【3DEVO】Filament Maker Two advances customized 3D printing filament production

Dutch technology company 3devo has launched Filament Maker Two, designed to allow users to produce their own 3D printing filaments using granules or powders, while improving stability, efficiency, and customization.

For many years, 3devo has been manufacturing compact wire fabricators, making its equipment a mainstay for polymer and wire companies worldwide. 3devo's equipment enables these companies to produce small batches of innovative wires for testing, research, and development.

Filament Maker Two

This new device was developed based on feedback from original Filament Maker ONE users and features significant technological upgrades to address the challenges of wire extrusion.

The goal of Filament Maker Two is to make improvements in several areas.

Key enhancements include a powerful drive system that combines a new stepper motor and gearbox, delivering up to three times the torque and ensuring minimal speed fluctuations.

This results in an extremely stable rotational rate, reducing inconsistencies in wire material quality.

The extended extruder screw, lengthened by 50 mm, enables optimal mixing and flow stability, resulting in more consistent wire diameter.

The longer screw also creates a thermal interruption between the heating zone and the hopper zone, preventing premature melting and maintaining a stable material flow.

Combined with automatic wire tensioning, Filament Maker Two can produce 3 kg of consumable spools.

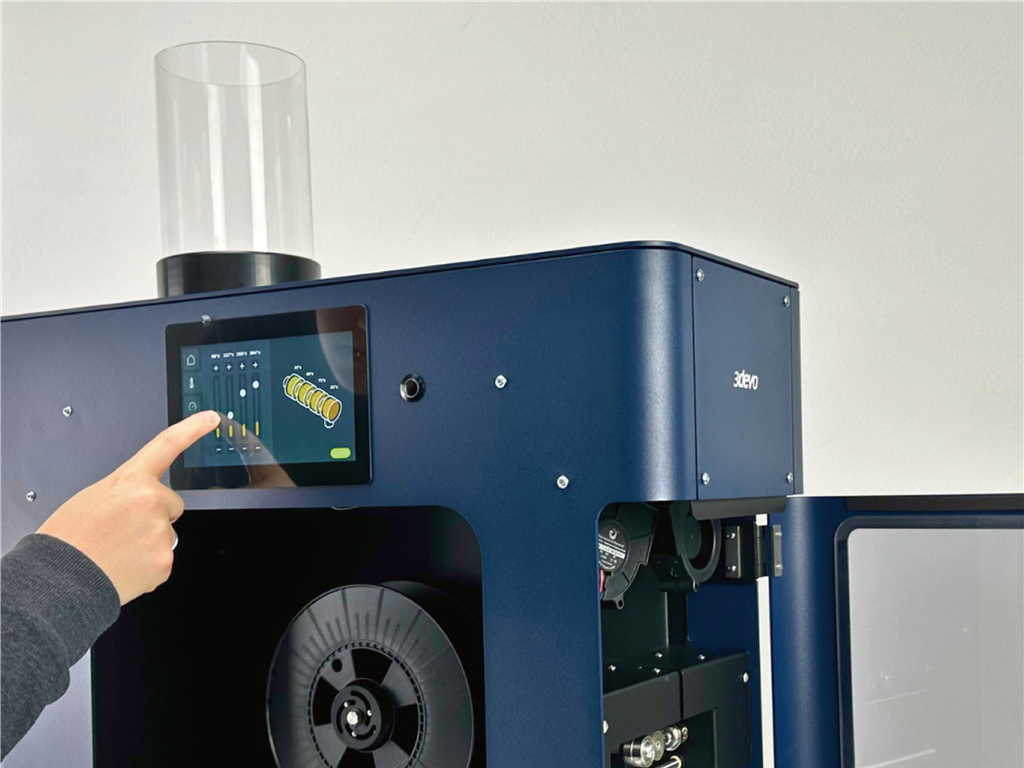

Filament Maker Two's intuitive touchscreen interface provides easier control, offering relevant extrusion data, notifications, and guidance.

Advanced monitoring features include a 3-axis camera sensor that can measure wire ellipticity and diameter with an accuracy of 10 micrometers.

This sensor can detect spool ellipticity and provide thermal measurements to maintain optimal temperature stability during extrusion.

"Filament Maker TWO is designed to enable faster R&D, allowing our customers to produce high-quality wires that perfectly suit their needs," said Louis Rinaldo, a materials expert with over seven years of experience at 3devo.

He continued, "Filament Maker TWO meets the stability, efficiency, and customization needs of wire extrusion. 3devo's latest machine promises to make more materials projects successful, with a real impact on the plastics recycling and wire extrusion sectors. "

He emphasized that the new stepper motor provides stable screw rotation, thereby stabilizing the flow of molten material more quickly and reducing the time spent on fine-tuning settings.

