[Waterjet Cutting] A Mini Knowledge Corner: What is Waterjet Cutting and Its Principles

Since ancient times, humans have utilized the impact force of water flow to create waterwheels, watermills, and other hydraulic machinery. The impact force is even greater when water is sprayed from a high-pressure water jet. When mixed with fine abrasive and emitted through a small-diameter nozzle under high pressure, it can cut hard objects such as metal or stone in minutes. With the increasing precision of CNC technology , waterjet cutting has become the preferred industrial precision cutting technology.

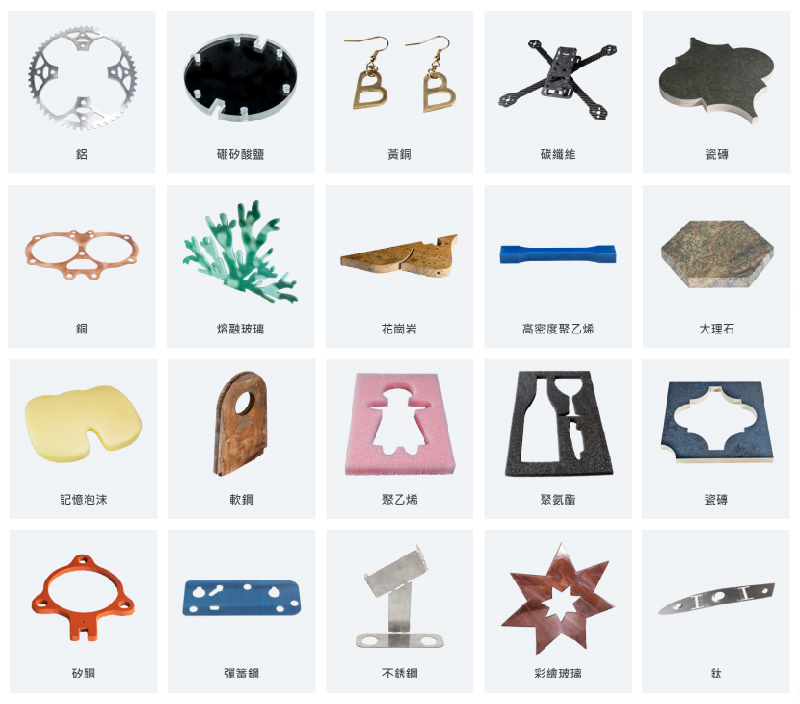

What can a water jet cutter cut?

This is a question that many people unfamiliar with this technology might have: waterjet cutting can cut almost anything, including metals (steel, aluminum, titanium, etc.), composite materials such as carbon fiber, ceramics, marble and granite, glass, soft materials, plastics, rubber and foam, and much more. There are virtually no limits!

This is a question that many people unfamiliar with this technology might have: waterjet cutting can cut almost anything, including metals (steel, aluminum, titanium, etc.), composite materials such as carbon fiber, ceramics, marble and granite, glass, soft materials, plastics, rubber and foam, and much more. There are virtually no limits!

