Bambu Lab P2S 3D Printer Series

Bambu Lab P2S 3D Printer Series - is backordered and will ship as soon as it is back in stock.

Choose add-on

Couldn't load pickup availability

Topzhu Bambu Lab P2S 3D Printer

Topzhu's classic P1S revolutionized the 3D printing industry and sparked a wave of popularity across the entire 3D printing sector.

With its speed, reliability, and cost-effectiveness, the P1S has become the preferred choice for 3D printing farms and enthusiasts.

Building upon its past achievements, the new generation Tuozhu P2 S now features Tuozhu's second-generation technology.

We strive for excellence and are committed to providing users with a better overall experience, while continuously delivering the outstanding printing quality that Tuozhu is known for.

Once again, it has become a classic.

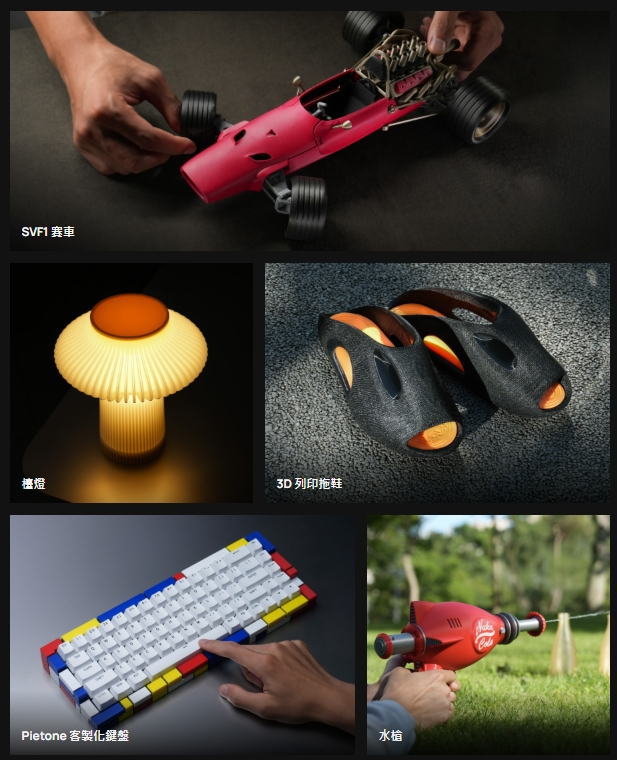

Productivity is readily available

P2S is the key to unlocking a whole new lifestyle, giving you readily available creativity to explore endless possibilities.

If you want it, you can have it!

