Sinterit | Product Model:

ST0060

Sinterit Lisa X SLS 3D printer high-performance bundle

Subtotal

—

Sinterit Lisa X SLS 3D printer high-performance bundle is backordered and will ship as soon as it is back in stock.

Choose add-on

Couldn't load pickup availability

Sinterit Lisa X SLS 3D printer high-performance bundle

The Sinterit Lisa X high-performance equipment package includes a complete powder processing station, sandblasting machine, and powder filter. It also comes with a dedicated Sinterit Lisa X SLS powder tool kit and vacuum cleaner, offering the most comprehensive and affordable package. From equipment startup and production completion to post-processing and cleaning, this package provides the most professional assistance!

Combination content:

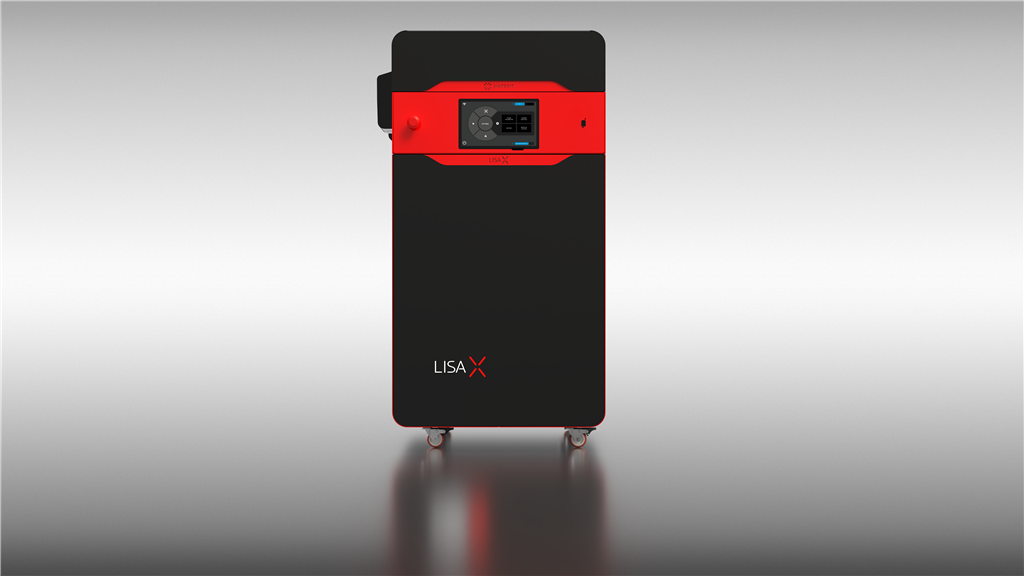

1. Sinterit Lisa X - The fastest desktop laser sintering 3D printer in this product line.

2. Sinterit Powder Handling Station (PHS)

3. Sinterit dedicated powder tool set

4. Sinterit ATEX industrial vacuum cleaners

5. Sinterit Sandblasting Machine SLS - An upgraded version of the Sinterit sandblasting machine, with a spacious interior, easy to operate with both hands, suitable for handling various fine details and complex items.

6. Sinterit Studio Advanced - In addition to the standard Sinterit Studio features, you can adjust 32 printing parameters, allowing you to use some third-party materials or experiment with printing settings.

