Bambu Lab | Product Model:

BLSP016

Sold out

5% off

5% off

Topzhu Bambu Lab H2D AMS COMBO 3D Printer Bundle [Extended Warranty]

Sale price

¥528,600 JPY

Regular price

¥554,600

Unit price

/

Unavailable

Subtotal

—

Topzhu Bambu Lab H2D AMS COMBO 3D Printer Bundle [Extended Warranty] is backordered and will ship as soon as it is back in stock.

Choose add-on

Couldn't load pickup availability

Topzhu Bambu Lab H2D AMS COMBO 3D Printer Bundle [Extended Warranty]

* Additional 3 months, for a total of 15 months of 'enhanced warranty' + reinforced packaging

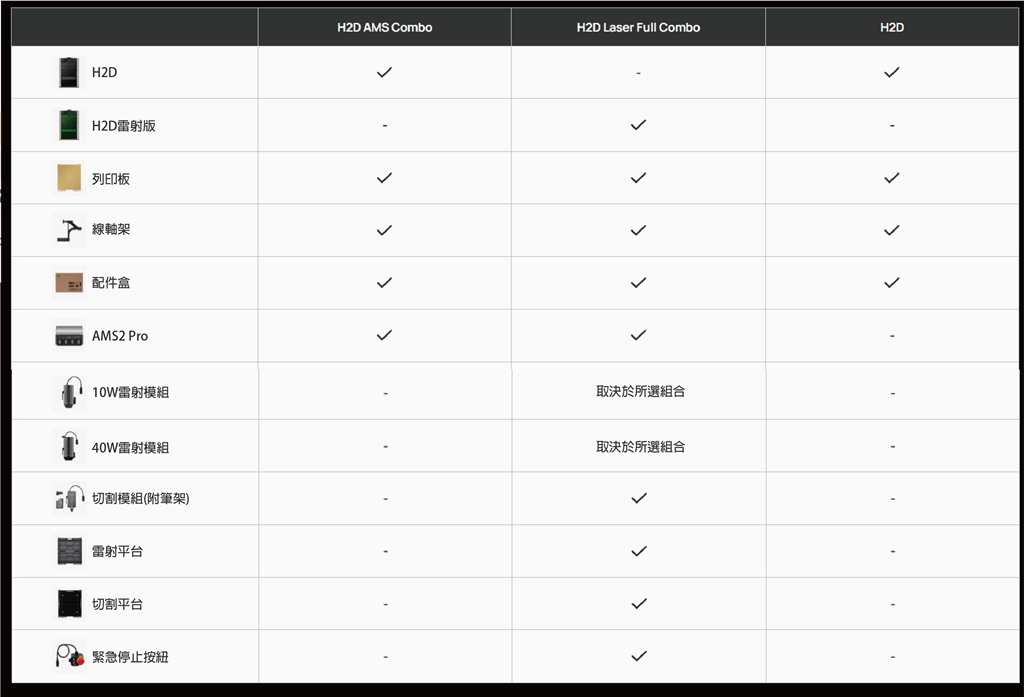

The H2D AMS COMBO 3D printer bundle provides everything you need, ready to use right out of the box, allowing for quick setup and excellent value! Check out what's included:

The H2D AMS COMBO 3D printer bundle provides everything you need, ready to use right out of the box, allowing for quick setup and excellent value! Check out what's included:

![Bambu Lab X1 Carbon Combo 3D Printer Bundle [Extended Warranty] Bambu Lab X1 Carbon Combo 3D列印機 同捆包【加強保固】](https://3dmart.com.tw/upload/Article2025/mark/0408/H2DAMS%e5%90%8c%e6%8d%86.png)

The bundle includes:

1. Bambu Lab H2D AMS COMBO 3D Printer [Enhanced Warranty]

2. Collector's Turbo-96P All-Function Dry Box

3.3D Printing Glue - Magigoo Original

4. Magigoo Pro PA 3D Printing Adhesive

5. Bambu Lab H2D Nozzle Series - 0.6mm Hardened Steel Nozzle

6. Bambu Lab H2D Nozzle Series - 0.8mm Hardened Steel Nozzle

7. Bambu Lab Smooth PEI Printing Platform Series - H2D

8. Bambu Lab PLA (one each of black, white, red, and blue)

9. Bambu Lab PLA Support Material

10. Bambu Lab PAHT-CF Black

11. Bambu Lab ABS - Black

12. Bambu Lab Shock-Absorbing Foot Pads - H2D

13. Hot-end silicone sleeve - H2D series

14. Lubricating oil (paste form)

15. Lubricating oil (sewing machine oil)

**Additional packing**

**Warranty + 3 months** ▶ This means a total of 15 months of 'enhanced warranty'

2. Collector's Turbo-96P All-Function Dry Box

3.3D Printing Glue - Magigoo Original

4. Magigoo Pro PA 3D Printing Adhesive

5. Bambu Lab H2D Nozzle Series - 0.6mm Hardened Steel Nozzle

6. Bambu Lab H2D Nozzle Series - 0.8mm Hardened Steel Nozzle

7. Bambu Lab Smooth PEI Printing Platform Series - H2D

8. Bambu Lab PLA (one each of black, white, red, and blue)

9. Bambu Lab PLA Support Material

10. Bambu Lab PAHT-CF Black

11. Bambu Lab ABS - Black

12. Bambu Lab Shock-Absorbing Foot Pads - H2D

13. Hot-end silicone sleeve - H2D series

14. Lubricating oil (paste form)

15. Lubricating oil (sewing machine oil)

**Additional packing**

**Warranty + 3 months** ▶ This means a total of 15 months of 'enhanced warranty'

One-year warranty & repair instructions

For Bambu Lab equipment purchases, Santima offers both standard and enhanced warranty options . For any operational inquiries, please contact Santima via email.

• If the machine malfunctions, please fill out the technical support form first. If the engineer assesses that the damage is not caused by human error, the following steps can be taken:

👨💻【 Enhanced Warranty Service】

Free round-trip shipping | Free testing | Free repair

San Di Ma will send someone to collect repair equipment free of charge. → Sandyma engineer repairs → After completion, Sandyma dispatches a vehicle to return it.

• Be sure to use the original complete packaging (outer box, protective foam, etc.) and include all original accessories (e.g., power supply, SD card, cable, printing materials used at the time, etc.) to avoid any omissions in the repair process.

• The engineer assessed the damage as being caused by human error or unauthorized modification . For non-human-caused damage, original manufacturer repair and warranty services are available. Consumables (such as spray nozzles) and spare parts are not covered by the warranty.

