3D-printed grips helped South Korean archers win gold medals at the Tokyo Olympics.

Photo courtesy of Yoon-Sik Kim / Hyundai Motor Group

With the help of 3D-printed grips provided by automaker Hyundai Motor Group, the South Korean archery team continued its dominance at the 2020 Tokyo Olympics.

The team won gold medals in the men's, women's, and mixed team events at this year's Olympics, bringing the total number of medals won by South Korean archers since 1984 to 103. Hyundai Group has provided technical support to the Korean Archery Association for over thirty years, utilizing technologies such as artificial intelligence (AI), biometrics, big data, and 3D printing since the last Rio Olympics.

In addition to providing archers with optimized 3D-printed grips, modern technology also uses 3D scanning to perform non-destructive testing on the team's bows.

The 3D-printed grips mounted on the bow vary greatly from athlete to athlete, including the required shape and material.

Optimize performance through 3D printing and scanning

During preparations for the 2020 Tokyo Olympics, Hyundai Motor provided technical support to the South Korean archery team, supplying them with qualified bows and arrows and optimizing equipment for each athlete.

Modern, advanced 3D CT scanning equipment was used to develop a new non-destructive testing model to analyze the team's bow. This technology measures the bow's internal condition by creating 3D model images , allowing for analysis of any damage during repeated drawing. As the bow rotates 360°, the 3D scanner takes tens of thousands of images to provide a comprehensive understanding of the bow's performance.

Hyundai has also improved the 3D-printed grips that it has been providing to the team since the 2016 Rio Olympics. The 3D-printed grips are customized to each athlete's hand shape, and now a wider variety of materials are available to suit the athletes' preferences.

Previously, grips were made only of synthetic resin materials, but now they are made of heat-resistant resin, a material that can be quickly customized. While PA12 material produced by the multinational printing company HP is durable, it takes longer to manufacture. The grip also uses newly developed materials, a combination of aluminides, aluminum, and polyamide, as well as solid wood and polyurethane, to provide a better grip. According to Hyundai Motor, archers Jin-Hyuk Oh and Woo-Jin Kim were particularly impressed with the 3D-printed grip. After testing by several athletes, the grip was deemed to have excellent usability and was used as the main grip by the archery team during the Tokyo Olympics.

The team won gold medals in the men's, women's, and mixed team events at this year's Olympics, bringing the total number of medals won by South Korean archers since 1984 to 103. Hyundai Group has provided technical support to the Korean Archery Association for over thirty years, utilizing technologies such as artificial intelligence (AI), biometrics, big data, and 3D printing since the last Rio Olympics.

In addition to providing archers with optimized 3D-printed grips, modern technology also uses 3D scanning to perform non-destructive testing on the team's bows.

The 3D-printed grips mounted on the bow vary greatly from athlete to athlete, including the required shape and material.

Optimize performance through 3D printing and scanning

During preparations for the 2020 Tokyo Olympics, Hyundai Motor provided technical support to the South Korean archery team, supplying them with qualified bows and arrows and optimizing equipment for each athlete.

Modern, advanced 3D CT scanning equipment was used to develop a new non-destructive testing model to analyze the team's bow. This technology measures the bow's internal condition by creating 3D model images , allowing for analysis of any damage during repeated drawing. As the bow rotates 360°, the 3D scanner takes tens of thousands of images to provide a comprehensive understanding of the bow's performance.

Hyundai has also improved the 3D-printed grips that it has been providing to the team since the 2016 Rio Olympics. The 3D-printed grips are customized to each athlete's hand shape, and now a wider variety of materials are available to suit the athletes' preferences.

Previously, grips were made only of synthetic resin materials, but now they are made of heat-resistant resin, a material that can be quickly customized. While PA12 material produced by the multinational printing company HP is durable, it takes longer to manufacture. The grip also uses newly developed materials, a combination of aluminides, aluminum, and polyamide, as well as solid wood and polyurethane, to provide a better grip. According to Hyundai Motor, archers Jin-Hyuk Oh and Woo-Jin Kim were particularly impressed with the 3D-printed grip. After testing by several athletes, the grip was deemed to have excellent usability and was used as the main grip by the archery team during the Tokyo Olympics.

