[3D Printing] Prusa proudly launches the CORE One upgrade system INDX!

Joseph Prusa, founder of PRUSA:

I made a prediction a few weeks ago, and now I'm very excited to finally get the Bondtech INDX system the attention it deserves!

INDX is a revolutionary tool changer design concept. It is not an upgrade of the wire switching unit, nor a slightly different tool changer, but a completely new architecture.

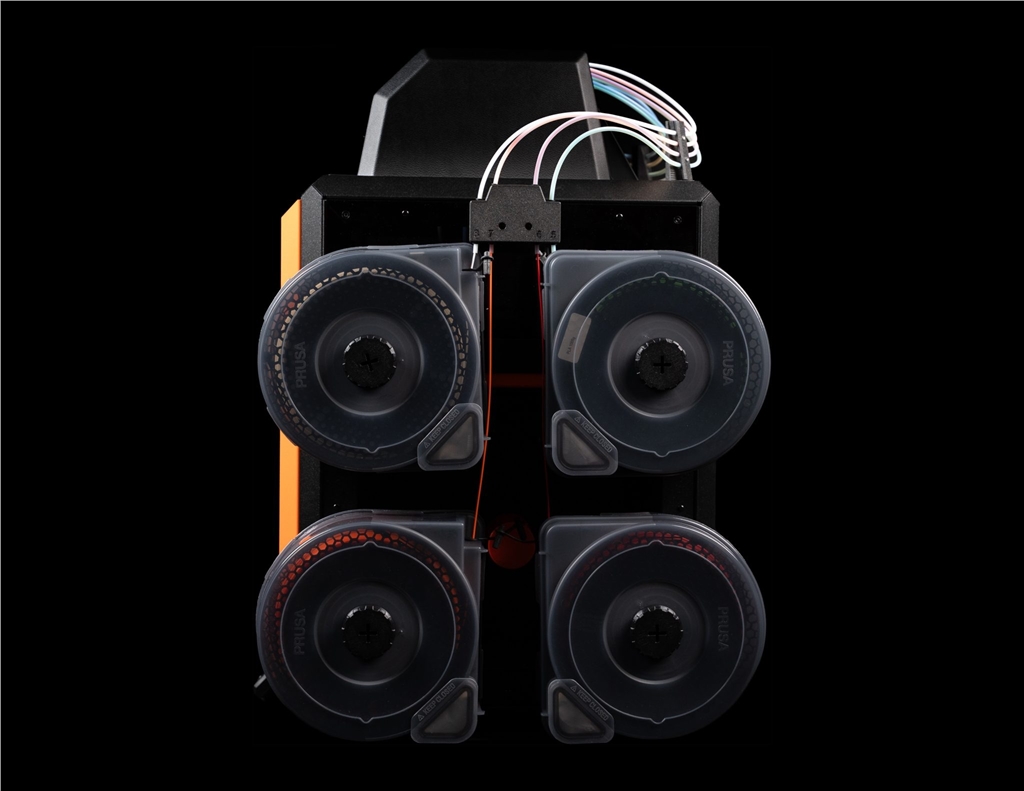

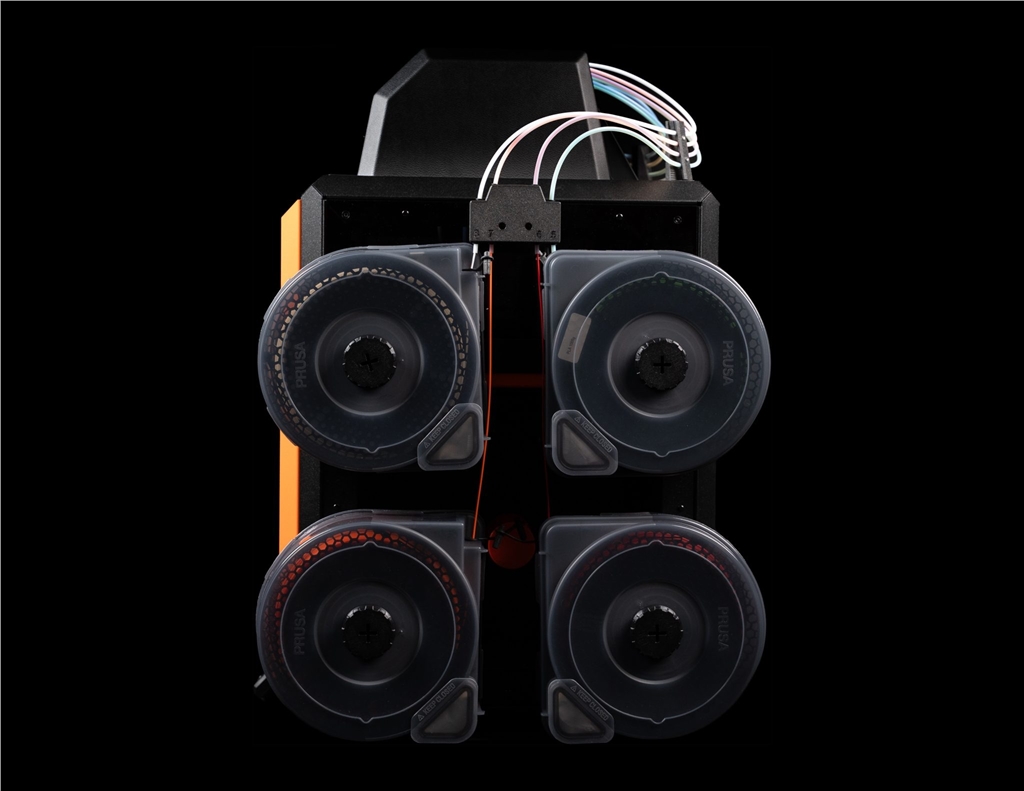

Imagine your CORE One printer is equipped with eight different spools, and you can change blades in just a few seconds with virtually zero waste.

This is a huge leap forward and an excellent example of how two European companies—Prusa Research and Bondtech, a Swedish leader in extrusion molding—are working together to drive the entire industry forward.

Bondtech's patented designs are both simple and ingenious.

A Journey Through Multiple Materials

We have extensive experience in multi-filament 3D printing. Back in September 2016, I introduced our first Multi-Material Upgrade Kit (MMU) in a blog post.

Today, the MMU3 has evolved to its third generation, offering a simple and cost-effective way to add full five-wire printing capabilities to a single printhead machine.

Subsequently, we created the first-generation Prusa XL equipped with an advanced tool changing system.

XL is ideal for high-end, high-reliability printing, as it supports replacing the entire tool head.

This allows you to use flexible and rigid materials in the same print job, or even switch to completely different tools, such as silicone printheads or the pick-and-place head we showcased at Formnext.

There are various solutions on the market, but each solution has some shortcomings.

Line-changing systems like MMU or AMS require repeated loading and unloading of consumables, which is slow and wasteful because the previous color needs to be removed from the nozzle.

