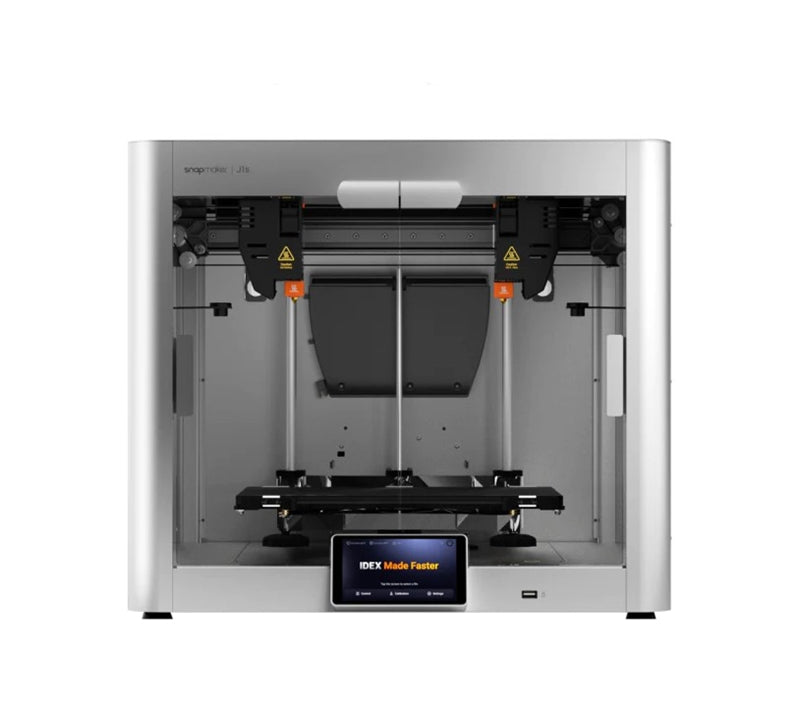

Snapmaker | Product Model:

SK0111

Snapmaker J1s IDEX Standalone Dual-Head 3D Printer

Regular price

¥239,800 JPY

Unit price

/

Unavailable

Subtotal

—

Snapmaker J1s IDEX Standalone Dual-Head 3D Printer is backordered and will ship as soon as it is back in stock.

Choose add-on

Couldn't load pickup availability

Snapmaker J1s IDEX Standalone Dual-Head 3D Printer

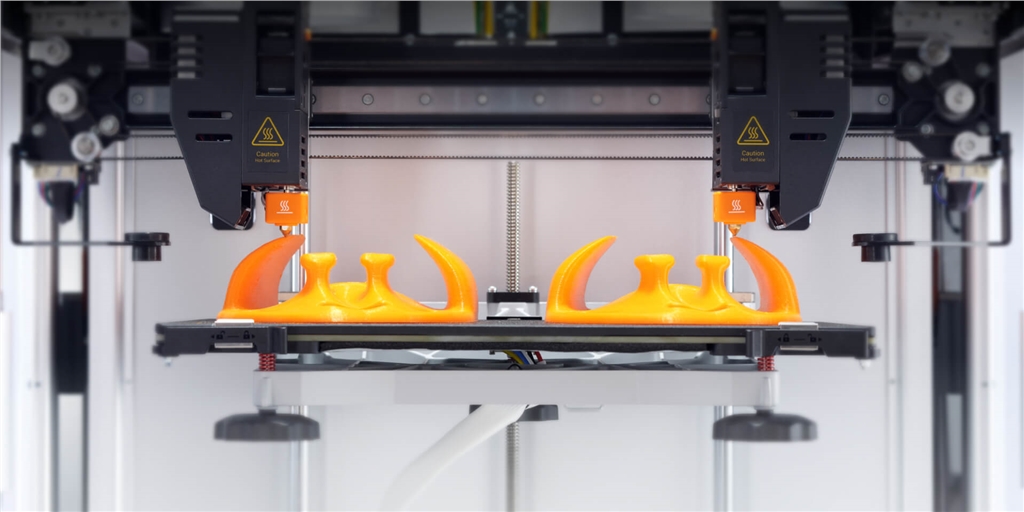

The Snapmaker J1s's new Independent Dual Printhead Technology (IDEX) creates amazing results with an astonishingly wide range of materials, delivering industrial-grade transfer precision. Industrial-grade transfer precision allows for effortless calibration to realize your creations! Compared to single-head printers printing multiple materials, IDEX dual printheads require less time to change lines, reducing unnecessary waste. Furthermore, IDEX dual printhead printers prevent cross-contamination.