Hyundai Motor Group provides each archer with a customized 3D grip made from various materials and optimized for different purposes . Photo credit : Yoon-Sik Kim

2020 Tokyo 3D Printing

Besides archery, 3D printing equipment has also been featured in several other events at this year's Olympics. More and more athletes are using this technology to gain a competitive edge in aerodynamics, weight, and time savings.

3D printing technology is being used in track cycling. The Italian national cycling team used the Calibry 3D scanner from Russian handheld 3D scanner developer Thor3D to streamline the aerodynamic design of its riders, while performance brand Vorteq used the Artec 3D scanner to create custom aerodynamic bodysuits for cyclists from five different Olympic teams.

The British cycling team also rode new track bikes designed by global engineering firms Renishaw, Lotus Engineering, and Hope Technology, featuring lightweight 3D-printed end-use parts. Additionally, several athletes are expected to wear Adidas' 3D-printed optimized running shoes, the Futurecraft STRUNG, which feature an upgraded 3D-printed 4DFWD midsole, and 3D-printed grips have been fitted to the pistol of multiple world shooting champion Céline Goberville.

Besides archery, 3D printing equipment has also been featured in several other events at this year's Olympics. More and more athletes are using this technology to gain a competitive edge in aerodynamics, weight, and time savings.

3D printing technology is being used in track cycling. The Italian national cycling team used the Calibry 3D scanner from Russian handheld 3D scanner developer Thor3D to streamline the aerodynamic design of its riders, while performance brand Vorteq used the Artec 3D scanner to create custom aerodynamic bodysuits for cyclists from five different Olympic teams.

The British cycling team also rode new track bikes designed by global engineering firms Renishaw, Lotus Engineering, and Hope Technology, featuring lightweight 3D-printed end-use parts. Additionally, several athletes are expected to wear Adidas' 3D-printed optimized running shoes, the Futurecraft STRUNG, which feature an upgraded 3D-printed 4DFWD midsole, and 3D-printed grips have been fitted to the pistol of multiple world shooting champion Céline Goberville.

The new Hope Lotus track bike has been unveiled by the British Cycling Association . Photo courtesy of Hope/Lotus British Cycling.

Performance brand Vorteq has partnered with Luxembourg-based 3D scanner manufacturer Artec 3D to create custom aerodynamic riding suits for riders.

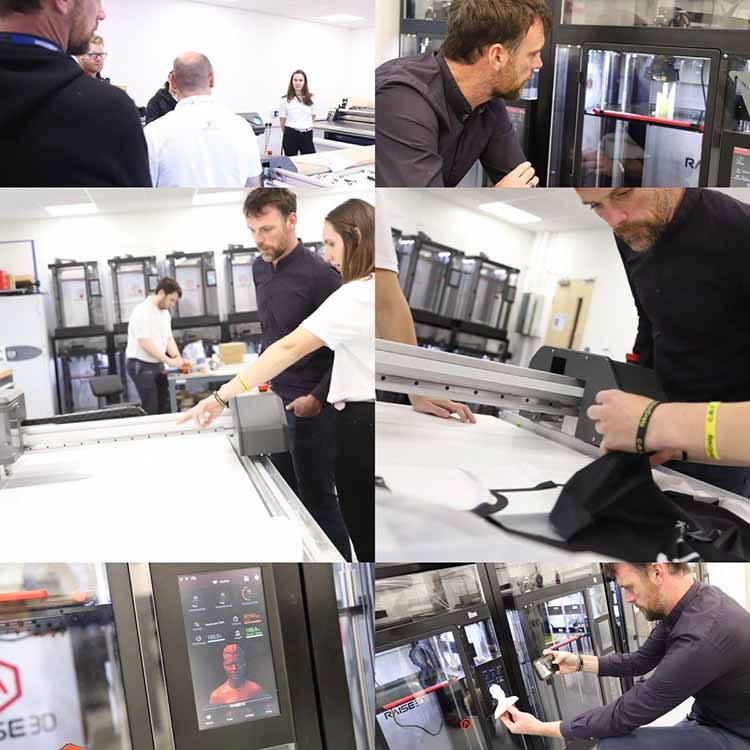

Vorteq, combining Artec's Leo 3D scanner, wind tunnel, and engineering technology, has designed what is touted as one of the "world's fastest" cycling suits. Currently, five different athletes are wearing this compression garment at the Tokyo Olympics; its design is lightweight, breathable, and significantly reduces drag.

