Mayku | Product Model:

MK0001

10% off

10% off

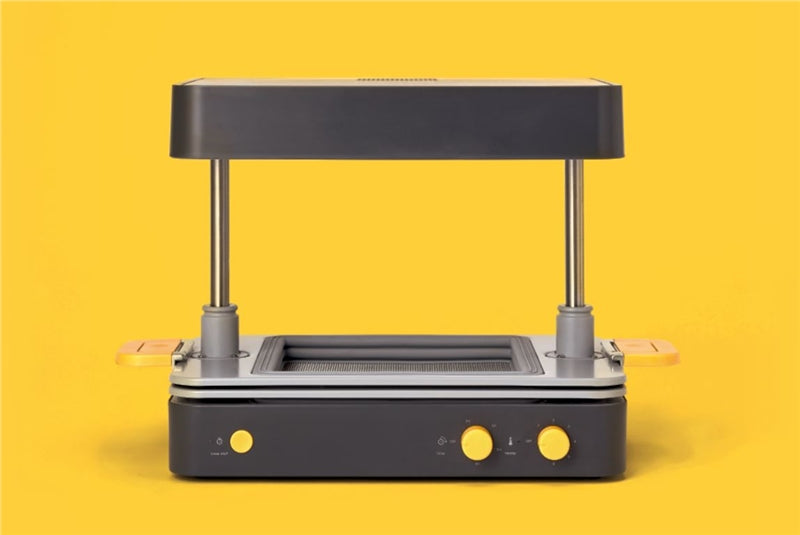

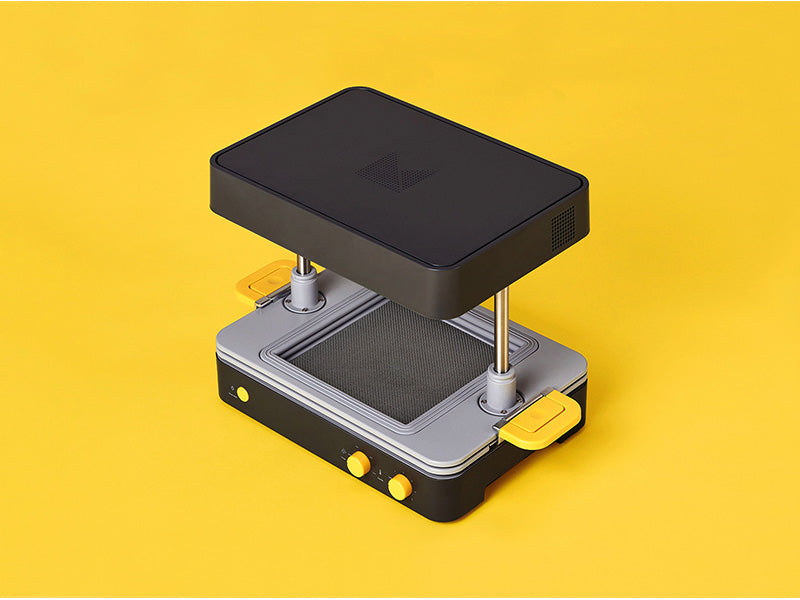

FormBox desktop vacuum forming machine

Sale price

¥129,900 JPY

Regular price

¥144,900

Unit price

/

Unavailable

Subtotal

—

FormBox desktop vacuum forming machine is backordered and will ship as soon as it is back in stock.

Choose add-on

Couldn't load pickup availability

FormBox desktop vacuum forming machine

FormBox brings industrial vacuum forming technology to the desktop, powered by any household vacuum cleaner and compatible with a wide variety of materials; fast, economical, multifunctional, and easy to use, it quickly turns your ideas into reality and mass production. SanDiMa is the sole authorized distributor of Mayku FormBox in Taiwan, providing comprehensive technical repair and after-sales service.

Unlimited copying

Mayku FormBox can complete molds in seconds, accelerating product development cycles and making the dream simpler than ever. Custom molds or packaging can be completed in just four steps:

Step 1: Place the 3D printed object, laser-processed object , or any sample prototype onto the FormBox platform.

Step 2: Press the material sheet down into the FormBox, and the mold will be automatically completed within a few seconds.

Step 3: Fill the mold with any materials you like, such as chocolate, resin , plaster, or cement.

Step 4: Once the product is removed, mass production can begin, and the outer packaging can be customized using FormBox!

.Features:

Material placement: The machine features an innovative material sheet loading system and an easy-to-use quick-press handle.

Ultra-fine mesh: composed of an ultra-fine mesh structure, which increases airflow.

Universal connector: With the universal connector, FormBox can be used with any household vacuum cleaner.