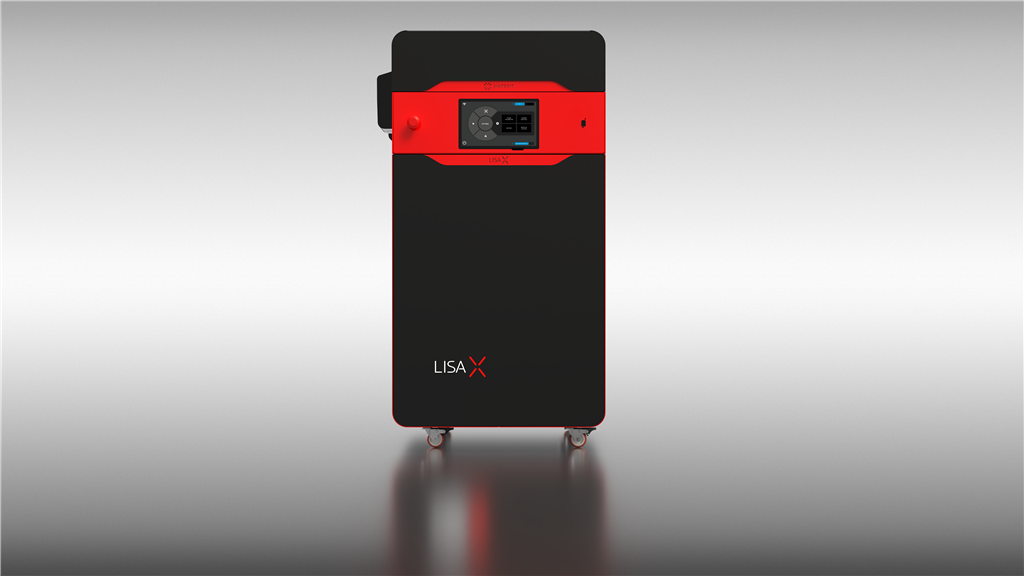

Sinterit Lisa X 3D Printer

The Lisa X offers lightning-fast 3D printing speeds, a large workspace, the ability to use a wide variety of materials, and an open environment. Its large build volume and industrial-grade speed are definitely its strengths in the compact series. It is ideal for users who want more 3D printing capabilities but do not require high-volume production. .png)

Accelerating Innovation

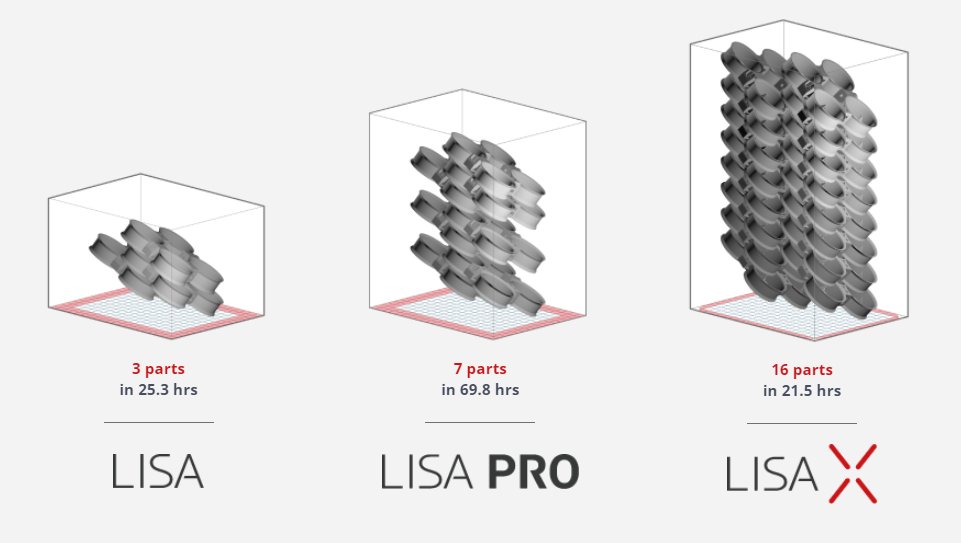

The Lisa X boasts an incredibly fast printing speed of 10-14 mm/hour, making it the fastest compact SLS 3D printer on the market. It can print up to 540 elements in 28 hours!

The Lisa X also features a special air blade that simplifies the 3D printer preparation process. The air blade automatically cleans the printer before it reaches the 3D printer.

