[Vacuum Forming Applications] FormBox Vacuum Forming and Mold Manufacturing Beginner's Guide! 7 Design Essentials You Should Know!

Before we begin, we hope everyone has a thorough understanding of the basic design principles of vacuum forming and mold making. We've invited manufacturing expert Agustín Arroyo to explain all of this.

Before using any equipment, it's essential to understand the design principles of the vacuum-formed Mayku FormBox. Similar to 3D printing , it's best to understand some 3D printing design logic before starting the design process. This will allow for easy application of 3D printing in products, packaging, electronic device casings, and more.

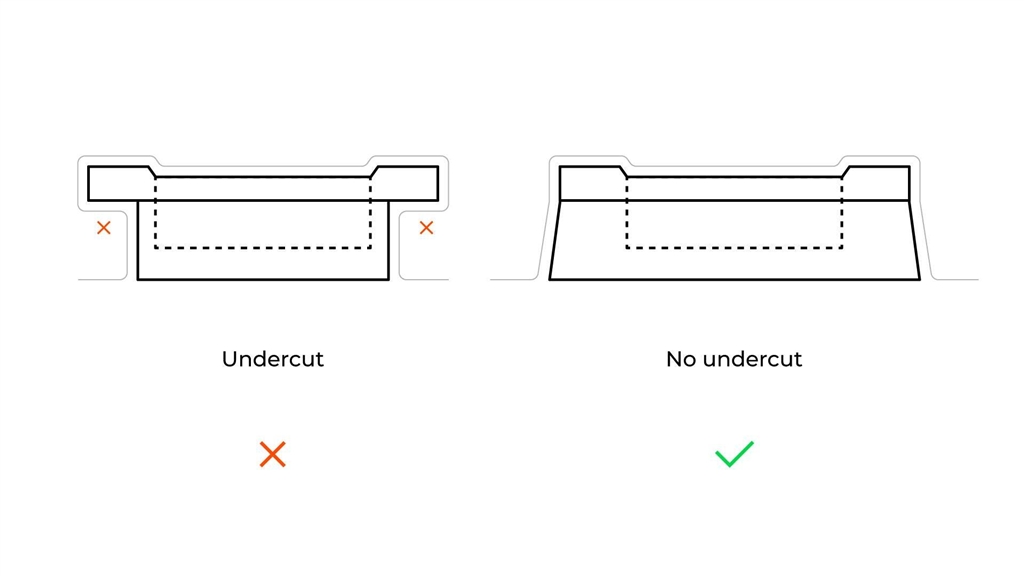

No suspension

If a model with protrusions or dents is vacuum-formed, the object will be impossible to remove once the material sheet cools down. Those familiar with FDM 3D printers know that overhangs must be avoided. When 3D-printed objects are used for vacuum-formed models, all overhangs must be avoided.

No suspension

If a model with protrusions or dents is vacuum-formed, the object will be impossible to remove once the material sheet cools down. Those familiar with FDM 3D printers know that overhangs must be avoided. When 3D-printed objects are used for vacuum-formed models, all overhangs must be avoided.

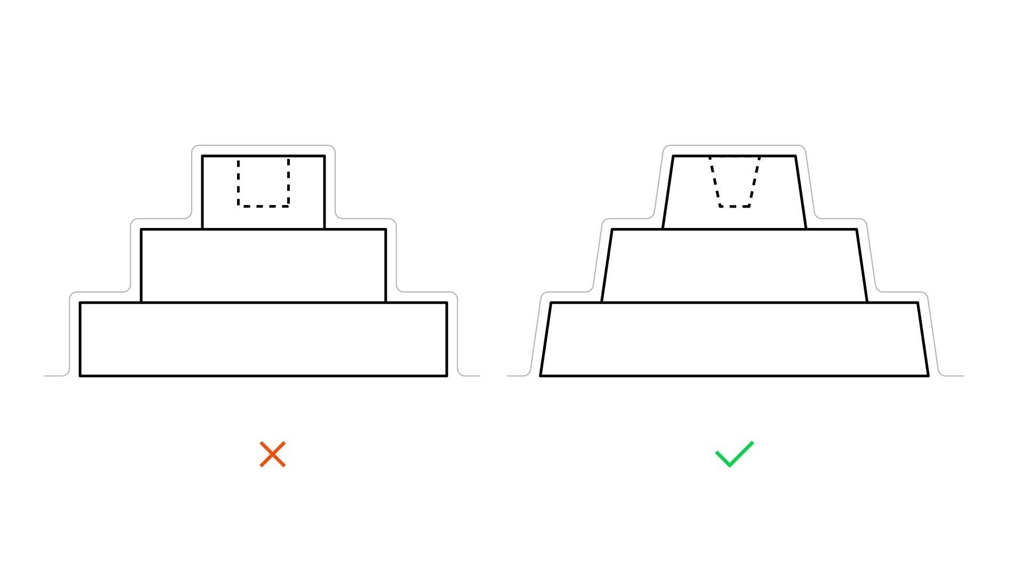

Increase demolding angle

During plastic injection, a draft angle is usually required to allow the molded part to be easily removed from the mold. The draft angle is the inclination applied to the surface of the mold, which helps in removing the mold from the sheet of material. If the mold had infinite height, it would become a cone.

