Sinterit | Product Model:

ST0050

Sinterit ATEX industrial vacuum cleaners

Subtotal

—

Sinterit ATEX industrial vacuum cleaners is backordered and will ship as soon as it is back in stock.

Choose add-on

Couldn't load pickup availability

Sinterit ATEX industrial vacuum cleaners

The Sinterit ATEX industrial vacuum cleaner safely recycles and cleans the work environment. It is simple to use and quickly collects all the powder spilled during the 3D printing process, keeping the environment clean at all times and ensuring user safety. It automatically puts the collected powder into a dedicated 12L container without manual transfer. It can be easily poured into the Sinterit powder sieve or turned off and left for further processing.

Product Features:

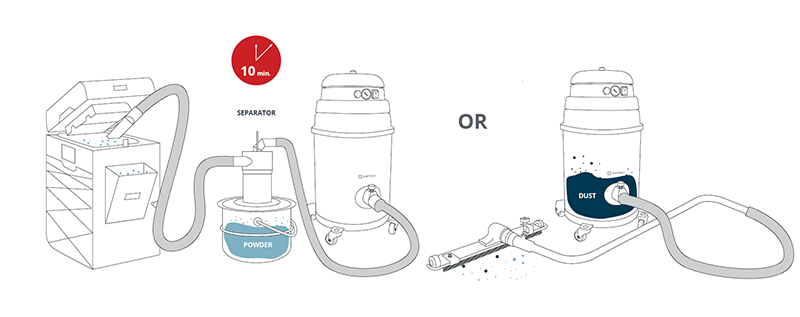

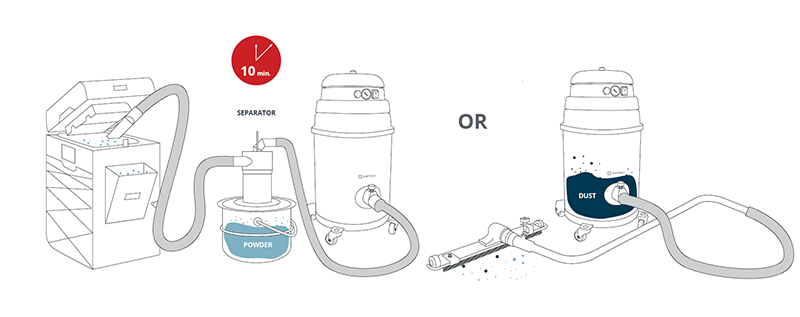

• Quick Powder Collection <br> When cleaning the Sinterit powder 3D printer , unused powder can be collected within 10 minutes, saving time and money. With the powder separator, all powder can be concentrated in the container and quickly sorted for the next production.

Clean working environment: Spilled powder is immediately recycled.

The Sinterit ATEX vacuum cleaner is easy to use and can quickly collect all the powder spilled during the 3D printing process, keeping the environment clean at all times and ensuring user safety.

Streamline workflow

The Sinterit ATEX vacuum cleaner comes equipped with a powder separator that automatically places collected powder into a dedicated 12L container, eliminating the need for manual transfer; it can be easily poured into the Sinterit powder sieve or turned off and left for further processing.

The Sinterit ATEX industrial vacuum cleaner safely recycles and cleans the work environment. It is simple to use and quickly collects all the powder spilled during the 3D printing process, keeping the environment clean at all times and ensuring user safety. It automatically puts the collected powder into a dedicated 12L container without manual transfer. It can be easily poured into the Sinterit powder sieve or turned off and left for further processing.

Product Features:

• Quick Powder Collection <br> When cleaning the Sinterit powder 3D printer , unused powder can be collected within 10 minutes, saving time and money. With the powder separator, all powder can be concentrated in the container and quickly sorted for the next production.

Clean working environment: Spilled powder is immediately recycled.

The Sinterit ATEX vacuum cleaner is easy to use and can quickly collect all the powder spilled during the 3D printing process, keeping the environment clean at all times and ensuring user safety.

Streamline workflow

The Sinterit ATEX vacuum cleaner comes equipped with a powder separator that automatically places collected powder into a dedicated 12L container, eliminating the need for manual transfer; it can be easily poured into the Sinterit powder sieve or turned off and left for further processing.

Vacuum cleaner

Click here to download the specifications (English version).

Powder Separator

Click here to download the specifications (English version).

| size | 440 x 420 x 780 mm |

| weight | 25kg |

| power | 1.1Kw |

| Voltage | 230 V/AC, 50/60 Hz 110 V/AC, 50/60 Hz |

| Noise Level | (EN ISO 3744) 77 dB(A) |

| Airflow rate | 215 [m³/h] |

| Inlet size | 50 mm |

| Filter type | M-level filtration |

| capacity | 40L |

| Packaging contents | ATEX vacuum cleaner + accessory set + dust remover + manual |

Powder Separator

| size | 550 x 305 x 300 mm |

| gross weight | 5 kg |

| air volume | 215 m³/h |

| Inlet size | 32 mm |

| capacity | 12L |

| Packaging contents | Sinterit Separator + Accessory Kit |