Roland | Product Model:

RL0003

SRM-20 benchtop CNC milling machine

Regular price

¥996,700 JPY

Unit price

/

Unavailable

Subtotal

—

SRM-20 benchtop CNC milling machine is backordered and will ship as soon as it is back in stock.

Choose add-on

Couldn't load pickup availability

SRM-20 benchtop CNC milling machine

Includes complete instructions and on-site installation.

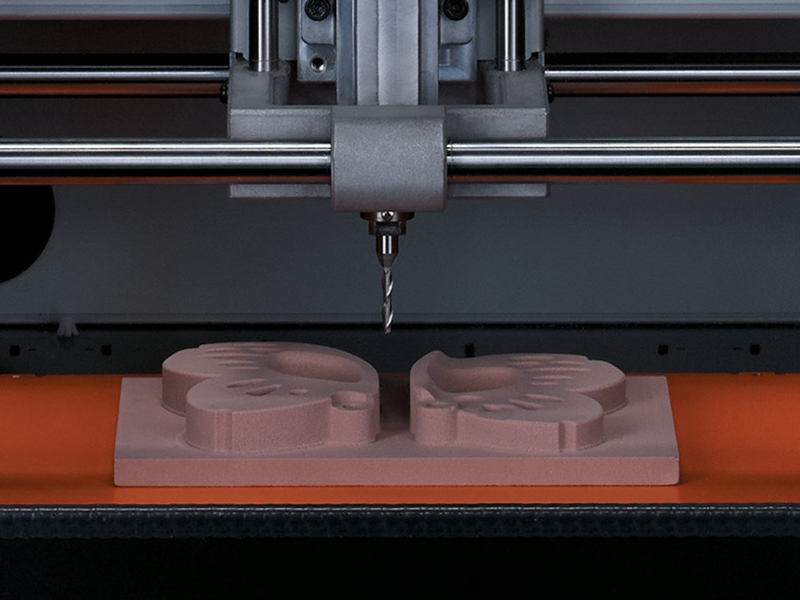

The SRM-20 is an affordable, compact, and powerful benchtop CNC milling machine that allows for the easy and convenient creation of realistic parts and prototypes in office, home, or classroom environments. For users with advanced CNC machining needs but lacking relevant expertise, the SRM-20 is the simplest and most precise small CNC milling machine in its class. The SRM-20 is a new generation of benchtop CNC tools , featuring a microstepping motor drive system, clear and precise forming technology, and an astonishing speed twice as fast as previous generations.

