FASTFORM | Product Model:

FF0020

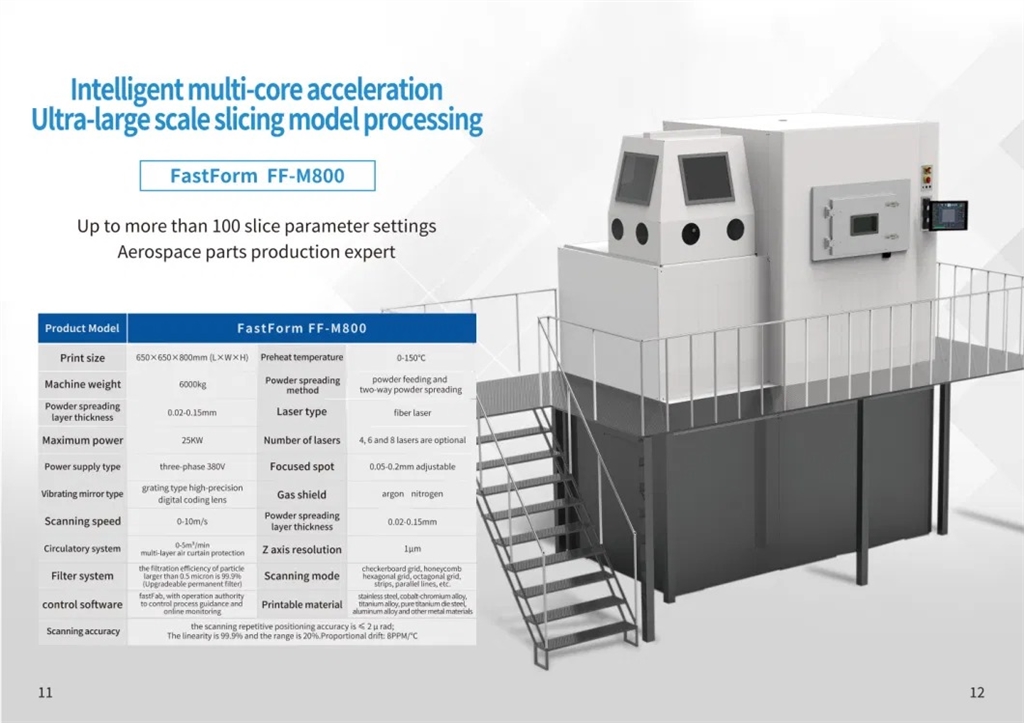

FF-M800 SLM Metal 3D Printer

Subtotal

—

FF-M800 SLM Metal 3D Printer is backordered and will ship as soon as it is back in stock.

Choose add-on

Couldn't load pickup availability

FF-M800 SLM Metal 3D Printer

• Eight lasers + LFPT bidirectional powder spreading improves production efficiency by 300%.

• Seamless dynamic splicing with zero touch sensitivity.

• Optimal mechanical structure reduces space costs by 30%.

• Scalable solutions, worry-free equipment purchase.

• Permanent filter cartridge: 0 cost, 0 replacement, 0 risk

• Seamless dynamic splicing with zero touch sensitivity.

• Optimal mechanical structure reduces space costs by 30%.

• Scalable solutions, worry-free equipment purchase.

• Permanent filter cartridge: 0 cost, 0 replacement, 0 risk

• Stable optical system • Highly efficient powder circulation system, suitable for mass production

Rapid construction

• High-efficiency filter cartridges, low powder consumption, reducing waste. • Layout and data processing completed within 5 minutes. • Two-way powder spraying for faster construction.

Enhance security

• Advanced manufacturing processes ensure reliability and safety. • Equipped with a camera for remote monitoring. • High stability and easy installation.

Our Advantages

• Dual laser dual galvanometer technology • Bidirectional variable speed powder feeding technology • Z-axis closed-loop system • High-efficiency air control system

FastLayer software

The 3D slicing software, developed independently over eight years, can automatically program and is suitable for dental and industrial precision design.

Layout and path planning can be completed with just one click. Users can customize the printing platform to adjust and annotate any model.

Rapid manufacturing

The interface is simple, the layout is logically clear, and it provides a variety of tools and functions.

This software is easy to use, with a streamlined workflow and intuitive controls, allowing users to easily start and complete printing tasks.

Camera integration

The camera integration function helps operators easily monitor the printing process while avoiding interference from the risk of laser radiation.

Print Log

The print log function records all printing process data, making it easy to review all printing records. This helps maintenance personnel analyze and troubleshoot, further improving the quality of metal powder printing.

| project | Specification |

|---|---|

| Molding size | 650mm × 650mm × 800mm (L × W × H) |

| Z-axis resolution | 1 μm |

| Equipment weight | 6000 kg |

| Printing layer thickness | 20 μm – 150 μm |

| scraper type | Flexible scraper |

| Number of lasers | 4, 6, 8 (optional), 500W power |

| Precision optical components | F-theta lens |

| Power type | AC380V |

| Rated power consumption | 25 kW |

| Protective gas | Nitrogen and argon |

| Preheating temperature | 0 – 200 ℃ |

| Powder spreading method | Top-feed powder, two-way powder spreading |

| Printable materials | Stainless steel, mold steel, aluminum alloy, cobalt-chromium alloy, titanium alloy, pure titanium, high-temperature alloy, etc. |

| Supporting software | FastLayer slicing software, FastFab control software |