Reliable machines = efficient processes + user peace of mind

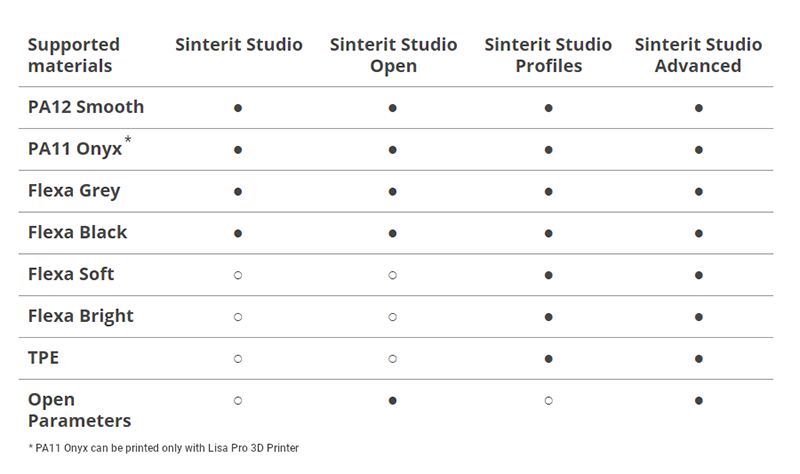

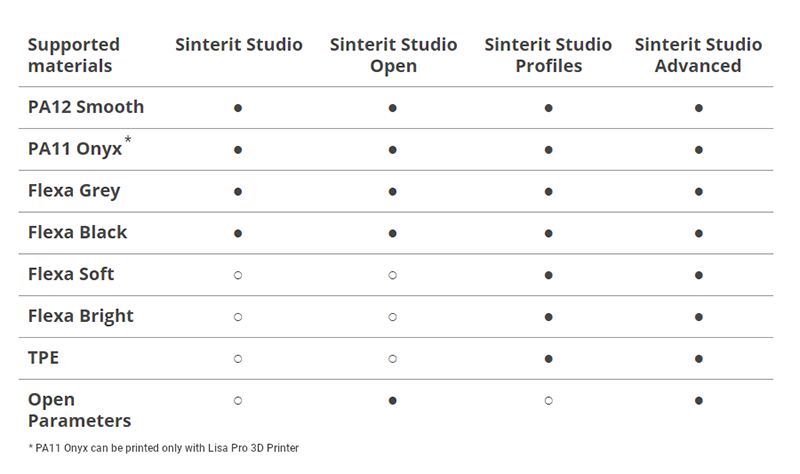

Sinterit Studio Advanced Edition

With a dedicated desktop application, you can prepare 3D models, place objects in printable areas, check for all collisions, and track the printing status in the most intuitive way.

In addition to the standard Sinterit Studio features, the premium version allows you to adjust 32 printing parameters, enabling you to use some third-party materials or experiment with printing settings.

Product Features:

Powder post-processing: 5 simple steps

2. Detail cleaning

3. Integrate the work area (sandblasting machine)

4. Clean the printing area and work area

5. Complete filtering and reuse

Main tools:

Sinterit ATEX Industrial Vacuum Cleaner

The Sinterit ATEX industrial vacuum cleaner safely recycles and cleans the work environment. It is simple to use and quickly collects all the powder spilled during the 3D printing process, keeping the environment clean at all times and ensuring user safety. It automatically puts the collected powder into a dedicated 12L container without manual transfer. It can be easily poured into the Sinterit powder sieve or turned off and left for further processing.

Product Features:

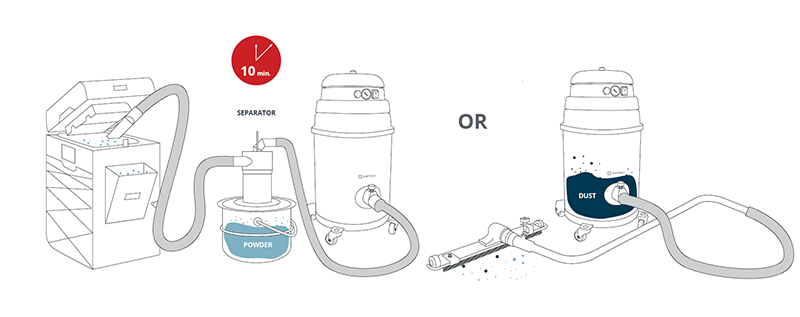

Rapidly collect powder

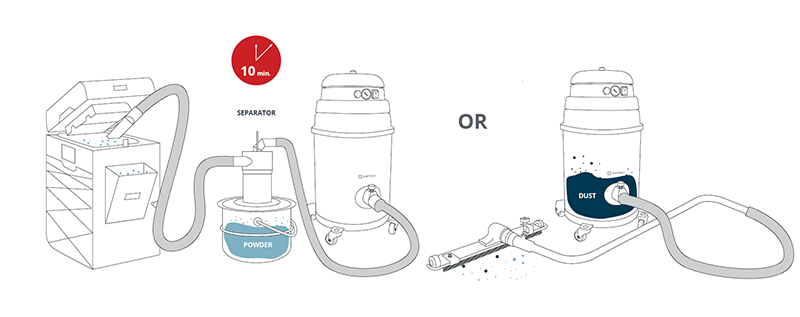

When cleaning the Sinterit powder 3D printer , unused powder can be collected within 10 minutes, saving time and money. With the powder separator, all powder can be concentrated in the container and quickly sorted for the next production.