• All operation training is quoted separately by a Sandima specialist. You can fill out the contact form to inquire.

Topzhu Bambu Lab H2D 3D Printer Series

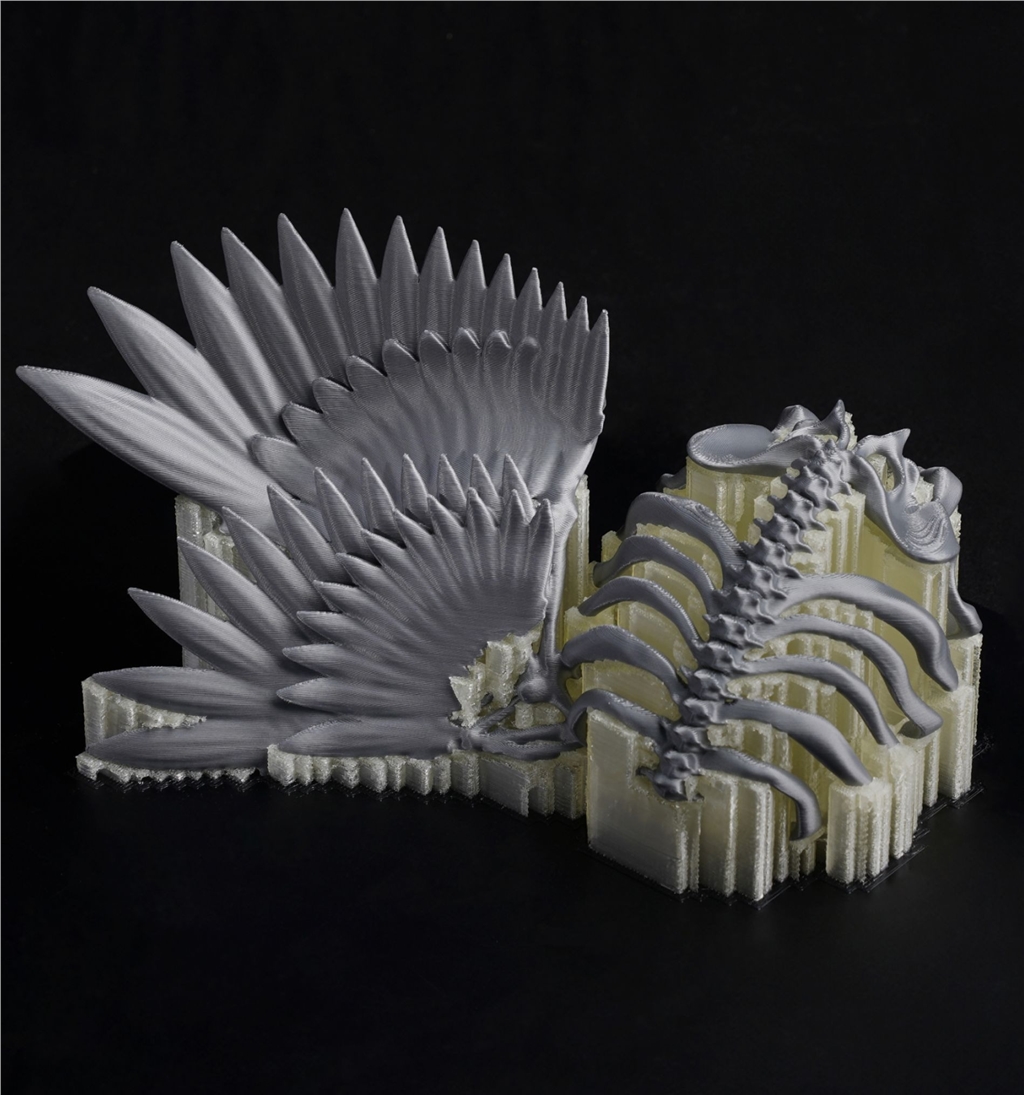

Flexible and rigid materials can be obtained in a single print, at low cost and with special materials.

By combining flexible and rigid materials in a single print, an impressive interlocking structure and innovative design that transcends traditional manufacturing methods are created.

Pairing high-performance materials with standard materials and using premium materials only when necessary further improves material efficiency.

Special support materials

Perfect support material that reduces waste, cleanup, and reloading.

Printing with support materials is no longer a headache.

