Bambu Lab | Product Model:

BL0192_175mm_750g

54% off

54% off

Bambu Lab PPS-CF Black

Sale price

¥10,900 JPY

Regular price

¥23,500

Unit price

/

Unavailable

Subtotal

—

Bambu Lab PPS-CF Black is backordered and will ship as soon as it is back in stock.

Choose add-on

Couldn't load pickup availability

Bambu Lab PPS-CF Black

PPS-CF is a composite material made of carbon fiber reinforced polyphenylene sulfide. The combination of PPS resin and carbon fiber gives PPS-CF excellent properties, including excellent solvent resistance, corrosion resistance, heat resistance and flame retardancy.

In addition, it possesses exceptional strength, stiffness, and dimensional stability, making it a special engineering plastic that can meet the needs of unique and challenging applications.

Features

● Ultra-high heat resistance ● Top-tier flame retardant properties ● Unparalleled mechanical properties ● Solvent and chemical resistance ● Ultra-low water absorption ● Equipped with cardboard spool ● Diameter: 1.75 mm +/- 0.05 mm

In addition, it possesses exceptional strength, stiffness, and dimensional stability, making it a special engineering plastic that can meet the needs of unique and challenging applications.

Features

● Ultra-high heat resistance ● Top-tier flame retardant properties ● Unparalleled mechanical properties ● Solvent and chemical resistance ● Ultra-low water absorption ● Equipped with cardboard spool ● Diameter: 1.75 mm +/- 0.05 mm

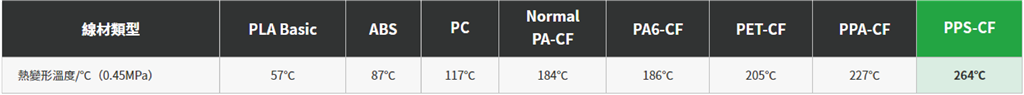

Ultra-high heat resistance

PPS-CF has a heat distortion temperature of up to 264℃ at 0.45MPa and can work continuously at temperatures exceeding 200℃.

This is significantly better than ordinary PA-CF materials with maximum temperatures of approximately 190°C and 120°C.

Its superior heat resistance ensures excellent creep resistance, making PPS-CF an ideal choice for demanding industrial environments and applications.

Excellent flame retardancy

PPS-CF achieves a UL-94 V-0 flame retardant rating, providing superior safety and reliability for critical applications such as electronics and automotive parts.

Even in the harshest environments, PPS-CF provides lasting durability and peace of mind.

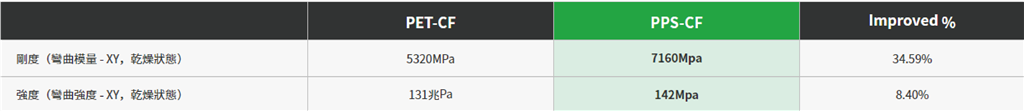

Unparalleled mechanical properties

PPS-CF combines the stiffness of PPS polymers with the reinforcing power of carbon fibers, providing superior stiffness, flexural strength, and tensile strength.

Its superior dimensional stability and anti-warping properties ensure that large prints maintain accuracy and avoid deformation during the printing process, making it ideal for high-precision applications.

Solvent resistance and chemical resistance

PPS-CF has excellent solvent and chemical resistance, second only to PTFE (Teflon).

At temperatures below 200°C, it is almost insoluble in any solvent and exhibits excellent resistance to acids, alkalis, and salts under normal conditions.

This makes PPS-CF an ideal choice for challenging environments where chemical stability is critical.

Ultra-low water absorption rate

PPS-CF has an extremely low moisture absorption rate of only 0.05%, and its mechanical and thermal properties remain stable even under humid conditions.

Unlike regular PA-CF, which softens and degrades when exposed to moisture, PPS-CF retains its strength and durability, making it the best choice for applications requiring high moisture resistance.

Parameter comparison

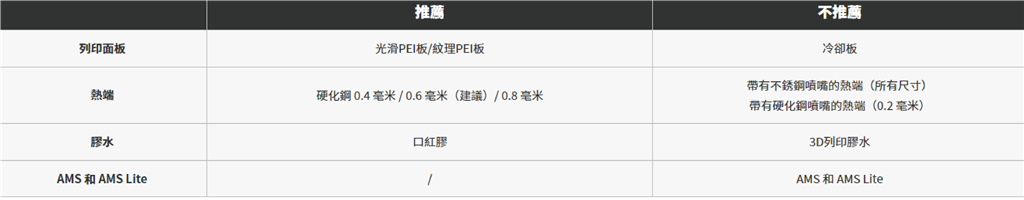

Parts compatibility

Product contents

Contact us for more information about Bambu Lab 3D printers !

| diameter | 1.75 mm |

| Net weight of wire | 750 g |

| spool material | carbon fiber + polyphenylene sulfide |

| Pre-print drying settings | 100-140 °C, 8-12 hours |

| Printing and storing humidity | < 20% RH (sealed, with desiccant) |

| Nozzle temperature | 310 - 340 ̊C |

| Printing plate type | Smooth PEI board or textured PEI board |

| Printing board surface temperature | 100-120 ̊C |

| Printing speed | < 100 mm/s |

| Internal temperature | 60 - 90 ̊C |

| Maximum bridging length | ~40 mm |

physical properties

| density | 1.26 g/cm³ |

| Vicat softening temperature | 268 ̊C |

| Heat distortion temperature | 264 ̊C |

| melting temperature | 284 ̊C |

| Melt Flow Index | 11.48 ± 1.23 g/10 minutes |

Mechanical properties

| Tensile strength | 87 ± 5 MPa |

| Elongation at break | 12 ± 0.4% |

| Flexural modulus | 7160 ± 280 MPa |

| Bending strength | 142 ± 5 MPa |

| Impact strength | 27.8 ± 2.3 kJ/ m² |