The Snapmaker J1s's new Independent Dual Printhead Technology (IDEX) creates amazing results with an astonishingly wide range of materials, delivering industrial-grade transfer precision. Industrial-grade transfer precision allows for effortless calibration to realize your creations! Compared to single-head printers printing multiple materials, IDEX dual printheads require less time to change lines, reducing unnecessary waste. Furthermore, IDEX dual printhead printers prevent cross-contamination.

Maximum speed: 350 mm/s, maximum acceleration: 10,000 mm/s²

Advanced control improves printing speed

Vibration compensation

The J1 delivers an ultra-fast printing speed of 350 mm/s while ensuring high-resolution printing. Vibration compensation technology optimizes and reduces vibrations caused by high-speed motion, minimizing amplitude to improve print quality. With a maximum acceleration of 10,000 mm/s², it efficiently produces small models with rich detail.

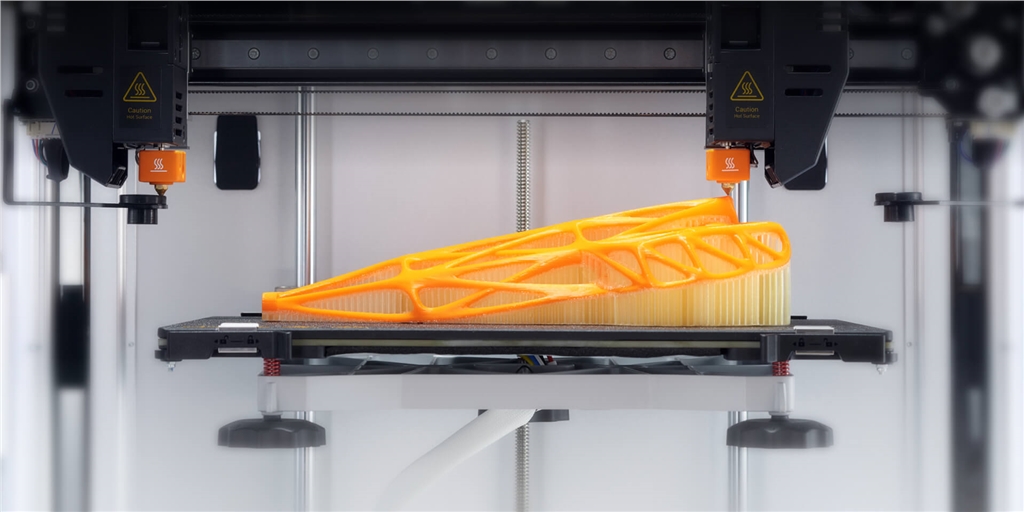

Detachable and removable supports

Building and removing supports can sometimes feel like rocket science—time-consuming to study and difficult to disassemble. The Snapmaker J1 optimizes the entire design, offering stable supports, a clean interface, effortless removal, and minimal post-processing to maintain high precision. The printed model will be exactly what you imagined—no more, no less!

Building and removing supports can sometimes feel like rocket science—time-consuming to study and difficult to disassemble. The Snapmaker J1 optimizes the entire design, offering stable supports, a clean interface, effortless removal, and minimal post-processing to maintain high precision. The printed model will be exactly what you imagined—no more, no less!

