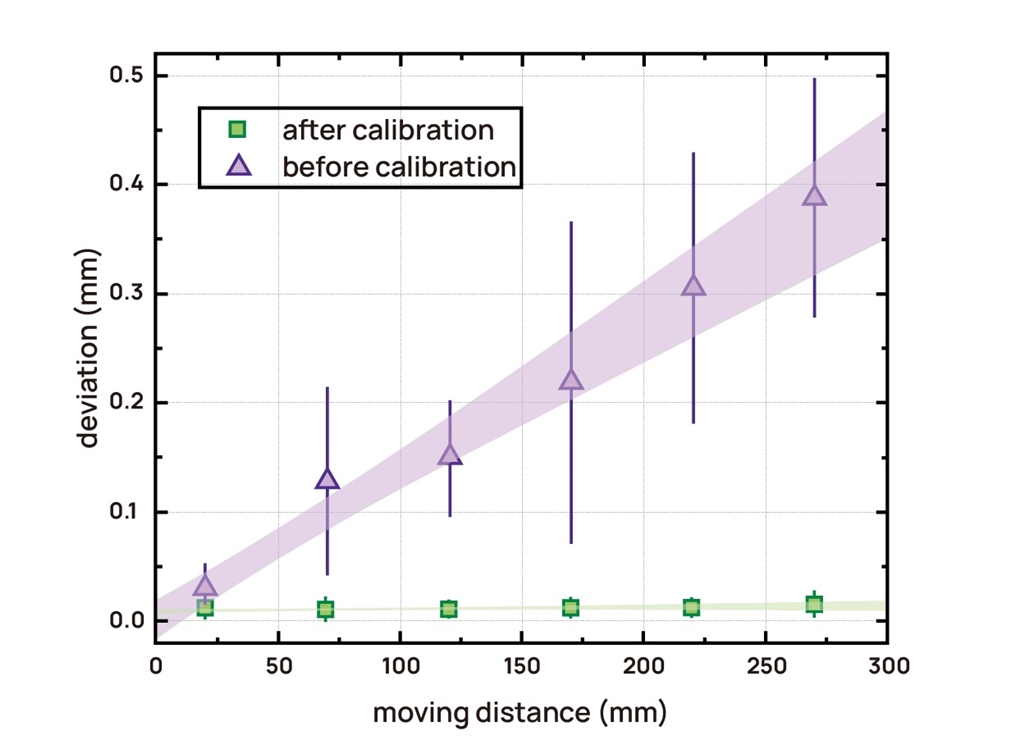

This advanced calibration tool can improve motion accuracy to below 50 μm, compensating for natural mechanical differences and long-term wear and tear on the machine.

This calibration is distance-independent, ensuring consistent accuracy regardless of model size, and its effects become more pronounced in larger prints.

Combined with Bambu Studio's unique automatic hole contour compensation feature, Vision Encoder enables injection-grade assembly of parts printed using Bambu Lab H2D.

Design, print, and install—it's that simple.

Motion accuracy below 50 μm – compensating for unavoidable uncertainties

Even the most precise 3D printers cannot avoid mechanical errors – but the Bambu Lab Vision Encoder ensures they won't ruin your prints.

