Bambu Lab H2D Pro 3D Printer

Bambu Lab H2D Pro 3D Printer is backordered and will ship as soon as it is back in stock.

Choose add-on

Couldn't load pickup availability

Topzhu Bambu Lab H2D Pro 3D Printer

(If multi-color printing is required for both left and right printheads, two AMS/AMS2 Pro units are needed.)

The Bambu Lab H2D Pro 3D printer is designed for professionals who demand superior quality, safety, and reliability, helping you experience exceptional production results.

It boasts advanced high-temperature material versatility, seamless enterprise integration, and enhances productivity with superior print quality.

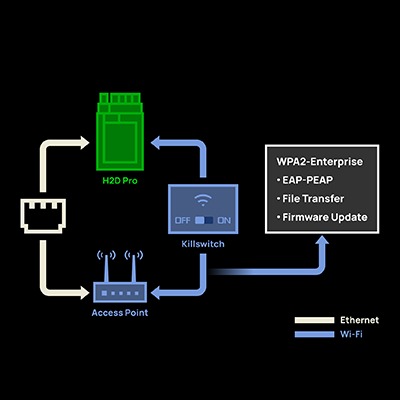

H2D Pro features a 350°C dual-nozzle system, secure Ethernet and WPA2-Enterprise connectivity, vision encoder calibration, and other functions to help your business achieve superior 3D printing with confidence and efficiency.

Key features of the Bambu Lab H2D Pro 3D printer:

A 350°C dual-nozzle system enables the versatility of advanced materials.

Tungsten carbide nozzles offer excellent durability and service life.

The 65°C heating chamber ensures that prints are firm and warp-free.

Secure Ethernet and WPA2-Enterprise Wi-Fi connectivity options.

The physical network disconnect switch meets stringent corporate safety standards.

Built-in vision encoder provides ultra-precise motion accuracy of 50µm.

Adaptive air circulation and HEPA filtration ensure a safer operating environment.

Includes an emergency stop button to meet industrial safety requirements.

