FLUX | Product Model:

FX0002

14% off

14% off

FLUX beambox laser cutting machine

Sale price

¥249,300 JPY

Regular price

¥289,300

Unit price

/

Unavailable

Subtotal

—

FLUX beambox laser cutting machine is backordered and will ship as soon as it is back in stock.

Choose add-on

Couldn't load pickup availability

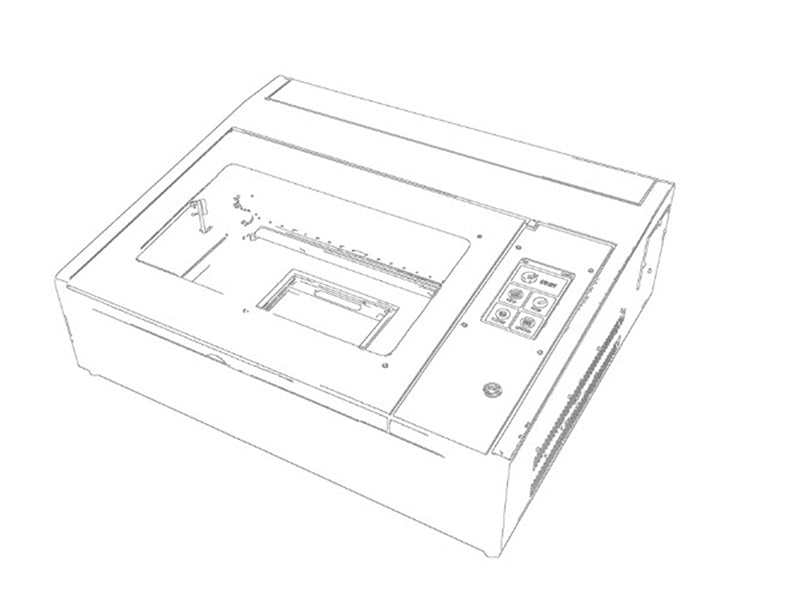

FLUX beambox laser cutting machine

The FLUX beambox uses a high-power laser system that can precisely cut and carve materials such as wood, leather, acrylic, and glass; the Beambox's high-efficiency linear guide rails ensure that every carving you create achieves industrial-grade quality.

