Formech | Product Model:

VF0020

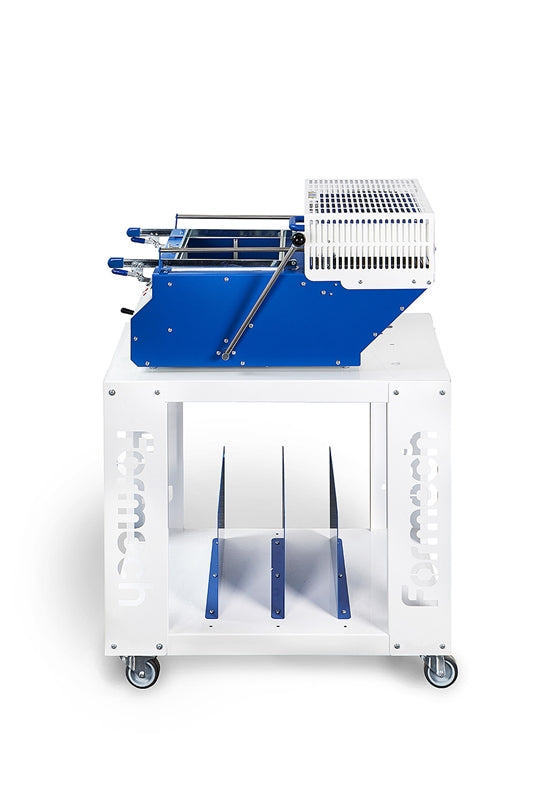

300DT Vacuum Forming Machine

Regular price

¥939,200 JPY

Unit price

/

Unavailable

Subtotal

—

300DT Vacuum Forming Machine is backordered and will ship as soon as it is back in stock.

Choose add-on

Couldn't load pickup availability

300DT Vacuum Forming Machine

The all-new Formech 300DT vacuum forming machine is the company's smallest benchtop machine to date. While retaining the functionality of its predecessor, the Compac Mini, the 300DT is smaller and lighter. Compared to other compact machines on the market, the 300DT features a quiet built-in vacuum pump and mold release function. Easy to carry, move, and use, the 300DT is the perfect solution for creative enthusiasts, artisans, and students.

【Main Features】

Safety interlock

Interlocking systems can prevent operational errors and ensure work safety.

After the vacuum-molded parts have cooled, air is injected between the mold and the plastic sheet to help the parts demold smoothly.

A visual vacuum pressure gauge displays the applied vacuum pressure ( in Hg/bar ).

A digital timer with a programmable countdown and an audible alarm helps achieve consistent cycle times.

【Optional Accessories】

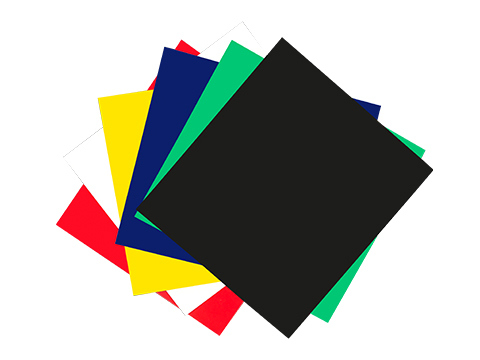

Vacuum forming material sheet kit

Various material sheets (HIPS, ABS, PETG) cut to fit the Formech vacuum forming machine. Includes: 10 sheets of black gloss/matte HIPS 1mm, 10 sheets of white gloss/matte HIPS 1mm, 30 sheets of mixed-color gloss/matte HIPS 1.5mm (blue, red, yellow), 10 sheets of black pinseal ABS 1.5mm, and 16 sheets of transparent PETG 0.5mm.

The all-new Formech 300DT vacuum forming machine is the company's smallest benchtop machine to date. While retaining the functionality of its predecessor, the Compac Mini, the 300DT is smaller and lighter. Compared to other compact machines on the market, the 300DT features a quiet built-in vacuum pump and mold release function. Easy to carry, move, and use, the 300DT is the perfect solution for creative enthusiasts, artisans, and students.

【Main Features】

Safety interlock

Interlocking systems can prevent operational errors and ensure work safety.

After the vacuum-molded parts have cooled, air is injected between the mold and the plastic sheet to help the parts demold smoothly.

A visual vacuum pressure gauge displays the applied vacuum pressure ( in Hg/bar ).

A digital timer with a programmable countdown and an audible alarm helps achieve consistent cycle times.

【Optional Accessories】

- Reduced window size - 125x100mm or custom sizes

- Tabletop trolley

Vacuum forming material sheet kit

Various material sheets (HIPS, ABS, PETG) cut to fit the Formech vacuum forming machine. Includes: 10 sheets of black gloss/matte HIPS 1mm, 10 sheets of white gloss/matte HIPS 1mm, 30 sheets of mixed-color gloss/matte HIPS 1.5mm (blue, red, yellow), 10 sheets of black pinseal ABS 1.5mm, and 16 sheets of transparent PETG 0.5mm.

- Spare parts kit

| Molding area | 280 x 230mm |

| Platform size | 300 x 250mm |

| Maximum depth | 136mm |

| Maximum material thickness | 4mm |

| Number of heating zones | 1 |

| Heater type | quartz |

| width | 454mm |

| high | 355mm |

| depth | 746 mm |

| weight | 27kg |

| Single-phase power supply requirements | 208-240V/13A |

| Europe - Three-phase power requirements | N / A |

| United States - Three-phase power requirements | N / A |

| Energy consumption | 1.1KW |

| Air requirements | N / A |

*As part of our ongoing product development program, the features and specifications of the desktop Formech machine are subject to change without notice.