[3D Printing News] The secret to Snapmaker J1's high efficiency and high quality revealed!

Those familiar with 3D printing know that it remains relatively slow, especially with FDM technology . Depending on the complexity, size, and accuracy requirements of the model, some types of printing can take hours or even days to complete. A trade-off must be made between time and quality.

The Snapmaker J1 successfully balances quality and speed. A major highlight of the J1 compared to other leading IDEX 3D printers on the market is its high-speed printing. IDEX 3D printers typically struggle to increase printing speed due to two independent printheads bearing greater weight, increasing inertia. Furthermore, the X-axis bears more weight while moving the two nozzles, making accurate movement more challenging. However, the Snapmaker J1 overcomes these difficulties, effectively improving printing speed while maintaining a layer height of 0.1 mm at 350 mm/s.

The Snapmaker J1 successfully balances quality and speed. A major highlight of the J1 compared to other leading IDEX 3D printers on the market is its high-speed printing. IDEX 3D printers typically struggle to increase printing speed due to two independent printheads bearing greater weight, increasing inertia. Furthermore, the X-axis bears more weight while moving the two nozzles, making accurate movement more challenging. However, the Snapmaker J1 overcomes these difficulties, effectively improving printing speed while maintaining a layer height of 0.1 mm at 350 mm/s.

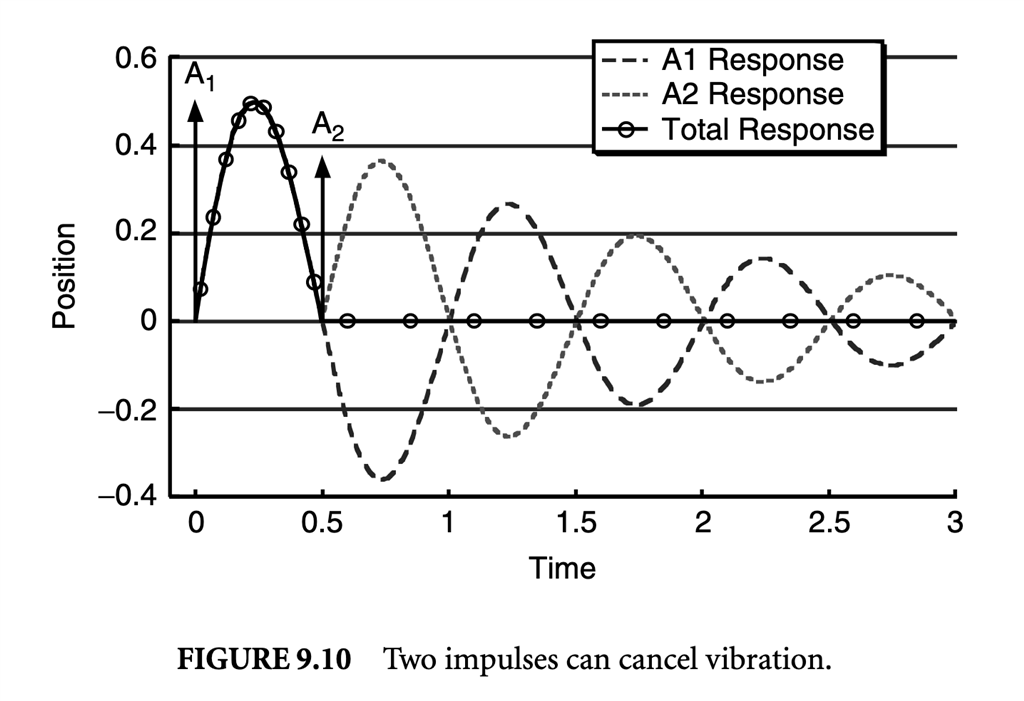

There are four solutions, based on both hardware and software, that can accomplish this seemingly impossible task. The first is vibration compensation, also known as input shaping. High-speed motion can easily produce excessive or residual vibration, especially at the end of the run, leaving unwanted vibration or ghosting effects on the printed objects, thus affecting quality.