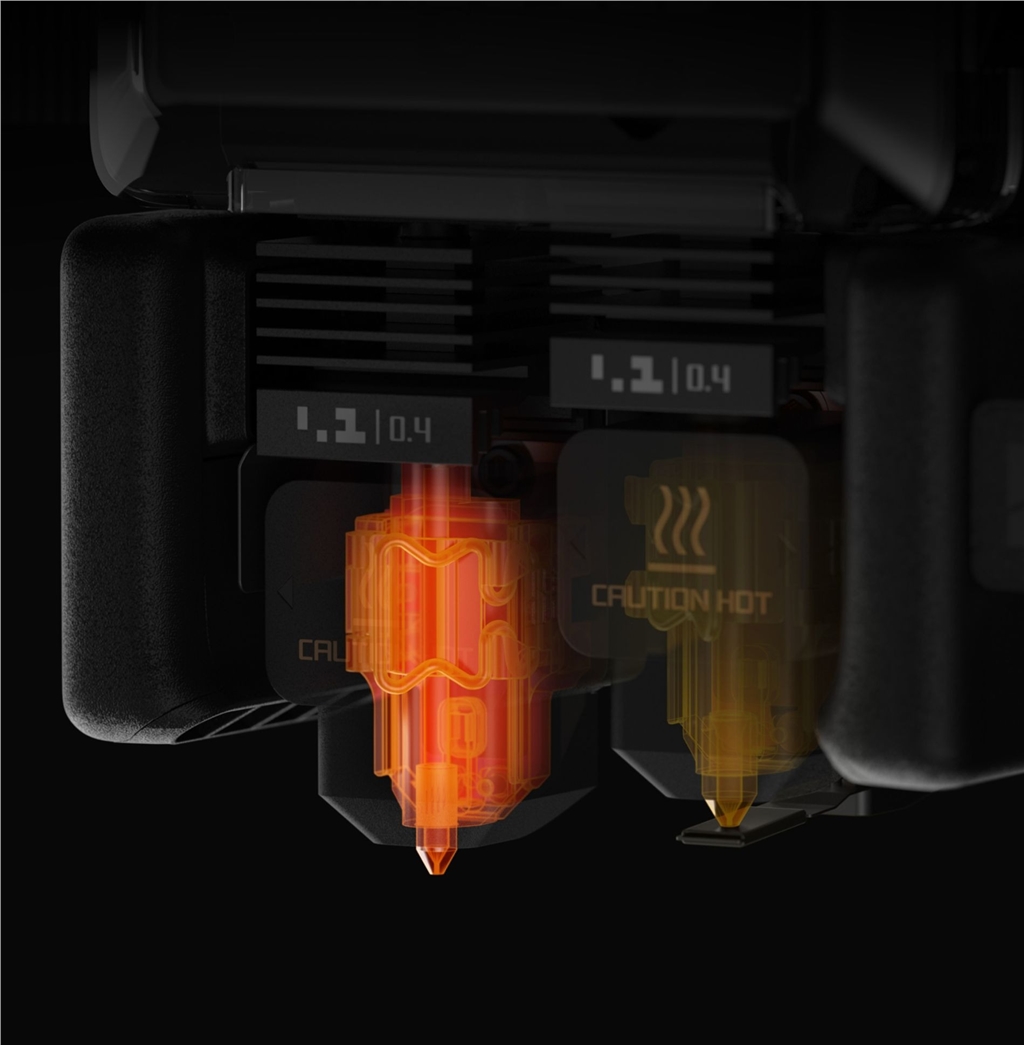

With H2D's dual-nozzle setup, one nozzle can be reserved for dedicated support material, making printing safer and providing a more perfect support interface.

High-efficiency multi-color printing

Fast and efficient multicolor printing

Dual-nozzle printing can reduce the cleaning cycle for multi-color printing.

H2D's intelligent algorithm can calculate the optimal amount of wire used, maximizing dual-nozzle efficiency and saving time and materials.

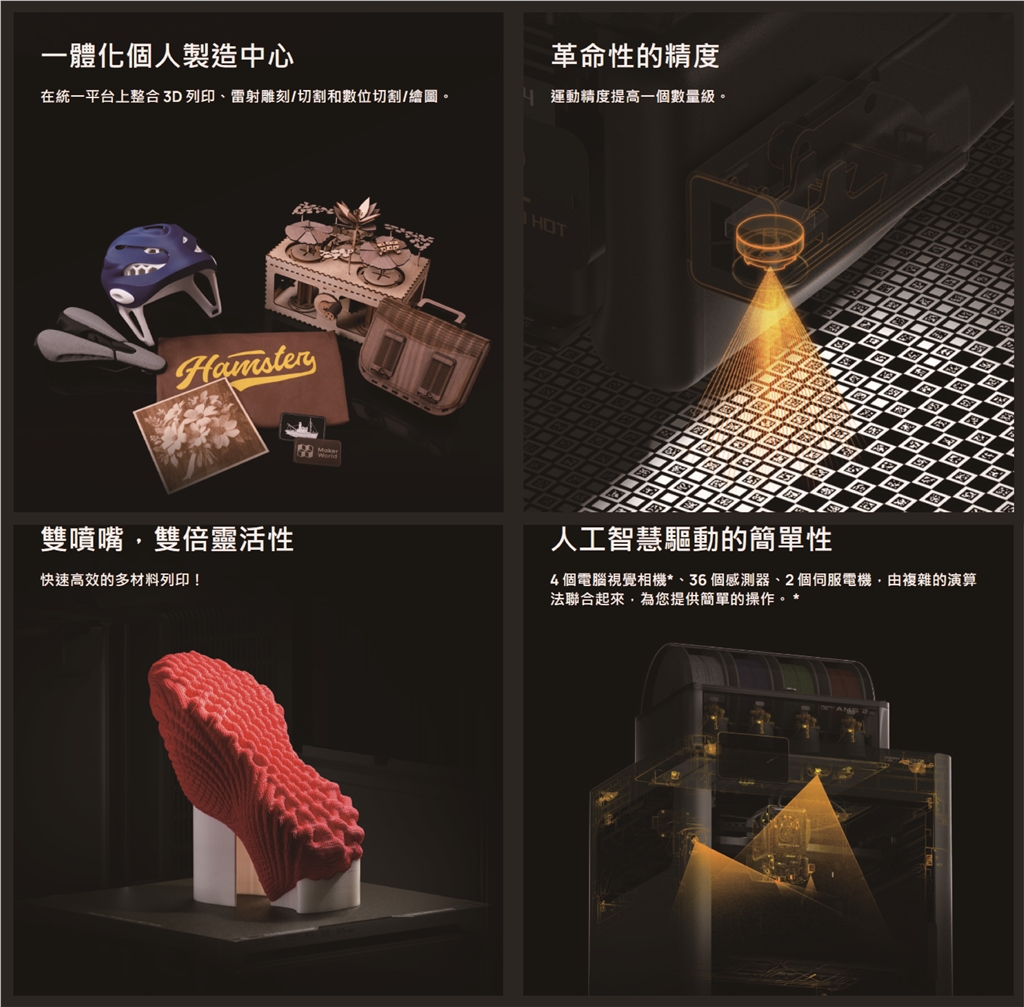

Personalized all-in-one solutions

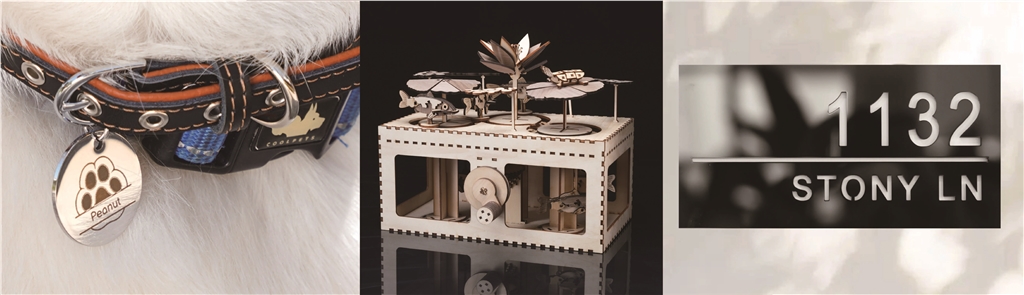

laser

10W and 40W 455nm lasers are used for engraving and cutting.

