[3D Printing] Red Wolf Technology collaborates with Bambu Lab to revolutionize mobile phone accessory customization

Red Wolf Technology helps retail and repair shops produce mobile phone accessories in-store according to customer needs, such as custom phone cases, screen protectors, and polishing kits.Their three flagship solutions are:

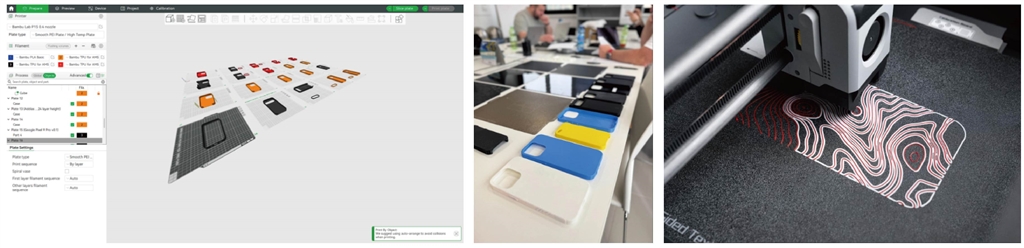

Primo Print3D: Print flexible, durable, and fully customized phone cases while customers wait.

Primo Protect: A screen protector cut to fit perfectly on any device.

Primo Polish: Restores scratched phone screens to like-new condition.

By localizing and just-in-time production, Red Wolf minimizes waste, lowers costs, speeds up turnover, and generates new revenue for retailers.

Before adopting Bambu Lab printers, Red Wolf faced two main obstacles:

1. Traditional manufacturing limitations

Injection molding requires expensive tools, long lead times, and large minimum operating volumes, making it impossible to achieve small-batch, on-demand production.

2. Disadvantages of existing 3D printers

Most desktop FDM printers are too slow, too expensive, or produce parts that are not suitable for retail.

Frequent malfunctions and inconsistent print quality undermined customer confidence.

These limitations made in-store, on-demand customized phone accessories impractical until Red Wolf discovered Bambu Lab.

Bambu Lab Solutions

Red Wolf Technology has implemented operational standardization across a range of Bambu Lab printers ( X1C , P1S , A1 , and A1 Mini ).

This enables rapid prototyping and scalable retail production.

In its central prototype lab, the X1C and P1 series utilize CoreXY mechanics and ultra-high acceleration (up to 50,000 mm/s²) to handle multi-material iterations and precision fixture manufacturing at speeds unmatched by other desktop systems.

For in-store deployments, the fully enclosed P1S (valued for its integrated AMS, robust deployment capacity, and balanced cost-effectiveness) provides customized printing services for global partners such as MediaMarkt and CPR Cell Phone Repair.

By integrating each machine onto Red Wolf’s customized Primo Print3D platform via the Bambu Farm Server SDK API over a secure LAN, they achieved seamless workflows, centralized material management, and real-time status monitoring across all locations.

Implementation and Workflow

At the company headquarters, Red Wolf's R&D team uses Bambu Studio and OrcaSlicer to complete the case model.

Red Wolf 's custom API-driven print farm application can schedule and monitor print jobs on more than 20 machines, ensuring optimal utilization and minimizing downtime.

At the retail location, staff guide customers in selecting equipment models, colors, and patterns.

They then send the selected print files directly to the on-site 3D printer.

Once printed, customers can pick up their orders directly, eliminating inventory guessing and waste.

Results and Benefits

Bambu Lab’s speed and quality have made in-store on-site printing a reality, creating hundreds of millions of dollars in new revenue opportunities.

100% of our printed materials are driven by customer demand; there is no inventory speculation or inventory pressure.

From the latest versions to older phone models, Red Wolf meets needs that other companies cannot.

92.7% of phone cases are for phones launched last year, 84.8% are for phones launched in the past two years, and 26% are for older devices—far beyond what traditional supply chains typically support.

Centralized line management reduces the amount of manual printing work by more than 60%, thereby increasing throughput and uptime.

From PLA to TPU, Bambu Labs' AMS provides customers with the flexibility, high quality of housings in a variety of materials, along with the reliability of an automated material system.

Looking to the future

Red Wolf continues to explore emerging hardware, software, and materials to expand its custom product offerings.

They are working on deeper integration with the Bambu Farm Server API to reduce reliance on the Bambu Handy application and simplify LAN mode switching.

The team is also piloting workflow improvements, such as automatic cache clearing and expanded API functionality, to improve efficiency and maintain the fastest, most flexible retail printing experience.

⚡Buy a Bambu Lab 3D printer now and unlock endless possibilities!

-Contact Us-

SanDiMa offers more than just 3D printing ; we provide three major OEM services: " 3D Printing Manufacturing ," " 3D Scanning Services ," and " Spatial 3D Scanning Services "!

Follow our fan page and stay up-to-date with the latest news:

Facebook | Instagram | T hreads