[Waterjet Cutting] Is waterjet cutting the next technological innovation? A new dawn for the medical device manufacturing industry!

The medical device industry today faces ever-changing challenges. With increasing development costs and the growing difficulty of maintaining quality, medical device manufacturers are seeking new technologies to streamline production processes while reducing costs. To address these challenges, a new wave of desktop manufacturing technologies is emerging, such as a waterjet cutting machine . Manufacturers can quickly prototype and validate concepts, offering localized and customized solutions, specialized materials, and the creation of tools to sustain high-volume production lines.

Accelerate the prototyping process

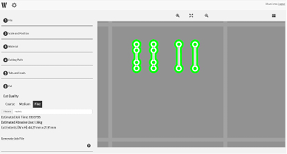

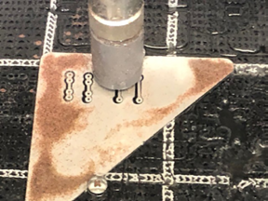

Prototyping is an iterative process encompassing design, construction, testing, and evaluation. It's a crucial step in creating medical devices. When prototyping orthopedic implants, product design engineers need to create test samples and fully functional prototypes to ensure implant performance. Due to the lack of access to the industrial manufacturing tools and machines required to cut certain metals, design engineers often outsource custom-made components. However, outsourcing can take weeks, creating a lengthy bottleneck that negatively impacts the prototype production phase. Benchtop waterjet cutters like WAZER allow engineers to build fully functional implant prototypes in-house. Testing can be performed much faster than outsourcing, and necessary adjustments can be made simultaneously.

Waterjet cutting allows engineers to create prototypes and test using any material, including those used in the final implant. Engineers can use the same materials for more accurate evaluation. Orthopedic implants made of titanium or stainless steel can be waterjet cut , but plasma or laser cutters cannot, as this could weaken the material or damage the cut edges.

Medical device companies often need to produce components quickly for clinical trials. Traditional manufacturing methods, such as sheet metal stamping, are costly, have long lead times, and are very inefficient. Desktop CNC waterjet cutting machines offer medical product design engineers an affordable option for small-batch prototyping. Desktop CNC waterjet cutting can be placed almost anywhere in an engineering workshop. WAZER waterjet cutting allows engineers to adjust and iterate based on prototype testing, reducing costs and waiting time.

Additive manufacturing and subtractive manufacturing are used together for prototyping.

Modern prototyping requires desktop subtractive and additive manufacturing equipment to provide the broadest possible in-house prototyping capabilities. Desktop 3D printers use resin materials to produce parts, while smaller waterjet cutters like WAZER use metal and specialized materials to cut prototype parts. With the ability to perform rapid, iterative computations, medical device design engineers can develop in a less costly manner, making changes early in the development process to reduce design risk.

Prototyping is an iterative process encompassing design, construction, testing, and evaluation. It's a crucial step in creating medical devices. When prototyping orthopedic implants, product design engineers need to create test samples and fully functional prototypes to ensure implant performance. Due to the lack of access to the industrial manufacturing tools and machines required to cut certain metals, design engineers often outsource custom-made components. However, outsourcing can take weeks, creating a lengthy bottleneck that negatively impacts the prototype production phase. Benchtop waterjet cutters like WAZER allow engineers to build fully functional implant prototypes in-house. Testing can be performed much faster than outsourcing, and necessary adjustments can be made simultaneously.

Waterjet cutting allows engineers to create prototypes and test using any material, including those used in the final implant. Engineers can use the same materials for more accurate evaluation. Orthopedic implants made of titanium or stainless steel can be waterjet cut , but plasma or laser cutters cannot, as this could weaken the material or damage the cut edges.

Medical device companies often need to produce components quickly for clinical trials. Traditional manufacturing methods, such as sheet metal stamping, are costly, have long lead times, and are very inefficient. Desktop CNC waterjet cutting machines offer medical product design engineers an affordable option for small-batch prototyping. Desktop CNC waterjet cutting can be placed almost anywhere in an engineering workshop. WAZER waterjet cutting allows engineers to adjust and iterate based on prototype testing, reducing costs and waiting time.

Additive manufacturing and subtractive manufacturing are used together for prototyping.

Modern prototyping requires desktop subtractive and additive manufacturing equipment to provide the broadest possible in-house prototyping capabilities. Desktop 3D printers use resin materials to produce parts, while smaller waterjet cutters like WAZER use metal and specialized materials to cut prototype parts. With the ability to perform rapid, iterative computations, medical device design engineers can develop in a less costly manner, making changes early in the development process to reduce design risk.

Unique materials used in specific treatment tools

Desktop 3D printers and waterjet cutters enable significant healthcare innovation while providing localized and customized treatments. Hospitals, clinics, and rehabilitation centers are using desktop devices, and currently 99% of U.S. hospitals have desktop 3D printers . By integrating desktop 3D printers into hospitals and laboratories, technicians can easily operate the software to produce results.

• Anatomical models for preoperative planning. • Surgical guides customized based on body scans. • Components designed to match body scans. • Dentures obtained directly from intraoral scans. • Custom-designed surgical instruments to the surgeon's specifications. As procedures and technologies used in healthcare evolve, so too must the equipment delivering these treatments. Desktop 3D printers and waterjet cutters enable hospitals and laboratories to reduce the time required by traditional methods and create disposable components without the need for a team to operate the equipment.

Special materials for desktop equipment

The use of specialized materials in today's medical devices presents a challenge for manufacturers, who need to find suitable tools to process these materials. For biocompatible, sterilization-resistant, and X-ray-opaque plastics such as polyetheretherketone (PEEK), polystyrene sulfate (PPSU), polyurethane (PSU), and polyoxymethylene (POM), there are often no available devices to process these materials.

Today, benchtop manufacturing machinery can overcome these challenges. Benchtop waterjet cutters are ideal for cutting special plastics and metal sheets with high strength-to-weight ratios, such as titanium, orthotics, and prostheses. Breathing connectors and adapters, however, require special plastics. Due to technological limitations, these materials are incompatible with benchtop 3D printers.

Continuous production operation

High-volume manufacturing requires precision tooling and fixtures to guide and control large-scale production. Whenever a part or machine changes, the tooling needs to be updated. Outsourcing tooling can take weeks or months, increasing time, cost, and the risk of errors. Without the right tooling, production can be forced to stop. For high-volume manufacturers, a week of downtime represents a significant cost. Benchtop waterjet cutting machines can manufacture tooling and fixtures in-house, reducing manufacturing costs and downtime while accelerating time to market. For example, consider a medical device manufacturer with 60 industrial machines whose molds need replacement. A benchtop waterjet cutting machine can produce the new molds in-house, much faster than outsourcing.

Increasing pressure for innovation and competition, coupled with the demands of high-volume production, necessitates rapid innovation and prototyping by medical device manufacturers. Benchtop manufacturing equipment enables companies to accelerate the design phase, reduce development risk, and manufacture medical devices in-house. These tools are a significant driver of medical device development and production due to their smaller footprint, affordability, and the ability for technicians to quickly learn and operate them in-house. Affordable benchtop waterjet cutters and continuously innovating 3D printers are consistently helping medical device manufacturers meet the new challenges of the future.

Did you enjoy this sharing? 3D printers offer more than just 3D printing . Contact us now to learn more about our 3D printers and 3D scanners .

Follow our fan page to stay up-to-date with the latest news: https://www.facebook.com/3dmart.com.tw/

https://www.instagram.com/3dmart/

References