Bambu Lab | Product Model:

39% off

18% off

3% off

33% off

10% off

Up to 39% off

Bambu Lab P1S 3D Printer Series

Sale price

¥74,000 JPY

Regular price

¥121,400

Unit price

/

Unavailable

Subtotal

—

Bambu Lab P1S 3D Printer Series - is backordered and will ship as soon as it is back in stock.

Choose add-on

Couldn't load pickup availability

One-year warranty & repair instructions

For Bambu Lab equipment purchases, Santima offers a one-year standard warranty or enhanced warranty option . For any operational inquiries, please contact Santima via email.

• We cannot accept additional orders for the "Enhanced Warranty Plan" after shipment . Please confirm the selected warranty plan that meets your needs when placing your order.

• If there is any problem with the machine, please fill out the technical support form .

• Be sure to use the original complete packaging (outer box, protective foam, etc.) and include all original accessories (e.g., power supply, SD card, cable, printing materials used at the time, etc.) to avoid any omissions in the repair process.

• The engineer assessed the damage as caused by human error or unauthorized modification . For non-human-caused damage, original manufacturer repair and warranty services are available. Consumables (such as spray nozzles) and spare parts are not covered under the warranty.

• All operation training is quoted separately by a Sandima specialist. You can fill out the contact form to inquire.

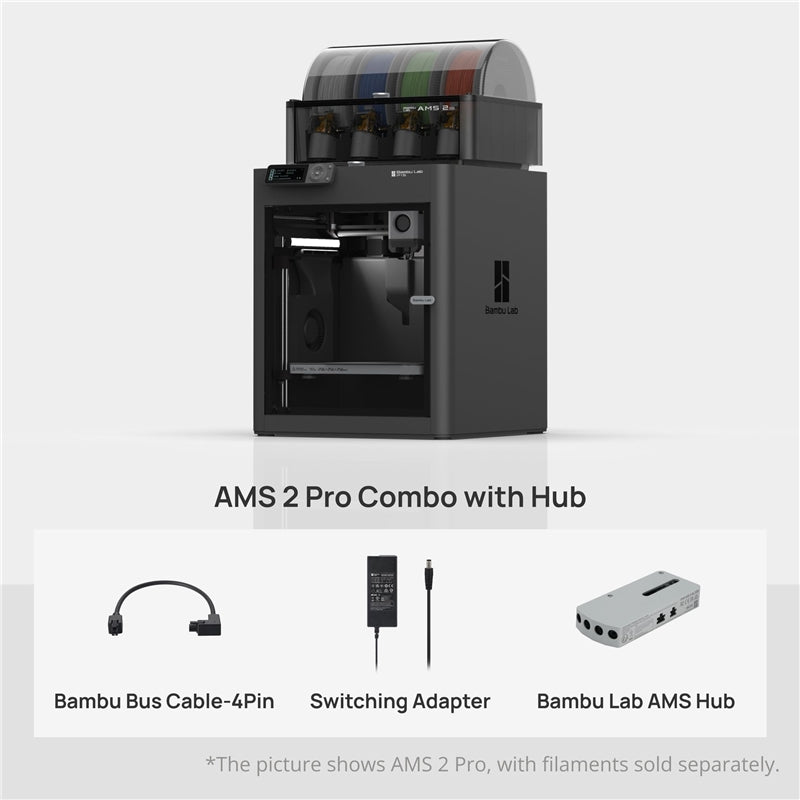

Please note: To ensure the stability of the AMS 2 Pro drying process, please use an official Bambu Lab power supply.

Using a third-party power supply may damage the product, and according to the warranty policy, damaged parts of the product itself are not covered by the warranty.

