Sinterit | Product Model:

ST0040

Sinterit Powder Handling Station (PHS)

Subtotal

—

Sinterit Powder Handling Station (PHS) is backordered and will ship as soon as it is back in stock.

Choose add-on

Couldn't load pickup availability

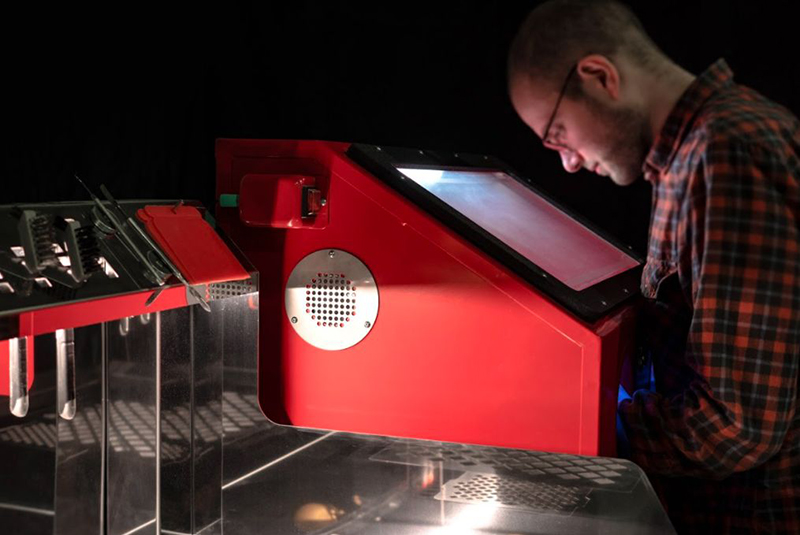

Sinterit Powder Handling Station (PHS)

The Sinterit Powder Handling Station (PHS) sets a new standard for post-sintering powder processing. Its ergonomic design facilitates smoother post-processing and powder recycling procedures, from initial sieving to complete filtration and reuse, while maintaining a clean working environment.

Product Features:

Integrate all powder printing processes in one place.

Ergonomic design

The necessary tools are readily available.

Easily remove powder in 5 simple steps.

It can be used with multiple 3D printers .

Powder post-processing: 5 simple steps

1. Preliminary powder screening

The large hole in the workbench allows unsintered powder to be poured in, simultaneously cleaning the printed objects and performing the first step of powder sieving. Excess powder flows from the hole into the sealed space below, leaving only the printed products to be cleaned above.

2. Detail cleaning

During detailed cleaning at the top of the fine dust chamber on the right (with a smaller mesh filter), the powder is drawn back into the dust chamber.

3. Integrate the work area (sandblasting machine)

A metal bracket is attached to the right side of the equipment, allowing the folding tray or sandblasting machine to be placed near the PHS working area, reducing working time and preventing powder from spreading outside the working area. (Specifically for Sinterit sandblasting machines and Sinterit XL sandblasting machines )

4. Clean the printing area and work area

The two-meter-long suction hose allows for easy movement within the Sinterit 3D printer and the entire PHS work area, cleaning the printer itself and the work area. All powder generated during cleaning can be reused.

5. Complete filtering and reuse

Finally, all the recovered powder is transferred to the screening module and then into a metal container. The sieve located below the workbench can filter and classify all the powder that falls out during the process and further process it by mixing the used powder with the fresh powder.

| size | 700 x 1000 x 1580mm |

| weight | 150kg |

| Complete equipment installation space | 1700 x 2200 x 1800mm |

| Sieving time | 25 minutes |

| Contents include | The sieving module has a built-in powder separator. 3 drawers (storage space) Sandblasting machine bracket hose, connector, special 3D printed vacuum hole LED light metal container |

| Powder capacity | Maximum 8/1.8 (l/gal) |

| Voltage | 110/230 [V] AC, 12 VDC 6,67 A, 80W |