Clean working environment: Spilled powder is immediately recycled.

The Sinterit ATEX vacuum cleaner is easy to use and can quickly collect all the powder spilled during the 3D printing process, keeping the environment clean at all times and ensuring user safety.

Streamline workflow

The Sinterit ATEX vacuum cleaner comes equipped with a powder separator that automatically places collected powder into a dedicated 12L container, eliminating the need for manual transfer; it can be easily poured into the Sinterit powder sieve or turned off and left for further processing.

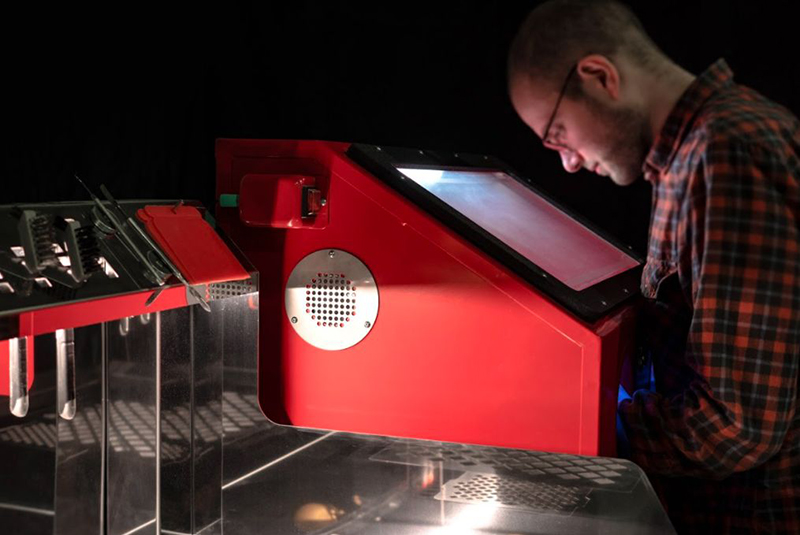

SLS sandblasting machine

The Sinterit sandblasting machine uses compressed air and fine particles to penetrate all the tiny gaps in an object. It can be easily operated with both hands and has a spacious interior, making it suitable for handling various fine details and complex items.

Product Features:

Spacious and ergonomically designed. Easy to operate and quick to change abrasives. Airflow can be adjusted via a pedal, allowing for free manipulation of the object being blasted. Air pressure can be easily adjusted and parameters precisely set.

Uniform internal lighting. Constructed from tightly powder-coated steel brass. Equipped with a handheld spray gun and five different diameter ceramic nozzles. Selectable abrasive grit sizes effectively clean even the most complex surfaces.

* Comes with original factory anti-collision protection box

The Sinterit Lisa X high-performance equipment package includes a complete powder processing station, sandblasting machine, and powder filter. It also comes with a dedicated Sinterit Lisa X SLS powder tool kit and vacuum cleaner, offering the most comprehensive and affordable package. From equipment startup and production completion to post-processing and cleaning, this package provides the most professional assistance!

Combination content:

1. Sinterit Lisa X - The fastest desktop laser sintering 3D printer in this product line.

2. Sinterit Powder Handling Station (PHS)

3. Sinterit dedicated powder tool set

4. Sinterit ATEX industrial vacuum cleaners

5. Sinterit Sandblasting Machine SLS - An upgraded version of the Sinterit sandblasting machine, with a spacious interior, easy to operate with both hands, suitable for handling various fine details and complex items.

6. Sinterit Studio Advanced - In addition to the standard Sinterit Studio features, you can adjust 32 printing parameters, allowing you to use some third-party materials or experiment with printing settings.

Sinterit Lisa X 3D Printer

The Sinterit Lisa X desktop SLS 3D printer is a revolution in the compact SLS field. It is the fastest compact SLS 3D printer in its class, designed for agility and productivity.

