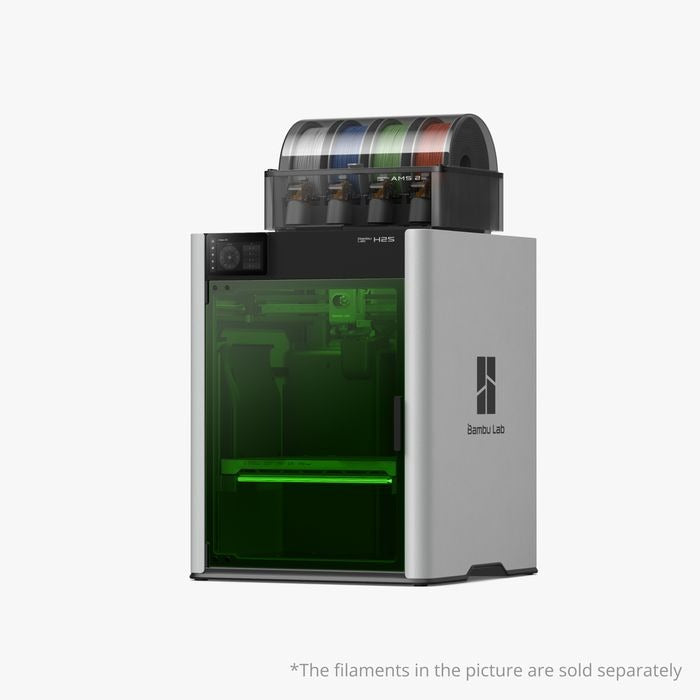

Bambu Lab H2S 3D Printer Series

Bambu Lab H2S 3D Printer Series - is backordered and will ship as soon as it is back in stock.

Choose add-on

Couldn't load pickup availability

Topzhu Bambu Lab H2S 3D Printer

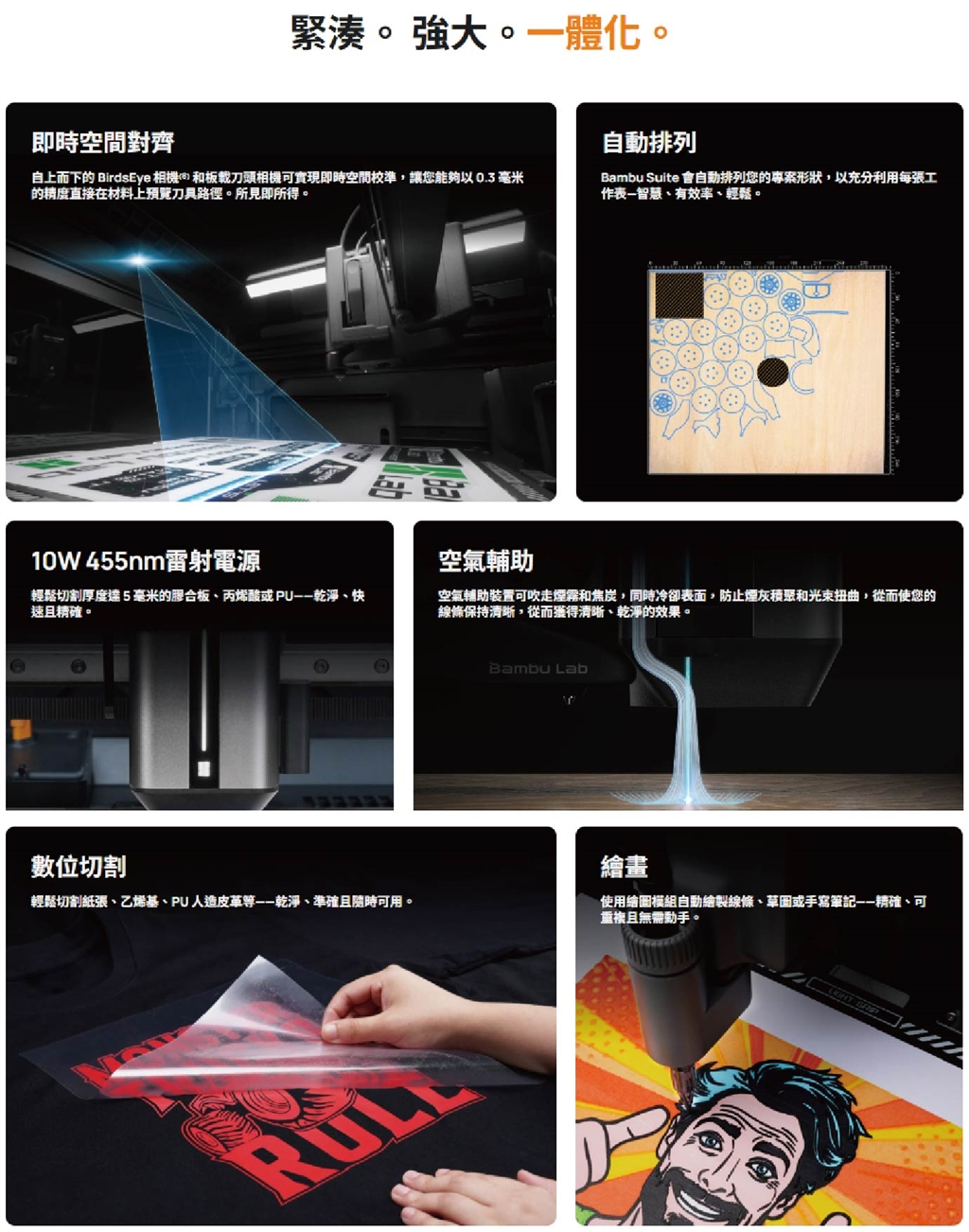

To suit your accuracy needs, correct for mechanical deviations.

Even if a printer is manufactured with extremely high precision, mechanical wear and differences are inevitable over time—but now, for the first time in the industry, a solution has been found.

Using a visual encoder, H2S achieves motion accuracy below 50 μm, unaffected by distance—fineer than a human hair. During calibration, it automatically compensates for mechanical drift, ensuring consistent accuracy and optimal performance.

One print, perfect fit

Bambu Lab's automatic hole/contour compensation feature minimizes printing tolerances, achieving machine shop-level hole dimensional accuracy.