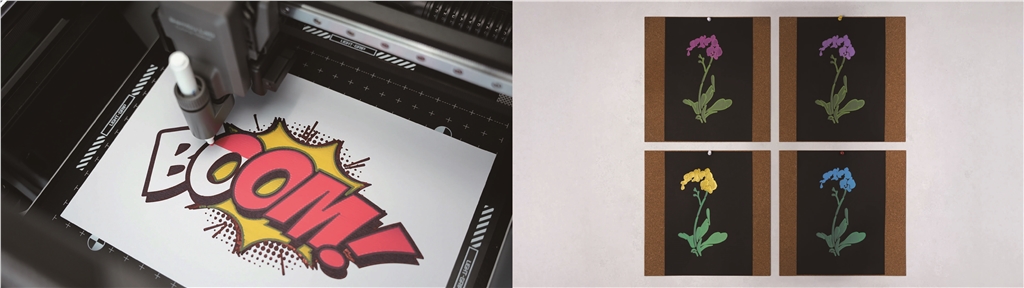

Digital cropping

Use a variety of multi-functional blades for precise cutting and hot stamping.

Enable your 3D printer to also draw and write.

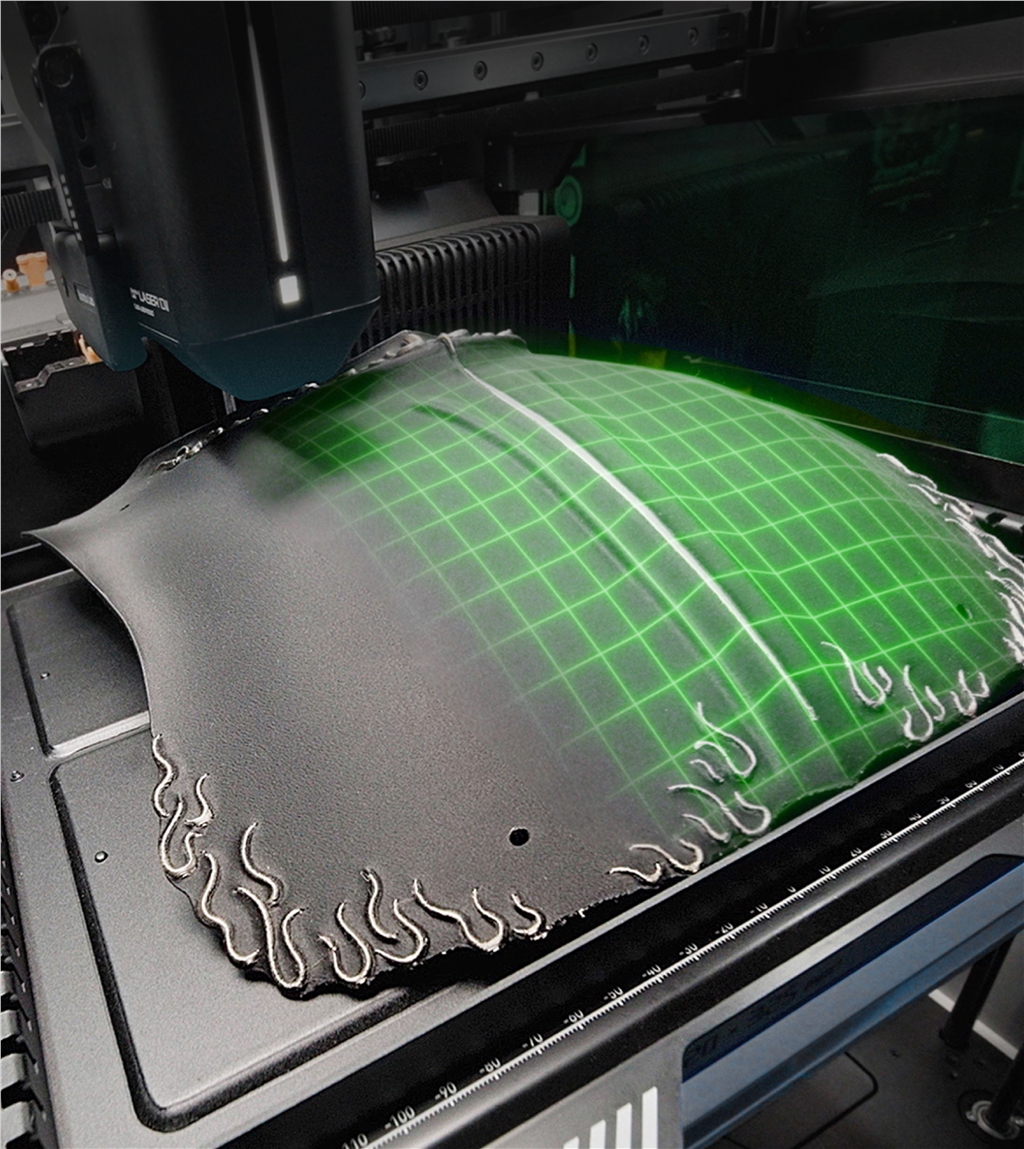

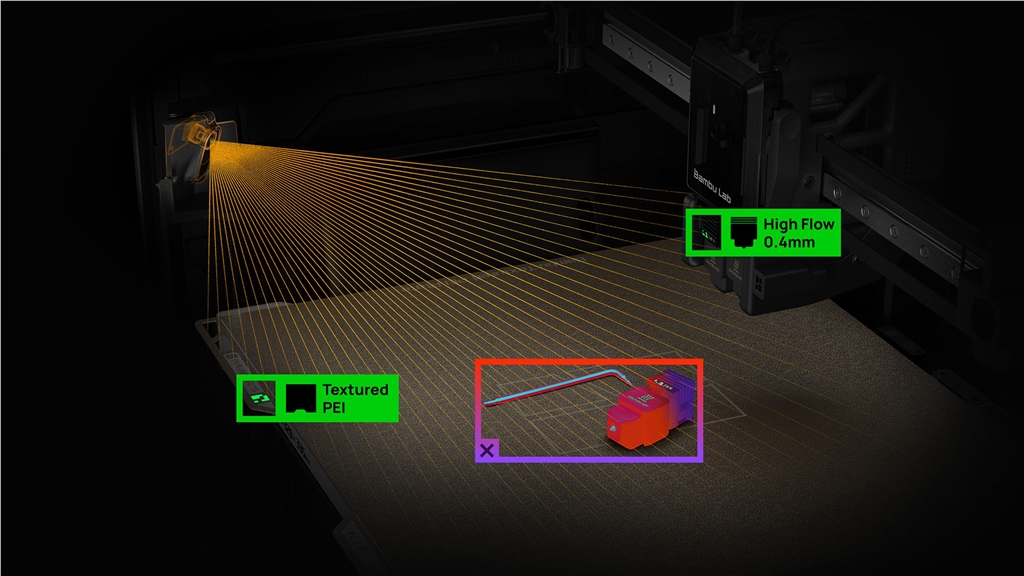

Instant Spatial Alignment

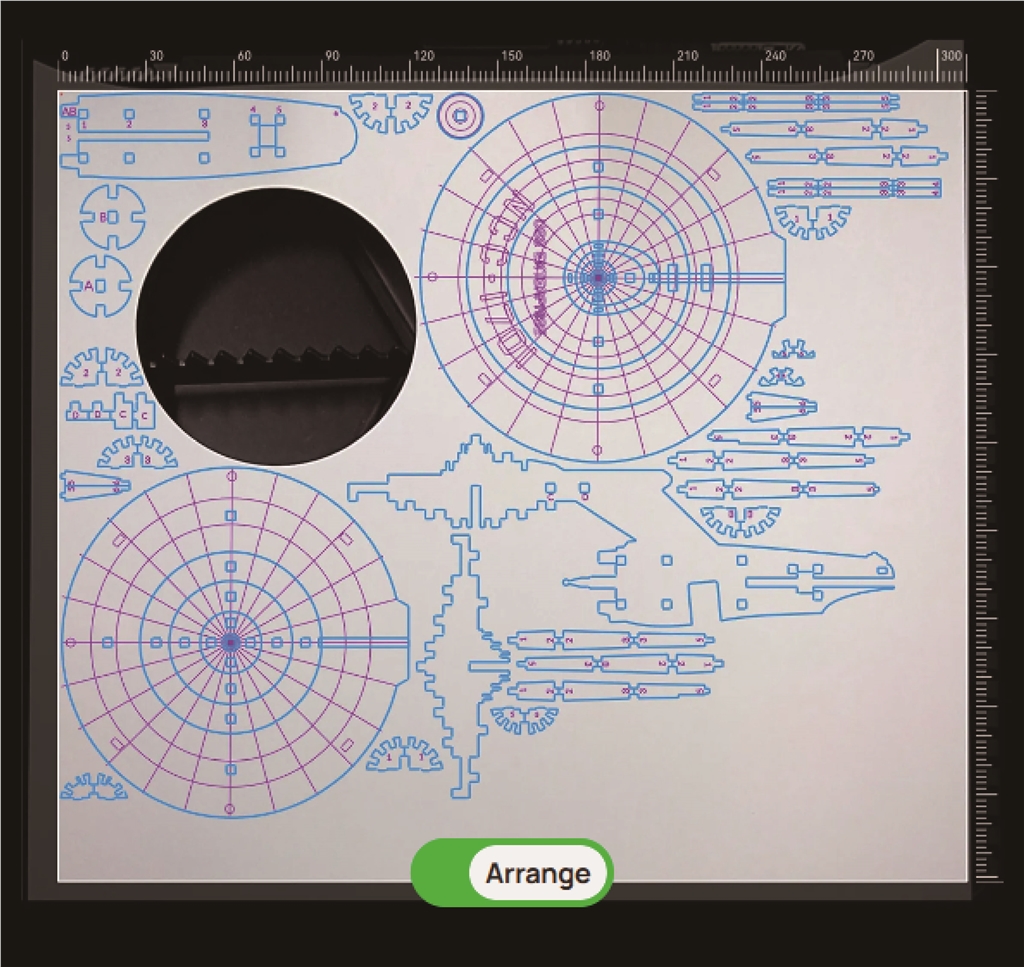

What you see is what you get

H2D's BirdsEye camera, combined with computer vision algorithms, can provide top-view alignment accuracy of up to 0.3mm.