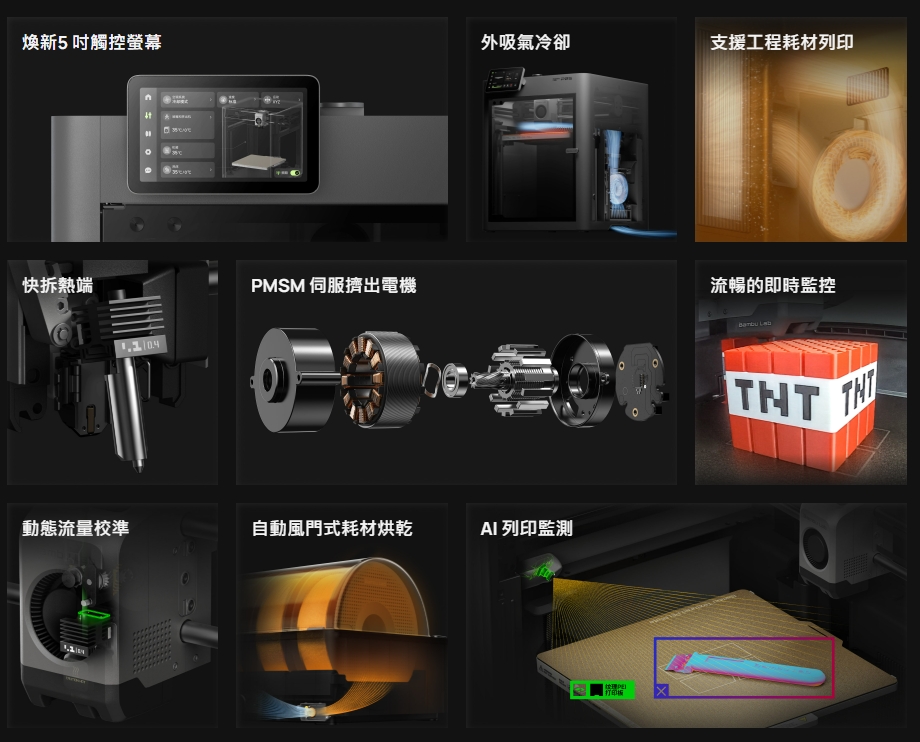

A smooth, mobile-like interactive experience

The P2S features a refreshed touchscreen and a powerful processor.

It adopts a more intuitive second-generation screen UI, bringing smoother interaction, richer icons, and clearer step-by-step guidance.

Permanent Magnet Synchronous Servo Extrusion Motor | Lingji Extruder

70% increase in extrusion power & instant problem detection.

The permanent magnet synchronous (PMSM) servo extrusion motor delivers a maximum extrusion force of up to 8.5 kg, 70% higher than its predecessor, significantly improving the stability of high-flow extrusion.

Topzhu's proprietary servo motor performs 20kHz current and position signal sampling to actively detect consumable abrasion and blockage in real time.

Smooth printing everywhere

P2S uses a high-resolution, high-frequency eddy current sensor to calibrate dynamic flow, and the intelligent algorithm actively adjusts the flow rate based on the measured parameters.

It delivers precise and consistent extrusion across every layer and corner of the model.

External air intake | Cooling mode

The adaptive air circulation system ensures stable suspension performance regardless of consumables or temperature.

Unlike traditional cooling systems that circulate hot air, the P2S's adaptive air circulation system can draw in cool air directly from outside the casing, significantly improving cooling efficiency.

When printing cryogenic consumables, you can confidently close the P2S door without worrying about hang quality issues or clogging.

Adaptive air circulation system

With a cavity temperature of 50°C, the engineering consumables are not surprising.

The P2S features an adaptive air circulation system that effectively retains heat inside the printer, making it easier to print easily warped engineering consumables.

At the same time, the high-performance multi-effect filter actively filters the internal air to ensure a clean and safe workspace.

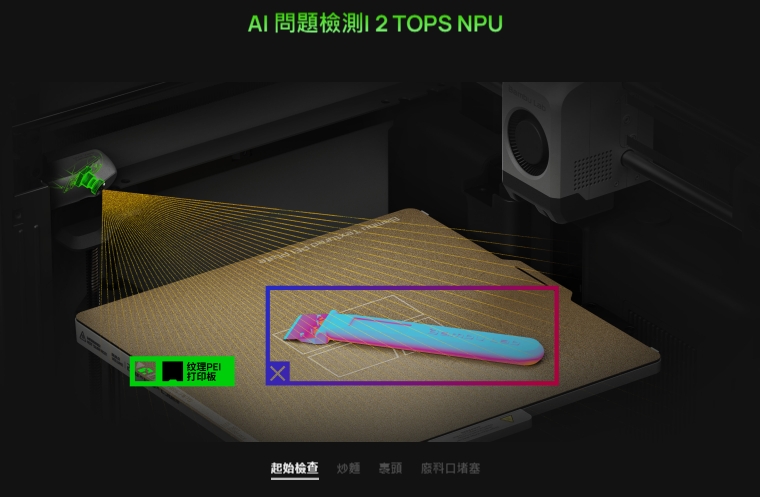

P2S incorporates advanced AI computer vision technology, which can proactively detect common printing problems, such as fried noodles or overprinted heads.

It will also check your basic printing settings to ensure that each print job is started safely and accurately.