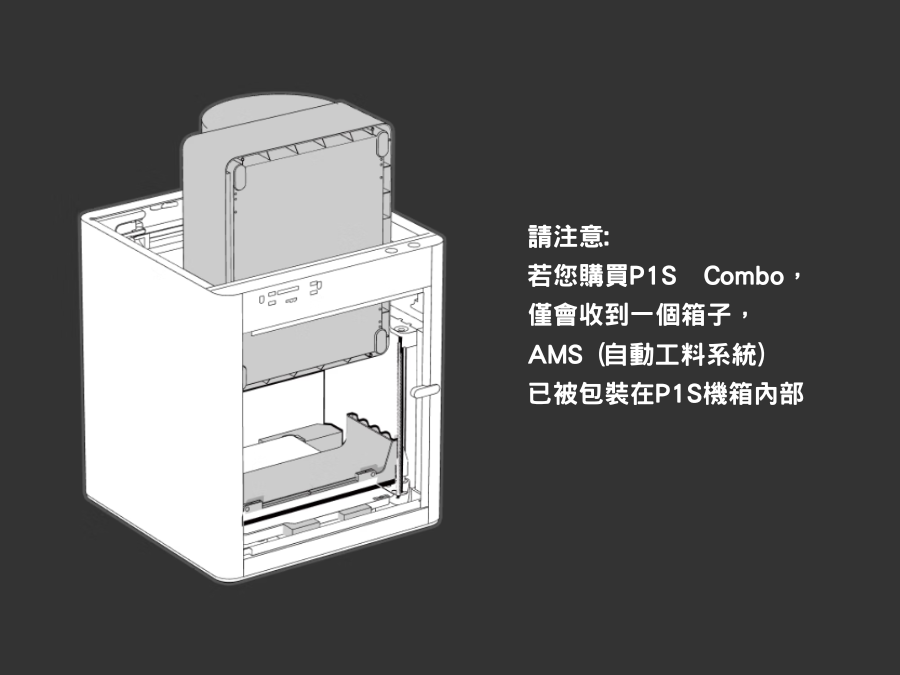

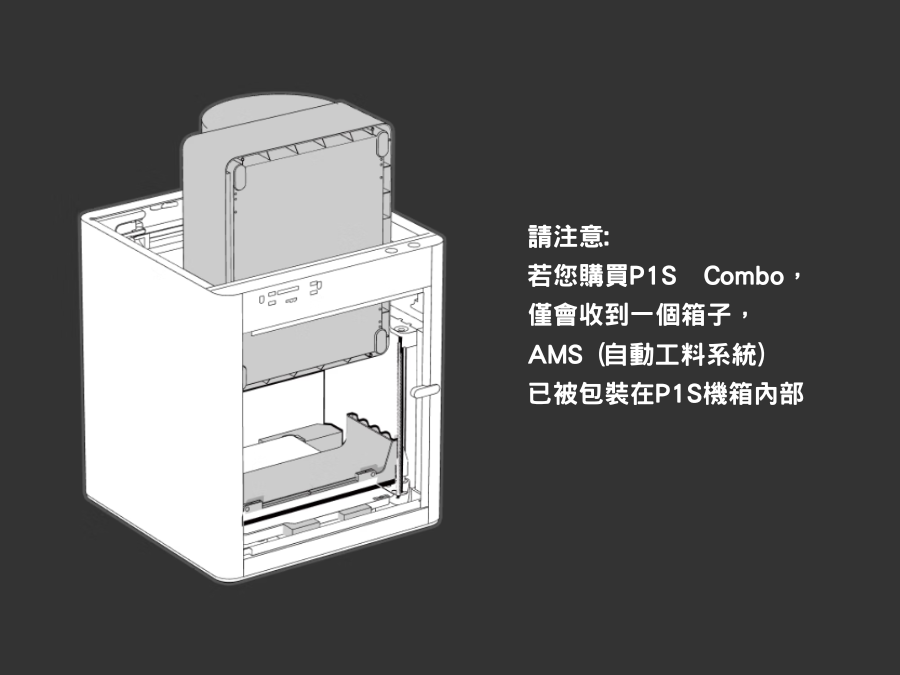

Topzhu Bambu Lab P1S Combo 3D Printer

* Packaging has been reinforced.

Almost every 3D printing enthusiast dreams of creating stunning works. With the new Tuozhu Bambu P1S , you can print your dream prints with incredible speed and exceptional quality!

Ready to use right out of the box

Ready to use right out of the box , setup takes only 15 minutes. You don't need to do anything; simply press the print button , and the printer will handle all the calibrations (automatic bed leveling, vibration compensation). Enjoy trouble-free printing with the P1S.