No need to wait

No need for outsourcing production or waiting in line; the mold is in your hands in just a few seconds.

Rapid Creativity

Quickly test ideas and make modifications until they are satisfactory. The desktop device is streamlined and affordable, and can be used immediately in the office or studio.

Cost savings

You can make just one! There is no minimum order quantity (MOQ). Whether you make 1 or 100, it only costs the price of one material piece.

Compared to outsourcing production, it saves thousands of dollars.

Bringing industrial-grade vacuum forming technology to the table can create more value for businesses.

Collaborating with materials companies worldwide

Different materials can be used to create designs in various forms, from product packaging to cultural and creative products or food molds, allowing you to choose according to your needs.

Product Contents:

Mayku FormBox Vacuum Forming Machine - 1 unit; Transparent Injection Sheets - 20 sheets; White Injection Sheets - 20 sheets; Beginner Kit - 3 types of injection molding materials - 1 kg

Extended Warranty - 2-Year Universal Vacuum Connector Set

A set of power connectors in this area

[Vacuum Machine Applications] Learn Online at Home During the Pandemic! FormBox Free Course 11 Lessons (Part 1)

[Vacuum Machine Applications] Learn Online at Home During the Pandemic! FormBox Free Course 11 Lessons (Part 2)

FormBox brings industrial vacuum forming technology to the desktop, powered by any household vacuum cleaner and compatible with a wide variety of materials; fast, economical, multifunctional, and easy to use, it quickly turns your ideas into reality and mass production. SanDiMa is the sole authorized distributor of Mayku FormBox in Taiwan, providing comprehensive technical repair and after-sales service.

Unlimited copying

Mayku FormBox can complete molds in seconds, accelerating product development cycles and making the dream simpler than ever. Custom molds or packaging can be completed in just four steps:

Step 1: Place the 3D printed object, laser-processed object , or any sample prototype onto the FormBox platform.

Step 2: Press the material sheet down into the FormBox, and the mold will be automatically completed within a few seconds.

Step 3: Fill the mold with any materials you like, such as chocolate, resin , plaster, or cement.

Step 4: Once the product is removed, mass production can begin, and the outer packaging can be customized using FormBox!

.Features:

Material placement: The machine features an innovative material sheet loading system and an easy-to-use quick-press handle.

Ultra-fine mesh: composed of an ultra-fine mesh structure, which increases airflow.

Universal connector: With the universal connector, FormBox can be used with any household vacuum cleaner.

No need to wait

No need for outsourcing production or waiting in line; the mold is in your hands in just a few seconds.

Rapid Creativity

Quickly test ideas and make modifications until they are satisfactory. The desktop device is streamlined and affordable, and can be used immediately in the office or studio.

Cost savings

You can make just one! There is no minimum order quantity (MOQ). Whether you make 1 or 100, it only costs the price of one material piece.

Compared to outsourcing production, it saves thousands of dollars.

Bringing industrial-grade vacuum forming technology to the table can create more value for businesses.

Collaborating with materials companies worldwide

Different materials can be used to create designs in various forms, from product packaging to cultural and creative products or food molds, allowing you to choose according to your needs.

Product Contents:

Mayku FormBox Vacuum Forming Machine - 1 unit; Transparent Injection Sheets - 20 sheets; White Injection Sheets - 20 sheets; Beginner Kit - 3 types of injection molding materials - 1 kg

Extended Warranty - 2-Year Universal Vacuum Connector Set

A set of power connectors in this area

[Vacuum Machine Applications] Learn Online at Home During the Pandemic! FormBox Free Course 11 Lessons (Part 1)

[Vacuum Machine Applications] Learn Online at Home During the Pandemic! FormBox Free Course 11 Lessons (Part 2)

| Appearance height | 315mm |

| External length (including handle) | 466mm |

| External width | 274mm |

| Molding area | 200mm x 200mm |

| Molding depth | 130mm |

| weight | 13KG |

| Ceramic heater temperature | 160°C - 340°C |

| Available materials | PETG, HIPS, PLA , Polypropylene, Polycarbonate, Polystyrene, PVC, Kydex, HDPE, LDPE, EVA foam, TPU , ABS , Extruded Acrylic |

| Prototype materials | 3D printing: FDM PLA , FDM ABS, FDM nylon , most 3D printing , most SLA 3D finished products, most SLS 3D printed products, wood, CNC milling and injection molding, plastics such as ABS or nylon , steel, aluminum, plaster, polyurethane rubber, hardened clay, silicone, paper and cards, tempered glass. |

| Material thickness | Thermoplastic sheets with a thickness of 0.25 to 1.5 mm |

| power supply | 110V 5A 1000W (depending on region) 240V 5A 1000W (depending on region) 2000W maximum power consumption |