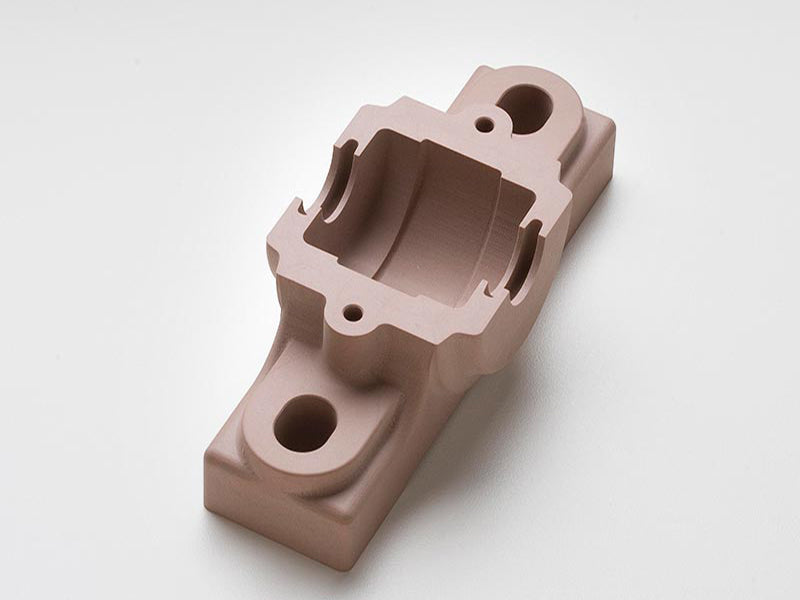

Precision and productivity

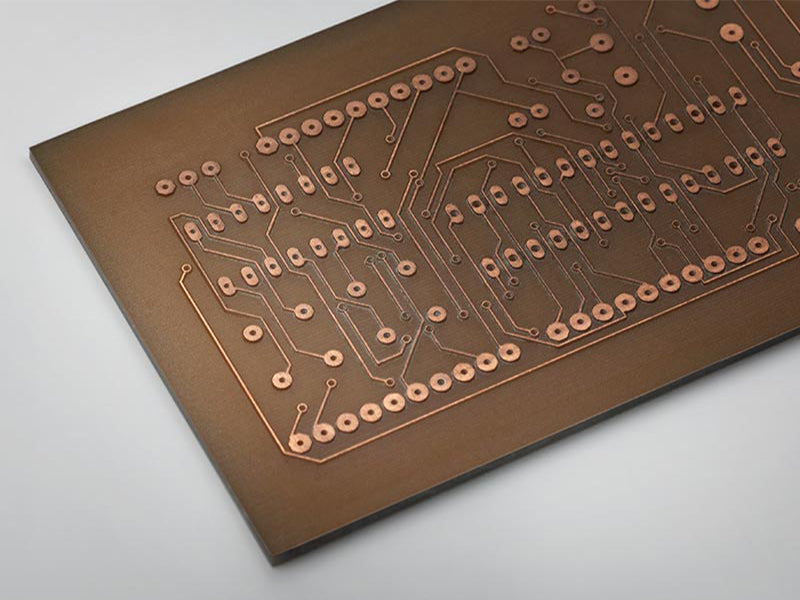

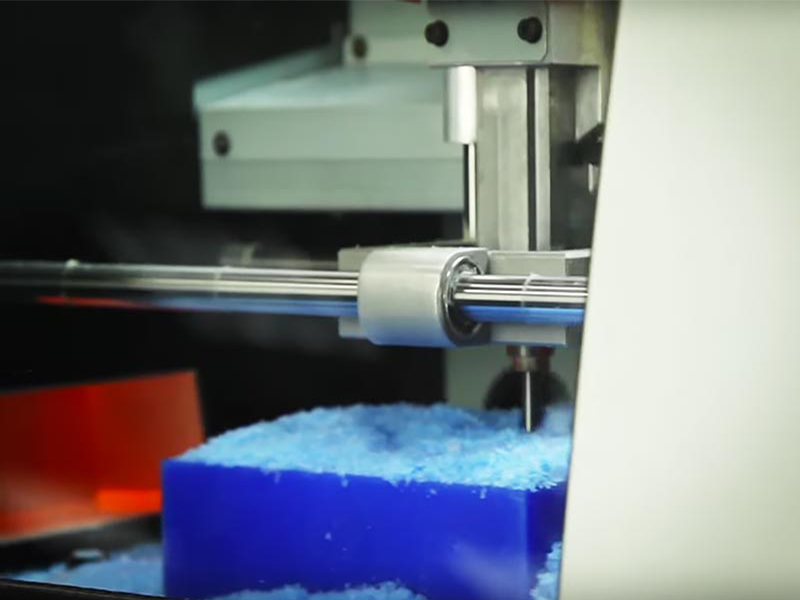

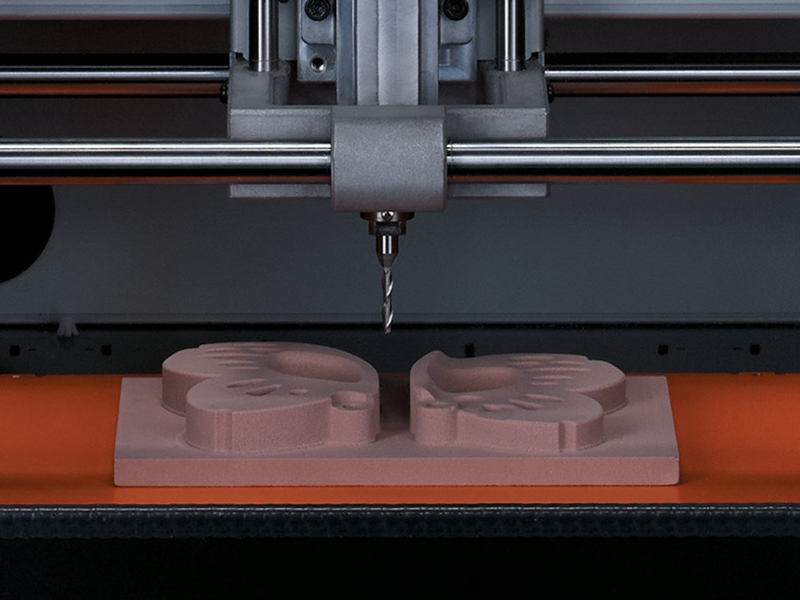

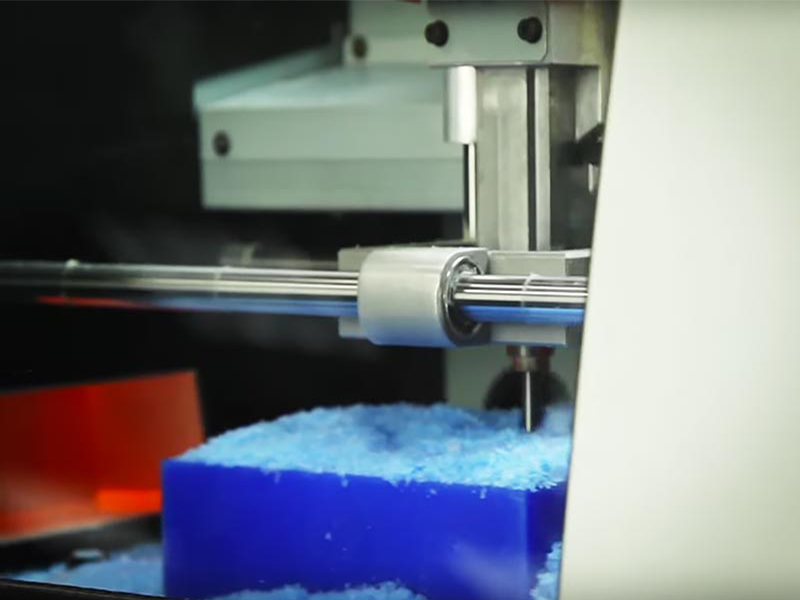

The SRM-20 can precisely cut various materials, including wax, wood, foam, acrylic, polyacetal, ABS, and PC sheets, allowing you to create realistic 3D prototypes. Common CNC applications include product invention, wax casting, industrial equipment, automotive prototyping, game development, and art production, enabling you to flexibly realize your imagination.

Multi-axis milling with X, Y, and Z control

The SRM-20 uses touch buttons and a VPanel controller to adjust speed, spindle speed, and milling on the entire X, Y, and Z axes, as well as a new independent chuck system for faster Z-axis start-up and quick tool change.

Features:

Easily perform CNC machining using VPanel

The SRM-20's VPanel controller features a simple interface that allows for tool position adjustment and cursor movement to set the cutting start point. Feed rate and spindle speed can be easily controlled via pause and resume operation, and X, Y, and Z axis machining can be performed using millimeter or inch data tracking.