Although the MMU is not as compact and streamlined as the AMS, we have successfully minimized the waste generated by the MMU—all waste is collected into a compact block.

Printers equipped with two switchable nozzles are a special case: they appear efficient and fast on paper (e.g., "only 8 seconds per nozzle switch"), but this is only true when using two different consumables.

Increasing the variety of cables would expose us to the same drawbacks and limitations as cable switching systems.

It's wasteful, and each cable replacement takes more than 40 seconds.

This is where we discovered the gap.

What if you want true printhead switching with almost zero waste and high speed, but also want the scalability and low cost of a line switcher?

INDX fills this gap perfectly.

New Architecture: Intelligent Head, Passive Tool

Designed by Bondtech, the INDX can be described as a lightweight tool changer.

However, unlike replacing the entire bulky and expensive printhead (including the extruder motor, gears, heater, thermistor, sensor, and all other parts), the INDX's design is extremely simple and streamlined. You can think of it as an electric razor: a blade body with replaceable (inexpensive) passive blades.

The intelligent head is the only movable component on the gantry.

It contains all the expensive parts: induction heating (IN) and sensing electronics, as well as a dynamic extruder (DX) drive system with a self-adjusting tension mechanism.

Then there are the passive tools at the front end: they are simple in structure and, most importantly, affordable.

They contain no wires, heaters, thermistors, or electronic components. They are essentially just a consumable channel and a special nozzle.

This architecture is key—it's highly scalable. This means that if you initially only have four tools, adding a fifth, sixth, or even eighth material will be very cost-effective.

Revolutionary induction heating

In INDX, "IN" stands for induction heating, or more accurately, induction heating.