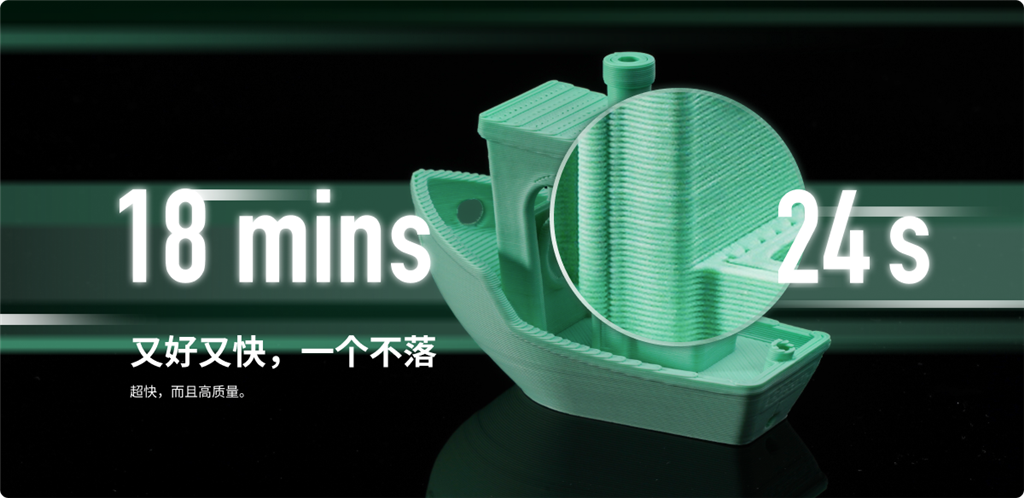

The acceleration efficiency of 20,000 mm/s² is more than doubled.

The P1S inherits the proven motion control system of the X1 series. It boasts a maximum printing speed of 500 mm/s and accelerates from zero to full speed in just 0.025 seconds.

The P1S inherits the proven motion control system of the X1 series. It boasts a maximum printing speed of 500 mm/s and accelerates from zero to full speed in just 0.025 seconds.

Vibration compensation and pressure propulsion compensation

Active vibration compensation and pressure advance algorithms make extrusion smoother.

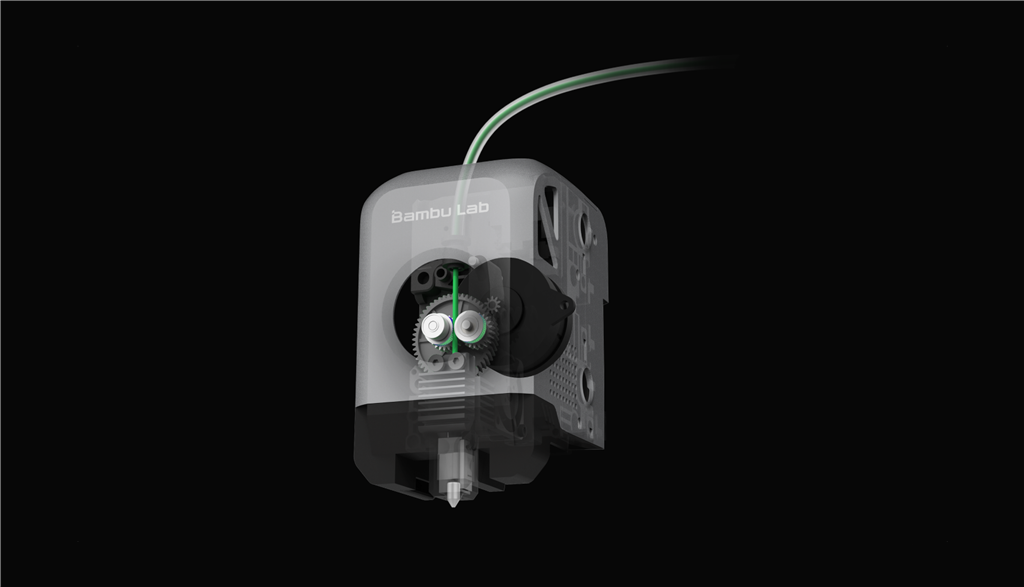

Near-field extrusion

By directly connecting the motor to the extruder, the P1S can better control the extrusion and retraction of consumables, reduce stringing, and make the printed parts smooth and precise.