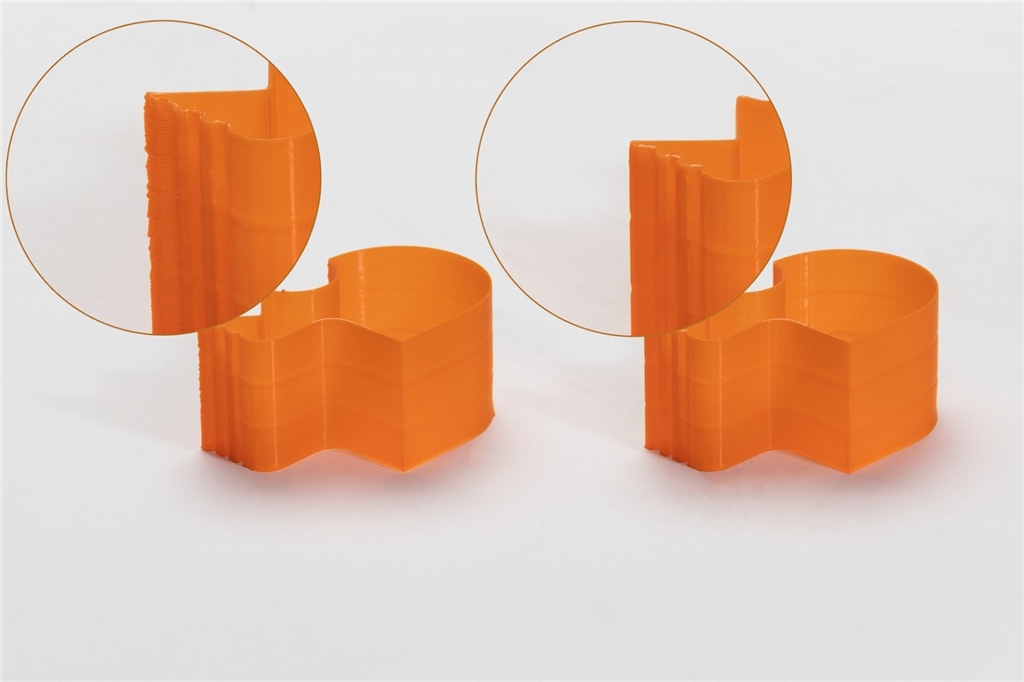

Below is a screenshot showing the vibration level when the Snapmaker J1 input shaping is turned on and off. As shown in the image, the unevenness of the lines indicates free vibration, which occurs when the nozzle changes direction.

Rapid 3D printing of pointed shapes can easily compromise print quality. Secondly, optimizing turning speeds by analyzing the direction of movement in advance improves print quality at turns.

Third, the nozzles that make short turns frequently accelerate and brake alternately. When the entire machine shakes together, the process can be very unstable and noisy. Therefore, the Snapmaker J1 adjusts the maximum printing speed when the print nozzles turn at high frequencies.

Fourth, the Snapmaker J1 incorporates a continuous printing switching mechanism in IDEX printing, fully leveraging the advantages of IDEX. This mechanism is suitable for situations such as two-color printing where two nozzles work alternately. Normally, when only one nozzle finishes printing, it will stop to one side, while the other nozzle heats up from its standby temperature to its initial printing temperature, and then switches back to continue printing.

Fourth, the Snapmaker J1 incorporates a continuous printing switching mechanism in IDEX printing, fully leveraging the advantages of IDEX. This mechanism is suitable for situations such as two-color printing where two nozzles work alternately. Normally, when only one nozzle finishes printing, it will stop to one side, while the other nozzle heats up from its standby temperature to its initial printing temperature, and then switches back to continue printing.

.png)

With the software and hardware improvements to the Snapmaker J1 , idle nozzles heat up to their initial printing temperature while waiting, and immediately fill the gap left by an active nozzle to continue printing. This allows for seamless switching between two independent nozzles. You can watch the video below to see how the Snapmaker J1 works.

In addition to improvements in both hardware and software, the Snapmaker J1 's body consists of a top frame, a unibody base, and four aluminum alloy rods. This makes it extremely robust and reliable, with minimal swaying and deformation. Furthermore, the industrial-grade linear guide rails, crafted using micro-nano-level CNC machining, ensure smooth operation.

Did you enjoy this sharing? 3D printers offer more than just 3D printing . Contact us now to learn more about our 3D printers and 3D scanners .

Follow our fan page to stay up-to-date with the latest news: https://www.facebook.com/3dmart.com.tw/

https://www.instagram.com/3dmart/

References

Follow our fan page to stay up-to-date with the latest news: https://www.facebook.com/3dmart.com.tw/

https://www.instagram.com/3dmart/

References