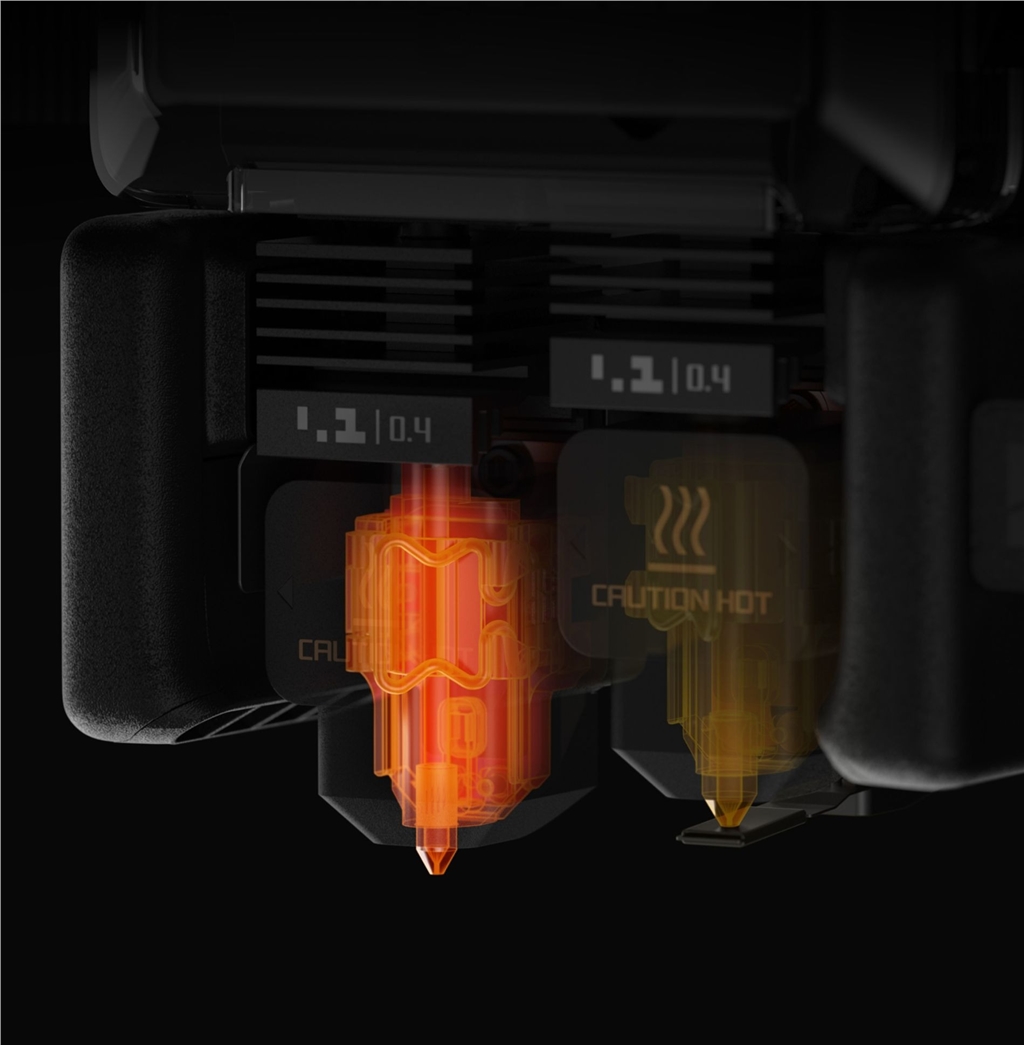

Designed for extreme materials

With Bambu Lab H2D Pro, you can confidently produce durable, practical parts using high-temperature materials.

This rugged machine features high-temperature nozzles, an active cavity heating system, and an enhanced cooling fan to minimize warping and clogging, and uses advanced engineered materials to deliver consistently precise and professional results.

With a maximum hot end temperature of up to 350°C (662°F), a 65°C active heating chamber reduces warping, and an enhanced cooling fan reduces blockage and jamming.

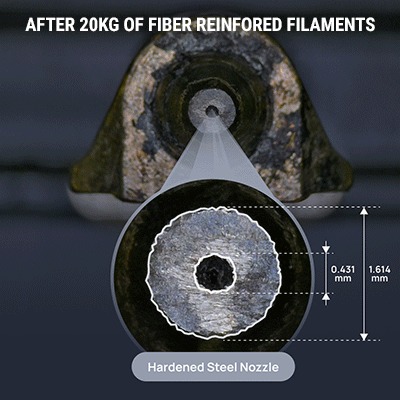

Enduring strength of excellence

H2D Pro's tungsten carbide nozzles maximize uptime and improve print quality.

With a hardness of up to HRA 90, it has excellent wear resistance and a 50% longer service life (ideal for high-performance consumables with strong abrasive properties).

Even in the most demanding production environments, it can achieve consistent printing results and reduce the number of nozzle changes.

The robust HRA 90 rating withstands tough filaments, and its superior abrasion resistance delivers consistent print quality, extends print life by 50%, and reduces nozzle maintenance.