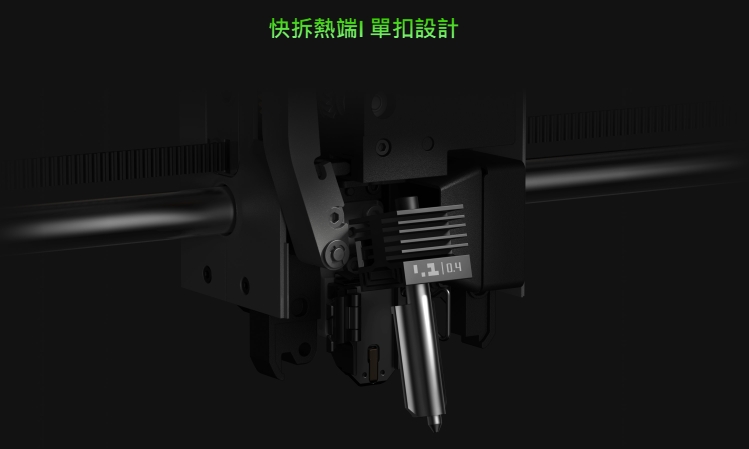

Replace nozzle every 30 seconds

The P2S features a quick-release hot-end design, eliminating the need to unplug cables. Simply open the hot-end latch to magnetically attach and detach the entire hot-end assembly.

This significantly reduces the time required to change nozzles and eliminates the risk of incorrect wiring.

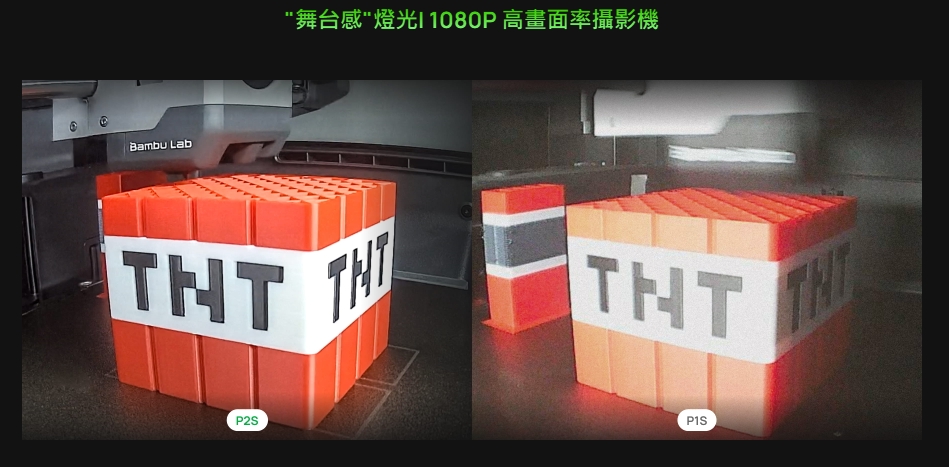

Latency-free real-time monitoring and high-quality time-lapse photography

Enhanced LED lighting significantly improves the clarity of live surveillance video and time-lapse photography.

With a high frame rate camera and dual-band Wi-Fi, you can easily monitor your printer remotely and capture well-lit time-lapse photos, perfect for sharing on social media platforms.

Reliable printing fiber-reinforced consumables

P2S's extrusion system and nozzles are made of hardened steel, offering superior durability and abrasion resistance, and are designed for stable, long-term printing of high-performance fiber-reinforced materials.