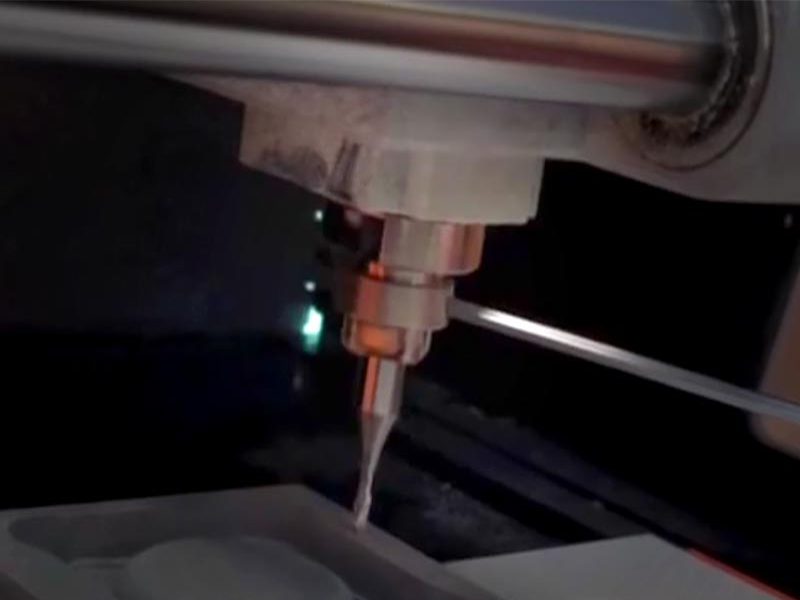

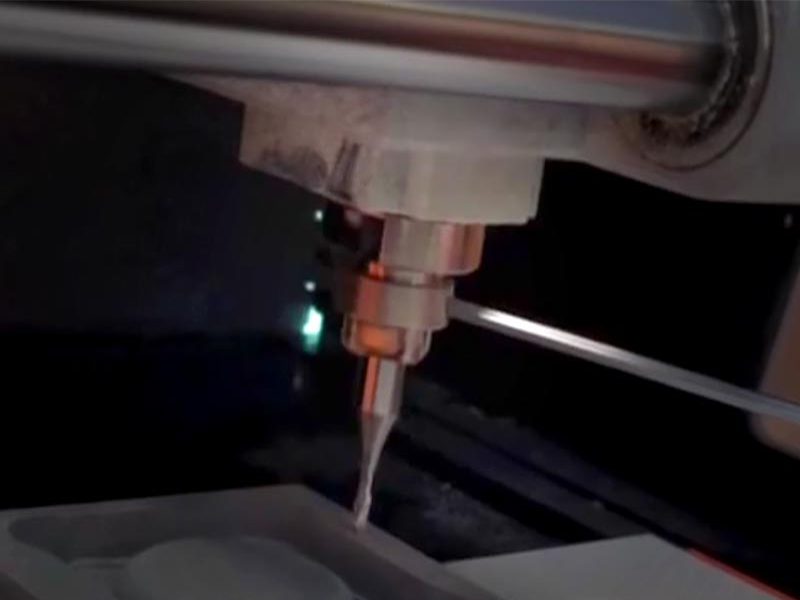

The efficient, independent chuck system allows for quicker Z-axis positioning and tool changes without needing to replace the spindle for different tool holder diameters.

Intelligent, safe, and clean.

The SRM-20's full-coverage design reduces dust and noise. It features viewing windows on both sides and an intelligent safety locking device that automatically pauses processing when the cover is opened and resumes when closed by selecting "continue," preventing any accidents. The SRM-20 incorporates several new technologies, such as an airtight design to prevent waste from entering the spindle and Y-axis, eliminating the impact of milling debris and ensuring smooth CNC operation over extended periods.

Suitable for the education system

The SRM-20 is ideal for classroom use, whether in design, technology, or industry. It enables students to create complex parts and test models, and CNC and 3D printers have become the preferred prototyping technologies for STEAM teachers in the classroom.

Stability and After-Sales Service: In addition to stable and reliable advanced technology, SanDiMa offers a one-year original manufacturer's warranty, complete training, and on-site installation. Equip your business with a simple and precise desktop CNC machining center and accelerate your product flow now. Contact us today for further purchasing information.

Includes complete instructions and on-site installation.