Design critical mating components with confidence – integrate shafts, bearings, and fasteners without trial and error.

Post-printing assembly has never been easier.

Engineering wires

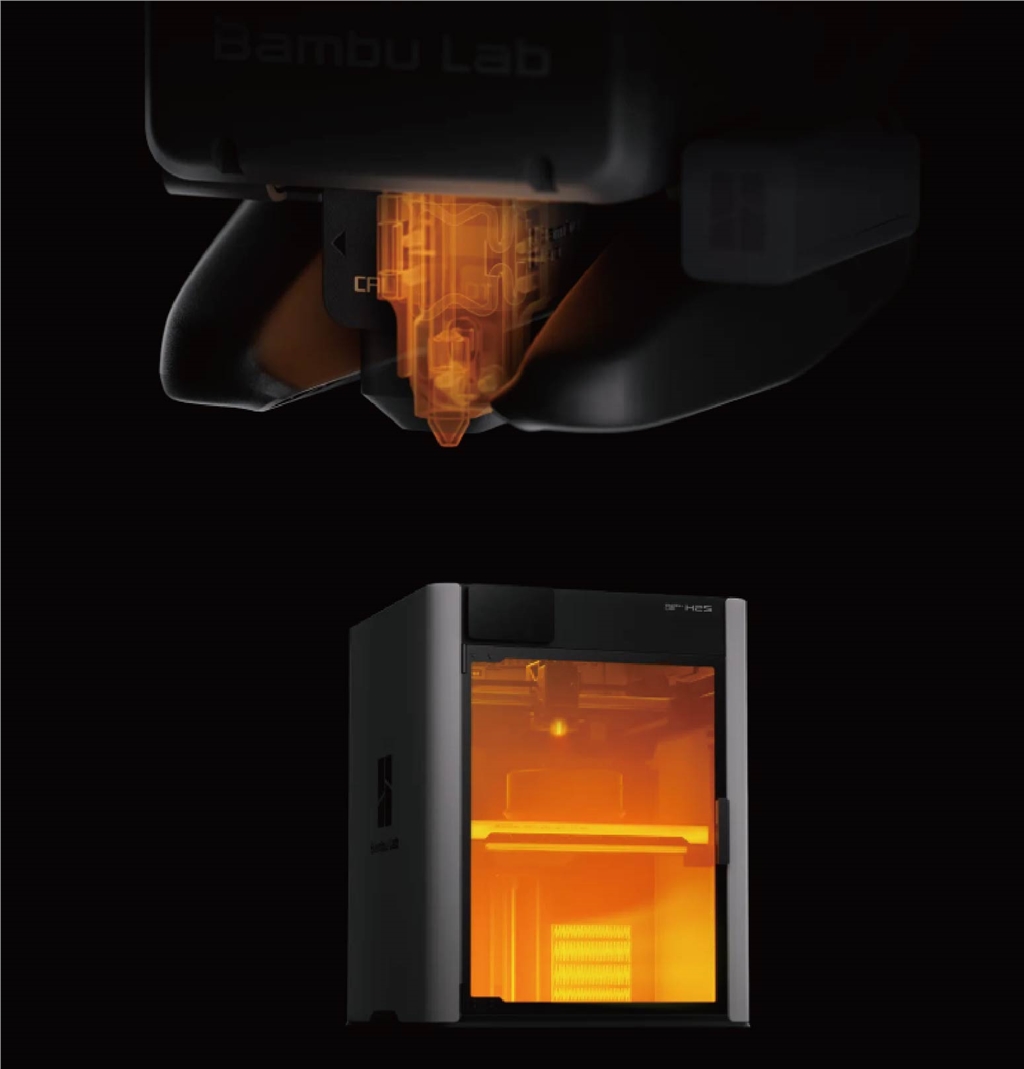

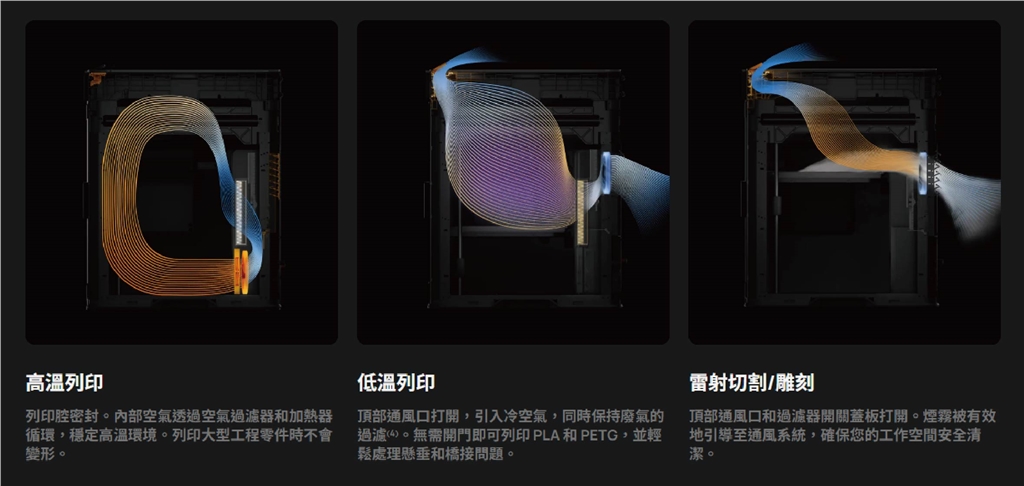

It features a 350 °C hot end and a 65 °C active heating chamber, supporting the entire Bambu consumable range—from PLA and PETG to PC and PPA.

H2S features closed-loop fan control and precise thermal management to minimize warpage and deformation while improving interlayer adhesion.

To create large, high-performance parts that are both functional and robust.