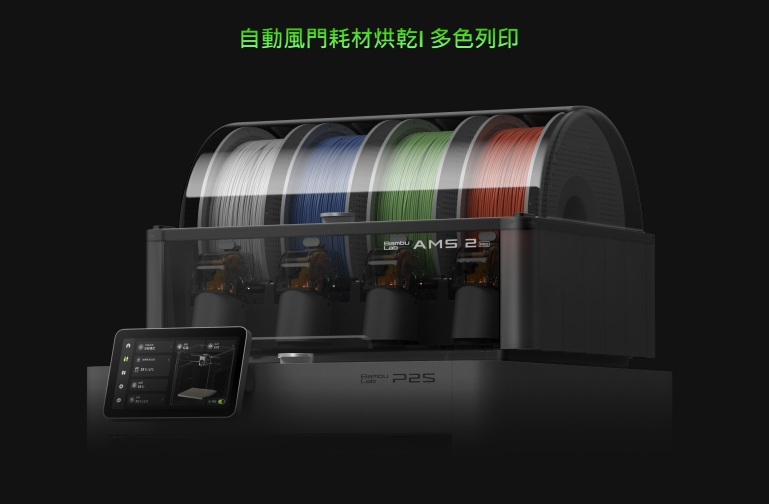

AMS 2 Pro handles consumables management, multi-color printing, and consumables drying all in one device.

Experience Tuozhu's most reliable multicolor printing system to date.

The AMS 2 Pro incorporates several key design enhancements to deliver a better user experience – particularly the much-anticipated consumables drying feature.

The groundbreaking active damper system allows AMS 2 Pro to dry consumables 30% faster than purely hermetically sealed heating, while maintaining low humidity for superior storage and printing quality.

Electromagnetic damper

The automatic damper function helps to remove moisture during the drying process and provides weeks of high-quality prints through airtight sealing during subsequent storage.

Faster multicolor printing

The permanent magnet synchronous servo feed motor increases the feeding speed by 60%, saving an average of 10 minutes of total printing time for every 100 material changes.

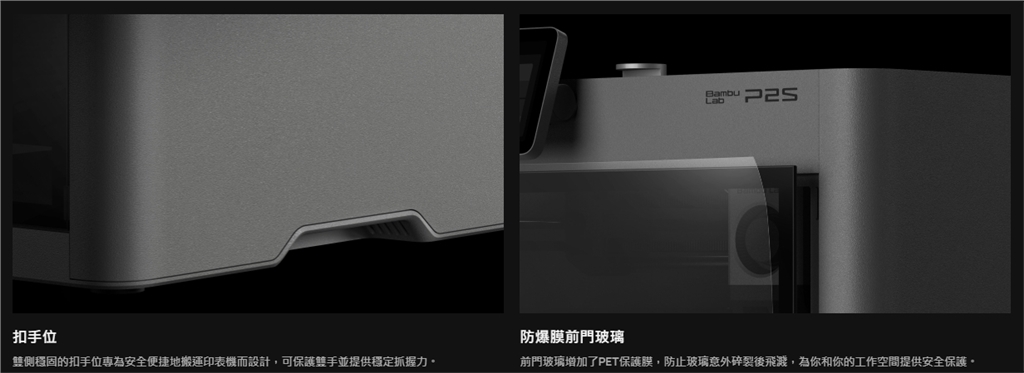

Details make classics

P2S has many optimizations made to improve the user experience.

Although these small improvements are not immediately obvious, Tuozhu always strives to start from the details, refine to the extreme, and create classics.

For Bambu Lab equipment purchases, Santima offers a one-year standard warranty or enhanced warranty option . For any operational inquiries, please contact Santima via email.

👨💻【Enhanced Warranty Service Plan】

Free shipping | Free testing |Free repair

San Di Ma will send someone to collect repair equipment free of charge. → Santima engineer performs repair → After completion, Santima dispatches a vehicle to return it.

• We cannot accept additional orders for the "Enhanced Warranty Plan" after shipment . Please confirm the selected warranty plan that meets your needs when placing your order.

• If there is any problem with the machine, please fill out the technical support form .

• Be sure to use the original complete packaging (outer box, protective foam, etc.) and include all original accessories (e.g., power supply, SD card, cable, printing materials used at the time, etc.) to avoid any omissions in the repair process.

• The engineer assessed the damage as caused by human error or unauthorized modification . For non-human-caused damage, original manufacturer repair and warranty services are available. Consumables (such as spray nozzles) and spare parts are not covered by the warranty.

• All operation training is quoted separately by a Sandima specialist. You can fill out the contact form to inquire.