This advanced spatial alignment feature allows users to place the toolpath in the correct position on the material, truly achieving "what you see is what you get".

Automatic arrangement

Optimize material efficiency and reduce waste

Using live footage from BirdsEye cameras, Bambu Suite can automatically arrange your projects to optimize material usage.

This feature ensures that waste is minimized while helping you make the most of every project.

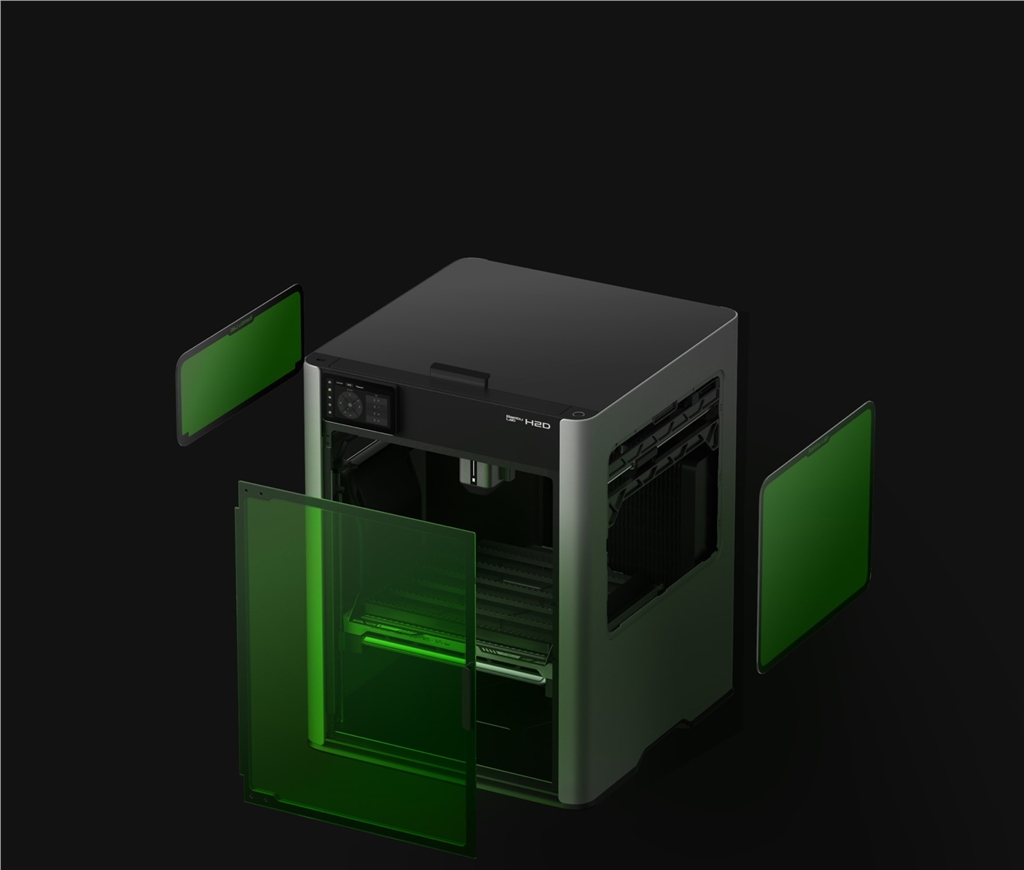

Don't worry about safety - we will provide you with protection.

