[3D Printing Application] Entering the Music Industry! 3D Printing a Playable Electric Guitar!

A 3D-printed electric guitar that can actually be played and has great sound quality? Want your own custom electric guitar or know how to build one? This article will teach you a simple way to design and assemble your own cool electric guitar!

Let's take a look at our own finished products first:

For this 3D printing, we used the Bambu Lab X1 Carbon 3D Printer! Let's go over the production steps in detail below:

• Easy to assemble, without complex assembly of dozens of parts. • No metal bars or other unnecessary hardware for reinforcement.

Simple and clear

The most important concern is the force exerted by the strings on the guitar body and neck, which, depending on the string size (thickness), can be approximately 50 kilograms. This 50 kilograms of weight could break the guitar in two, tear the bridge from the body, and severely bend the neck . Therefore, using a real wooden neck is essential to prevent this from happening .

While you might say this guitar is no longer a "fully 3D printed" piece, the neck is a critical and vulnerable part of the guitar, and if I wanted to print it, the entire project would be affected (although that's possible). The wooden neck is very smooth and straight, with a durable metal flute and an internal adjustment bar for adjusting the embossing (concave or convex bowing).

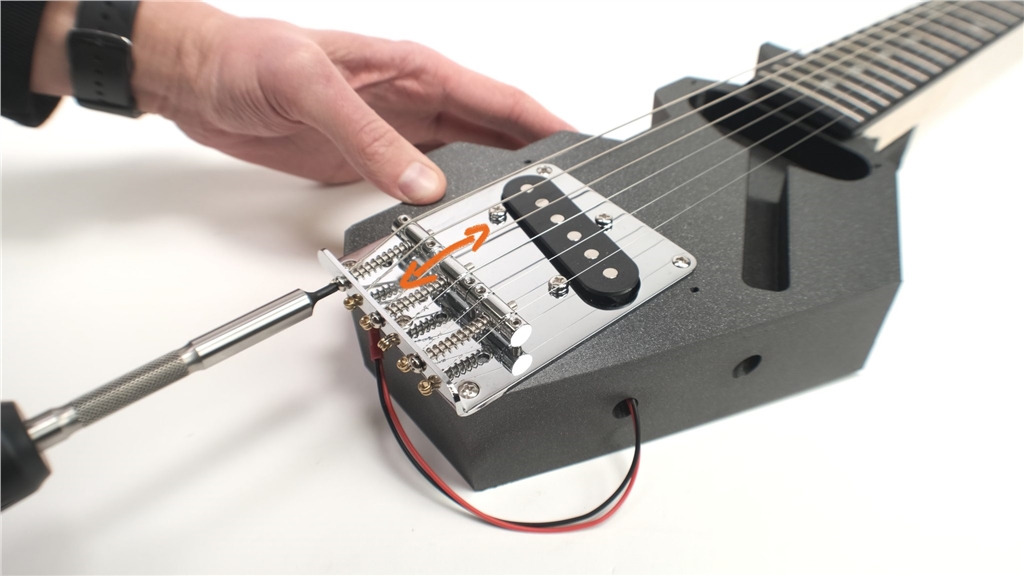

Solving the bridge problem requires more consideration . The bridge of an electric guitar is a small metal component used to secure the lower end of the strings. It is usually fixed to the body with a few screws. If we look at the most common guitar designs, one bridge might seem particularly suitable for a 3D- printed guitar. Can you guess which one it is?

Aside from a common guitar design, all other guitars have very small bridges, sometimes secured with just two screws. However, the Telecaster bridge is different! This large metal plate not only secures the bottom strings but also integrates the bottom pickups and features up to five screw holes spaced far apart, which better distributes the leverage effect of the bridge across the entire metal plate and the underlying printed components.

Hardware selection

Since we've chosen to use the Telecaster bridge , we must procure all the components. Generally, there are three ways to solve this problem:

1. Buy a cheap Telecaster guitar, then disassemble it to find parts.

2. Purchase all parts separately.

3. Purchase Telecaster hardware kit

Buying a fully functional guitar only to take it apart immediately seems like a mistake and a waste. It's only a good idea if you find a badly damaged guitar, but whose hardware and neck are still intact.

Buying all the parts individually is definitely a viable option. You will need

1) Guitar neck with tuner

2) One independent single-coil pickup

3) Bridge with integrated single-coil pickup

4) Telecaster control panel with 3-way switch and two knobs

5) Output jack

The problem is that buying these parts individually would be expensive . Even if you choose the cheapest option, it could still cost several hundred dollars , so the T-shaped electric guitar kit was ultimately chosen .