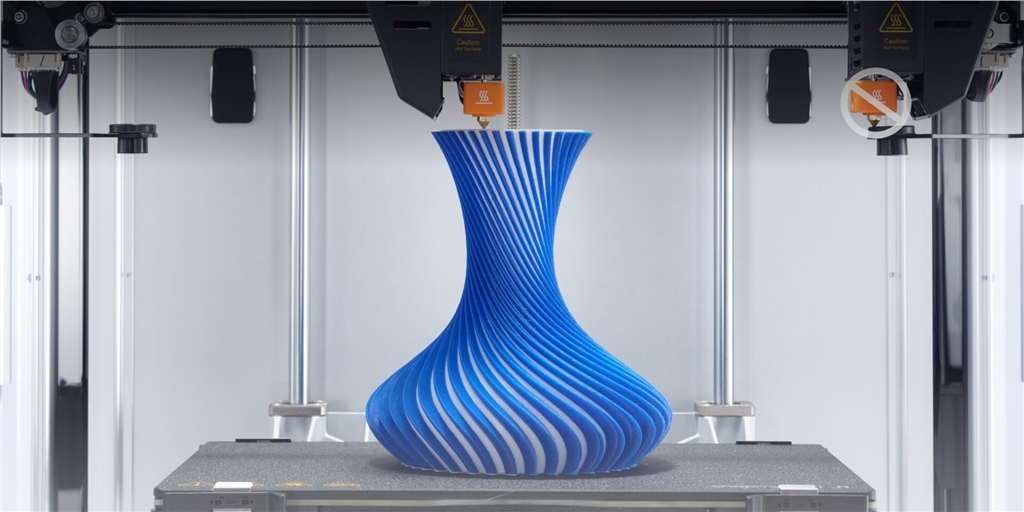

Dual Material Printing

In printing, the properties of both nylon and TPU can be fully utilized, combining their strength and flexibility to create more functional objects. Models that were originally multiple objects can also be combined for printing. Because assembly is eliminated, the objects achieve stronger interconnectivity and are less prone to damage.

Copy and mirror modes

It halves waiting time for printing and doubles productivity. IDEX is the only extrusion system with two independent dual-head printers moving independently on the X-axis, allowing two print samples to be run simultaneously.

It halves waiting time for printing and doubles productivity. IDEX is the only extrusion system with two independent dual-head printers moving independently on the X-axis, allowing two print samples to be run simultaneously.

Backup mode

In backup mode, while one printhead is printing, another stands by. If the printhead malfunctions, the standby printhead will seamlessly take over, ensuring a perfect print! No valuable time is wasted.

In backup mode, while one printhead is printing, another stands by. If the printhead malfunctions, the standby printhead will seamlessly take over, ensuring a perfect print! No valuable time is wasted.

Overall characteristics:

- Separable and dissolvable supports allow for effortless removal.

- Acceleration up to 10,000 mm/s² and printing speed up to 350 mm/s

- Copy mode and mirror mode double productivity

- 300℃ hot end and 100℃ heated bed

- Print volume 300 × 200 × 200 mm³.

- Easy-to-replace multi-diameter hot ends

- Double-sided PEI glass panel

- 5-inch intuitive touchscreen

- Built-in nozzle wiper

- Separable and dissolvable supports allow for effortless removal.

- Acceleration up to 10,000 mm/s² and printing speed up to 350 mm/s

- Copy mode and mirror mode double productivity

- 300℃ hot end and 100℃ heated bed

- Print volume 300 × 200 × 200 mm³.