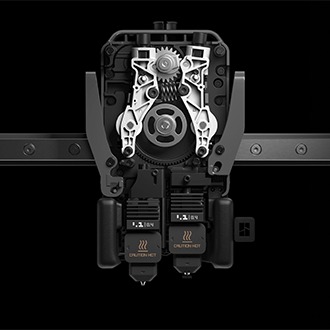

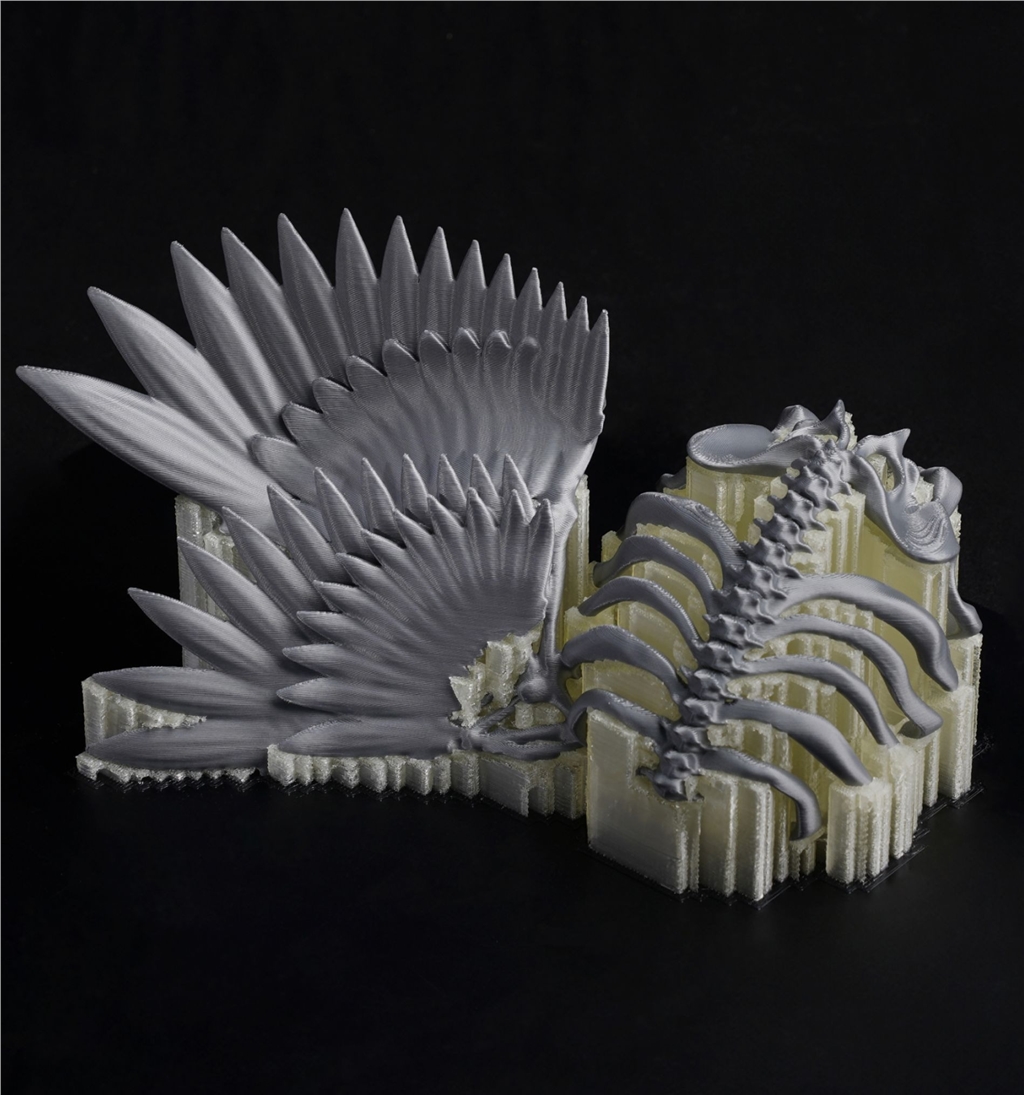

Double extrusion, double the efficiency

Bambu Lab H2D Pro's dual extrusion system enhances productivity.

Easily print multi-material or multi-color parts, combining flexible and rigid elements to achieve a perfect support interface.

Even the most complex designs can reduce material waste, lower costs, and streamline workflows.

Every print job has unparalleled precision.

The included vision encoder board enhances your Bambu H2D Pro experience, achieving motion accuracy of 50µm and precise calibration.

It ensures that even complex parts can be manufactured with reliable, repeatable precision. It is ideal for demanding applications where accuracy and consistency are critical.

Connect with confidence

Protect your data and operations with the advanced network security features of Bambu Lab H2D Pro.

Enjoy robust Ethernet connectivity, WPA2-Enterprise Wi-Fi authentication, and a physical network kill switch for uncompromising protection and reliable communication, even in complex or high-traffic environments.

Extend your application

The Bambu Lab H2D Pro boasts an extra-large print volume of 350 × 320 × 325 mm, maximizing productivity and innovation.