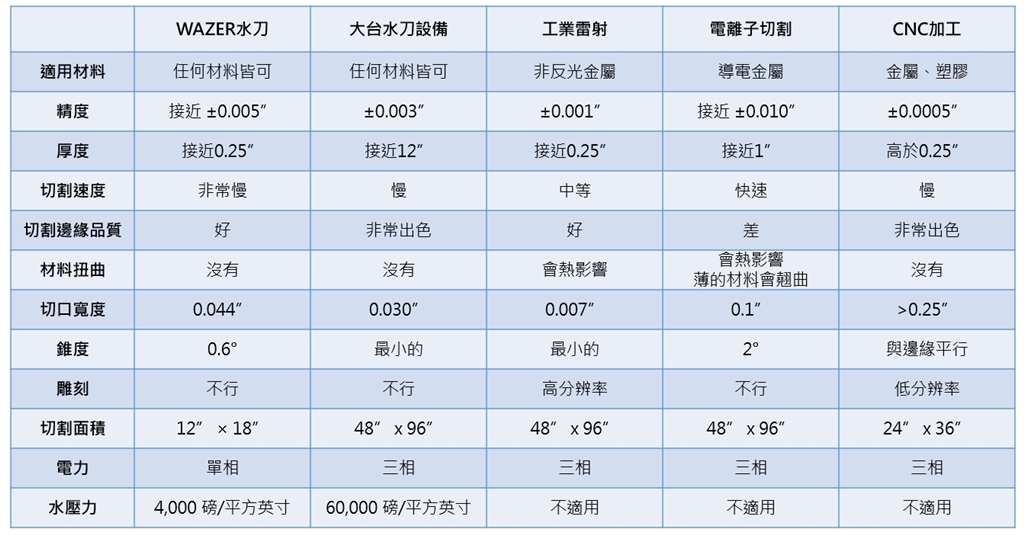

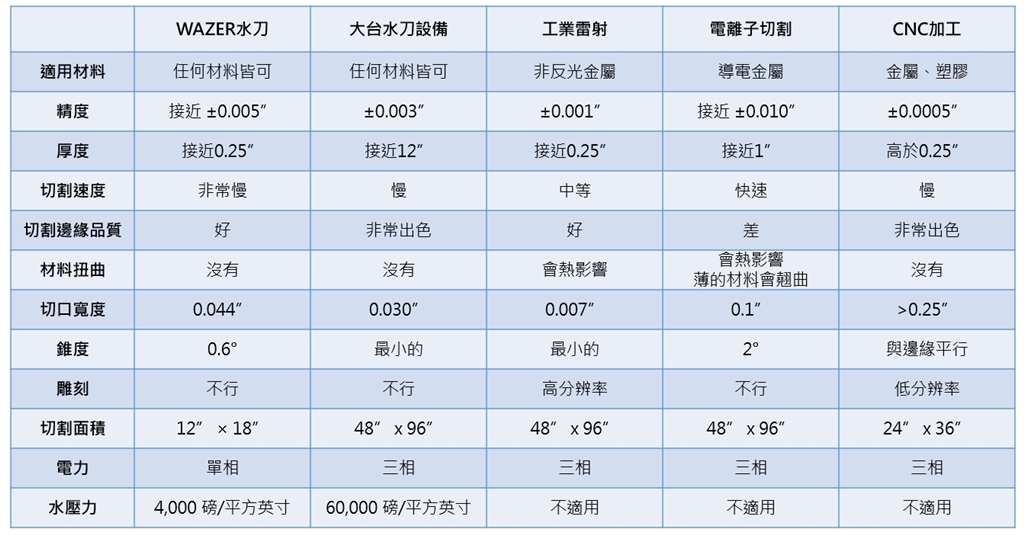

Waterjet cutting vs. other cutting techniques

Common cutting technologies on the market include blades, lasers, electrocautery, and waterjet cutting. Each cutting technology has its advantages and disadvantages, and the user should choose the most suitable method based on their specific needs. Compared with other cutting technologies, waterjet cutting has the following characteristics:

• Material integrity: The material will not affect the cut edge due to thermal reaction.

• Improved safety. • Improved cut width.

• Save on technology costs

Note: This table is only a general summary of the key points, showing a comparison between waterjet cutting and general cutting techniques. There is no strict requirement to use any particular technology or equipment; the actual choice should be based on the material being cut.

Who can use a waterjet cutter? How is it applied?

It's applicable to virtually every industry, with almost no limitations. It's suitable for any industry and material, from sheet metal and metal parts cutting. It's especially useful in the automotive, aerospace, and metal processing industries. Applications include rapid prototyping, disposable tools, customized parts, and small-batch production. In fact, there's demand and application for it throughout the manufacturing sector. Today, high schools, vocational schools, and universities are training students to use CNC technology to develop hands-on skills and execute creative ideas, becoming the next generation of engineers. Many artists also use waterjet cutting to create their designs, reducing excessive manual labor.

WAZER is the world's first desktop waterjet cutting machine.

WAZER is the world's first desktop waterjet cutting machine.

Below are the technical specifications of WAZER's desktop waterjet cutting machine . Historically, waterjet cutting has been limited to industrial applications due to the large size and high cost of the equipment. NOW! WAZER brings industrial-grade waterjet cutting technology to factories, companies, schools, and individual studios. Join the maker movement!