Please note: To ensure the stability of the AMS 2 Pro drying process, please use an official Bambu Lab power supply.

Contact us for more information about the Bambu Lab 3D printer !

| thing | Specification |

|---|---|

| Printing technology | Fused deposition modeling |

| Print volume (width, depth, height) | 256x256x256 mm |

| chassis | Steel, plastic and glass |

| Equipment size | 392x406x478 mm |

| net weight | 14.9 kg |

| Tool Head - Hot End | All Metal |

| Tool head - Extruder gear | Hardened steel |

| Tool head - nozzle | Hardened steel |

| Maximum nozzle temperature | 300 ℃ |

| Including nozzle diameter | 0.4 mm |

| Supported nozzle diameter | 0.2, 0.4, 0.6, 0.8 mm |

| Wire cutting machine | built-in |

| wire diameter | 1.75 mm |

| Extruder motor | Bambu Lab high-precision permanent magnet synchronous motor |

| Types of heated bed support plates | Textured PEI board, smooth PEI board |

| Maximum heated bed temperature | 110 ℃ |

| Maximum speed | 600 mm/s |

| Maximum acceleration | 20,000 mm/s² |

| Maximum flow rate at hot end | 40 mm³/s (Test: ABS 280℃) |

| Air purification - activated carbon | Coconut shell pellets |

| VOC filtration | superior |

| Particulate filtration | support |

| Cooling fan | The components, hot air, and auxiliary component cooling fans are all under closed-loop control. |

| Supported cable types | PLA, PETG, ABS, ASA, TPU, support PLA, support PLA/PETG, support ABS, PET, PA, PC, PVA, PLA-CF, PETG-CF, ABS-GF, ASA-CF, PA6-CF, PA6-GF, PAHT-CF, PPA-CF, PET-CF |

| Live View Camera | Built-in; 1920*1080 |

| Sensor - Cable exhausted / Entanglement |

support |

| Sensor - Wire Odometer | AMS support |

| Power outage recovery | support |

| Voltage requirements | 100-120V / 200-240V, 50/60Hz |

| Maximum power | 1200W @220V / 1000W @110V |

| touchscreen | 5-inch 854*480 |

| store | Built-in 8GB eMMC + USB port |

| Control Interface | Touchscreen, mobile applications, PC applications |

| software | Bambu Studio supports third-party slicers (Super Slicer, PrusaSlicer, Cura, etc.) that export standard G-code. |

| Support operating system | MacOS, Windows, Linux |

| Wireless Network - Frequency | 2.4GHz (2412-2472MHz, 2400-2483.5MHz), 5GHz (5150-5850MHz) |

| Wireless Network Protocol | IEEE 802.11 a/b/g/n |

*To ensure the heated bed reaches the required temperature (35-110°C) quickly, the printer will maintain maximum power for approximately 3-5 minutes.

One-year warranty & repair instructions

For Bambu Lab equipment purchases, Santima offers a one-year standard warranty or enhanced warranty option . For any operational inquiries, please contact Santima via email.

👨💻【Enhanced Warranty Service Plan】

Free shipping | Free testing |Free repair

San Di Ma will send someone to collect repair equipment free of charge. → Santima engineer performs repair → After completion, Santima dispatches a vehicle to return it.

• We cannot accept additional orders for the "Enhanced Warranty Plan" after shipment . Please confirm the selected warranty plan that meets your needs when placing your order.

• If there is any problem with the machine, please fill out the technical support form .

• Be sure to use the original complete packaging (outer box, protective foam, etc.) and include all original accessories (e.g., power supply, SD card, cable, printing materials used at the time, etc.) to avoid any omissions in the repair process.

• The engineer assessed the damage as caused by human error or unauthorized modification . For non-human-caused damage, original manufacturer repair and warranty services are available. Consumables (such as spray nozzles) and spare parts are not covered by the warranty.

• All operation training is quoted separately by a Sandima specialist. You can fill out the contact form to inquire.