Basic Design

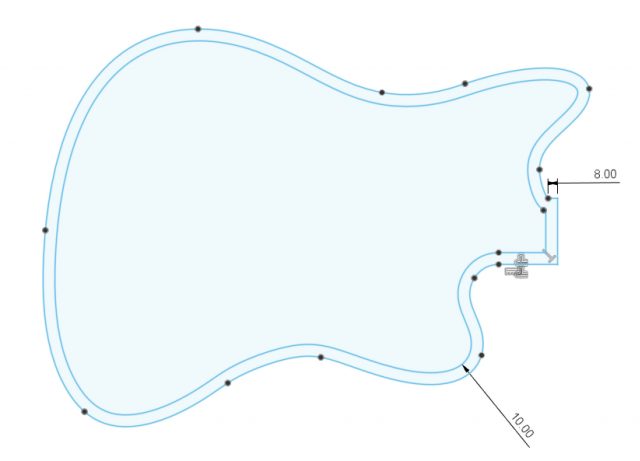

Designing the guitar body using Fusion 360. A crucial starting point is correctly designing all screw holes, neck mounts, and electronic component slots. This is made much easier by including a basic wooden body in the kit.

The mounting holes are in place; it's time to get creative!

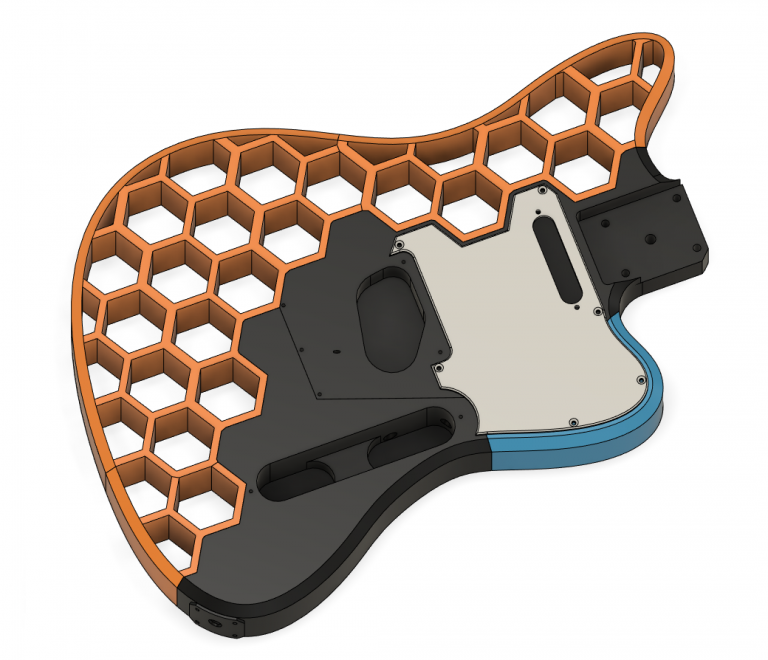

Although we 're using Telecaster hardware, we don't intend to simply replicate the old Telecaster design. With 3D printing technology, any shape is possible, and it would be a shame not to take advantage of it!

.jpg)

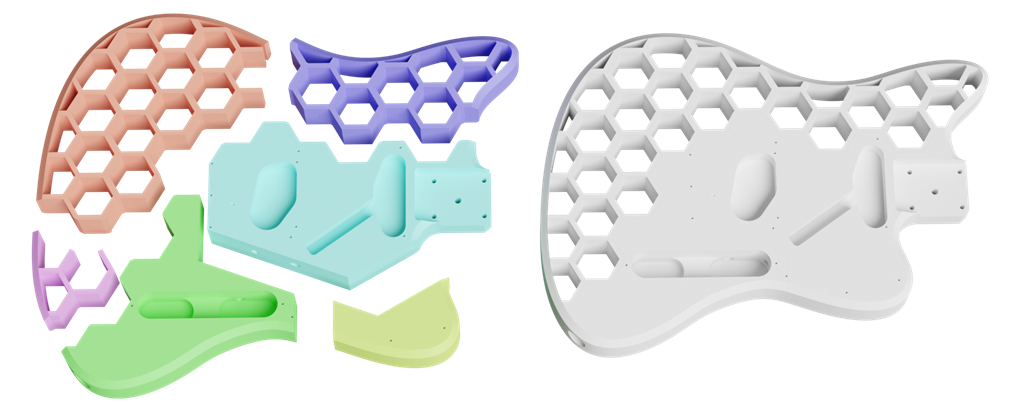

Disassemble the guitar into several parts

Remember the 50 kg force the strings exert on the neck and body mentioned earlier? Ideally, the section of the guitar between the neck and bridge should be made from a single piece of material. Making the connection between these two parts strong enough would be incredibly complex. Fortunately, with some imagination, this has finally become possible.

The top edge is defined by a hexagonal pattern. Another noticeable cut is directly below the mounting bracket hole. This allows the part to be as short as possible. A clever cut on the lower left aligns the longest side of the model with the diagonal of the print volume. This even allows the part to be printed without a support.

However, we decided to use PrusaSlicer's organic support for a more aesthetically pleasing finish on the suspended surface.

