[3D Printing Applications] 3D printing combined with drones can repel pests without the need for pesticides!

Traditional agriculture relies on spraying pesticides to control pests on crops. These methods harm the environment and threaten the health of farmers and consumers. The French agricultural innovation team " Agri.Builders " has successfully developed a biologically certified treatment method. Using 3D printing technology to create devices, drones are then used to disperse the hormone " pheromone " in orchards. This effectively prevents pest infestations of crops, significantly reduces pesticide consumption, and alleviates the labor burden on farmers. Watch the full process now:

The main method involves spreading the bio-hormone "pheromone," which prevents insects from finding mates and thus inhibits mating. This process does not cause any harm to plants or insects, making it an environmentally friendly and safe approach.

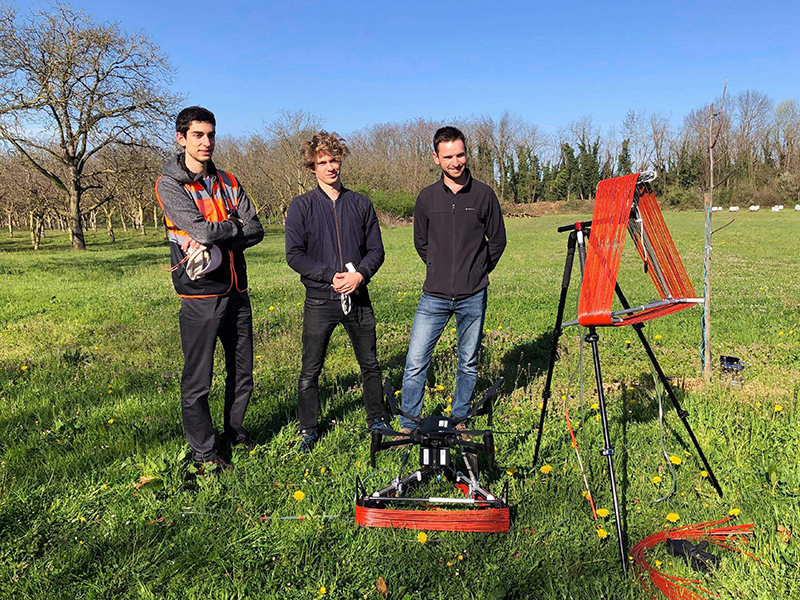

This operation must be carried out before the insect breeding season. The "Agri.Builders" team will install a fixed amount of pheromone hormone on drones and fly them over designated areas to release it one by one. This not only saves labor costs, but also ensures that the pheromone hormone is evenly dispersed through system calculations.

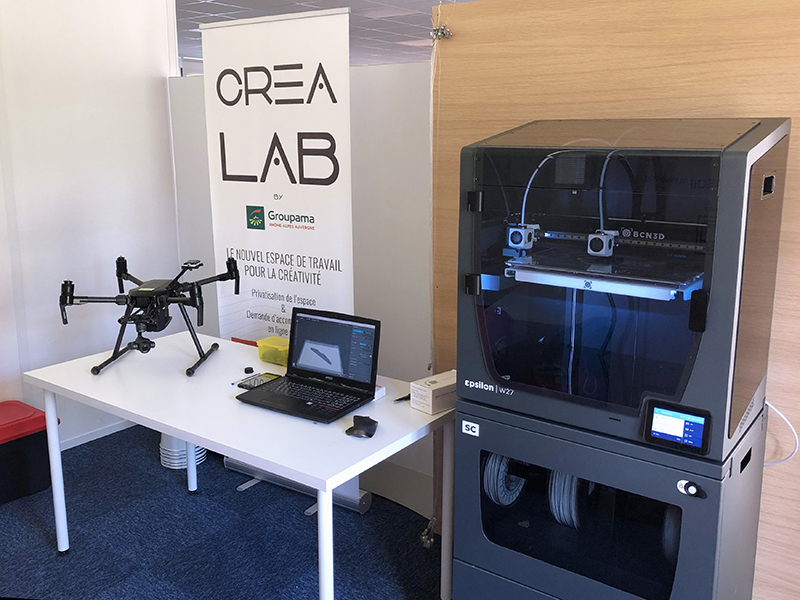

However, how can the drone safely carry the pheromone? The team used 3D printing technology and PLA filaments for 3D printing . After repeated testing and modification, they finally designed the parts required for the drone's pheromone. As shown in the picture above, the white area below the drone is the design drawing of the device, which is mainly composed of three crossbars and assembled parts.

(Made using the BCN3D 3D printer and paired with the BCN3D intelligent filament dehumidifier , which not only automates feeding and simplifies the workflow, but also allows the 3D printing filament to be stored in an optimal humidity environment, improving the stability of the finished product. )

When drones are operating, they fly outdoors for extended periods, inevitably exposed to wind, sun, and rain. Therefore, mechanical properties such as waterproofing and UV resistance are crucial. When the drone lands, it must also withstand its own weight and the weight of the 2-kilogram lifting ring. The "Agri.Builders" team chose ABS wire specially designed for engineering to manufacture the final equipment, effectively improving the system's strength and impact resistance.

Finally, to make the sports belt for the fixed device, the team utilized the wear-resistant properties of TPU filaments , which have a maximum elongation of 450%. Like rubber, it has high elasticity, high strength, and flexibility, making it extremely flexible!

Follow our fan page to stay up-to-date with the latest news: https://www.facebook.com/3dmart.com.tw/

https://www.instagram.com/3dmart/

References