[Vacuum Forming Application] DIY Whiskey Spherical Ice Mold: Create Creative Ice Cube Drinks!

DIY Spherical Ice Mold: Create 360° 3D Coffee Ice Balls! A new Children's Day toy—make your own drinks at home! Thick ice cubes won't melt easily in beverages. Design endless shapes and variations. 3D printing combined with vacuum forming technology . Free download of the model is included at the end of the article. Making your own ice balls is super fun! Learn the steps now:

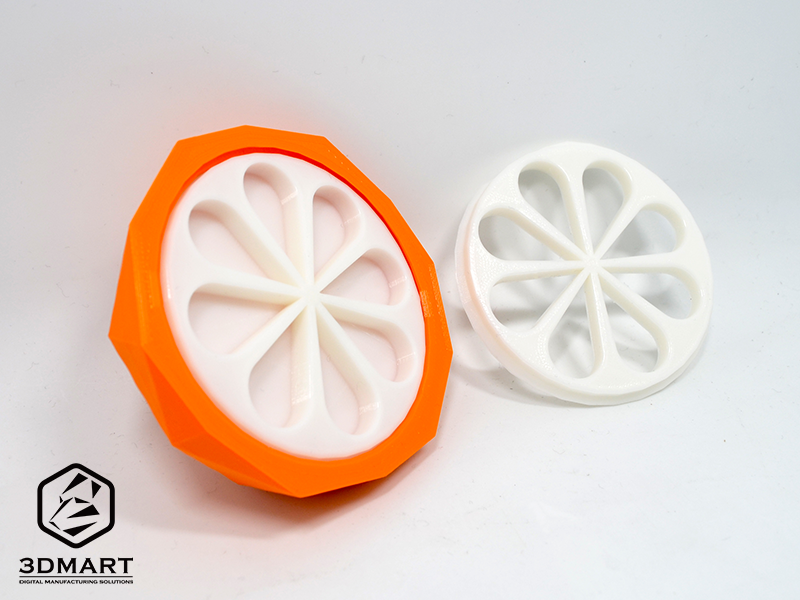

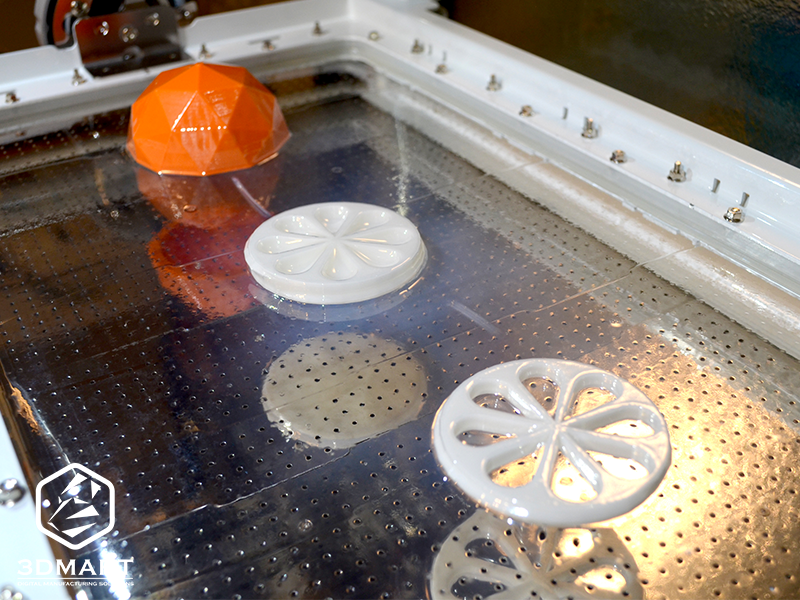

First, design or select the desired 3D printing mold shape, and then use vacuum forming technology to create a 360-degree three-dimensional ice hockey puck. We chose a semi-circular, fruit-slice model. To create a three-dimensional mold for both sides, we will vacuum-form the orange semi-circle and the white petal-shaped fruit pieces separately. ( Click to see: Simple 4 Steps: Double-Sided Molding Techniques for 360-Degree Three-Dimensional Fish-Shaped Ice Balls! )

(The ice block model was created using an Ultimaker S5 3D printer and orange and white Ultimaker PLA filaments .)