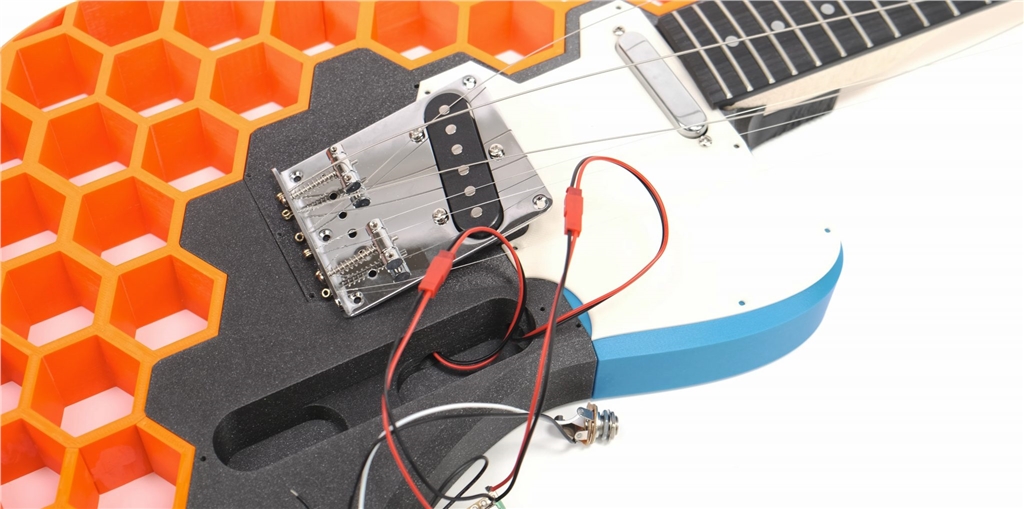

Printing and assembly

Material Selection for the Middle Section <br> The only section that needs to withstand significant mechanical loads is the middle section . Printing the middle section with materials such as PETG might increase strength. However, in our case, a very stiff material with a high flexural modulus was specifically required. Surprisingly, PLA excels in this regard!

The following is the printing process we used with the Bambu Lab X1 Carbon 3D printer :

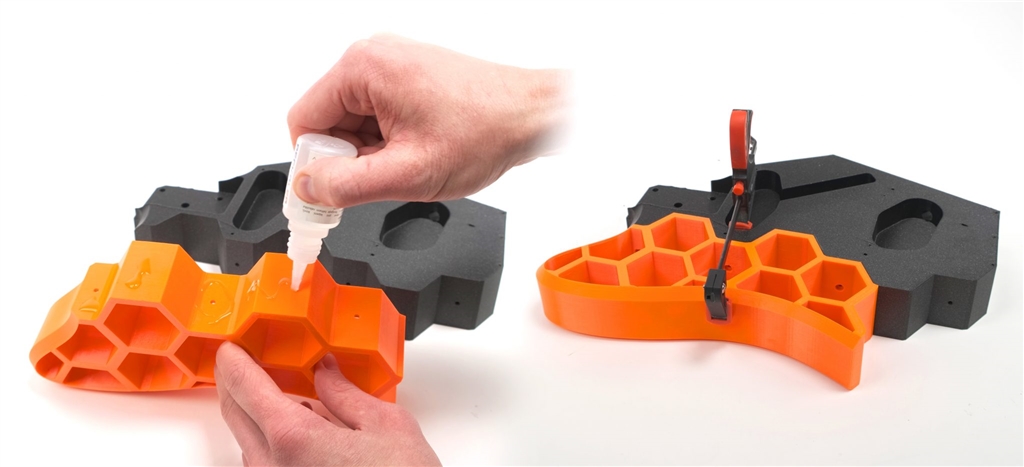

Connecting components

All components have a large contact area with the central component , and all components are glued together using a large amount of strong adhesive.

Wiring an electric guitar

Connect all the cables together , making sure the cable for the top pickup is connected to the cable on top of the selector switch.

Finally, adjust the guitar tuning settings.

After the guitar is fully assembled, you can string and tune it. Once tuned, you can adjust the guitar's intonation to ensure it remains perfectly in tune throughout the entire fretboard.

A fully assembled guitar - our finished product!

detail:

How was the performance?

The guitar plays exceptionally well! The strings hold their tone perfectly, and the guitar's intonation is near perfect. For the price, this is a very good result!

Related products in this article:

1) Bambu Lab X1 Carbon 3D Printer

2) PLA cable

Download electric guitar design

Want to learn more about 3D printing after reading this article, or are you interested in trying it out? Feel free to contact us !

SanDiMa offers more than just 3D printing ; we provide three major OEM services: " 3D Printing Manufacturing ," " 3D Scanning Services ," and " Spatial 3D Scanning Services "!

Follow our fan page and stay up-to-date with the latest news:

Facebook: https://www.facebook.com/3dmart.com.tw/

Instagram: https://www.instagram.com/3dmart

LinkedIn: https://www.linkedin.com/company/3dmart/

References