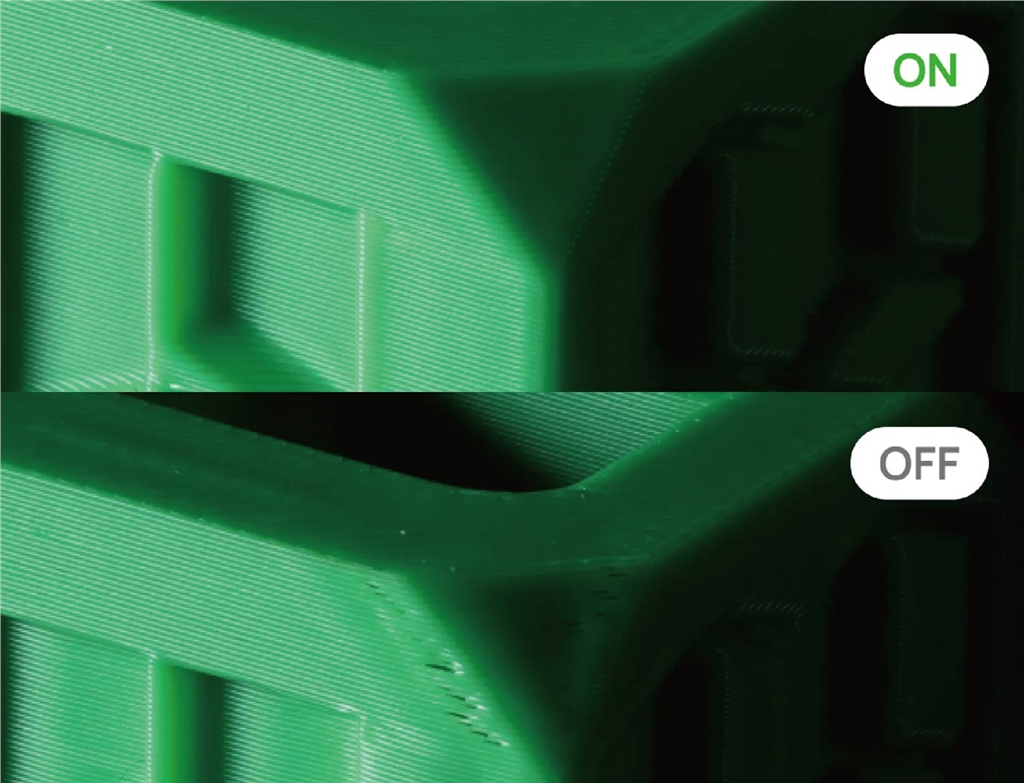

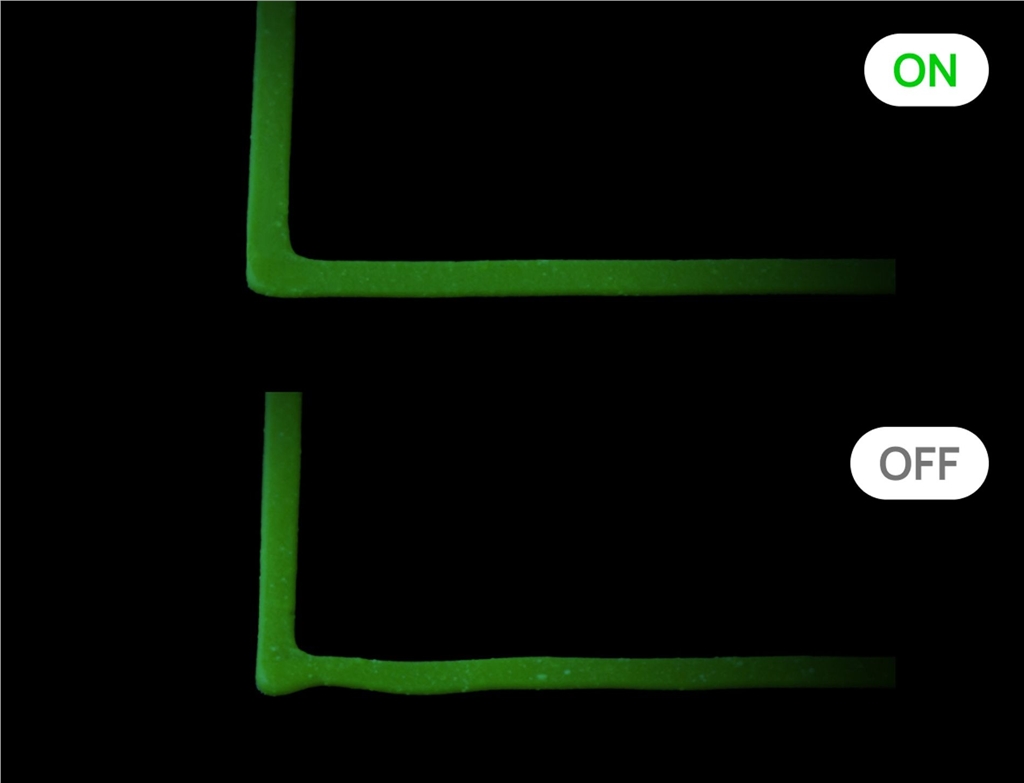

Smooth surface, clear edges

H2S utilizes the sensing capabilities of the servo motor on the extruder and the high-resolution eddy current sensor on the nozzle to precisely control extrusion by measuring nozzle pressure and calibrating the PA parameters of each wire, thereby improving surface smoothness and edge sharpness.

Precision movement

Active vibration compensation can instantly eliminate micro-vibrations and resonances, thereby achieving superior print quality at higher speeds.

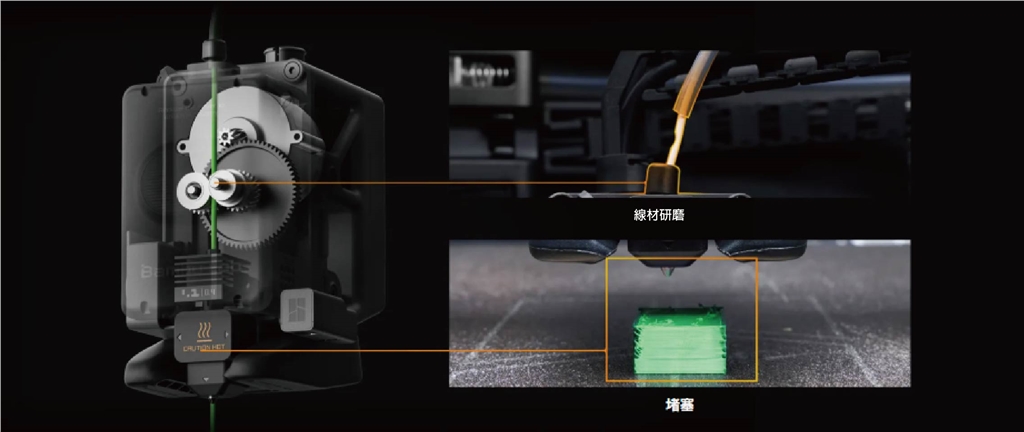

20,000 checks per second, closed-loop feedback, real-time control

Bambu Lab’s proprietary PMSM servo system enables 20 kHz resistance and position sampling, thereby dynamically adjusting the electromagnetic torque vector.