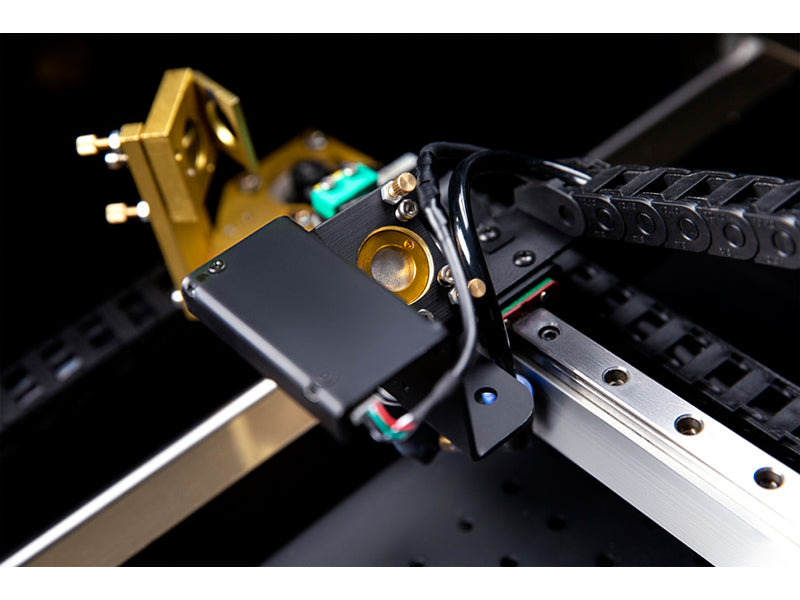

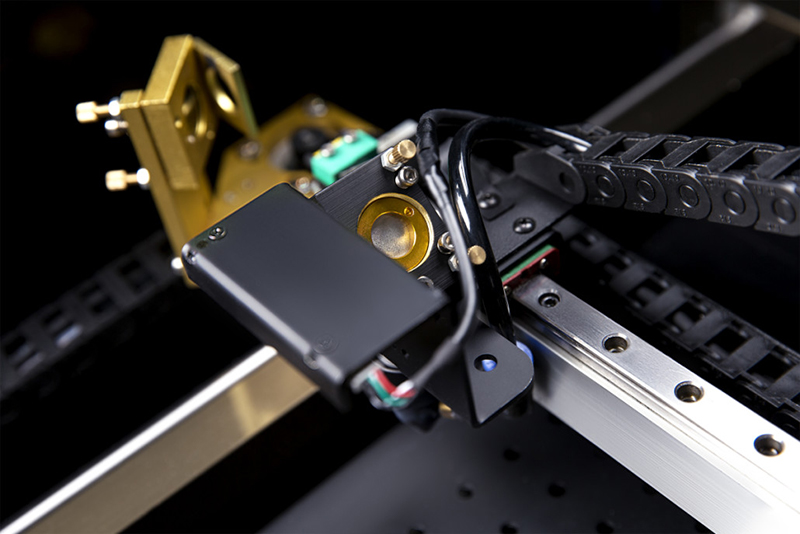

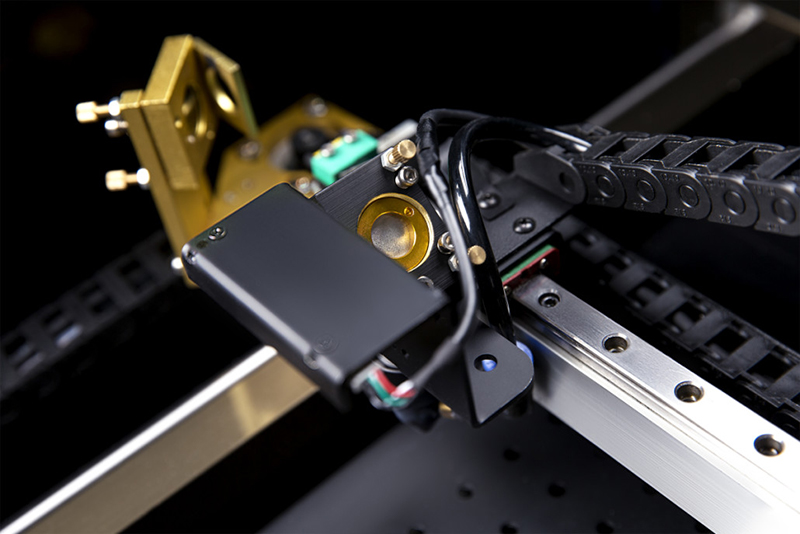

Industrial-grade engraving performance

The FLUX beambox uses the industry's preferred linear guide rails, and the laser features high efficiency and durability. The internal water cooling system keeps the parts at the appropriate ambient temperature, and the exhaust system can remove exhaust gases to ensure safety during operation.

Precise and accurate preview

Using Beambox's high-resolution touchscreen, you can directly check the machine status and work progress; the built-in HD high-definition camera can preview the path and engraved graphics, effectively improving work stability.

Large space, large imagination

The FLUX beambox has a working area of up to 40 x 37.5 cm² , with a cutting thickness of up to 10 mm. Paired with professional software Beam Studio for editing, adjusting, and setting cutting/carving power and speed, anyone can enjoy the fun of creation.

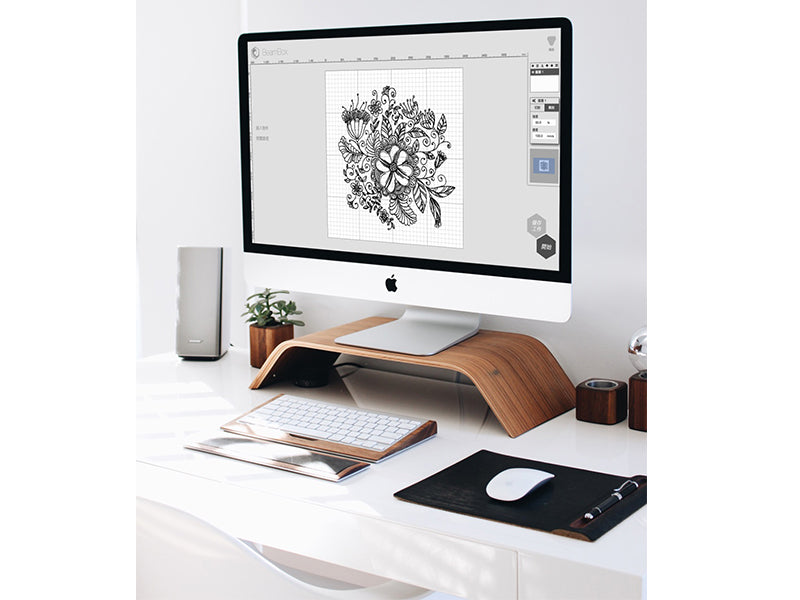

The software is simple and easy to use.

The FLUX beambox laser cutter can be controlled via network connection, allowing multiple computers to use it simultaneously; it supports JPG / PNG / SVG / DXF file formats, making it easy to edit files using design software such as Adobe Illustrator and AutoCAD.

Diverse application materials

Laser cutting machines offer designers a wide range of creative possibilities. With a simple and fast workflow, various types of products can be produced. Contact us now for more details.

The FLUX beambox uses a high-power laser system that can precisely cut and carve materials such as wood, leather, acrylic, and glass; the Beambox's high-efficiency linear guide rails ensure that every carving you create achieves industrial-grade quality.