Did you enjoy this sharing? 3D printers offer more than just 3D printing . Contact us now to learn more about our 3D printers and 3D scanners .

Follow our fan page to stay up-to-date with the latest news: https://www.facebook.com/3dmart.com.tw/

https://www.instagram.com/3dmart/

References

Common cutting technologies on the market include blades, lasers, electrocautery, and waterjet cutting. Each cutting technology has its advantages and disadvantages, and the user should choose the most suitable method based on their specific needs. Compared with other cutting technologies, waterjet cutting has the following characteristics:

• Material integrity: The material will not affect the cut edge due to thermal reaction.

• Improved safety. • Improved cut width.

• Save on technology costs

Note: This table is only a general summary of the key points, showing a comparison between waterjet cutting and general cutting techniques. There is no strict requirement to use any particular technology or equipment; the actual choice should be based on the material being cut.

Who can use a waterjet cutter? How is it applied?

It's applicable to virtually every industry, with almost no limitations. It's suitable for any industry and material, from sheet metal and metal parts cutting. It's especially useful in the automotive, aerospace, and metal processing industries. Applications include rapid prototyping, disposable tools, customized parts, and small-batch production. In fact, there's demand and application for it throughout the manufacturing sector. Today, high schools, vocational schools, and universities are training students to use CNC technology to develop hands-on skills and execute creative ideas, becoming the next generation of engineers. Many artists also use waterjet cutting to create their designs, reducing excessive manual labor.

Below are the technical specifications of WAZER's desktop waterjet cutting machine . Historically, waterjet cutting has been limited to industrial applications due to the large size and high cost of the equipment. NOW! WAZER brings industrial-grade waterjet cutting technology to factories, companies, schools, and individual studios. Join the maker movement!

| Main unit size | 850 mm x 650 mm x 560 mm |

| Main unit dimensions (including tripod) | 850 mm x 650 mm x 1220 mm |

| Main unit weight | 50kg |

| Pump tank size | 530 mm x 380 mm x 280 mm |

| Pump tank weight | 42kg |

| Scope of work | 305 mm x 460 mm |

| Cutting pad size | 330 mm x 485 mm |

| Cut width | 1.2mm |

| power supply | 100-240 VAC, 50/60Hz, 2.5A |

| Pump box | 110-120 VAC; 60Hz; 15A; 1700W |

| Applicable water sources | tap water |

| Inlet filter | ~300 mesh |

| Water intake requirements | >3.8 L/min; >35 Psi (2.4 Bar); Total solids content |

| drain | Household drainage, 180 mg/L; >130F/54°C |

| Drainage pipe | Length less than 9 meters |

| Water cycle | Not recommended |

| Abrasive flow rate | 140g ~150g/min |

| Abrasive capacity | 13.5 kg |

| Abrasive type | Garnet sand (80 mesh) |

| Maximum linear velocity | 75 IPM (1905 mm/min) |

| Y-axis positioning accuracy | 0.8 mm |

| WAM software supports browsers. | Chrome, Internet Explorer, Safari, firefox |

| Supported file types | DXF, SVG |

| Connection method | SD card |

| Noise emissions | 74 +/- 3dB |

| Noise pressure level | 87 +/- 3dB |

| Ambient temperature | 0°C - 40°C / 32°F - 104°F for long-term storage 0°C - 70°C / 32°F - 160°F 24 hours |

| Maximum working pressure and flow rate | 4600 PSI (32 MPa) at 1.9 L/min |

| Contents | WAZER main unit and pump box cutting pad (3 pieces per set) Abrasive barrel (total 50 kg) Water sensors (2 pieces) Accessory kit (1 set) Installation kit (1 set) Pipe kit (1 set) Spare parts (1 set) Instruction manual (1 copy) |

Did you enjoy this sharing? 3D printers offer more than just 3D printing . Contact us now to learn more about our 3D printers and 3D scanners .

Follow our fan page to stay up-to-date with the latest news: https://www.facebook.com/3dmart.com.tw/

https://www.instagram.com/3dmart/

References