Using desktop 3D printers with selective laser sintering technology, compact and well-designed 3D printers allow users to create ultra-fast prototypes without compromising quality or durability, and most 3D printer outputs can be completed within 24 hours.

The Lisa X offers lightning-fast 3D printing speeds, a large workspace, the ability to use a wide variety of materials, and an open environment. Its large build volume and industrial-grade speed are definitely its strengths in the compact series. It is ideal for users who want more 3D printing capabilities but do not require high-volume production.

.png)

Accelerating Innovation

The Lisa X boasts an incredibly fast printing speed of 10-14 mm/hour, making it the fastest compact SLS 3D printer on the market. It can print up to 540 elements in 28 hours!

The Lisa X also features a special air blade that simplifies the 3D printer preparation process. The air blade automatically cleans the printer before it reaches the 3D printer.

Reliable machines = efficient processes + user peace of mind

Sinterit Studio Advanced Edition

With a dedicated desktop application, you can prepare 3D models, place objects in printable areas, check for all collisions, and track the printing status in the most intuitive way.

In addition to the standard Sinterit Studio features, the premium version allows you to adjust 32 printing parameters, enabling you to use some third-party materials or experiment with printing settings.

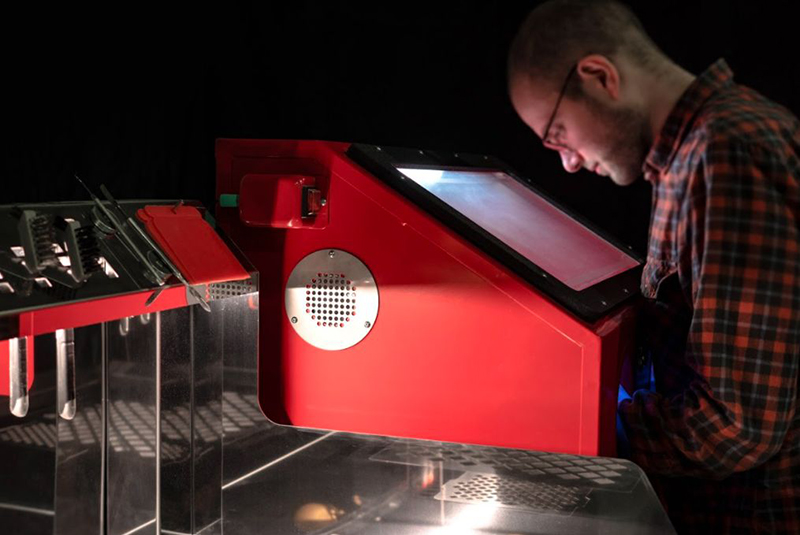

Sinterit Powder Handling Station (PHS)

The Sinterit Powder Handling Station (PHS) sets a new standard for post-sintering powder processing. Its ergonomic design facilitates smoother post-processing and powder recycling procedures, from initial sieving to complete filtration and reuse, while maintaining a clean working environment.

Product Features:

Integrate all powder printing processes in one place.

Ergonomic design

The necessary tools are readily available.

Easily remove powder in 5 simple steps.

It can be used with multiple 3D printers .

Powder post-processing: 5 simple steps

1. Preliminary powder screening

The large hole in the workbench allows unsintered powder to be poured in, simultaneously cleaning the printed objects and performing the first step of powder sieving. Excess powder flows from the hole into the sealed space below, leaving only the printed products to be cleaned above.

2. Detail cleaning

During detailed cleaning at the top of the fine dust chamber on the right (with a smaller mesh filter), the powder is drawn back into the dust chamber.

3. Integrate the work area (sandblasting machine)

A metal bracket is attached to the right side of the equipment, allowing the folding tray or sandblasting machine to be placed near the PHS working area, reducing working time and preventing powder from spreading outside the working area. (Specifically for Sinterit sandblasting machines and Sinterit XL sandblasting machines )

4. Clean the printing area and work area

The two-meter-long suction hose allows for easy movement within the Sinterit 3D printer and the entire PHS work area, cleaning the printer itself and the work area. All powder generated during cleaning can be reused.