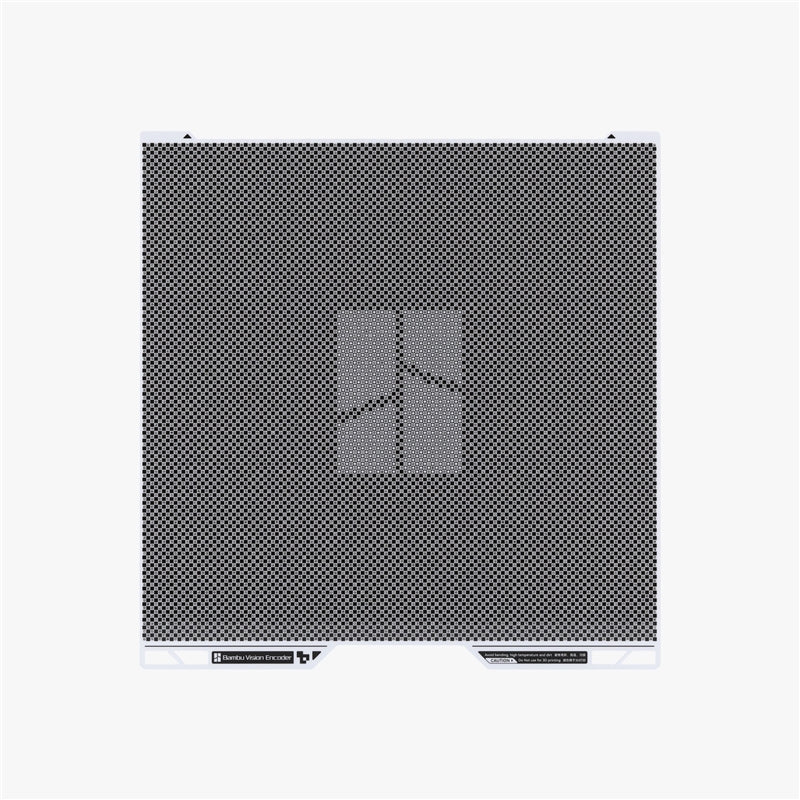

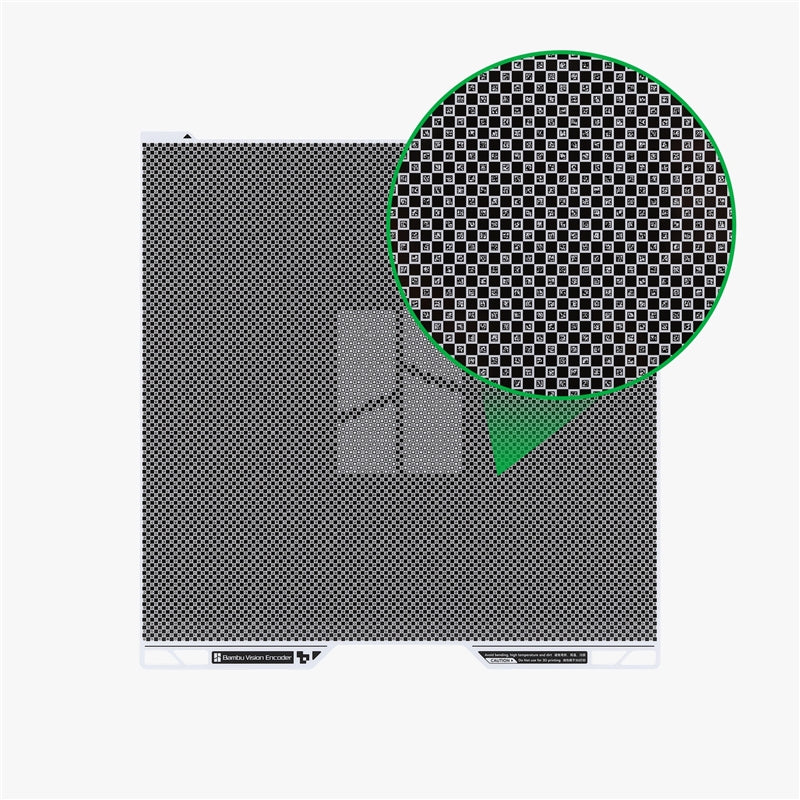

This advanced XY-axis calibration solution features a 10⁴ coded marker matrix and 5μm resolution optical measurement capabilities, providing motion accuracy within 50μm—finer than a human hair.

The Vision Encoder not only compensates for inherent mechanical differences, but also adapts over time to correct for issues such as belt loosening and mechanical wear, maintaining accuracy throughout the Bambu Lab H2D journey.

Even the most precise 3D printers cannot avoid mechanical errors – but the Bambu Lab Vision Encoder ensures they won't ruin your prints.

This advanced XY-axis calibration solution features a 10⁴ coded marker matrix and 5μm resolution optical measurement capabilities, providing motion accuracy within 50μm—finer than a human hair.