The system can ensure stable extrusion and proactively detect grinding or clogging in real time.

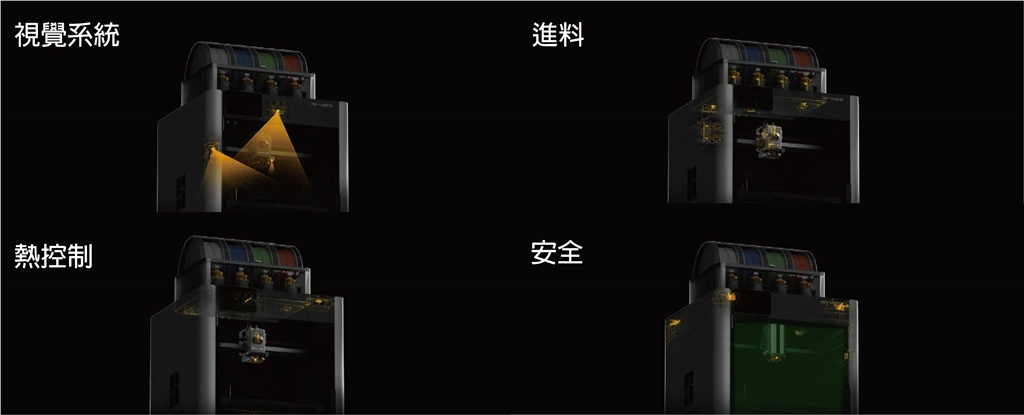

23 sensors + 3 cameras, each potential risk has its own detector.

Vision System: With AI-driven real-time monitoring, the vision system can instantly detect problems such as material clumping, noodle-like patterns, and clogged waste trays, thereby helping to prevent printing failures.

This vision system also supports a number of advanced features, such as real-time spatial alignment for precise laser and cutting calibration, and vision encoder technology to improve positioning accuracy.

Feeding: Wire path sensors work together to monitor feed speed and position, detect wire tangling and abrasion risks, track wire mileage and spool usage, and ensure that AMS, buffers, cutters and tools on the feed path are ready, ensuring that every tool is in place and every action is under control.

Thermal control: Five NTC temperature sensors are cleverly distributed across the nozzle, heated bed, and printing chamber.

The system works in conjunction with an integrated airflow sensor to actively monitor and regulate internal temperature and circulation, and maintain an ideal printing environment through real-time feedback control.

Safety: The H2S is equipped with five flame sensors, front door and roof sensors, and an emergency stop button, forming a complete safety system.

It can detect fire risks, monitor cabinet alignment, and shut down immediately when needed, thus always protecting your projects and workplace.

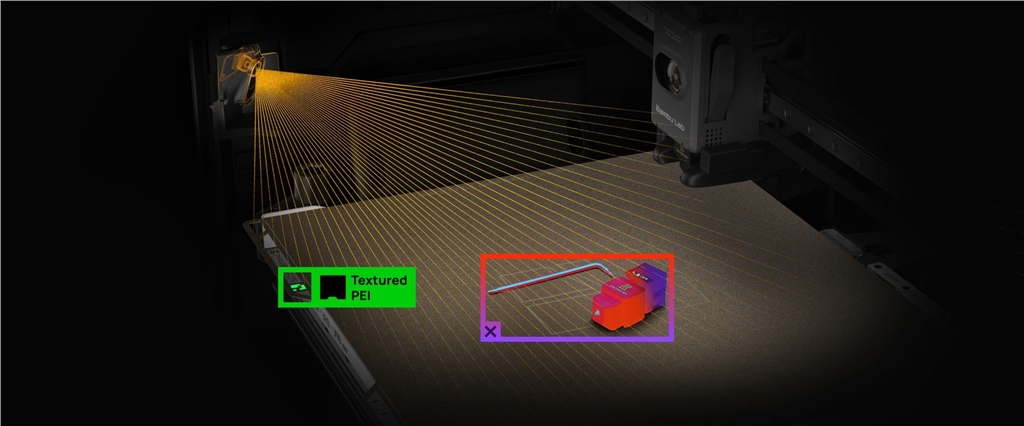

Artificial Intelligence Pre-Flight Checklist

Before the start of each operational cycle, the H2S vision system initiates a comprehensive pre-flight checklist:

Chamber integrity scan – detects debris across the entire print surface.

Hardware configuration audit – instantly identify the attributes of the printing platform.

flap switch airflow and filtration system

3D printing and laser cutting.

Three modes, integrated.

Maximum output. Highest productivity.

The H2S has a print volume of 340×320×340 cubic millimeters, making it the printer with the largest print space among all Bambu Lab printers.

Your vision can be realized with a single print.

Extremely fast. More reliable.

Bambu Lab’s proprietary PMSM servo extrusion system can increase extrusion force by 67%, providing robust support for high-volume printing.

With printhead speeds up to 1000 mm/s and accelerations up to 20,000 mm/s², your H2S can finally run at full speed, reducing printing time by up to 30% while maintaining top-quality prints.