- Easy-to-replace multi-diameter hot ends

- Double-sided PEI glass panel

- 5-inch intuitive touchscreen

- Built-in nozzle wiper

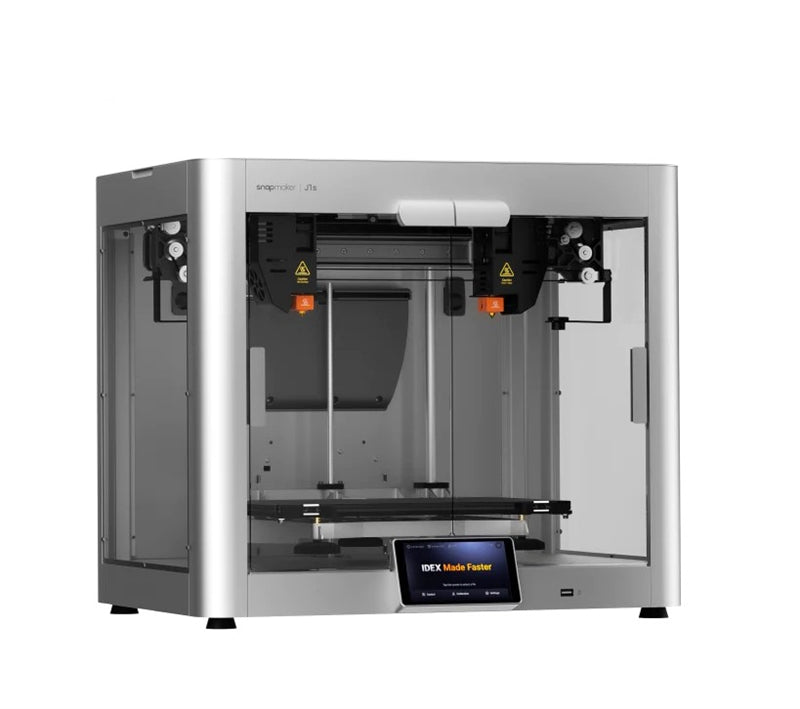

The main differences between backup modes J1 and J1s are as follows:

1. The J1s comes equipped with an additional printing cooling fan. You do not need to remove the top plate to print PLA.

2. In the J1s package, Snapmaker replaces the white PLA with PLA Breakaway Support, so you can try out support printing right away.

3. Snapmaker also comes pre-installed with doors and side panels, making it easier for you to get started right away.

4. If you plan to purchase the J1 model and have additional printing cooling requirements, you can choose the J1 plus upgrade kit or the J1s.

Comparison of Snapmaker J1 3D Printing Modes

Printing specifications

Equipment Specifications

| Maximum speed (mm/s) | 300 | 250 | 200 | 160 | 350 |

| Floor height (mm) | 0.12 | 0.16 | 0.2 | 0.24 | 0.1 |

Printing specifications

| Printing technology | Thermal fusion lamination (FFF) |

| Print mode | 1. Preset Mode 2. Backup Mode 3. Copy Mode 4. Mirror Mode |

| Build volume (width x depth x height) |

Preset mode and backup mode: 300 mm x 200 mm x 200 mm |

| Replication mode: 160 mm x 200 mm x 200 mm | |

| Mirror mode: 150 mm x 200 mm x 200 mm | |

| floor height (Using a 0.4mm nozzle) |

0.05mm-0.3mm |

| Printing Platform | PEI glass plate |

| Maximum heated bed temperature | 100℃ |

| Nozzle diameter | 0.4mm 0.2 mm, 0.6 mm, 0.8 mm, and hardened steel nozzles (sold separately) |

| Maximum nozzle temperature | 300℃ |

| wire diameter | 1.75mm |

| Support cable materials | PLA, ABS, HIPS, PC, TPU, TPE, PETG, ASA, PP, PVA, PA, PA-GF, PA-CF *When printing with PA, PA-GF, or PA-CF nozzles, it is recommended to use a hardened steel nozzle. |

| Transmission method | USB data cable, USB hard drive |

| Operating noise | <50 decibels |

Equipment Specifications

| Volume | 539 mm x 401 mm x 464 mm |

| weight | 22kg |

| touchscreen | 5-inch operating system: Android Resolution: 1280 x 720 primitives |

| memory | 1 GB RAM, 8 GB eMMC |

| Repeatability of linear orbits | ± 0.03 mm (X/Y) ± 0.02 mm (Z) *Data may vary depending on testing conditions and product updates; for reference only. |

| Approximate lifespan of a linear orbit | 10 years or more *Data may vary depending on testing conditions and product updates; for reference only. |

| Operating environment | Temperature: 10ºC–35ºC Relative humidity: 10%–90% (non-condensing) |

| Storage environment | Temperature: -20℃–55℃ Relative humidity: 10%–90% (non-condensing) |

| enter | Rated voltage: AC 100 V–240 V, 50 Hz/60 Hz Rated current: 4.4 A Max. |

| Output | DC 24 V, maximum output 400 W |

| Using software | Luban supports third-party software. |

| Luban operating system | Windows, macOS |

| Supported file formats | STL, OBJ, 3MF |

| Export file format | G code |