The Vision Encoder not only compensates for inherent mechanical differences, but also adapts over time to correct for issues such as belt loosening and mechanical wear, maintaining accuracy throughout the Bambu Lab H2D journey.

The larger the print size, the more noticeable the accuracy.

With Bambu Lab's vision coding board, motion accuracy of <50μm is independent of distance, ensuring consistent accuracy regardless of print size.

In fact, the larger the print size, the more obvious the accuracy, making it ideal for architectural prototypes and full-size functional components that require strict size compliance.

Unparalleled accuracy can be achieved regardless of scale.

Achieve injection molding quality

Equipped with a vision encoder, the Bambu Lab H2D utilizes Bambu Studio's proprietary automatic hole profile compensation, temperature-controlled chamber, and pre-adjusted filament parameters, surpassing desktop 3D printing to deliver mechanical-grade precision and injection-molding quality.

Say goodbye to massive tweaks and post-processing—seamlessly integrate components and streamline your workflow like never before.

Equipped with a vision encoder, the Bambu Lab H2D utilizes Bambu Studio's proprietary automatic hole profile compensation, temperature-controlled chamber, and pre-adjusted filament parameters, surpassing desktop 3D printing to deliver mechanical-grade precision and injection-molding quality.

Say goodbye to massive tweaks and post-processing—seamlessly integrate components and streamline your workflow like never before.

Just 5 minutes of calibration to maintain accuracy for weeks . Place, calibrate, and go.

A quick 5-minute calibration ensures weeks of high-precision printing without any hassle.

A few minutes of setup can reverse long-term wear and tear - keeping printing accurate and workflow smooth. Absolutely worth it!

A quick 5-minute calibration ensures weeks of high-precision printing without any hassle.

A few minutes of setup can reverse long-term wear and tear - keeping printing accurate and workflow smooth. Absolutely worth it!

Usage Tips

1. Machine performance characteristics will inevitably change due to time factors, operating modes, and environmental influences.

This progress is reflected through the following mechanisms:

• Ambient temperature fluctuations • Structural micro-deformations caused by operational vibrations or relocation • Stress relaxation of the outer shell material

Therefore, the calibration effectiveness will gradually decrease.

The degradation rate is directly related to the severity of environmental impact and the intensity of use.

For applications requiring high-precision maintenance, we recommend implementing a calibration protocol every two weeks to ensure consistent measurement accuracy.

2. The Bambu Lab Vision Encoder is for motion accuracy calibration only and must not be used as a printing plate.

After calibration, please remove and store the vision encoder properly.

3. Before using the Bambu Lab Vision Encoder for calibration, please ensure the following:

• Ensure the tool head camera is functioning properly and there are no HMS errors (e.g., lens dirt).

• Remove all debris from the heated bed.

• Ensure the surface of the vision encoder is clean and all grid patterns are clearly visible.

• Before calibration, ensure the heated bed is at room temperature. Avoid placing the vision encoder on the heated bed to prevent errors caused by thermal expansion.

1. Machine performance characteristics will inevitably change due to time factors, operating modes, and environmental influences.

This progress is reflected through the following mechanisms:

• Ambient temperature fluctuations • Structural micro-deformations caused by operational vibrations or relocation • Stress relaxation of the outer shell material

Therefore, the calibration effectiveness will gradually decrease.

The degradation rate is directly related to the severity of environmental impact and the intensity of use.

For applications requiring high-precision maintenance, we recommend implementing a calibration protocol every two weeks to ensure consistent measurement accuracy.

2. The Bambu Lab Vision Encoder is for motion accuracy calibration only and must not be used as a printing plate.

After calibration, please remove and store the vision encoder properly.

3. Before using the Bambu Lab Vision Encoder for calibration, please ensure the following:

• Ensure the tool head camera is functioning properly and there are no HMS errors (e.g., lens dirt).

• Remove all debris from the heated bed.

• Ensure the surface of the vision encoder is clean and all grid patterns are clearly visible.

• Before calibration, ensure the heated bed is at room temperature. Avoid placing the vision encoder on the heated bed to prevent errors caused by thermal expansion.

カスタム製品仕様