"Our mission is to help serious athletes, many of whom are already at or near their peak, find those 'tiny' improvements that, when you put them together, can really give athletes an edge, help them surpass their peak, and ultimately achieve victory," said Sam Quilter, a metrology engineer at Vorteq. "Compared to our previous scanners, Leo gives us tremendous flexibility; we can practically carry one with us. This freedom is especially important when you need to go to random locations where conditions aren't in a lab."

Vorteq, combining Artec's Leo 3D scanner, wind tunnel, and engineering technology, has designed what is touted as one of the "world's fastest" cycling suits. Currently, five different athletes are wearing this compression garment at the Tokyo Olympics; its design is lightweight, breathable, and significantly reduces drag.

"Our mission is to help serious athletes, many of whom are already at or near their peak, find those 'tiny' improvements that, when you put them together, can really give athletes an edge, help them surpass their peak, and ultimately achieve victory," said Sam Quilter, a metrology engineer at Vorteq. "Compared to our previous scanners, Leo gives us tremendous flexibility; we can practically carry one with us. This freedom is especially important when you need to go to random locations where conditions aren't in a lab."

Metrology engineer Sam Quilter used Artec Leo to perform a 3D scan of the knight. Image courtesy of Vorteq.

Arctec 3D Scan

Artec 3D has been shortlisted for the 3D Printing Industry Awards for the second consecutive year (nominations for this year's awards are still open) – its product line includes the Eva, Space Spider, Leo, and Ray scanners, which can be used for a variety of different purposes.

Artec's scanners have previously been used by Marinebedrijf Koninklijke Marine, the materials and asset maintenance company for the Royal Netherlands Navy, for reverse engineering of parts, and by Triebold Paleontology for the digital preservation of a 26-foot-long Stegosaurus at the Denver Museum of Natural Science. The company's scanners are also used in vehicle restoration in the automotive industry and for full-body 3D scans of dolphins, sharks, and large sea turtles to create customized tracking tags that provide information on migration patterns and the impact of ocean temperature.

Artec 3D has been shortlisted for the 3D Printing Industry Awards for the second consecutive year (nominations for this year's awards are still open) – its product line includes the Eva, Space Spider, Leo, and Ray scanners, which can be used for a variety of different purposes.

Artec's scanners have previously been used by Marinebedrijf Koninklijke Marine, the materials and asset maintenance company for the Royal Netherlands Navy, for reverse engineering of parts, and by Triebold Paleontology for the digital preservation of a 26-foot-long Stegosaurus at the Denver Museum of Natural Science. The company's scanners are also used in vehicle restoration in the automotive industry and for full-body 3D scans of dolphins, sharks, and large sea turtles to create customized tracking tags that provide information on migration patterns and the impact of ocean temperature.

An Artec Leo 3D scanner equipped with Artec Studio software displays a scanned image of the rider at the Silverstone Circuit Sports Engineering Center . Image courtesy of Vorteq .

Aerodynamic 3D Scan

In the world of high-performance cycling, speed is everything; success and failure often hinge on fractions of a second. On the track, cyclists contend with wind and air resistance with every pedal stroke. It's reported that up to 90% of a cyclist's energy output is used to overcome air resistance, making reducing this resistance crucial.

Vorteq is using the sports-specific wind tunnel and fabric wind tunnel at Silverstone Circuit's Sports Engineering Center (SSEH), along with the latest 3D scanning technology, to create custom cycling apparel for cyclists that reduces air resistance while being comfortable, lightweight, and breathable.

Artec 3D's Artec Leo handheld scanner is a key element in riding suit design, digitally capturing the rider's precise anatomy in under six minutes. The scanner features a built-in touchscreen, a capture rate of 44 frames per second, and can scan medium-sized objects, including people, in minutes.