The SRM-20 is an affordable, compact, and powerful benchtop CNC milling machine that allows for the easy and convenient creation of realistic parts and prototypes in office, home, or classroom environments. For users with advanced CNC machining needs but lacking relevant expertise, the SRM-20 is the simplest and most precise small CNC milling machine in its class. The SRM-20 is a new generation of benchtop CNC tools , featuring a microstepping motor drive system, clear and precise forming technology, and an astonishing speed twice as fast as previous generations.

Precision and productivity

The SRM-20 can precisely cut various materials, including wax, wood, foam, acrylic, polyacetal, ABS, and PC sheets, allowing you to create realistic 3D prototypes. Common CNC applications include product invention, wax casting, industrial equipment, automotive prototyping, game development, and art production, enabling you to flexibly realize your imagination.

Multi-axis milling with X, Y, and Z control

The SRM-20 uses touch buttons and a VPanel controller to adjust speed, spindle speed, and milling on the entire X, Y, and Z axes, as well as a new independent chuck system for faster Z-axis start-up and quick tool change.

Features:

Easily perform CNC machining using VPanel

The SRM-20's VPanel controller features a simple interface that allows for tool position adjustment and cursor movement to set the cutting start point. Feed rate and spindle speed can be easily controlled via pause and resume operation, and X, Y, and Z axis machining can be performed using millimeter or inch data tracking.

The efficient, independent chuck system allows for quicker Z-axis positioning and tool changes without needing to replace the spindle for different tool holder diameters.

Intelligent, safe, and clean.

The SRM-20's full-coverage design reduces dust and noise. It features viewing windows on both sides and an intelligent safety locking device that automatically pauses processing when the cover is opened and resumes when closed by selecting "continue," preventing any accidents. The SRM-20 incorporates several new technologies, such as an airtight design to prevent waste from entering the spindle and Y-axis, eliminating the impact of milling debris and ensuring smooth CNC operation over extended periods.

Suitable for the education system

The SRM-20 is ideal for classroom use, whether in design, technology, or industry. It enables students to create complex parts and test models, and CNC and 3D printers have become the preferred prototyping technologies for STEAM teachers in the classroom.

Stability and After-Sales Service: In addition to stable and reliable advanced technology, SanDiMa offers a one-year original manufacturer's warranty, complete training, and on-site installation. Equip your business with a simple and precise desktop CNC machining center and accelerate your product flow now. Contact us today for further purchasing information.

| model | SRM-20 |

| Cuttable materials | Wax, wood, foam, acrylic, polyacetate, ABS, PC board |

| XYZ axis travel | 203.2 (X) x 152.4 (Y) x 60.5 (Z) mm |

| working area | 232.2 (X) x 156.6 (Y) mm |

| Distance between spindle head and worktable | Maximum value: 130.75mm |

| Loadable workpiece weight | 2kg |

| XYZ axis drive system | Stepper motor |

| Operation speed | 6 – 1800mm/min |

| Software resolution | 0.01mm/step (RML-1), 0.001mm/step (NC code) |

| Machine resolution | 0.000998594 mm/step |

| spindle motor | DC motor Type 380 |

| spindle speed | Adjustable: 3,000 – 7,000 rpm |

| Cutting tools | Clamp type |

| Transmission interface | USB |

| Control settings | RML-1, NC code |

| power supply | Machine: DC24V, 2.5A Dedicated power supply: AC 100-240V ±10%, 50/60Hz |

| Power consumption | 50W |

| Noise Level | Usage status: less than 65 dB (A) Standby mode: less than 45 dB (A) |

| External dimensions | 451.0 (W) x 426.6 (D) x 426.2 (H) mm |

| weight | 19.6 kg |

| Work environment | Temperature: 5°C to 40°C Humidity: 35 to 80% (non-condensing) |

| Included accessories | USB cable, power supply, power cord, cutting tools, clamps, screws, wrenches, hex wrenches, positioning pins, double-sided tape, start-up instructions |