Ultimaker | Product Model:

UMRB220999

Ultimaker PVA cleaning machine demonstration machine

Regular price

¥129,400 JPY

Unit price

/

Unavailable

Subtotal

—

Ultimaker PVA cleaning machine demonstration machine is backordered and will ship as soon as it is back in stock.

Choose add-on

Couldn't load pickup availability

Ultimaker PVA Cleaning Machine Demonstration Unit

The "3DMart demo machine" is a 3D printer that was previously used only for customer demonstrations and printing services. It is operated and maintained by professional engineers and internal staff and is still in good working order. It is not a machine under repair, a defective machine, or a customer's machine.

To stay at the forefront of the 3D printing industry, we must continuously update our machines and use them ourselves. We also pay great attention to the maintenance of our 3D printers . In addition to replacing parts and consumables, our engineers regularly clean and maintain them. And these 3D printers we use are still in perfect working order. Therefore, we offer you another option at a discounted price.

All our used 3D printers have undergone thorough testing and finishing before being sold. Since these are not brand new, there may be some signs of use, color variations, minor scratches, etc.; however, this does not affect the functionality of the product model, and they still provide stable, high-quality prints. We also offer a three-month warranty and a more favorable price; these machines are extremely limited, so please seize this opportunity!

Simple post-processing for faster object acquisition

Save effort and increase productivity

Reduce operation time by up to 80%! The Ultimaker PVA cleaner takes only a few minutes per operation and requires minimal maintenance. Simply press the start button to begin operation immediately, and you can remove your items once finished.

Maintain the security of printed products

The rinsing basket allows the printed product to be safely placed in water. Then, by lifting the rinsing basket, the water drains naturally, and the printed product can be easily removed.

The "3DMart demo machine" is a 3D printer that was previously used only for customer demonstrations and printing services. It is operated and maintained by professional engineers and internal staff and is still in good working order. It is not a machine under repair, a defective machine, or a customer's machine.

To stay at the forefront of the 3D printing industry, we must continuously update our machines and use them ourselves. We also pay great attention to the maintenance of our 3D printers . In addition to replacing parts and consumables, our engineers regularly clean and maintain them. And these 3D printers we use are still in perfect working order. Therefore, we offer you another option at a discounted price.

All our used 3D printers have undergone thorough testing and finishing before being sold. Since these are not brand new, there may be some signs of use, color variations, minor scratches, etc.; however, this does not affect the functionality of the product model, and they still provide stable, high-quality prints. We also offer a three-month warranty and a more favorable price; these machines are extremely limited, so please seize this opportunity!

Simple post-processing for faster object acquisition

When creating complex parts or stunning visual prototypes using PVA support material, the Ultimaker PVA cleaning machine offers faster and easier post-processing. Using the same 3D printing platform throughout ensures faster design iterations, minimizes operation time, and avoids clutter.

PVA removal speed increased by 4 times

The Ultimaker PVA cleaner is driven by a magnetic rotor, enabling a high-speed dissolution process. Compared to removing PVA using still water in a temporary container, this device can remove PVA up to four times faster, even in complex designs with hard-to-reach pores.

The Ultimaker PVA cleaner is driven by a magnetic rotor, enabling a high-speed dissolution process. Compared to removing PVA using still water in a temporary container, this device can remove PVA up to four times faster, even in complex designs with hard-to-reach pores.

Save effort and increase productivity

Reduce operation time by up to 80%! The Ultimaker PVA cleaner takes only a few minutes per operation and requires minimal maintenance. Simply press the start button to begin operation immediately, and you can remove your items once finished.