During plastic injection, a draft angle is usually required to allow the molded part to be easily removed from the mold. The draft angle is the inclination applied to the surface of the mold, which helps in removing the mold from the sheet of material. If the mold had infinite height, it would become a cone.

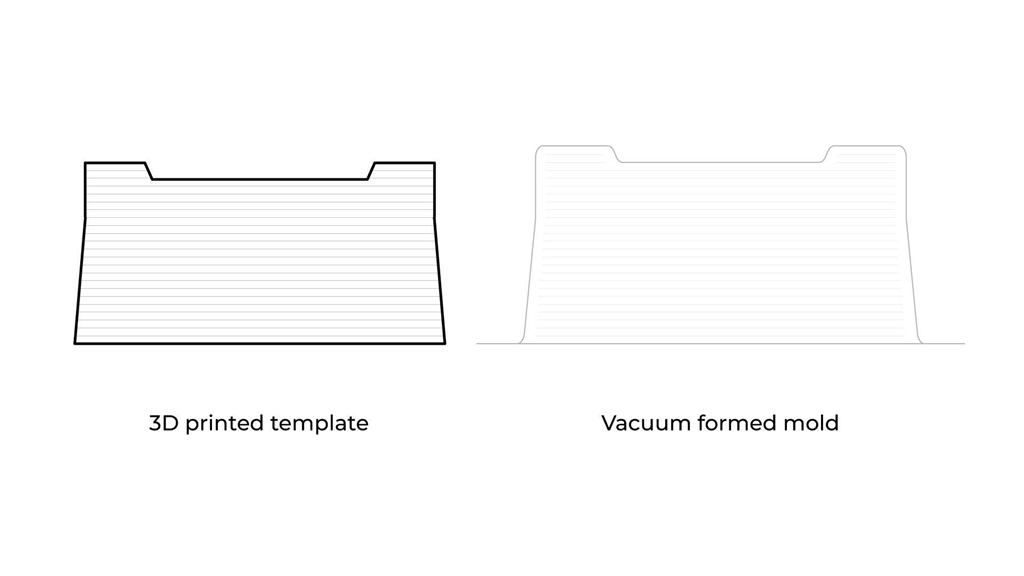

3D printing layer texture

Due to the manufacturing process, 3D printed objects often have unique surface textures. Even if many materials visually hide layer lines, they are still there, and FormBox excels at picking up textures.

Due to the manufacturing process, 3D printed objects often have unique surface textures. Even if many materials visually hide layer lines, they are still there, and FormBox excels at picking up textures.

To achieve a smooth surface on a mold, the first step is to use thin layers for 3D printing . 3D printing with 0.1mm layers will produce a smooth surface. However, for a perfect surface, post-processing of the part is necessary. Using fillers and sanding is the simplest method, although it's not suitable for small details. Sandblasting might be a better option.