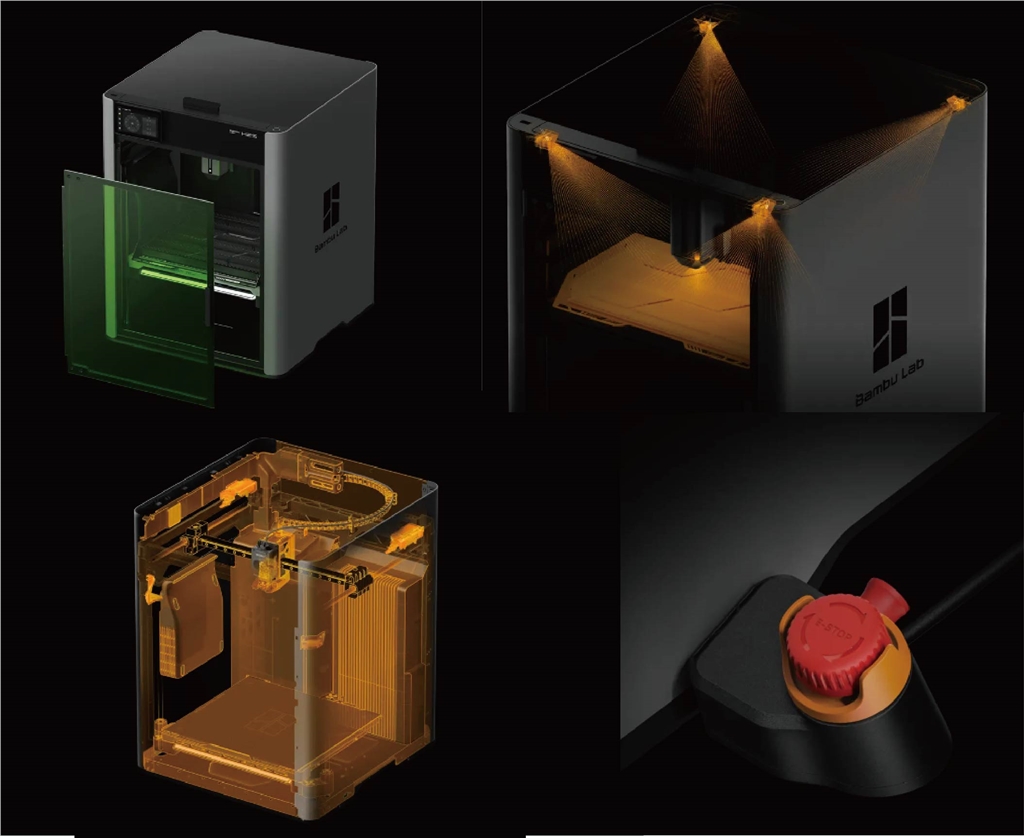

Built-in security

Laser safety window: Protects your eyes from 455 nm laser beams while keeping your workspace clearly visible.

Five flame sensors: Advanced sensors continuously monitor fire risks. Once a problem is detected, a loud buzzer and cell phone alarm will immediately notify you, allowing you to take swift action to ensure safety.

Flame-retardant compartment: This compartment is constructed entirely of fire-resistant materials, providing passive protection and increasing safety.

Emergency Stop: If you feel anything unusual, stop operating immediately - giving you complete control and greater peace of mind.

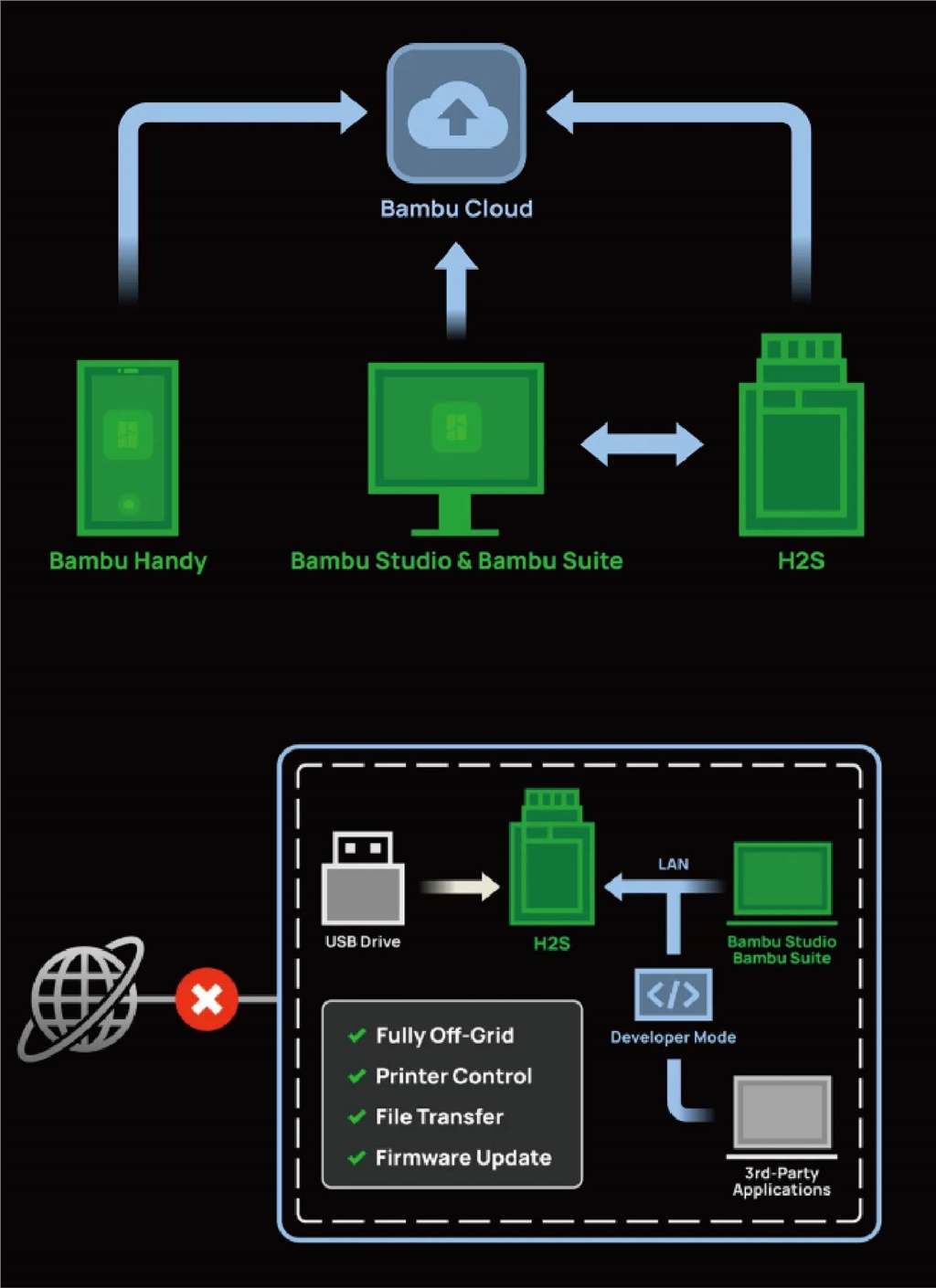

Designed with all possible connectivity and privacy

H2S provides seamless cloud connectivity, enabling remote control from any device.