It easily accommodates large prototypes, functional components, and instructional models, streamlining workflows and reducing printing. It helps your institution or organization handle complex projects and deliver professional-grade results without being affected.

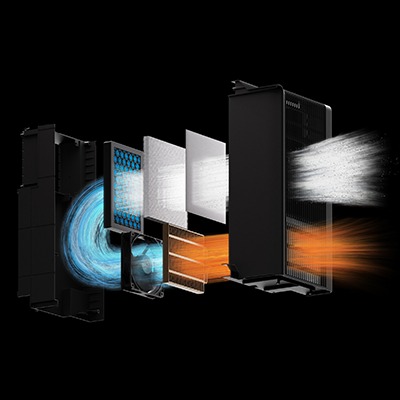

Breathing smoothly, printing safely

Bambu Lab H2D Pro's multi-layer filtration system helps you create a healthy printing environment.

It is equipped with a G3 pre-filter, an H12 HEPA filter, and an activated carbon filter, which can effectively remove particulate matter and volatile organic compounds (VOCs) to minimize odors and health risks.

Even in enclosed spaces, you can enjoy odor-free and safe operation.

Flexible and rigid materials can be obtained in a single print, at low cost and with special materials.

By combining flexible and rigid materials in a single print, an impressive interlocking structure and innovative design that transcends traditional manufacturing methods are created.

Pairing high-performance materials with standard materials and using premium materials only when necessary further improves material efficiency.

Special support materials

Perfect support material that reduces waste, cleanup, and reloading.

Printing with support materials is no longer a headache.

With H2D's dual-nozzle setup, one nozzle can be reserved for dedicated support material, making printing safer and providing a more perfect support interface.

High-efficiency multi-color printing

Fast and efficient multicolor printing

Dual-nozzle printing can reduce the cleaning cycle for multi-color printing.

H2D's intelligent algorithm can calculate the optimal amount of wire used, maximizing dual-nozzle efficiency and saving time and materials.

H2D can automatically scan QR codes on footage and load perfect presets*.

An ultra-precise vision encoder, combined with optical measurement at 5μm resolution, can track and correct the movement of the cutter head.

This allows H2D to achieve a consistent and reliable 50μm zero-distance motion accuracy across the entire working area, an order of magnitude higher than the previous generation.

Extra-large work area

Get rid of size limitations

Print sizes up to 350mm×320mm×325mm*, making large projects easier than ever!

Print extra-large models; the expanded capacity allows you to bring your most ambitious ideas to life.

350°C hot end and 65°C room temperature heating

Fully realize the potential of high-performance materials

The H2D features active cavity heating at 65°C and a high-temperature hot end at up to 350°C, providing precise closed-loop temperature control.

This advanced system effectively eliminates warping and deformation of high-performance materials, ensuring excellent interlayer bonding and fully realizing the potential of the materials.