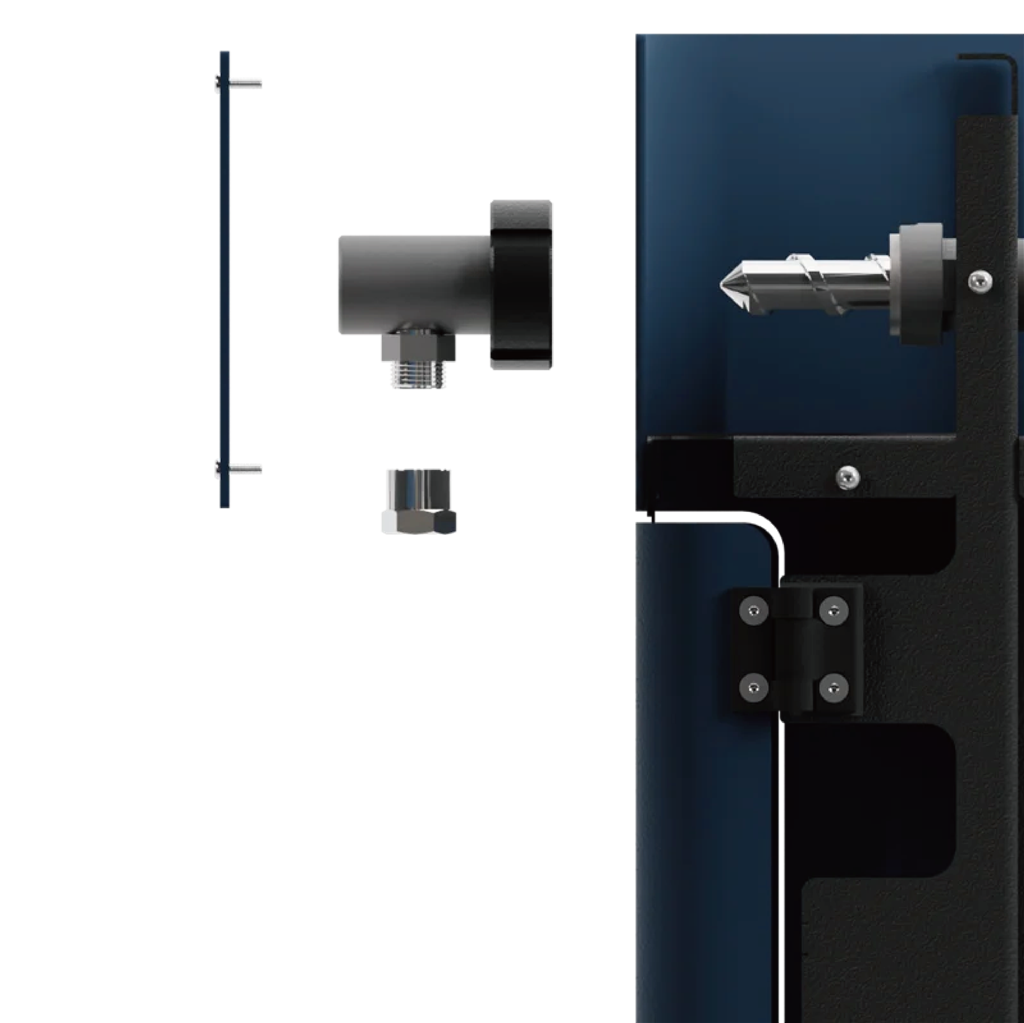

The machine is designed to allow for internal maintenance and features easily disassembled components such as nozzles and screws.

This helps to quickly troubleshoot and repair equipment without having to return it to the manufacturer, thus reducing downtime and improving long-term reliability.

Open-source APIs allow users to integrate their own development projects, enabling the system to adapt to future enhancements based on user feedback.

Thermal sensors also help ensure that the wire is at the optimal winding temperature.

3devo states that the image processing capabilities will help users discover defects or flaws, and the product is expected to be released in 2025.

Users control the machine via a 7-inch touchscreen, and its software is built on an open-source API.

3devo indicates that the internal components are easy to access, maintain, replace, or upgrade.

The equipment also features advanced data logging capabilities and has been tested on materials such as PLA, ABS, PC, PS, PETG, TPU, TPE, PPS, PVA, PE, PET, PA6, PA12, PA66, PEEK, PEKK, and other PAEK series materials.

Advances in consumables technology and drying solutions

Italian company Xenia Materials also launched new high-performance consumables at Formnext 2024, continuing to drive the development of consumables technology.

Xenia’s 3DF Materials division focuses on thermoplastic composites and has launched four wires designed for industries that require lightweight, structural, and sustainable materials.

One notable product is XECARB® SL 3DF, a PA11 composite material reinforced with carbon fiber that provides enhanced strength while maintaining low density.

These materials are designed to meet the complex needs of industries such as aerospace and automotive, where structural integrity and weight reduction are critical.

German manufacturer BigRep has released the DRYCON 3D printing wire dryer, which addresses wire quality issues from different perspectives.

This new system is suitable for industrial users who use high-performance and moisture-sensitive materials, and features a dual-chamber design that allows for the simultaneous drying, storage, and annealing of spools and parts.

By maintaining optimal drying conditions, it aims to improve print quality, reduce extrusion problems, and enhance the mechanical strength of printed parts.

The ability to anneal parts directly in the chamber also helps to release internal stress, improve dimensional accuracy and interlayer adhesion.

3Devo's Plastic Shredder GP20 can recycle plastics of any shape and size into granular 3D printing material.

This dual design combines a smart plastic crusher with an integrated pelletizer, allowing you to focus on your needs. The crusher's functionality gives you the freedom and flexibility to integrate it into any project in any industry.

► 3Devo Filament Maker ONE Series

► 3Devo Filament Maker TWO Series

► 3Devo Plastic Shredder GP20

Want to learn more about 3Devo products? Contact us below!

-Contact Us-

SanDiMa offers more than just 3D printing ; we provide three major OEM services: " 3D Printing Manufacturing ," " 3D Scanning Services ," and " Spatial 3D Scanning Services "!

Follow our fan page and stay up-to-date with the latest news:

Facebook | Instagram