Industrial-grade engraving performance

The FLUX beambox uses the industry's preferred linear guide rails, and the laser features high efficiency and durability. The internal water cooling system keeps the parts at the appropriate ambient temperature, and the exhaust system can remove exhaust gases to ensure safety during operation.

Precise and accurate preview

Using Beambox's high-resolution touchscreen, you can directly check the machine status and work progress; the built-in HD high-definition camera can preview the path and engraved graphics, effectively improving work stability.

Large space, large imagination

The FLUX beambox has a working area of up to 40 x 37.5 cm² , with a cutting thickness of up to 10 mm. Paired with professional software Beam Studio for editing, adjusting, and setting cutting/carving power and speed, anyone can enjoy the fun of creation.

The software is simple and easy to use.

The FLUX beambox laser cutter can be controlled via network connection, allowing multiple computers to use it simultaneously; it supports JPG / PNG / SVG / DXF file formats, making it easy to edit files using design software such as Adobe Illustrator and AutoCAD.

(Simple 3-step operation: Import using design software or existing files > Edit in Beamo Studio > Connect to FLUX beambox pro, confirm the operating mode, and you can start making.)

Diverse application materials

| Material | Cutting | engraving |

| wood | 5mm | Can |

| Acrylic | 5mm | Can |

| leather | 6mm | Can |

| cardboard | 7mm | Can |

| felt | 10mm | Can |

| rubber | 5mm | Can |

| paper | 5mm | Can |

| Glass | No | Can |

| Anode metal | No | Can |

| Stainless steel (requires FLUX stainless steel spray) | No | Can |

Click here for usage instructions

Click here to go to the free resource library

Click here for a quick and easy guide to the FLUX series laser cutting machines.

Click here to go to the free resource library

Click here for a quick and easy guide to the FLUX series laser cutting machines.

Laser cutting machines offer designers a wide range of creative possibilities. With a simple and fast workflow, various types of products can be produced. Contact us now for more details.