Laser safety window

With our safety window, laser projects can be operated and monitored safely without the need for goggles.

air purifier

An optional air purifier ensures clean air, even when operating the laser indoors.

No need to worry about the setup - we've taken care of everything for you.

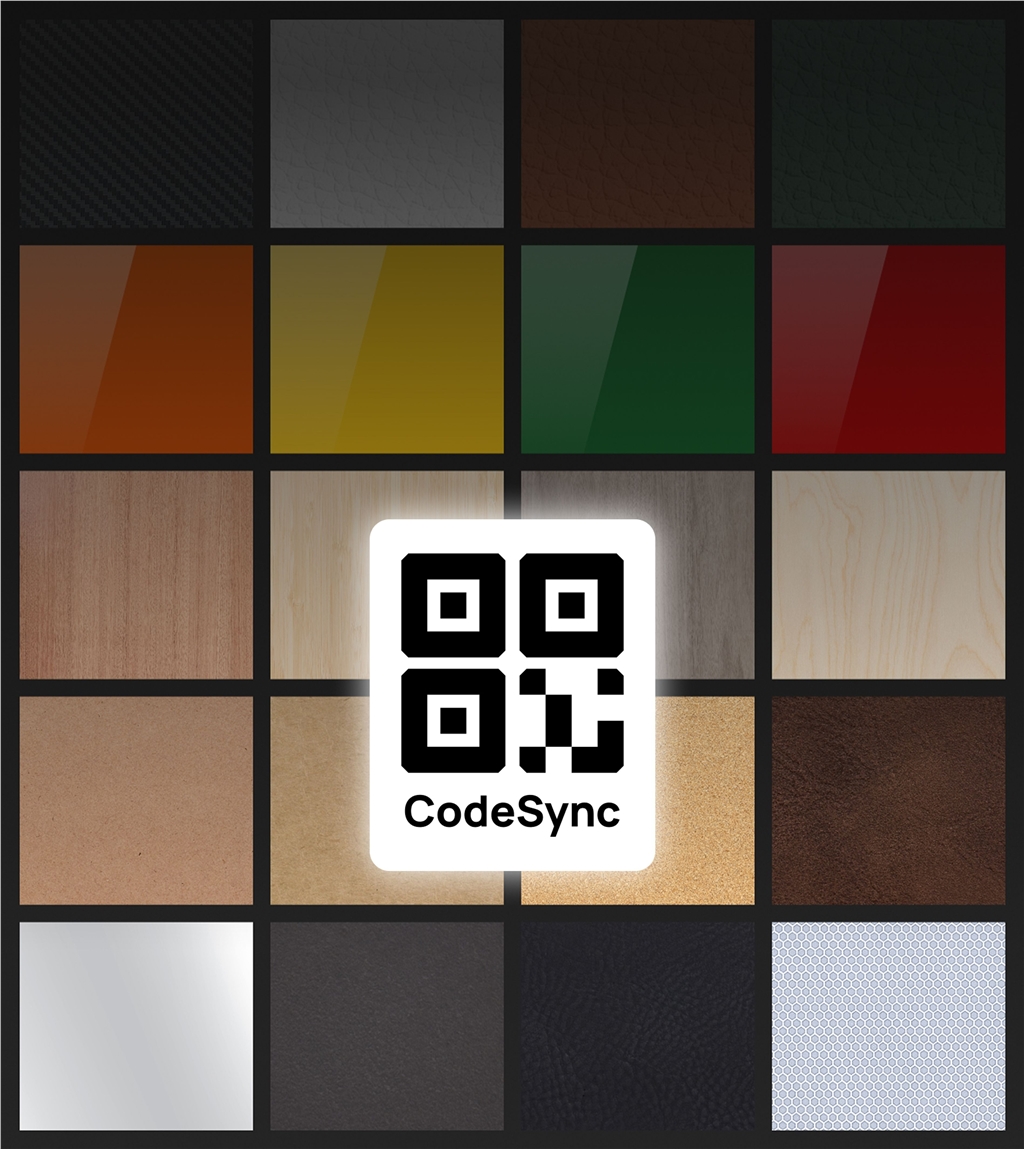

Material code synchronization

H2D can automatically scan QR codes on footage and load perfect presets*.

Fully automatic calibration

With just a touch, you can activate automatic laser focus verification and material identification, eliminating the need for manual module adjustments, while also allowing for precise configuration of material thickness and positioning.