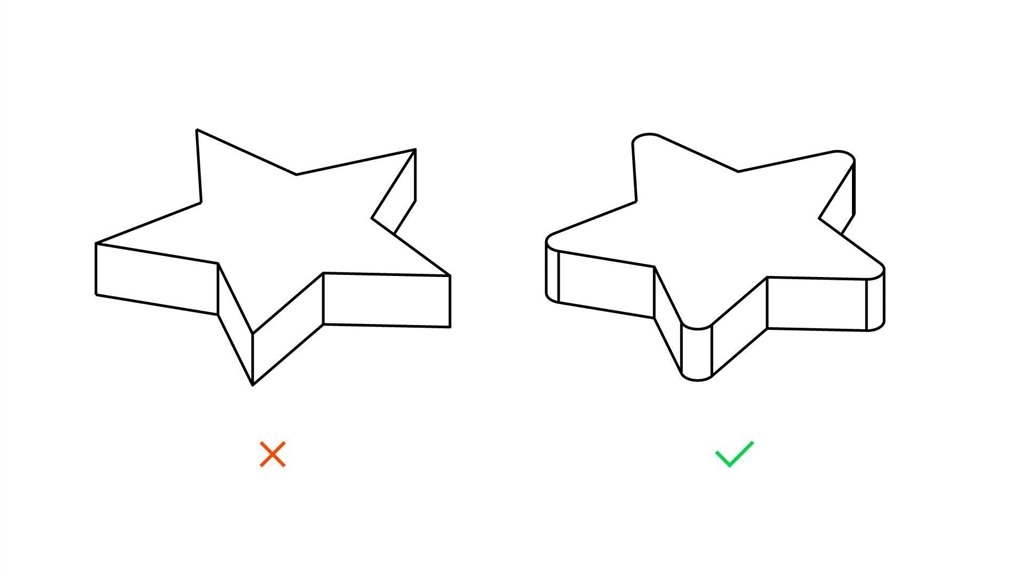

Avoid sharp angles

Due to manufacturing processes, vacuum forming is not suitable for objects with sharp edges. The main reason is that the plastic sheet may fold back towards itself at the sharp edges, reducing the molding quality.

Avoid sharp angles

Due to manufacturing processes, vacuum forming is not suitable for objects with sharp edges. The main reason is that the plastic sheet may fold back towards itself at the sharp edges, reducing the molding quality.

For example, if a star-shaped object is used as a template, the pointed ends of the star may produce a mesh-like pattern because the angles are very sharp. On the other hand, a pentagonal template or a star-shaped template with rounded corners will produce a high-quality mold because there are no sharp angles.

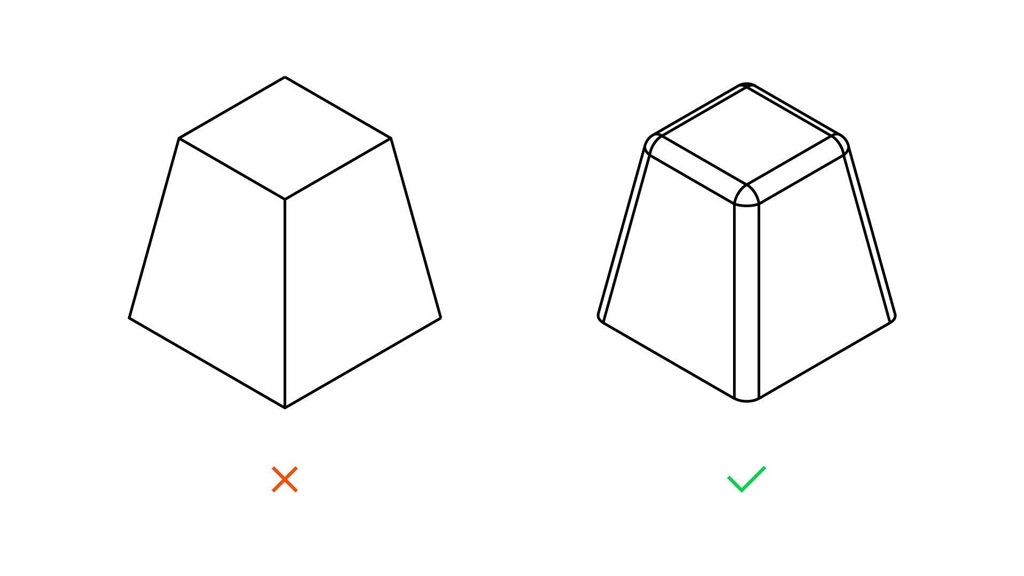

Chamfer all edges

In plastic injection molding, chamfering the edges of the mold is common. Chamfering not only improves ergonomics but also helps the mold eject from the plastic sheet. A 2mm chamfer reduces texture and improves the surface finish of the mold.

Chamfer all edges

In plastic injection molding, chamfering the edges of the mold is common. Chamfering not only improves ergonomics but also helps the mold eject from the plastic sheet. A 2mm chamfer reduces texture and improves the surface finish of the mold.