"The rider rides his bike into the wind tunnel, I mount it on the platform, and then he jumps on. In just five to six minutes, I can capture two of the rider's poses using precise, high-resolution color 3D imaging," Quilter said. "Basically, this means I can completely get the rider figured out in ten minutes, and they can go somewhere else. I'm ready with everything I need to design an ergonomic, bullet-speed Vorteq cycling suit. No rescanning, not even once."

When making the leotards, Vorteq directly uses scan data from Artec Leo, which provides precise body data for athletes, eliminating inaccuracies and imprecise measurements. The scans then go through a post-processing workflow using Artec Studio software, where engineers carefully examine the data and eliminate any rare errors or unwanted data captures, such as wrinkles. "From the moment the athlete walks in, we start scanning with Leo, then post-process the scans with Artec Studio, followed by 3D modeling in Geomagic Wrap, and finally exporting the 3D model for leotard production. The whole process takes about two hours, which was absolutely impossible in the past, far from enough," Quilter continued. "Currently, we need two days for the total production time to prepare leotards for competition, but that gap is narrowing. Our goal is a 24-hour turnaround time, and we're sure we'll achieve that soon."

In the world of high-performance cycling, speed is everything; success and failure often hinge on fractions of a second. On the track, cyclists contend with wind and air resistance with every pedal stroke. It's reported that up to 90% of a cyclist's energy output is used to overcome air resistance, making reducing this resistance crucial.

Vorteq is using the sports-specific wind tunnel and fabric wind tunnel at Silverstone Circuit's Sports Engineering Center (SSEH), along with the latest 3D scanning technology, to create custom cycling apparel for cyclists that reduces air resistance while being comfortable, lightweight, and breathable.

Artec 3D's Artec Leo handheld scanner is a key element in riding suit design, digitally capturing the rider's precise anatomy in under six minutes. The scanner features a built-in touchscreen, a capture rate of 44 frames per second, and can scan medium-sized objects, including people, in minutes.

"The rider rides his bike into the wind tunnel, I mount it on the platform, and then he jumps on. In just five to six minutes, I can capture two of the rider's poses using precise, high-resolution color 3D imaging," Quilter said. "Basically, this means I can completely get the rider figured out in ten minutes, and they can go somewhere else. I'm ready with everything I need to design an ergonomic, bullet-speed Vorteq cycling suit. No rescanning, not even once."

When making the leotards, Vorteq directly uses scan data from Artec Leo, which provides precise body data for athletes, eliminating inaccuracies and imprecise measurements. The scans then go through a post-processing workflow using Artec Studio software, where engineers carefully examine the data and eliminate any rare errors or unwanted data captures, such as wrinkles. "From the moment the athlete walks in, we start scanning with Leo, then post-process the scans with Artec Studio, followed by 3D modeling in Geomagic Wrap, and finally exporting the 3D model for leotard production. The whole process takes about two hours, which was absolutely impossible in the past, far from enough," Quilter continued. "Currently, we need two days for the total production time to prepare leotards for competition, but that gap is narrowing. Our goal is a 24-hour turnaround time, and we're sure we'll achieve that soon."

Designed and manufactured by Vorteq . Image courtesy of Vorteq .

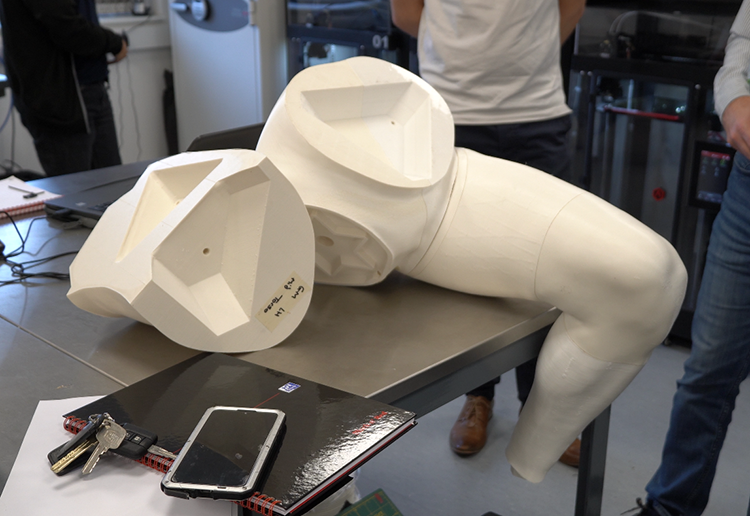

Using Artec Leo, Vorteq can also 3D print anatomically accurate mannequins of athletes, which can be used to create compression garments for them without the need for fittings. With the mannequins, Vorteq can customize a compression garment for an athlete, test various fabrics and styles in a wind tunnel, and then complete the garment within a few hours before delivering it to the athlete's doorstep. Currently, this process takes less than two days, but the company hopes to reduce the time from 3D scanning to completion to 24 hours in the future.