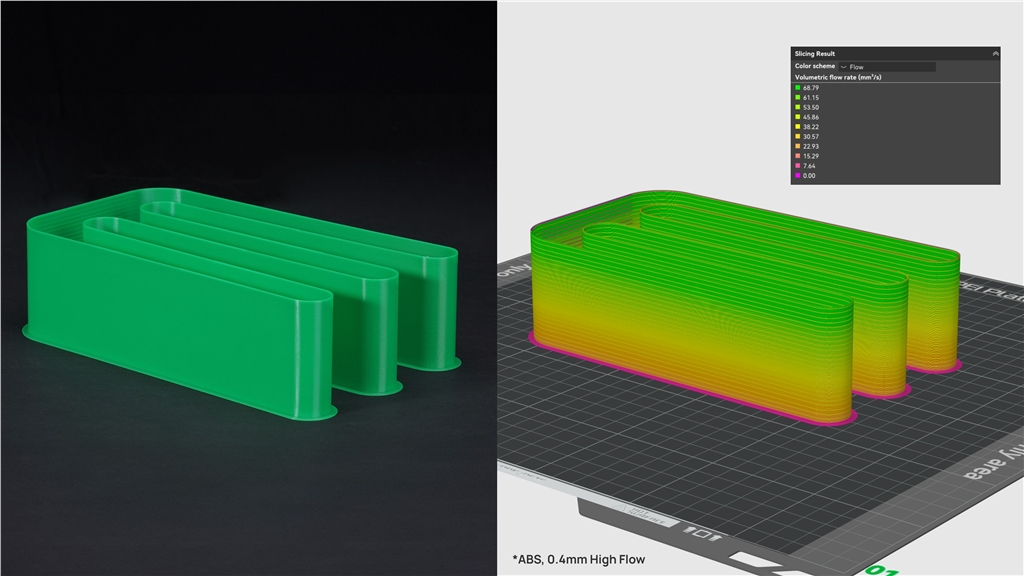

True high-flow hotspot

Easily print continuously at a speed of 600mm/s

H2D's dedicated high-flow hot end ensures reliable high-speed printing at 600mm/s.

Designed for consistent performance, it eliminates mid-line printing speed limitations, enabling uninterrupted high-speed printing regardless of print size or complexity.

Intelligent sensing for precise squeeze control

Bambu Lab's proprietary PMSM servo architecture establishes an intelligent extrusion control system.

It performs 20kHz torque/resistance and position sampling to dynamically adjust the electromagnetic torque vector, reduce VFA, and detect wire wear and blockage.

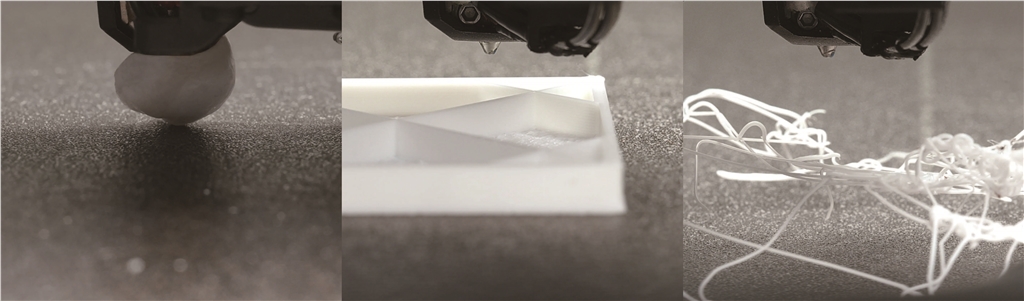

Nozzle camera

Monitor the extrusion at the nozzle tip

H2D is equipped with an AI-supported nozzle camera and macro lens.

This intelligent monitoring system continuously tracks the extrusion pattern and immediately detects material accumulation, wire deviation, and extrusion failures.

Early detection of problems saves time and cables:

Spaghetti

Nozzle Clumping

Air printing will no longer be a hassle for you!

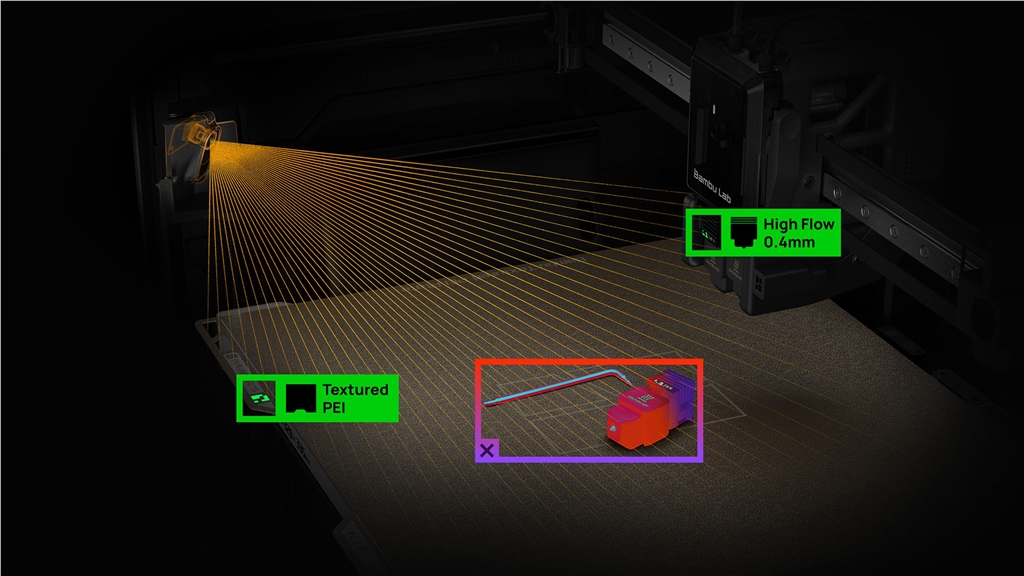

AI-powered pre-print checklist

Print with peace of mind every time.