5. Complete filtering and reuse

Finally, all the recovered powder is transferred to the screening module and then into a metal container. The sieve located below the workbench can filter and classify all the powder that falls out during the process and further process it by mixing the used powder with the fresh powder.

Sinterit Lisa SLS Dedicated Powder Tool Set

No mess, no waste! The Sinterit Lisa SLS Powder Tool Kit is a comprehensive set of powder tools that saves time and powder usage while keeping the workspace clean, boosting 3D printing efficiency by 2 times! The powder tools cover the entire 3D printing process, from equipment startup, production completion, post-processing to cleaning, providing direct assistance to all aspects.

Main tools:

1. powder funnel

Without spraying powder into the air, using a powder funnel allows for the fastest filtration, inversion, and concentration of powder.

2. Powder compactor (for uniformly flattening density)

Ensure uniform pressure distribution and appropriate powder density.

3. IO BOX Powder Replacement Box

Pour the powder you want to use into the container. After the 3D printing is complete, invert one of the containers. This allows you to move any unused powder to another storage space without spilling it on your desk or other workspace.

4. Foldable dustbin

Foldable and lightweight, it is very easy to store, helps catch falling powder, easily collects and vacuums it, and can also directly pour the powder into the bucket.

5. Consumables and accessories package

Includes the necessary maintenance kit, drive lines, silicone oil, cleaning cloths, cotton cloths, and spare heater supplies, enabling the Sinterit SLS 3D printer to operate continuously for 1000 hours, ensuring the most thorough preparation for maintenance.

Product Features:

Saves powder usage and reduces waste.

The workspace can be kept clean at all times.

Workflow

Sinterit ATEX Industrial Vacuum Cleaner

The Sinterit ATEX industrial vacuum cleaner safely recycles and cleans the work environment. It is simple to use and quickly collects all the powder spilled during the 3D printing process, keeping the environment clean at all times and ensuring user safety. It automatically puts the collected powder into a dedicated 12L container without manual transfer. It can be easily poured into the Sinterit powder sieve or turned off and left for further processing.

Product Features:

Rapidly collect powder

When cleaning the Sinterit powder 3D printer , unused powder can be collected within 10 minutes, saving time and money. With the powder separator, all powder can be concentrated in the container and quickly sorted for the next production.

Clean working environment: Spilled powder is immediately recycled.

The Sinterit ATEX vacuum cleaner is easy to use and can quickly collect all the powder spilled during the 3D printing process, keeping the environment clean at all times and ensuring user safety.

Streamline workflow

The Sinterit ATEX vacuum cleaner comes equipped with a powder separator that automatically places collected powder into a dedicated 12L container, eliminating the need for manual transfer; it can be easily poured into the Sinterit powder sieve or turned off and left for further processing.

SLS sandblasting machine

The Sinterit sandblasting machine uses compressed air and fine particles to penetrate all the tiny gaps in an object. It can be easily operated with both hands and has a spacious interior, making it suitable for handling various fine details and complex items.

Product Features:

Spacious and ergonomically designed. Easy to operate and quick to change abrasives. Airflow can be adjusted via a pedal, allowing for free manipulation of the object being blasted. Air pressure can be easily adjusted and parameters precisely set.

Uniform internal lighting. Constructed from tightly powder-coated steel brass. Equipped with a handheld spray gun and five different diameter ceramic nozzles. Selectable abrasive grit sizes effectively clean even the most complex surfaces.

* Comes with original factory anti-collision protection box

Sinterit Lisa X

| 技術 | SLS |

| 雷射光類型 | Galvo |

| 尺寸 | 650 x 610 x 1200mm |

| 重量 | 145KG |

| 最大列印體積 | TPU based / Flexible: 130 x 180 x 330mm PA / PP: 130 x 180 x 330mm |

| 層厚 | 0.075-0.175mm |

| 軟體 | Sinterit Studio |

| 檔案類型 | STL、3MF、OBJ、3DS、FBX、DAE |

| 操作系統 | Microsoft Windows 10(含)以上 |

| 傳輸方式 | WiFi、Ethernet、USB |

| 材料 | PA12 Smooth PA11 Onyx PA11 CF PA11 ESD PP Polypropylene Flexa Bright Flexa Soft Flexa Grey TPE |