By directly connecting the motor to the extruder, the P1S can better control the extrusion and retraction of consumables, reduce stringing, and make the printed parts smooth and precise.

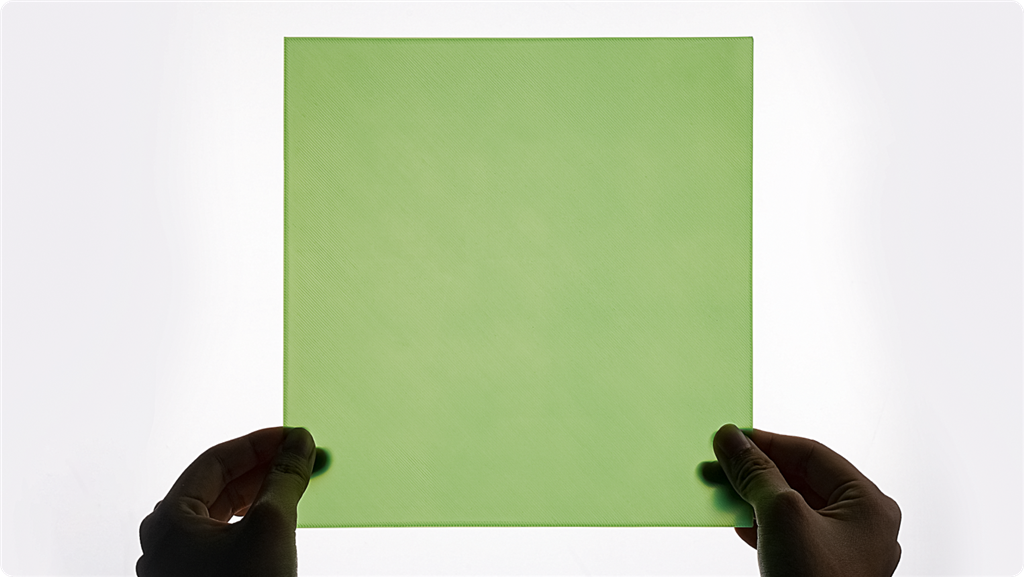

Automatic leveling and flawless first layer printing

The automatic leveling (ABL) sensor properly calibrates and levels the heated bed, ensuring a smooth and flawless finish for each primary layer.

All-metal hot end

Made of high-temperature resistant materials, it supports high-performance materials such as nylon and polycarbonate. It can be upgraded to a hardened hot end, easily handling carbon fiber reinforced functional plastics.

Material breakage detection

Eliminate the hassle of running out of materials; you can replace consumables and resume printing when the material hopper is empty.

Power outage resume printing

No need to worry about power outages; simply restart printing from where it stopped.

Semi-automatic belt tensioner

Belt tension is crucial for ensuring dimensional accuracy. Resonant frequencies are identified during each run to indicate the need for maintaining proper belt tension.

Fan speed feedback

Monitor fan speed to ensure the fan is always running at the optimal speed.

【P1S Combo Additional Attachments List】

Contact us to learn more about Bambu Lab 3D printers and accessories !

Made of high-temperature resistant materials, it supports high-performance materials such as nylon and polycarbonate. It can be upgraded to a hardened hot end, easily handling carbon fiber reinforced functional plastics.

Material breakage detection

Eliminate the hassle of running out of materials; you can replace consumables and resume printing when the material hopper is empty.

Power outage resume printing

No need to worry about power outages; simply restart printing from where it stopped.

Semi-automatic belt tensioner

Belt tension is crucial for ensuring dimensional accuracy. Resonant frequencies are identified during each run to indicate the need for maintaining proper belt tension.

Fan speed feedback

Monitor fan speed to ensure the fan is always running at the optimal speed.

