Bambu Lab ASA Cable Series

Bambu Lab ASA Cable Series - is backordered and will ship as soon as it is back in stock.

Choose add-on

Couldn't load pickup availability

Bambu ASA is a highly durable material with excellent UV resistance, weather resistance, mechanical properties, and heat resistance. Its unique combination of properties makes it ideal for printing outdoor models (plant signs, mailboxes, weather vanes, etc.) and structural components that need to be exposed to challenging outdoor conditions for extended periods.

Exceptional weather resistance and UV protection

Bambu ASA has exceptional UV resistance, antioxidant and anti-aging properties, effectively preventing damage and color fading during long-term outdoor use.

Sturdy and durable

Due to its toughness and high impact strength, it is suitable for outdoor applications and conventional structural requirements.

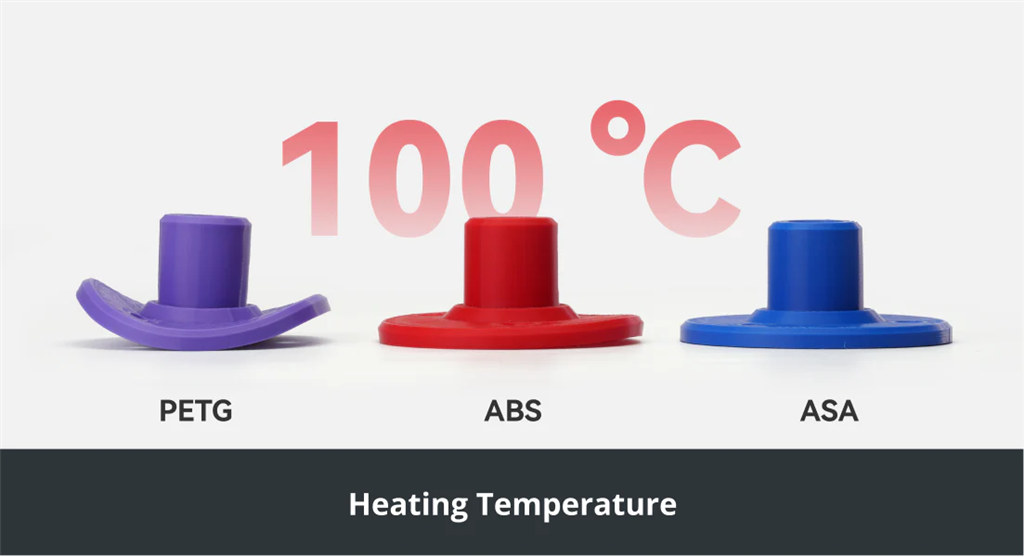

Better temperature resistance

Compared to regular PETG or ABS, Bambu ASA can maintain its shape even at temperatures up to 100°C.

Frequently Asked Questions

1. What is the difference between ABS and ASA?

| ABS | ASA | |

| composition | Acrylonitrile, butadiene, and styrene | Acrylonitrile, styrene, and acrylate. |

ASA is an improved version of ABS, containing additional acrylate components to enhance its weather resistance and UV resistance .

ASA retains the impact resistance and processability of ABS, while offering better resistance to fading, yellowing, and solar degradation. Both can release pungent and unpleasant odors during printing, but the odor of ASA is significantly milder than that of ABS.

2. What is the difference between ABS and ASA?

ASA offers enhanced weather resistance and color stability, making it ideal for outdoor applications such as automotive exterior parts, signage, and outdoor equipment. ABS, on the other hand, is a versatile material with excellent mechanical properties and is typically used for indoor applications.

3. What are the similarities between ABS and ASA?

In terms of physical and mechanical properties, both exhibit good impact resistance and high tensile strength, with nearly identical levels of strength, toughness, and stiffness. Both ABS and ASA may release pungent and unpleasant odors during printing and share similar warping tendencies and closed-system printer requirements when printing large-size and/or high-fill-density models.

Product contents

1 spool & 1 desiccant

Cable label *1

Outer packaging *1

| diameter | 1.75 mm |

| Net weight of wire | 1000 g |

| spool material | PC+ABS (temperature resistant to 90°C) |

| spool size | Diameter: 200 mm; Height: 67 mm |

| Pre-print drying settings | 80 °C, 8 hours |

| Printing and storing humidity | < 20% RH (sealed with desiccant) |

| Nozzle temperature | 240-270 ̊C |

| Printing plate type | Low-temperature plate , high-temperature printing platform , or textured PEI platform |

| heated bed temperature | 80-100 ̊C |

| Cooling fan | 0-80% |

| Printing speed | < 250 mm/s |

| Retraction length | 0.8 - 1.4 mm |

| Retraction speed | 20 - 40 mm/s |

| Internal temperature | 45 - 60 °C |

| Maximum overhang angle | 70 ̊ |

| Maximum bridging length | 40 mm |

physical properties

| density | 1.05 g/cm³ |

| Vicat softening temperature | 106 ̊C |

| Heat distortion temperature | ISO 75 1.8 MPa: 92 °C / ISO 75 0.45 MPa: 100 °C |

| melting temperature | 210 ̊C |

| Melt Flow Index | 7.0 ± 0.8g / 10 min |