“For example, we can conduct wind tunnel tests on fabrics only on one arm using a full-size mannequin to understand how different fabrics and patterns affect drag reduction,” Quilter explained. This is where marginal benefits really come into play. Because in a wind tunnel, a live rider moves, and even slight movements affect the results. You can never get the same precise measurements from a live rider as you can from a completely stationary mannequin; the only factor that changes is the fabric they're wearing. Previously, Vorteq only worked with Olympic teams and other elite athletes, but since the beginning of 2020, the company's custom cycling apparel has been available to cyclists of all experience levels to help them achieve their best performance.

“For example, we can conduct wind tunnel tests on fabrics only on one arm using a full-size mannequin to understand how different fabrics and patterns affect drag reduction,” Quilter explained. This is where marginal benefits really come into play. Because in a wind tunnel, a live rider moves, and even slight movements affect the results. You can never get the same precise measurements from a live rider as you can from a completely stationary mannequin; the only factor that changes is the fabric they're wearing. Previously, Vorteq only worked with Olympic teams and other elite athletes, but since the beginning of 2020, the company's custom cycling apparel has been available to cyclists of all experience levels to help them achieve their best performance.

Vorteq human model components for assembly and wind tunnel use . Photo courtesy of Vorteq .

How 3D printing can contribute to Olympic performance

Previously, many Olympic athletes have used 3D printing technology to create personalized gear for benefits such as saving time and reducing weight. For example, Shelly-Ann Fraser-Pryce's 3D-printed running shoes were showcased at the last Rio Olympics, while Adidas and 3D printer manufacturer Carbon's latest 3D-printed 4DFWD midsole is currently being worn by several athletes at this year's Tokyo Olympics.

Previously, the French Cycling Union had utilized 3D printing technology to deploy customized handlebars to improve aerodynamic efficiency, and global engineering company Renishaw had partnered with Lotus Engineering and Hope Technology to design a new track bike for the British cycling team. Recently, the Italian national cycling team revealed that, ahead of the Tokyo Olympics, they used a Russian handheld 3D scanner to improve the aerodynamic performance of their bicycles.

Previously, many Olympic athletes have used 3D printing technology to create personalized gear for benefits such as saving time and reducing weight. For example, Shelly-Ann Fraser-Pryce's 3D-printed running shoes were showcased at the last Rio Olympics, while Adidas and 3D printer manufacturer Carbon's latest 3D-printed 4DFWD midsole is currently being worn by several athletes at this year's Tokyo Olympics.

Previously, the French Cycling Union had utilized 3D printing technology to deploy customized handlebars to improve aerodynamic efficiency, and global engineering company Renishaw had partnered with Lotus Engineering and Hope Technology to design a new track bike for the British cycling team. Recently, the Italian national cycling team revealed that, ahead of the Tokyo Olympics, they used a Russian handheld 3D scanner to improve the aerodynamic performance of their bicycles.

Want to learn more about 3D printers and 3D scanners ? Contact us below!

-Contact Us-

SanDiMa offers more than just 3D printing ; we provide three major OEM services: " 3D Printing Manufacturing ," " 3D Scanning Services ," and " Spatial 3D Scanning Services "!

Follow our fan page and stay up-to-date with the latest news:

Facebook | Instagram | Threads

-Contact Us-

SanDiMa offers more than just 3D printing ; we provide three major OEM services: " 3D Printing Manufacturing ," " 3D Scanning Services ," and " Spatial 3D Scanning Services "!

Follow our fan page and stay up-to-date with the latest news:

Facebook | Instagram | Threads