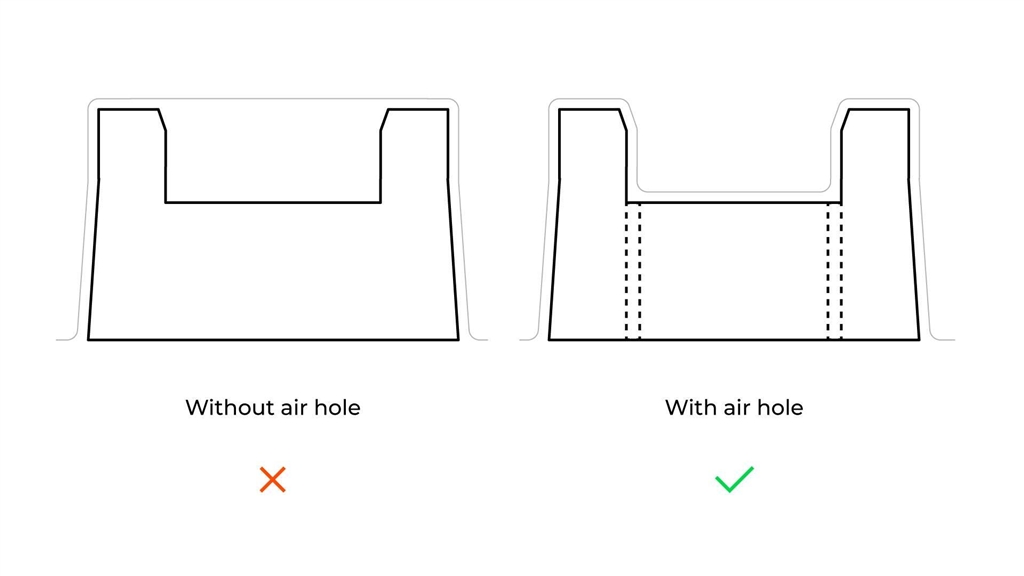

Increase air holes

The better the airflow, the more detail the mold will capture. When the material plate is deposited onto the object, there's a very short window of time during which the material plate is hot enough for air to move. Ideally, the faster the airflow, the better the material plate will capture detail.

The better the airflow, the more detail the mold will capture. When the material plate is deposited onto the object, there's a very short window of time during which the material plate is hot enough for air to move. Ideally, the faster the airflow, the better the material plate will capture detail.

If the mold design contains parts where air could get trapped, it is recommended to add small holes in these areas. A 1mm hole is invisible to the naked eye on the mold, but it can greatly improve the quality of the mold.

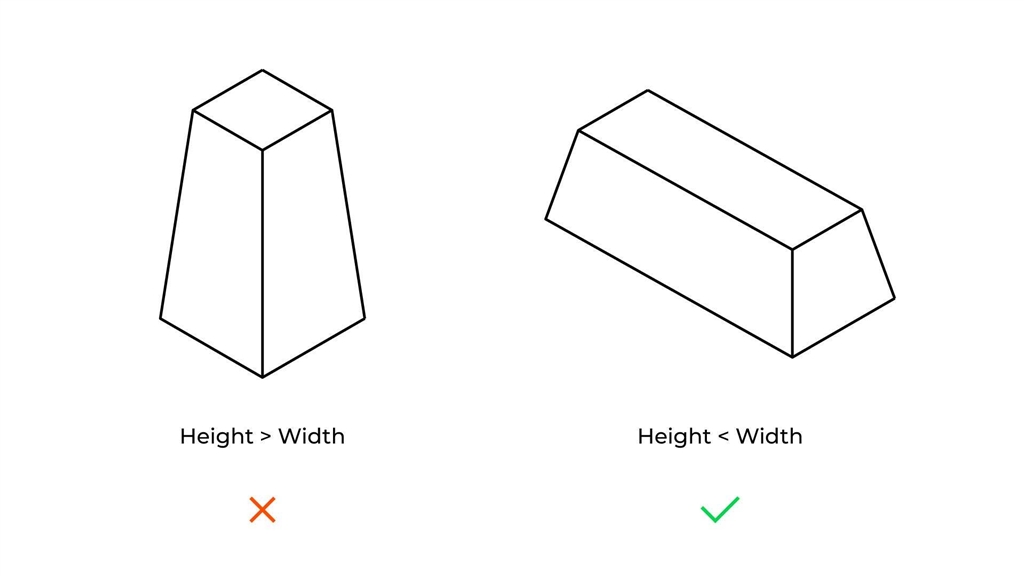

Height and width of the object

The maximum mold size for using FormBox is determined by the complexity of the overall shape. A little tip is that wider objects are easier to mold than taller ones.

Height and width of the object

The maximum mold size for using FormBox is determined by the complexity of the overall shape. A little tip is that wider objects are easier to mold than taller ones.

Even after taking all factors into account, FormBox can still mold tall objects. Generally, it's recommended to use it with objects that are wider than tall, or to use a larger draft angle.

Did you enjoy this presentation? 3D printing offers more than just 3D printing ; contact us now to learn more about vacuum forming applications.

Follow our fan page to stay up-to-date with the latest news: https://www.facebook.com/3dmart.com.tw/

https://www.instagram.com/3dmart/

References

Did you enjoy this presentation? 3D printing offers more than just 3D printing ; contact us now to learn more about vacuum forming applications.

Follow our fan page to stay up-to-date with the latest news: https://www.facebook.com/3dmart.com.tw/

https://www.instagram.com/3dmart/

References