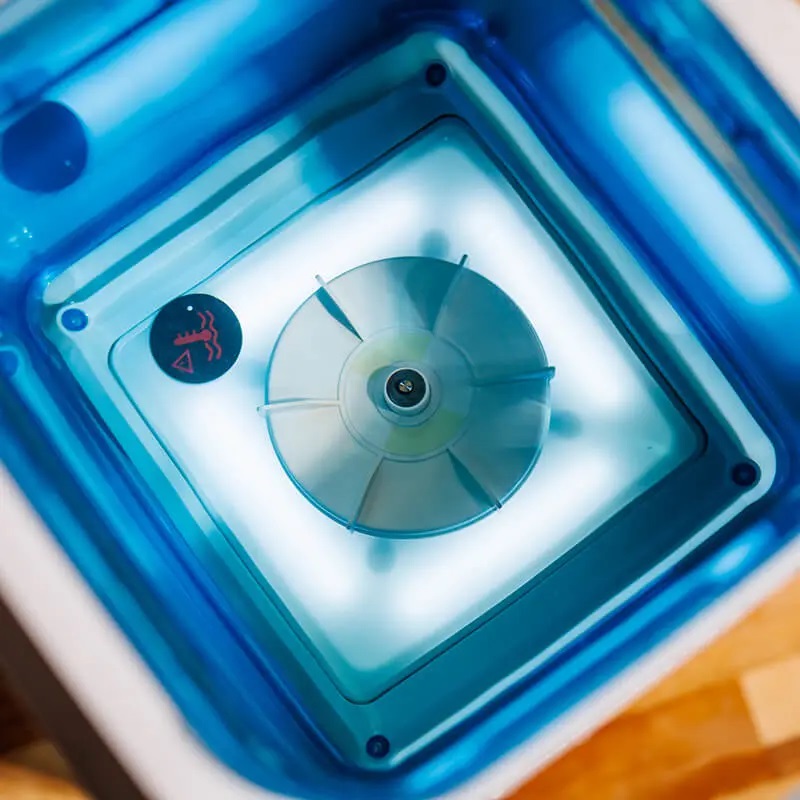

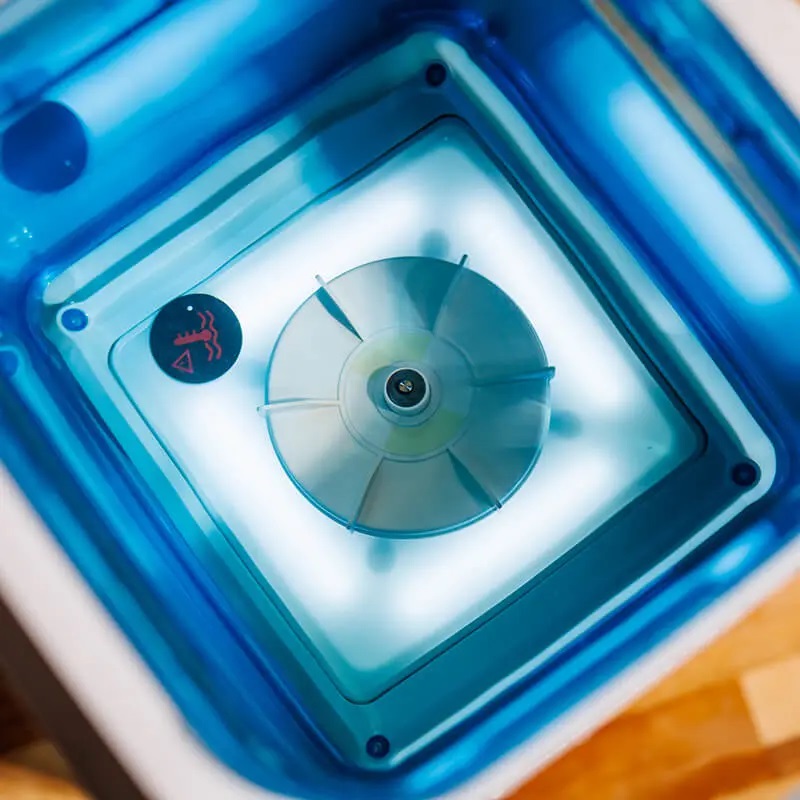

Water circulation driven by a rotor

Choose either 100 or 225 RPM depending on the fragility of the parts. Every two minutes, the rotor changes direction, pushing the water evenly onto the model.

Choose either 100 or 225 RPM depending on the fragility of the parts. Every two minutes, the rotor changes direction, pushing the water evenly onto the model.

Maintain the security of printed products

The rinsing basket allows the printed product to be safely placed in water. Then, by lifting the rinsing basket, the water drains naturally, and the printed product can be easily removed.

Easy to track progress

The illuminated, transparent container allows you to easily and accurately track the rinsing progress and when it's ready. Additionally, the screen displays reminders when fresh water needs to be changed.

The illuminated, transparent container allows you to easily and accurately track the rinsing progress and when it's ready. Additionally, the screen displays reminders when fresh water needs to be changed.

Main features:

| Container capacity | 13.7 liters (3.6 US gallons) |

| Maximum Capacity Item Size | 200 x 230 x 165 mm |

| Applicable support materials | Optimized for PLA and PVA, it is also applicable to PETG, Tough PLA, Nylon, and CPE combined with PVA (and supports similar materials from other manufacturers). |

| Applicable solvents | water |

| Rotation speed | 225 RPM (Normal) 100 RPM (Low) |

| Operating noise | < 50 dBA |

| Machine size | 303 x 325 x 374 mm |

| Handle extension size | 303 x 325 x 528 mm |

| net weight | 6.35 kg |

| Container weight (empty) | 4.2 kg |

| Shipping container dimensions | 400 x 400 x 500 mm |

| Shipment weight | 8.5 kg |

| Operating temperature environment | 15 – 32 °C |

| Non-working temperature environment | 0 – 32 °C |

| relative humidity | 10% – 90% (non-condensing) |

| Voltage | 100 – 240 VAC |

| frequency | 50 – 60 Hz |

| power | 38W |

| Warranty | 1 year |