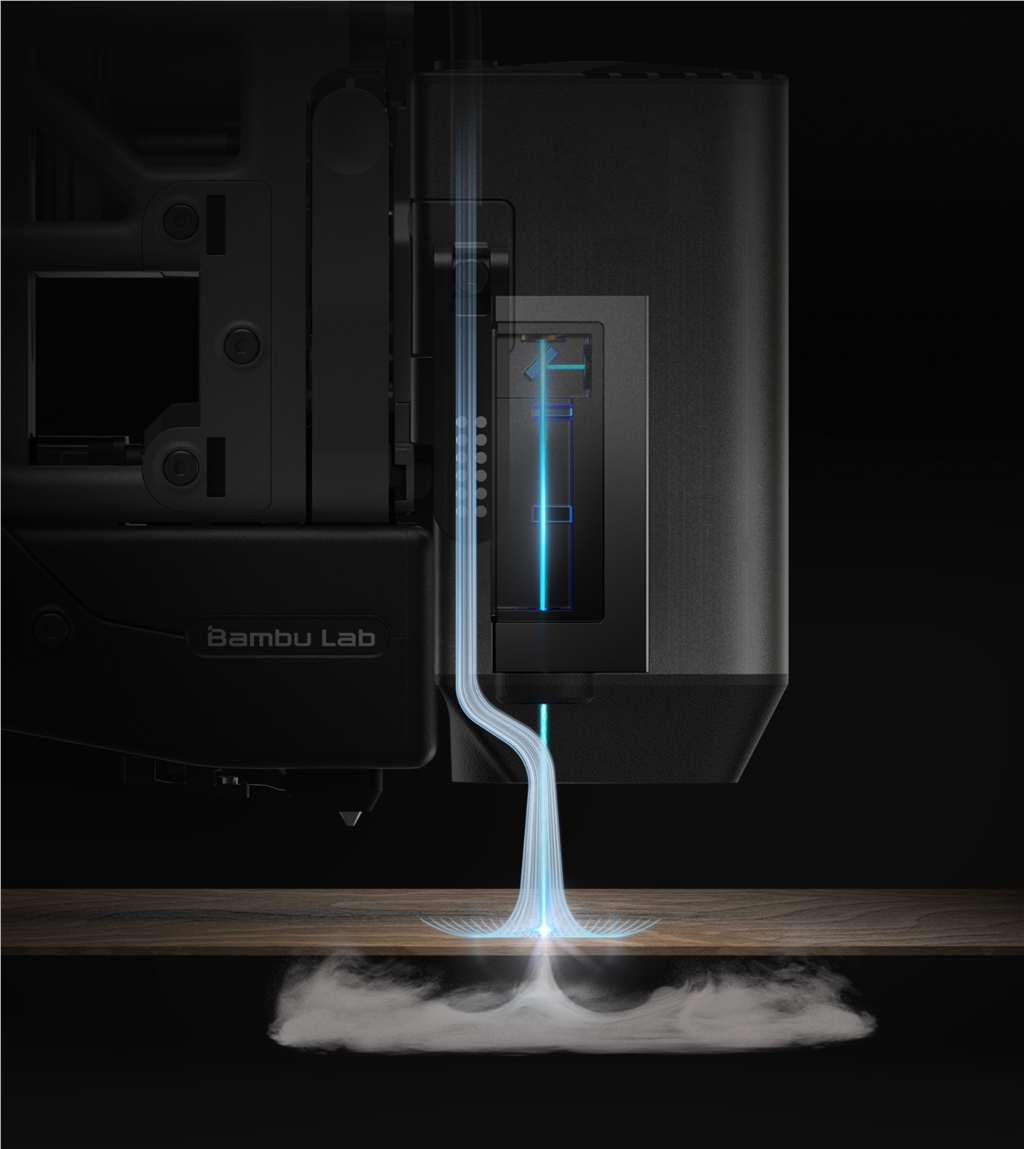

Air assist

By guiding high-speed air to cool the laser path, surface quality is improved, ensuring cleaner and more accurate results.

Non-contact 3D mesh

Advanced optical height measurement technology can create detailed 3D meshes without physical contact, enabling precise laser processing on curved surfaces.

Big, fast, precise

Our secret weapon: Vision Encoder with 50µm ultra-fine motion accuracy.

An ultra-precise vision encoder, combined with optical measurement at 5μm resolution, can track and correct the movement of the cutter head.

This allows H2D to achieve a consistent and reliable 50μm zero-distance motion accuracy across the entire working area, an order of magnitude higher than the previous generation.

Extra-large work area

Get rid of size limitations

Print sizes up to 350mm×320mm×325mm*, making large projects easier than ever!

From laser engraving on large objects to printing extra-large models, expanded capacity allows you to bring your most ambitious ideas to life.

350°C hot end and 65°C room temperature heating

Fully realize the potential of high-performance materials

The H2D features active cavity heating at 65°C and a high-temperature hot end at up to 350°C, providing precise closed-loop temperature control.

This advanced system effectively eliminates warping and deformation of high-performance materials, ensuring excellent interlayer bonding and fully realizing the potential of the materials.

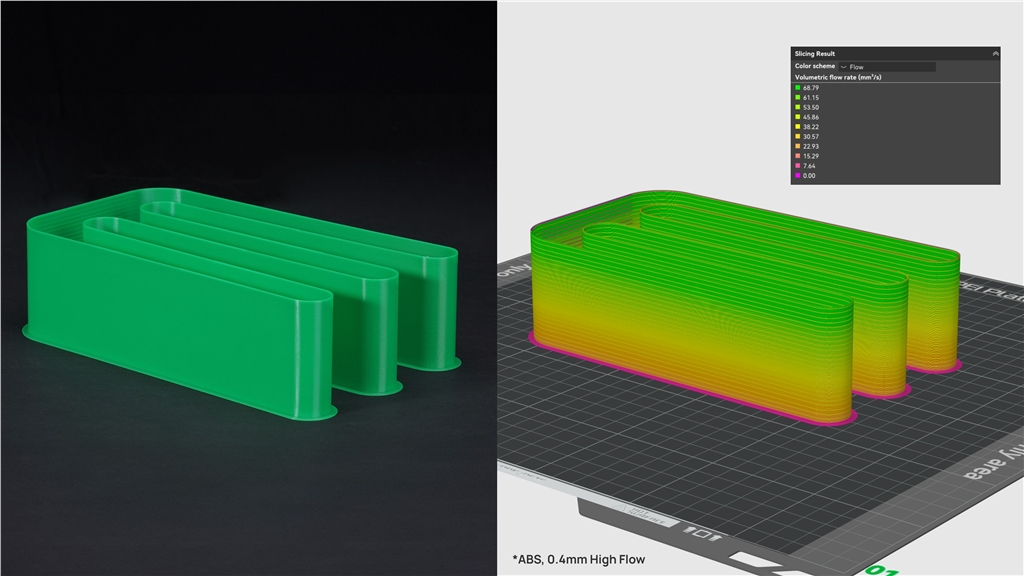

True high-flow hotspot

Easily print continuously at a speed of 600mm/s

H2D's dedicated high-flow hot end ensures reliable high-speed printing at 600mm/s.

Designed for consistent performance, it eliminates mid-line printing speed limitations, enabling uninterrupted high-speed printing regardless of print size or complexity.

Intelligent sensing for precise squeeze control

Bambu Lab's proprietary PMSM servo architecture establishes an intelligent extrusion control system.

It performs 20kHz torque/resistance and position sampling to dynamically adjust the electromagnetic torque vector, reduce VFA, and detect wire wear and blockage.

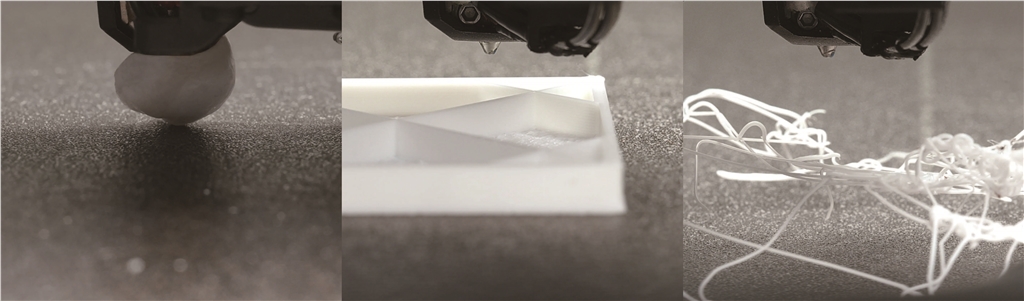

Nozzle camera

Monitor the extrusion at the nozzle tip

H2D is equipped with an AI-supported nozzle camera and macro lens.