For security-sensitive applications, it also provides full offline functionality to ensure physical isolation during operation.

Users can control printers, transfer files, and upgrade firmware without an internet connection.

In addition, developer mode unlocks MQTT port access, enabling developers and integrators to easily connect third-party components and custom software.

Quick nozzle change

Nozzle can be changed in seconds – no tools required, easy and convenient.

Whether you're replacing a high-flow nozzle or a nozzle of a different size, the redesigned nozzle allows for easy and intuitive operation, making it easy for even first-time users to get started.

Quiet design

The H2S is equipped with active motor noise reduction technology and professional duct noise reduction technology, and the noise level is below 50 decibels when it is running.

Even if printed overnight or in a public space, it will not disturb your environment.

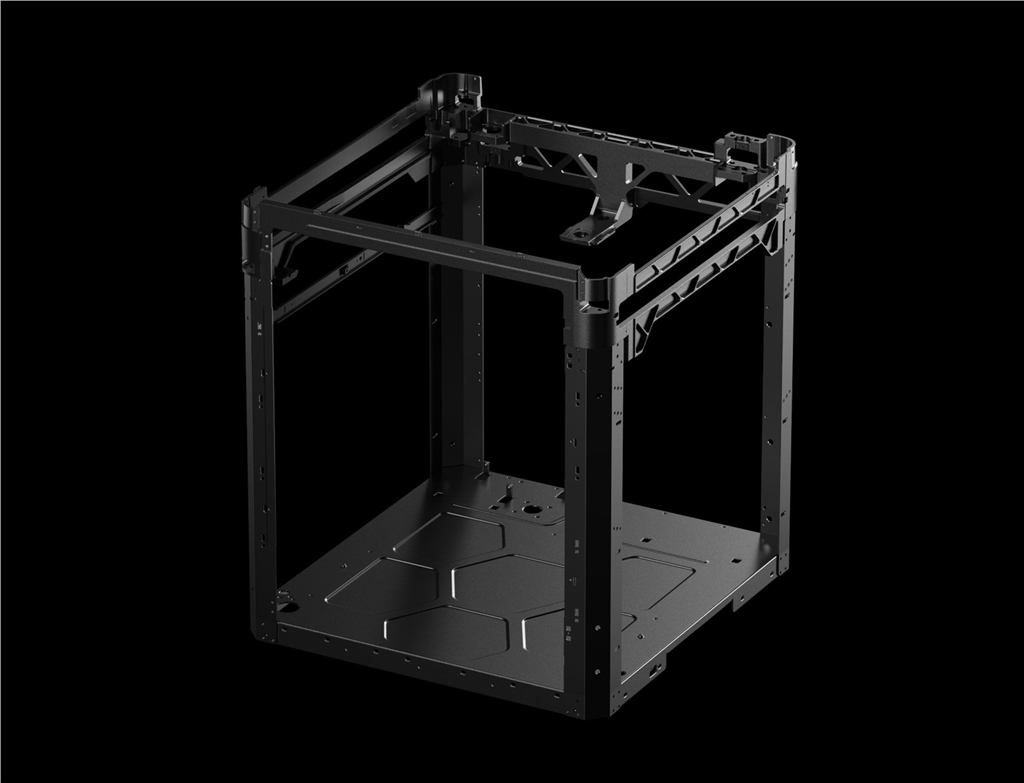

All-metal die-cast body

The unibody die-cast aluminum alloy chassis is robust and stable, providing a solid foundation for high-speed, large-format printing while minimizing precision loss caused by micro-torsion.