【P1S Combo Additional Attachments List】

Contact us to learn more about Bambu Lab 3D printers and accessories !

| Print size (length × width × height) | 256x256x256 mm |

| frame | steel |

| shell | Plastic and glass |

| hot end | All Metal |

| Extruder gears | steel |

| nozzle | Stainless steel |

| Nozzle maximum temperature | 300 ℃ |

| Nozzle diameter (default setting) | 0.4 mm |

| Nozzle diameter (sold separately) | 0.2 mm, 0.6 mm, 0.8 mm |

| Tool head cutter | built-in |

| wire diameter | 1.75 mm |

| Print panel (included by default) | Texture PEI Printing Panel |

| Print panel (sold separately) | Low temperature printing panel |

| High-temperature printing panel | |

| Engineering Materials Printing Panel | |

| Heated bed supports maximum temperature | 100℃ |

| Maximum tool head movement speed | 500 mm/s |

| Maximum acceleration of tool head movement | 20 m/s² |

| Maximum flow rate at the hot end | 32 mm³/s @ABS (Model: 150*150mm single-layer outer wall;) |

| Wire material: Bambu ABS; Temperature: 280℃ | |

| Component cooling fan | Closed-loop control |

| Hot end fan | Closed-loop control |

| Auxiliary component cooling fan | Closed-loop control |

| Control board fan | Closed-loop control |

| Body temperature regulating fan | Closed-loop control |

| PLA, PETG, TPU, ABS, ASA, PVA, PET | Suitable for printing |

| Nylon wire (PA), polycarbonate wire (PC) | Can print |

| Carbon/glass fiber reinforced wire | Not recommended |

| Main unit casing surveillance camera | Low frame rate camera 1280 x 720 / 0.5fps (optional) |

| Supports time-lapse photography | |

| Material breakage detection | support |

| Wire material usage and surplus material inspection | Supports when used with AMS |

| Power outage printing resume | support |

| Product dimensions (length × width × height) | 389 x 389 x 458 mm |

| Packaging weight | 21.6 kg |

| Input voltage | 100-240 VAC, 50/60 Hz |

| Maximum power | 1000W@220V, 350W@110V |

| USB output | 5V/1.5A |

| Display screen | 2.7-inch, 192x64 screen |

| Connection method | Bluetooth, Bambu-Bus |

| storage | Micro SD card |

| User interface | Buttons, mobile app, PC application |

| motion controller | Dual-core Cortex-M4 processor |

| Slicing software | Bambu Studio |

| It supports other vendor slicers that can export standard G-code, such as Superslicer, Prusaslicer, and Cura, but some smart features may not be supported. | |

| The slicing software supports operating systems. | MacOS, Windows |

| Products include | Bambu Lab P1S Stainless steel hot end nozzle Bambu textured PEI board Bambu PLA cable unclogging pins tool power cord accessory box Bambu Lab AMS Automated Feeding System Spare Wire Cutter x2 Bambu Bus Cable - 6 Pin Bambu Bus Cable - 4 Pins Bambu PLA cable x1 Bambu cable (random) x2 |

Authorized and certified by the National Communications Commission (NCC)※

One-year warranty & repair instructions

For any Bambu Lab equipment purchases, SanDima provides a one-year warranty and maintenance service . For any operational questions, please contact SanDima via email .

• If the machine malfunctions, please fill out the technical support form first. If the engineer assesses that the damage is not caused by human error, the following two methods can be used:

🔧【 Customer DIY Parts Repair】

We will ship the parts to the designated location free of charge → Customers will assemble the parts themselves.

👨💻【Sandyma Engineer Repair Service】

1. Original packaging available → Pay shipping + repair fee $2000 → Sandima dispatches a vehicle to pick up the machine → Sandima engineer performs maintenance → Sandima dispatches a vehicle to return the machine after completion

2. No original packaging → You are responsible for arranging your own shipping or retrieval costs → Send to Sandima Co., Ltd. → Sandima engineers will repair the machine → After completion, retrieve the machine from Sandima Co., Ltd.

• The engineer assessed the damage as caused by human error or unauthorized modification . For non-human-caused damage, original manufacturer repair and warranty services are available. Consumables (such as spray nozzles) and spare parts are not covered by the warranty.

• All operation training is quoted separately by a Sandima specialist. You can fill out the contact form to inquire.