This intelligent monitoring system continuously tracks the extrusion pattern and immediately detects material accumulation, wire deviation, and extrusion failures.

Early detection of problems saves time and cables:

Spaghetti

Nozzle Clumping

Air printing will no longer be a hassle for you!

AI-powered pre-print checklist

Print with peace of mind every time.

Before each print job, H2D's vision system initiates a comprehensive pre-print checklist:

Cavity Integrity Scan - Detects debris across the entire print surface.

Hardware configuration audit - Instantly identify nozzle size and board attributes.

Digital physical alignment - Automatically verifies the consistency between detected hardware specifications and the parameters of the slicer in operation.

SOTA Cable Monitoring

15 sensors on a single wire path

Traditional systems rely on a single wire detector, while H2D can provide complete material flow sensing.

Throughout the AMS-to-nozzle process, 15 strategically positioned sensors form an intelligent monitoring network that continuously tracks five key dimensions: feed rate, tension fluctuations, tip positioning, thermal environment in the extruder, and dynamic extrusion pressure – together establishing the industry's state-of-the-art wire behavior control system.

Product Contents

| body | H2D | ||||||

| technology | Fused deposition modeling | ||||||

| Print size (length × width × height) | Single printhead printing: 325×320×325mm Dual printhead printing: 300×320×325mm Overall dimensions of dual nozzles: 350×320×325mm |

||||||

| External dimensions | 494×514×626mm | ||||||

| net weight | 31kg | ||||||

| Chassis and outer shell | Aluminum, steel, plastics and glass | ||||||

| tool head | |||||||

| hot end | All Metal | ||||||

| Nozzle and extruder teeth | Hardened steel | ||||||

| Extruder | High-precision permanent magnet synchronous motor | ||||||

| Nozzle maximum temperature | 350℃ | ||||||

| Nozzle diameter (default setting) | 0.4mm | ||||||

| Nozzle diameter (optional) | 0.2mm, 0.6mm, 0.8mm | ||||||

| wire diameter | 1.75 mm | ||||||

| Supported cables | |||||||

| PLA, PETG, TPU, PVA, BVOH | optimal | ||||||

| ABS, ASA, PC, PA, PET | excellence | ||||||

| Carbon/ Glass Fiber Reinforced PLA, PETG, PA, PET, PC, ABS, ASA | excellence | ||||||

| PPA-CF/ GF, PPS, PPS-CF/ GF | ideal | ||||||

| heating | |||||||

| Active cavity heating | have | ||||||

| Maximum control temperature of the machine body | 65℃ | ||||||

| Air purification | |||||||

| Pre-filtering level | G3 | ||||||

| HEPA high-efficiency air filter rating | H12 | ||||||

| Activated carbon filter type | Coconut shell pellets | ||||||

| Network control | |||||||

| Ethernet | have | ||||||

| Automatic disconnection | Ethernet | ||||||

| Detachable network module | have | ||||||

| 802.1X Network Access Control | have | ||||||

| heated bed | |||||||

| Supports printing plates | Textured PEI Printing Platform / Smooth PEI Printing Platform | ||||||

| Maximum temperature of printing plate | 110℃ | ||||||

| speed | |||||||

| Maximum speed of tool head | 1000mm/s | ||||||

| Maximum acceleration of tool head | 20000 mm/s² | ||||||

| sensor | |||||||

| Live View Camera | Built-in 1920*1080 | ||||||

| Nozzle camera | Built-in 1920*1080 | ||||||

| Bird's-eye view camera | Built-in 3264*2448 (laser version) | ||||||

| tool head camera | Built-in 1920*1080 | ||||||

| Door opening detection | support | ||||||

| Material breakage detection | support | ||||||

| Wire odometer | Supports when used with AMS | ||||||

| Power outage resume printing | support | ||||||

| Electricity demand | |||||||

| Voltage | 100-240 VAC, 50/60 Hz | ||||||

| Maximum power | 2200W@220V, 1320W@110V | ||||||

| electronic devices | |||||||

| Display screen | 5-inch 1280×720 touchscreen | ||||||

| capacity | 8GB eMMC and USB connectivity | ||||||

| User interface | Touchscreen, mobile app, desktop application | ||||||

| Neural Network Processing Unit | 2 Tops | ||||||

| software | |||||||

| Slicing software | It supports other vendor slicers that can export standard G-code, such as Superslicer, Prusaslicer, and Cura, but some smart features may not be supported. | ||||||

| The slicing software supports operating systems. | MacOS, Windows | ||||||

| cool down | |||||||

| Component cooling fan | Closed-loop control | ||||||

| Hot end fan | Closed-loop control | ||||||

| Main control board fan | Closed-loop control | ||||||

| Cooling main unit casing temperature control fan | Closed-loop control | ||||||

| Auxiliary component cooling fan | Closed-loop control | ||||||

| 10W & 40W laser modules | |||||||

| Laser type | Semiconductor laser | ||||||

| laser wavelength | Engraving laser: 455mm±5nn blue light; Height measurement laser: 850mm±5nn infrared light | ||||||

| Laser power | 10 watts ± 1 watt, 40 watts ± 2 watts | ||||||

| Laser beam size | 10 watts: 0.3 mm - 0.14 mm 40 watts: 0.2 mm - 0.14 mm |

||||||

| Operating temperature | 0℃~35℃ | ||||||

| Maximum carving speed | 10 watts: 400 mm/s 40 watts: 1000 mm/s |

||||||

| Maximum cutting thickness | 10 watts: 5mm 40 watts: 15mm (basswood plywood) |

||||||

| Laser module laser safety level | 4 categories | ||||||

| Overall laser safety level | Class 1 | ||||||

| Sculpture area | 10W: 310mm*270mm 40 watts: 310mm*250mm |

||||||

| XY positioning accuracy | Less than 0.3mm | ||||||

| Z-height measurement method | Miniature LightScan | ||||||

| Z-height measurement accuracy | ±0.1nn | ||||||

| Flame detection | support | ||||||

| Temperature detection | support | ||||||

| Door sensor | support | ||||||

| Laser module installation and testing | support | ||||||

| Security Key | have | ||||||

| outer diameter of ventilation pipe joint | 100mm | ||||||

| Support materials | Wood, rubber, metal sheets, leather, dark acrylic, stone, etc. | ||||||

| Cut drawing module | |||||||

|

|||||||

custom.product_specification