Thanks to this ingenious design, INDX does not require a hot end.

The working principle is as follows: The smart head has a built-in induction coil.

When it senses a passive tool, the coil is energized.

This generates a high-frequency magnetic field, which instantly heats the nozzle.

Moreover, the nozzle itself has "almost no mass".

Almost all of the heating energy is used to melt the plastic, rather than to heat a large block of aluminum.

The INDX nozzle is so fast because it uses a combination of direct heating and low heat capacity.

The nozzle can be heated from a low temperature to the printing temperature in just a few seconds.

At the same time, it cools down very quickly, which is crucial for multi-material printing: it effectively prevents material from spilling when the tool is parked without having to go through a long and slow reheating process.

So, how do you control the temperature of a wireless, passive metal object?

The intelligent nozzle can read the nozzle temperature without any contact or wires—essentially a non-contact thermal measurement.

Self-adjusting extruder suitable for any material

"DX" stands for Dynamic eXtruder.

Anyone who has ever used PLA and TPU for printing knows that there is no universal gear tension that works for all materials; you either need to adjust it manually or you have to accept suboptimal tension.

The "DX" extruder eliminates this compromise. It is a self-adjusting extruder that requires no user intervention.

The ingenuity lies in the fact that it uses a responsive cam mechanism, rather than just a spring.

When the extruder is subjected to high back pressure (such as during high-volume printing), the tension of the wire acts on the drive gear, and the cam mechanism mechanically converts this tension into a stronger gripping force.

When printing on low-flow soft TPU materials, it employs a gentler grip. It can dynamically provide the optimal pretension needed for printing any material and allows for setting any flow rate as required.

The mechatronics design is ingenious: the lightweight stepper motor that drives the consumables also drives the cam mechanism, which fully opens the drive gear, thereby releasing the consumables and unlocking the passive tool when replacing the consumables.

One motor, three functions.

Easy, fast, and flexible printing

By integrating all components together, a seamless experience can be achieved.

Simply place the eight spools on the CORE One and then load them into their respective dedicated passive tools.

No buffering device is needed, no wire rewinding into the outer box is required, no wire cutting is required, no wire rinsing is required, no preheating is required, and no complex mechanical structure is needed.

The entire process—stopping the current tool, moving, selecting a new tool, heating it to working temperature, and resuming printing—can be completed in as little as 12 seconds, depending on the consumables used.

The CORE One+, equipped with the INDX system, is expected to launch in the first quarter of 2026. Stay tuned for more updates!

I made a prediction a few weeks ago, and now I'm very excited to finally get the Bondtech INDX system the attention it deserves!

INDX is a revolutionary tool changer design concept. It is not an upgrade of the wire switching unit, nor a slightly different tool changer, but a completely new architecture.

Imagine your CORE One printer is equipped with eight different spools, and you can change blades in just a few seconds with virtually zero waste.

This is a huge leap forward and an excellent example of how two European companies—Prusa Research and Bondtech, a Swedish leader in extrusion molding—are working together to drive the entire industry forward.

Bondtech's patented designs are both simple and ingenious.

A Journey Through Multiple Materials

We have extensive experience in multi-filament 3D printing. Back in September 2016, I introduced our first Multi-Material Upgrade Kit (MMU) in a blog post.

Today, the MMU3 has evolved to its third generation, offering a simple and cost-effective way to add full five-wire printing capabilities to a single printhead machine.

Subsequently, we created the first-generation Prusa XL equipped with an advanced tool changing system.

XL is ideal for high-end, high-reliability printing, as it supports replacing the entire tool head.

This allows you to use flexible and rigid materials in the same print job, or even switch to completely different tools, such as silicone printheads or the pick-and-place head we showcased at Formnext.

There are various solutions on the market, but each solution has some shortcomings.

Line-changing systems like MMU or AMS require repeated loading and unloading of consumables, which is slow and wasteful because the previous color needs to be removed from the nozzle.

Although the MMU is not as compact and streamlined as the AMS, we have successfully minimized the waste generated by the MMU—all waste is collected into a compact block.

Printers equipped with two switchable nozzles are a special case: they appear efficient and fast on paper (e.g., "only 8 seconds per nozzle switch"), but this is only true when using two different consumables.

Increasing the variety of cables would expose us to the same drawbacks and limitations as cable switching systems.

It's wasteful, and each cable replacement takes more than 40 seconds.