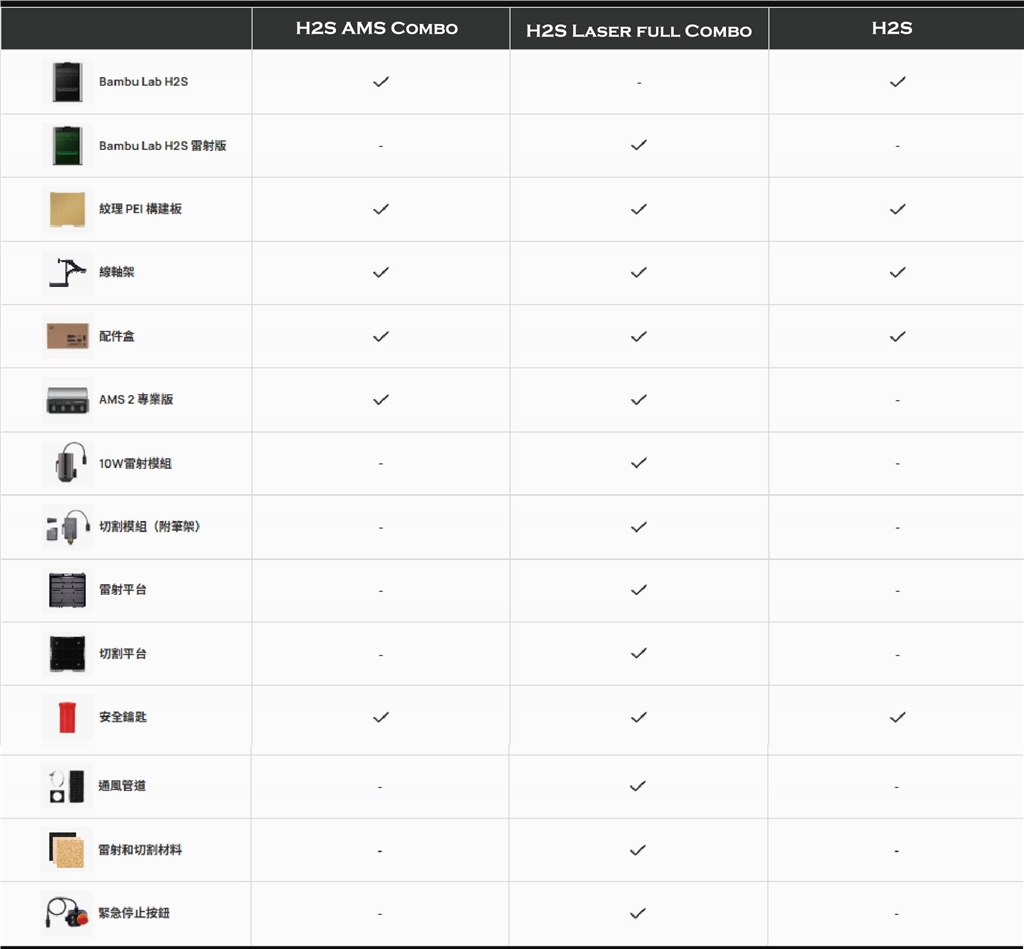

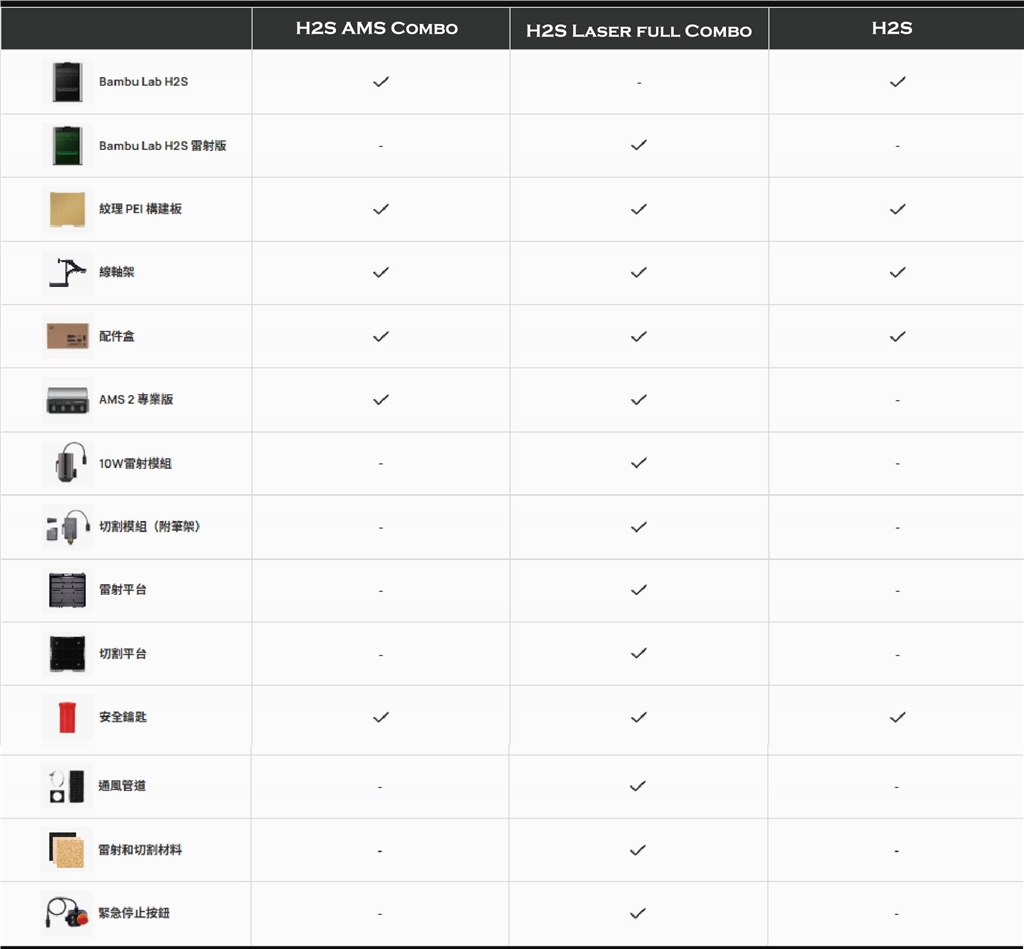

Product Contents

One-year warranty & repair instructions

For Bambu Lab equipment purchases, Santima offers a one-year standard warranty or enhanced warranty option . For any operational inquiries, please contact Santima via email.

👨💻【Enhanced Warranty Service Plan】

Free shipping | Free testing |Free repair

San Di Ma will send someone to collect repair equipment free of charge. → Santima engineer performs repair → After completion, Santima dispatches a vehicle to return it.

• We cannot accept additional orders for the "Enhanced Warranty Plan" after shipment . Please confirm the selected warranty plan that meets your needs when placing your order.

• If there is any problem with the machine, please fill out the technical support form .

• Be sure to use the original complete packaging (outer box, protective foam, etc.) and include all original accessories (e.g., power supply, SD card, cable, printing materials used at the time, etc.) to avoid any omissions in the repair process.

• The engineer assessed the damage as caused by human error or unauthorized modification . For non-human-caused damage, original manufacturer repair and warranty services are available. Consumables (such as spray nozzles) and spare parts are not covered by the warranty.

• All operation training is quoted separately by a Sandima specialist. You can fill out the contact form to inquire.

Please note: To ensure the stability of the AMS 2 Pro drying process, please use an official Bambu Lab power supply.