Before each print job, H2D's vision system initiates a comprehensive pre-print checklist:

Cavity Integrity Scan - Detects debris across the entire print surface.

Hardware configuration audit - Instantly identify nozzle size and board attributes.

Digital physical alignment - Automatically verifies the consistency between detected hardware specifications and the parameters of the slicer in operation.

SOTA Cable Monitoring

15 sensors on a single wire path

Traditional systems rely on a single wire detector, while H2D can provide complete material flow sensing.

Throughout the AMS-to-nozzle process, 15 strategically positioned sensors form an intelligent monitoring network that continuously tracks five key dimensions: feed rate, tension fluctuations, tip positioning, thermal environment in the extruder, and dynamic extrusion pressure – together establishing the industry's state-of-the-art wire behavior control system.

One-year warranty & repair instructions

For Bambu Lab equipment purchases, Santima offers a one-year standard warranty or enhanced warranty option . For any operational inquiries, please contact Santima via email.

👨💻【Enhanced Warranty Service Plan】

Free shipping | Free testing |Free repair

San Di Ma will send someone to collect repair equipment free of charge. → Santima engineer performs repair → After completion, Santima dispatches a vehicle to return it.

• We cannot accept additional orders for the "Enhanced Warranty Plan" after shipment . Please confirm the selected warranty plan that meets your needs when placing your order.

• If there is any problem with the machine, please fill out the technical support form .

• Be sure to use the original complete packaging (outer box, protective foam, etc.) and include all original accessories (e.g., power supply, SD card, cable, printing materials used at the time, etc.) to avoid any omissions in the repair process.

• The engineer assessed the damage as caused by human error or unauthorized modification . For non-human-caused damage, original manufacturer repair and warranty services are available. Consumables (such as spray nozzles) and spare parts are not covered by the warranty.

• All operation training is quoted separately by a Sandima specialist. You can fill out the contact form to inquire.

Please note: To ensure the stability of the AMS 2 Pro drying process, please use an official Bambu Lab power supply.

Contact us for more information about the Bambu Lab 3D printer !

| category | project | Specification |

|---|---|---|

| generally | science and technology | Fused Deposition Modeling (FDM) |

| musculoskeletal system | CoreXY | |

| Machine size | External dimensions (excluding AMS) | 492 × 514 × 626 mm (19.4" × 20.2" × 24.6") |

| Net weight (excluding AMS) | 31 kg (68.4 lbs) | |

| Print parameters | Construction volume (single extrusion) | 325 × 320 × 325 mm (12.79" × 12.59" × 12.79") |

| Construction volume (twin extrusion) | 300 × 320 × 325 mm (11.81" × 12.59" × 12.79") | |

| Total volume of two nozzles | 350 × 320 × 325 mm (13.77" × 12.59" × 12.79") | |

| filament diameter | 1.75 mm | |

| Extrusion method | Double extrusion | |

| Extruder motor | Bambu Lab high-precision permanent magnet synchronous motor | |

| Extruder gears | Hardened steel | |

| hot end | All Metal | |

| Nozzle material | Tungsten carbide | |

| Maximum nozzle temperature | 350°C | |

| Nozzle size | 0.4 mm | |

| Maximum build plate temperature | 120°C | |

| Surface construction | Flexible textured PEI board (smooth PEI board optional) | |