This is where we discovered the gap.

What if you want true printhead switching with almost zero waste and high speed, but also want the scalability and low cost of a line switcher?

INDX fills this gap perfectly.

New Architecture: Intelligent Head, Passive Tool

Designed by Bondtech, the INDX can be described as a lightweight tool changer.

However, unlike replacing the entire bulky and expensive printhead (including the extruder motor, gears, heater, thermistor, sensor, and all other parts), the INDX's design is extremely simple and streamlined. You can think of it as an electric razor: a blade body with replaceable (inexpensive) passive blades.

The intelligent head is the only movable component on the gantry.

It contains all the expensive parts: induction heating (IN) and sensing electronics, as well as a dynamic extruder (DX) drive system with a self-adjusting tension mechanism.

Then there are the passive tools at the front end: they are simple in structure and, most importantly, affordable.

They contain no wires, heaters, thermistors, or electronic components. They are essentially just a consumable channel and a special nozzle.

This architecture is key—it's highly scalable. This means that if you initially only have four tools, adding a fifth, sixth, or even eighth material will be very cost-effective.

Revolutionary induction heating

In INDX, "IN" stands for induction heating, or more accurately, induction heating.

Thanks to this ingenious design, INDX does not require a hot end.

The working principle is as follows: The smart head has a built-in induction coil.

When it senses a passive tool, the coil is energized.

This generates a high-frequency magnetic field, which instantly heats the nozzle.

Moreover, the nozzle itself has "almost no mass".

Almost all of the heating energy is used to melt the plastic, rather than to heat a large block of aluminum.

The INDX nozzle is so fast because it uses a combination of direct heating and low heat capacity.

The nozzle can be heated from a low temperature to the printing temperature in just a few seconds.

At the same time, it cools down very quickly, which is crucial for multi-material printing: it effectively prevents material from spilling when the tool is parked without having to go through a long and slow reheating process.

So, how do you control the temperature of a wireless, passive metal object?

The intelligent nozzle can read the nozzle temperature without any contact or wires—essentially a non-contact thermal measurement.

Self-adjusting extruder suitable for any material

"DX" stands for Dynamic eXtruder.

Anyone who has ever used PLA and TPU for printing knows that there is no universal gear tension that works for all materials; you either need to adjust it manually or you have to accept suboptimal tension.

The "DX" extruder eliminates this compromise. It is a self-adjusting extruder that requires no user intervention.

The ingenuity lies in the fact that it uses a responsive cam mechanism, rather than just a spring.

When the extruder is subjected to high back pressure (such as during high-volume printing), the tension of the wire acts on the drive gear, and the cam mechanism mechanically converts this tension into a stronger gripping force.

When printing on low-flow soft TPU materials, it employs a gentler grip. It can dynamically provide the optimal pretension needed for printing any material and allows for setting any flow rate as required.

The mechatronics design is ingenious: the lightweight stepper motor that drives the consumables also drives the cam mechanism, which fully opens the drive gear, thereby releasing the consumables and unlocking the passive tool when replacing the consumables.

One motor, three functions.

Easy, fast, and flexible printing

By integrating all components together, a seamless experience can be achieved.

Simply place the eight spools on the CORE One and then load them into their respective dedicated passive tools.

No buffering device is needed, no wire rewinding into the outer box is required, no wire cutting is required, no wire rinsing is required, no preheating is required, and no complex mechanical structure is needed.

The entire process—stopping the current tool, moving, selecting a new tool, heating it to working temperature, and resuming printing—can be completed in as little as 12 seconds, depending on the consumables used.

The CORE One+, equipped with the INDX system, is expected to launch in the first quarter of 2026. Stay tuned for more updates!

Did you enjoy this sharing session?

The CORE One+, powered by INDX, is expected to launch in the first quarter of 2026. Stay tuned for more updates!

Contact us now to learn more about Original Prusa .

The CORE One+, powered by INDX, is expected to launch in the first quarter of 2026. Stay tuned for more updates!

Contact us now to learn more about Original Prusa .

-Contact Us-

SanDiMa offers more than just 3D printing ; we provide three major OEM services: " 3D Printing Manufacturing ," " 3D Scanning Services ," and " Spatial 3D Scanning Services "!

Follow our fan page and stay up-to-date with the latest news:

Facebook | Instagram | Threads