Contact us for more information about the Bambu Lab 3D printer !

| 物品 | 規格 |

|---|---|

| 列印技術 | 熔融沈積成型 |

| 列印體積(寬深高) | 340x320x340 毫米 |

| 機殼 | 鋁、鋼、塑膠和玻璃 |

| 雷射安全窗 | 裝備在雷射版上,普通 H2S 可透過雷射升級套件升級 |

| 空氣輔助幫浦 | 裝備在雷射版上,普通 H2S 可透過雷射升級套件升級 |

| 設備尺寸 | 492x514x626 毫米 |

| 淨重 | H2S:30 公斤 / H2S 雷射版:30.5 公斤 |

| 工具頭 - 熱端 | 全金屬 |

| 工具頭 - 擠出機齒輪 | 硬化鋼 |

| 工具頭 - 噴嘴 | 硬化鋼 |

| 最高噴嘴溫度 | 350 ℃ |

| 包含噴嘴直徑 | 0.4 毫米 |

| 支援的噴嘴直徑 | 0.2、0.4、0.6、0.8 毫米 |

| 線材切割機 | 內建 |

| 線材直徑 | 1.75 毫米 |

| 擠出機電機 | Bambu Lab 高精度永磁同步電機 |

| 熱床支援板類型 | 紋理 PEI 板、光滑 PEI 板 |

| 最高熱床溫度 | 120 ℃ |

| 最大轉速 | 1000 毫米/秒 |

| 最大加速度 | 20,000 毫米/秒² |

| 熱端最大流量(標準) | 40 mm³/s(測試:ABS 280℃) |

| 熱端最大流量(高流量) | 65 mm³/s(測試:ABS 280℃) |

| 腔體溫度控制 | 主動腔體加熱,最高 65 ℃ |

| 空氣淨化 - 預過濾 | G3 |

| 空氣淨化 - HEPA | H12 |

| 空氣淨化 - 活性碳 | 椰殼顆粒 |

| VOC 過濾 | 優越 |

| 顆粒物過濾 | 支援 |

| 冷卻風扇 | 零件、熱端、主控板、室內排氣、箱體熱循環、輔助部件皆閉環控制 |

| 支援線材類型 | PLA、PETG、TPU、PVA、BVOH、ABS、ASA、PC、PA、PET、PPS;碳/玻璃纖維增強 PLA、PETG、PA、PET、PC、ABS、ASA、PPA、PPS |

| 感應器 - 即時取景相機 | 內建;1920*1080 |

| 感應器 - 工具頭相機 | 內建;1600*1200 |

| 感應器 - 鳥瞰相機 | 內建;3264*2448(雷射版) |

| 感應器 - 門感應器 | 支援 |

| 感應器 -線材耗盡/纏結 | 支援 |

| 感應器 - 線材里程計 | AMS 支援 |

| 斷電恢復 | 支援 |

| 電壓需求 | 100-120V / 200-240V,50/60Hz |

| 最大功率 | 2050W @220V / 1170W @110V |

| 工作溫度 | 10-30 ℃ |

| 觸控螢幕 | 5 吋 720*1280 |

| 儲存 | 內建 8GB EMMC + USB 連接埠 |

| 控制介面 | 觸控螢幕、行動應用、PC 應用 |

| 軟體 | Bambu Studio;支援匯出標準 G-code 的第三方切片(Super Slicer、PrusaSlicer、Cura 等) |

| 支援作業系統 | MacOS、Windows、Linux |

| 無線網路 - 頻率 | 2.4GHz (2412-2472MHz, 2400-2483.5MHz)、5GHz (5150-5850MHz) |

| 無線網路 - 協議 | IEEE 802.11 a/b/g/n |

| 10W 雷射模組 - 類型 | 半導體雷射 |

| 10W 雷射模組 - 波長 | 455nm ±5nm 藍光;850nm ±5nm 紅外線 |

| 10W 雷射模組 - 功率 | 10W ±1W |

| 10W 雷射模組 - 光斑尺寸 | 0.03*0.14 mm² |

| 10W 雷射模組 - 雕刻區域 | H2D:310270 mm²;H2S:310260 mm² |

| XY 定位 | 視覺定位,精度 <0.3 毫米 |

| Z 高度測量 | 微型光達,精度 ±0.1 毫米 |

| 雷射模組安全等級 | 模組:4 級 / 整體:1 級 |

| 火焰/溫度/門感測 | 支援 |

| 雷射模組安裝檢測 | 支援 |

| 安全鑰匙 | 包含 |

| 氣泵 | 內建;30 kPa,30 L/min |

| 通風管接頭外徑 | 100 毫米 |

| 支援雕刻材料 | 木材、橡膠、金屬板、皮革、深色壓克力、石材等 |

| 切割模組 - 區域 | H2D:300285 mm²;H2S:297.5300 mm² |

| 切割模組 - 繪圖區域 | 300*255 mm² |

| 切割模組 - 支援筆直徑 | 10.5-12.5 毫米 |

| 切割模組 - 切割墊類型 | LightGrip、StrongGrip |

| 切割模組 - 刀片 | 45°*0.35 毫米 |

| 切割模組 - 壓力範圍 | 50g-600g |

| 切割模組 - 最大厚度 | 0.5 毫米 |

| 切割模組 - 刀片/筆識別 | 支援 |

| 切割模組 - 圖像類型 | 點陣圖與向量圖 |

| 切割模組 - 支援材料 | 紙張、PVC、乙烯基、皮革等 |

為確保加熱床快速達到所需溫度,印表機將保持最大功率約 3 分鐘。 ² 當印表機的保護完成且正常運作時,印表機和雷射模組將作為 1 類雷射產品運作。

一年保固&維修說明

購買Bambu Lab相關機台,三帝瑪提供您一年一般保固或加強保固服務選擇,任何操作疑問聯絡 三帝瑪信箱 詢問

👨💻【加強保固服務方案】

| 免來回運費 | 免檢測費 | 免維修費 |

三帝瑪免費派人收取維修設備 → 三帝瑪工程師維修 → 完成後三帝瑪派車送回

• 本公司於出貨後即無法受理加購【加強保固方案】,請於下訂時確認選擇符合您需求的保固方案內容

• 機器如有狀況請先填寫技術支援表單

• 務必使用原廠完整包裝(外箱、防護泡棉等),一併附上所有原廠配件(例如:電源供應器、SD卡、電線、列印當時所使用之材料…等等),以避免任何維修上的遺漏。

• 經工程師評估為人為損壞、自行改裝損壞 或 非人為損傷之原廠維修保固服務,消耗品(如:噴頭等)、零配件不在保固範圍內

• 所有操作教學由三帝瑪專員另外報價,可填寫聯絡表單詢問

商品內容