| 列印速度 | 14mm/ h |

| 電源輸入(出) | 230 [V] AC, 50/60 [Hz], 7.5 [A] or 100-130 [V] AC, 50/60 [Hz], 15 [A] |

| 平均耗電 | 0.8 kW |

| 最大耗電 | 1.4 kW |

Sinterit Powder Handling Station(PHS)粉末處理站

| 尺寸 | 700 x 1000 x1580mm |

| 重量 | 150kg |

| 全套設備安裝空間 | 1700 x 2200 x 1800mm |

| 篩粉時間 | 25分鐘 |

| 內容包含 | 篩分模塊 內置粉末分離器 3個抽屜(儲物空間) 噴砂機托架 軟管、連接器、特殊3D列印真空孔 LED燈 金屬容器 |

| 粉末容量 | 最高8/1.8 (l/gal) |

| 電壓 | 110/230 [V] AC, 12 VDC 6,67 A, 80W |

噴砂機SLS-升級版

| 尺寸 | 760 x 550 x 720mm |

| 重量 | 30.5KG |

| 壓力 | 0.5 – 0.86 [MPa] / 72.5 – 125 [psi] |

| 工作區域 | 675 x 450 x 415mm |

| 最高磨料容量 | 10KG |

| 照明功率 | 8W |

| 電源 | 110 / 230 [V] AC, 50/60 [Hz] |

Sinterit ATEX工業吸塵器-吸塵器

| 尺寸 | 440 x 420 x 780 mm |

| 重量 | 25kg |

| 功率 | 1.1Kw |

| 電壓 | 230 V/AC, 50/60 Hz 110 V/AC, 50/60 Hz |

| 噪音等級 | (EN ISO 3744)77 dB(A) |

| 空氣流量(速率) | 215 [m 3 / h] |

| 吸入口尺寸 | 50 mm |

| 過濾器類型 | M級過濾 |

| 容量 | 40L |

| 包裝內容 | ATEX吸塵器+配件組+除粉器+手冊 |

Sinterit ATEX工業吸塵器-粉末分離器

| 尺寸 | 550 x 305 x 300 mm |

| 總重量 | 5公斤 |

| 風量 | 215 m 3 / h |

| 吸入口尺寸 | 32 mm |

| 容量 | 12L |

| 包裝內容 | Sinterit分離器+配件套 |

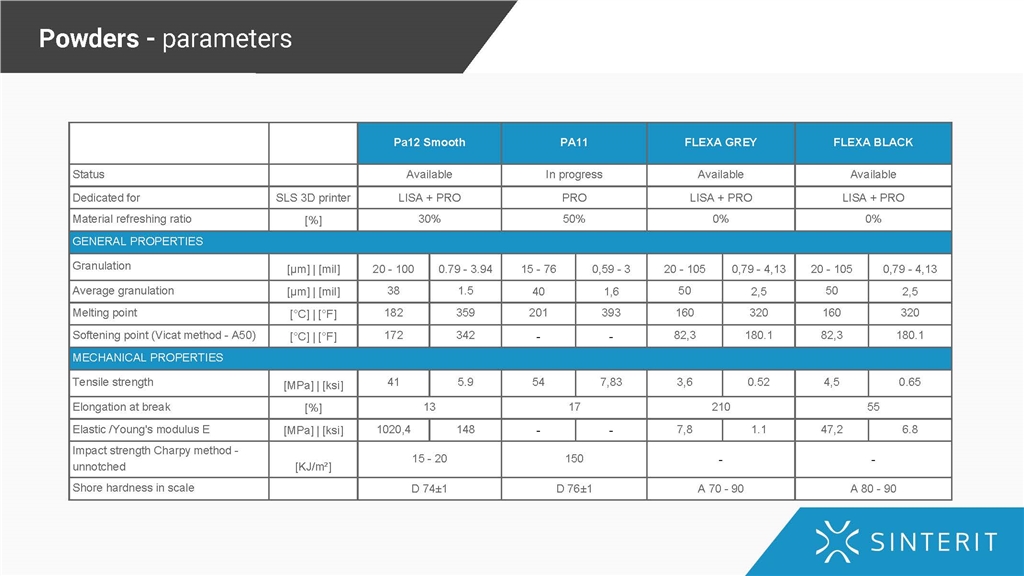

.粉末參數比較表