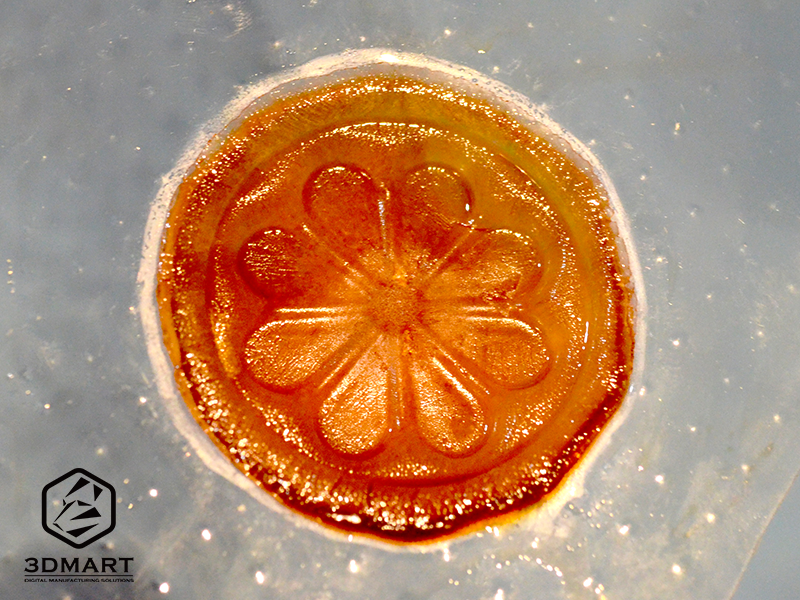

The 3D printed model is vacuum-formed using MY YARD vacuum forming transparent PET material sheet , combined with TPU soft material sheet , to create a mold for the upper and lower parts. After vacuum forming and cooling, the MY YARD vacuum forming machine automatically sends air to demold, allowing you to easily obtain the finished mold without manual disassembly!

Due to the elasticity of TPU soft material molds, the mold can be easily removed with a simple bend, achieving a better demolding effect. ( Click to see: Silicone flip-flop molds, self-contained production line, no outsourcing required! )

.gif)

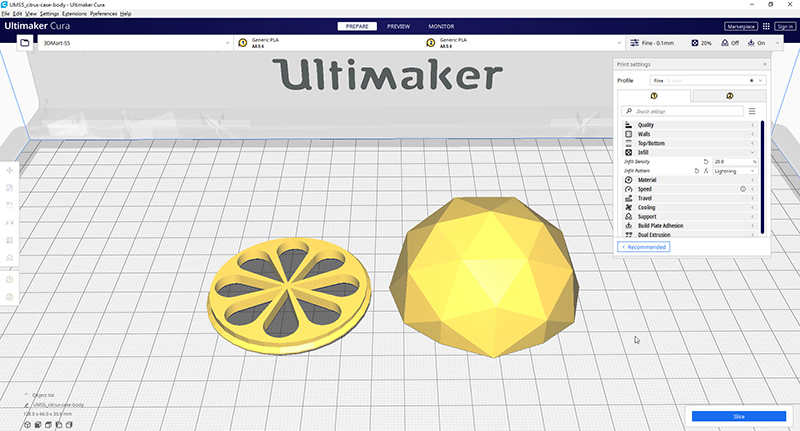

Vacuum forming model design tips! Leave holes at the bottom of the model. During vacuum forming, airflow can reach the bottom of the model directly, allowing excess air to escape through the holes. This improves the fit between the material sheet and the model. Compared to a solid bottom, paying attention to this detail in model selection or design can enhance the precision of the finished vacuum-formed product. ( Click to see: 3 tips for vacuum forming: Elevate the quality of blister packaging! )

Using the Ultimaker Cura slicing software, you can adjust the model's position, size, and other details at this step. After vacuum molding is complete, you can see the petal shape on the right. Because the bottom is an open hole, the right side has the best molding effect compared to the solid model below the middle petal shape!

Cut the molds you'll be using from the material sheet, pour espresso into the ice cube molds, cover them with the petal-shaped mold lids, and finally put them in the freezer to freeze. Your homemade shaped ice ball is almost done!

Finally, pour in milk, soy milk, or other beverages, and your homemade drink is complete! Using the same principle, the possibilities are endless. Through 3D printing and vacuum forming technology , whether it's food, desserts, or beverages, you're not limited by traditional molds; a variety of shapes allow you to unleash your creativity!

Did you enjoy this sharing? With the Qingming Festival long weekend coinciding with Children's Day, let's have some fun DIY projects! Industrial technologies such as 3D printing and vacuum forming are gradually integrating into daily life. By understanding and skillfully combining these technologies, we can create all sorts of unexpected and creative ways to play! SanDiMa offers more than just 3D printing ; contact us now to learn more about the MY YARD series vacuum forming machines .

Click to download: 3D printed fruit box

Follow our fan page to stay up-to-date with the latest news: https://www.facebook.com/3dmart.com.tw/

https://www.instagram.com/3dmart