| Maximum cutting head speed | 1000 mm/s | |

| Maximum acceleration | 20,000 mm/s² | |

| Maximum flow rate (standard hot end) | 40 mm³/s | |

| Active cavity heating | support | |

| Maximum chamber temperature | 65°C | |

| Pre-filtration level | G3 | |

| HEPA filtration level | H12 | |

| air purification | Activated carbon filter | Coconut shell pellets |

| VOC filtration | superior | |

| Particulate filtration | support | |

| cool down | Parts cooling fan | Closed-loop control |

| Hot end cooling fan | Closed-loop control | |

| Main control board fan | Closed-loop control | |

| Indoor exhaust fan | Closed-loop control | |

| Enclosure heat circulation fan | Closed-loop control | |

| Auxiliary component cooling fan | Closed-loop control | |

| Printer functions | Closed | It is (plastic + glass) |

| frame | Aluminum and steel | |

| Filament cutter | built-in | |

| Construction board | Magnetic, flexible | |

| Leveling the bed surface | Fully automatic | |

| Emergency button | ✓ | |

| Replaceable nozzle system | ✓ | |

| Power outage recovery | ✓ | |

| camera | Live View Camera | 1920 × 1080 |

| Nozzle camera | 1920 × 1080 | |

| Bird's-eye view camera | 3264 × 2448 | |

| tool head camera | 1920 × 1080 | |

| sensor | Door sensor | support |

| Cable depletion sensor | support | |

| Wire tangling sensor | support | |

| Wire odometer | AMS support | |

| Compatible materials | Third-party cables | support |

| Support materials | PLA, PETG, TPU, PVA, BVOH, ABS, ASA, PC, Nylon/PA, PET, PPS, PPA and their carbon/glass fiber reinforced variants | |

| communicate | Display screen | 5-inch capacitive touchscreen with a resolution of 720 × 1280 |

| Storage | Built-in 8GB eMMC + USB port | |

| Control Interface | Touchscreen, mobile app, PC app | |

| motion controller | Dual-core Cortex-M4 + Single-core Cortex-M7 | |

| processor | Quad-core 1.5GHz ARM A7 | |

| Neural processing unit | 2 Tops | |

| Network control | Connectivity | Wi-Fi, Ethernet |

| Wi-Fi frequency range | 2.4GHz (2400-2483.5 MHz) | |

| Wi-Fi WPA2 Enterprise Edition | EAP-PEAP, EAP-TLS, EAP-TTLS | |

| Wi-Fi transmit power (EIRP) | ≤ 21.5 dBm (FCC), ≤ 20 dBm (CE/SRRC) | |

| Wi-Fi protocol | IEEE 802.11 b/g/n | |

| Ethernet socket | RJ45, 100 Mbps Full-duplex | |

| Detachable network module | yes | |

| 802.1X Network Access Control | yes | |

| software | Slicing software | Bambu Studio (supports third-party slicing software) |

| Compatible systems | Windows, macOS | |

| Supported formats | STL, 3MF | |

| Power requirements | Input voltage | 100-120V AC / 200-240V AC, 50/60Hz |

| Maximum power | 1320W@110V / 2200W@220V | |

| Average power | 1050W |

For Bambu Lab equipment purchases, Santima offers a one-year standard warranty or enhanced warranty option . For any operational inquiries, please contact Santima via email.

👨💻【Enhanced Warranty Service Plan】

Free shipping | Free testing |Free repair

San Di Ma will send someone to collect repair equipment free of charge. → Santima engineer performs repair → After completion, Santima dispatches a vehicle to return it.

• We cannot accept additional orders for the "Enhanced Warranty Plan" after shipment . Please confirm the selected warranty plan that meets your needs when placing your order.

• If there is any problem with the machine, please fill out the technical support form .

• Be sure to use the original complete packaging (outer box, protective foam, etc.) and include all original accessories (e.g., power supply, SD card, cable, printing materials used at the time, etc.) to avoid any omissions in the repair process.

• The engineer assessed the damage as caused by human error or unauthorized modification . For non-human-caused damage, original manufacturer repair and warranty services are available. Consumables (such as spray nozzles) and spare parts are not covered under the warranty.

• All operation training is quoted separately by a Sandima specialist. You can fill out the contact form to inquire.