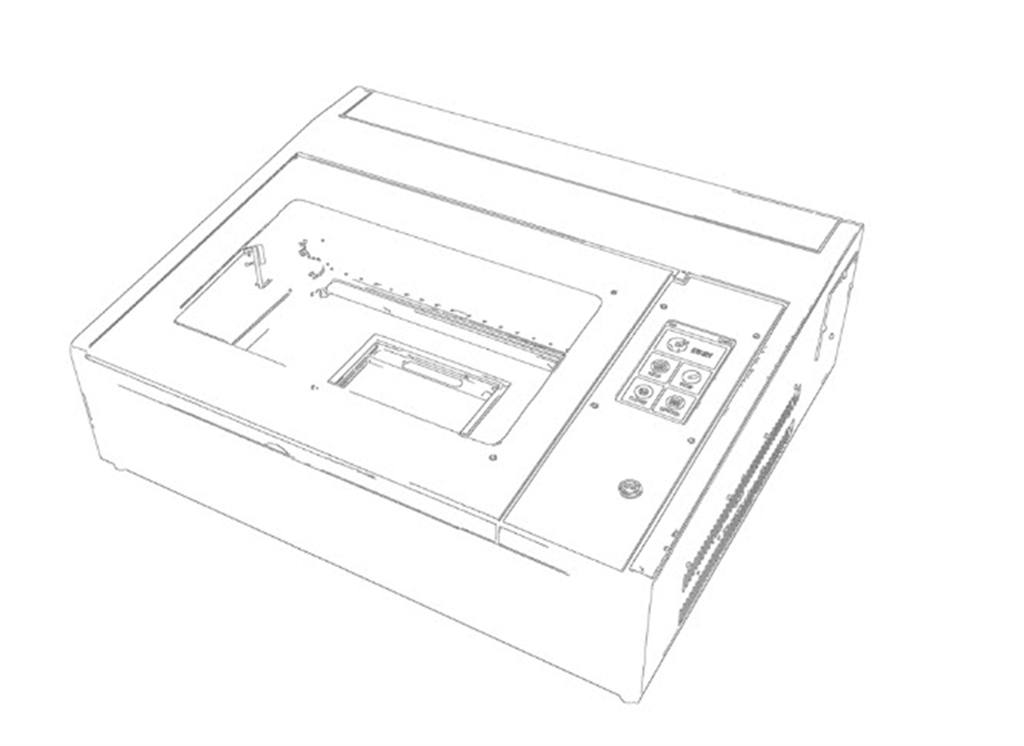

| 尺寸 | 25 x 83 x 67 cm |

| 重量 | 40 kg |

| 最大工作區域 | 40 x 37.5 cm |

| 相機預覽區域 | 40 x 36 cm |

| 工作區域深度 | 8 cm |

| 電力需求 | AC 110V |

| 觸控面板 | 1024 x 600 LCD |

| 相機鏡頭 | HD CMOS |

| 傳輸介面 | Wi-Fi / Ethernet |

| 雷射規格 | 40 W CO2 Laser |

| 雷射波長 | 10640 nm |

| 雕刻速度 | 0 ~ 300 mm/s |

| 切割厚度 | 0 - 10 mm (視材料而定) |

| 軟體運作模式 | 路徑/填充 (黑白、漸層) |

| 作業系統 | Windows / macOSX / Linux |

| 檔案格式 | JPG / PNG / SVG / DXF |

*注意:FLUX危險材料

・PVC / 聚氯乙烯

PVC 是常見,但實際上不可以進行雷射加工的材料,燃燒時會產生 HCl (鹽酸氣)危害肺部健康、腐蝕機器零件。除此之外,PVC 燃燒時亦會產生戴奧辛或多氯聯苯等高度致癌物質,是劇毒。PVC 常以貼紙、薄膜或是透明板材的方式呈現,例如卡典西德。如果遇到貼紙類的材料,切勿切到 PVC。

・ABS / 丙烯腈-丁二烯-苯乙烯共聚物

ABS 也是常見,但實際上不建議進行雷射加工的材料,不完全燃燒時有機會產生 A、 B 跟 S,也就是丙烯腈、丁二烯、苯乙烯,分別為 2B 類、1 類、2B 類致癌物質,對人體皆有刺激性。

・學名中有氯、苯、氨、氟、酚、醛,或是分子式中有六角型苯環的塑膠

擁有以上元素或是有機結構的塑膠分子燃燒時,產生致癌及有毒物質的機會極高,不建議進行雷射加工。

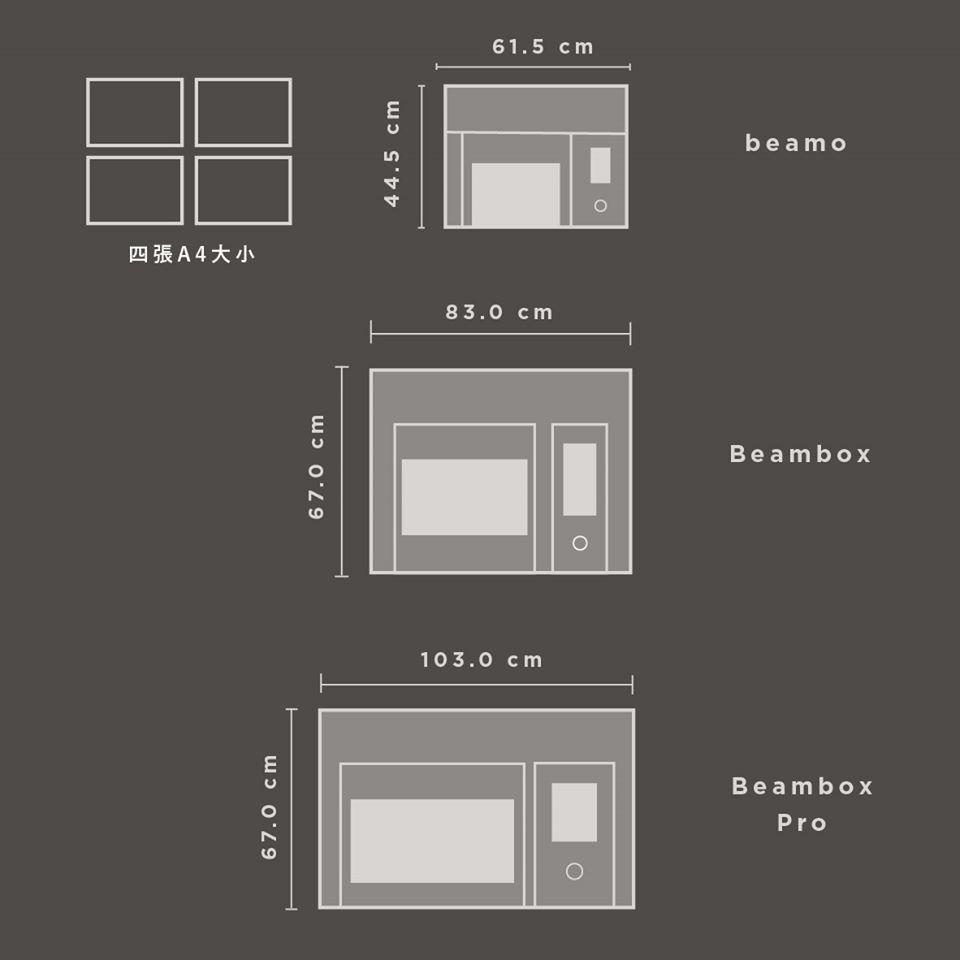

FLUX系列雷射切割機尺寸