Bambu Lab A1 Mini 3D Printer Series

Bambu Lab A1 Mini 3D Printer Series - is backordered and will ship as soon as it is back in stock.

Choose add-on

Couldn't load pickup availability

For Bambu Lab equipment purchases, Santima offers a one-year standard warranty or enhanced warranty . For any operational inquiries, please contact Santima via email.

• We cannot accept additional orders for the "Enhanced Warranty Plan" after shipment . Please confirm the selected warranty plan that meets your needs when placing your order.

• If there is any problem with the machine, please fill out the technical support form .

• Be sure to use the original complete packaging (outer box, protective foam, etc.) and include all original accessories (e.g., power supply, SD card, cable, printing materials used at the time, etc.) to avoid any omissions in the repair process.

• The engineer assessed the damage as caused by human error or unauthorized modification . For non-human-caused damage, original manufacturer repair and warranty services are available. Consumables (such as spray nozzles) and spare parts are not covered by the warranty.

• All operation training is quoted separately by a Sandima specialist. You can fill out the contact form to inquire.

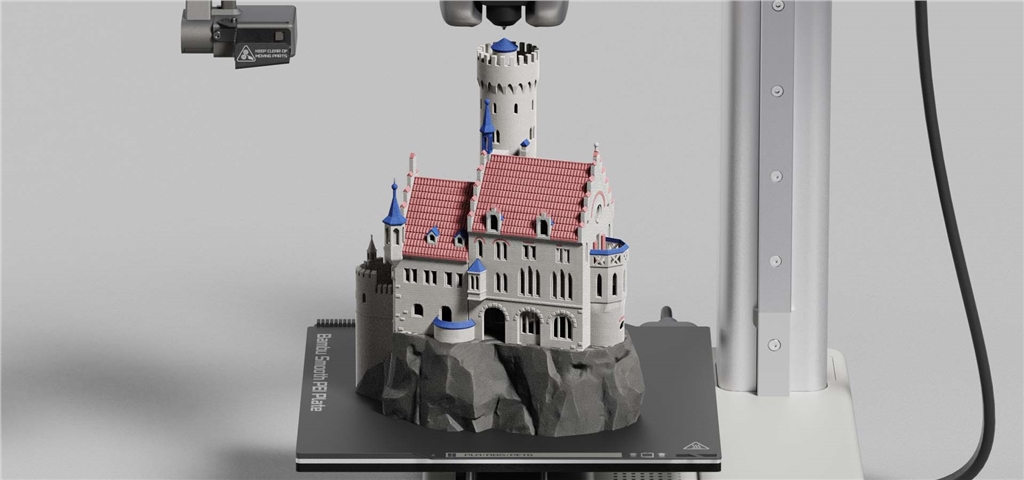

Topzhu Bambu Lab A1 Mini Combo 3D Printer (with AMS Lite)

Bambu Lab has launched its new entry-level 3D printer, the A1 Mini, which is the lightest, smallest, most affordable, and easiest to use among Bambu Lab's many 3D printers !

For a hands-on review, please click here 👉 Bambu Lab A1 Mini Combo: A high-performance multi-color 3D printer with excellent value!

Overall characteristics

• Fully automatic calibration

• Use AMS lite for four-color printing

• Noise level below 48 decibels in silent mode

• All-metal linear guides and bearings

• Vibration and flow velocity compensation

Simple and easy-to-use multicolor printing

The new AMS lite automatic feeding system is compact and reliable, and when paired with the A1 mini, it makes multi-color 3D printing easy for everyone.

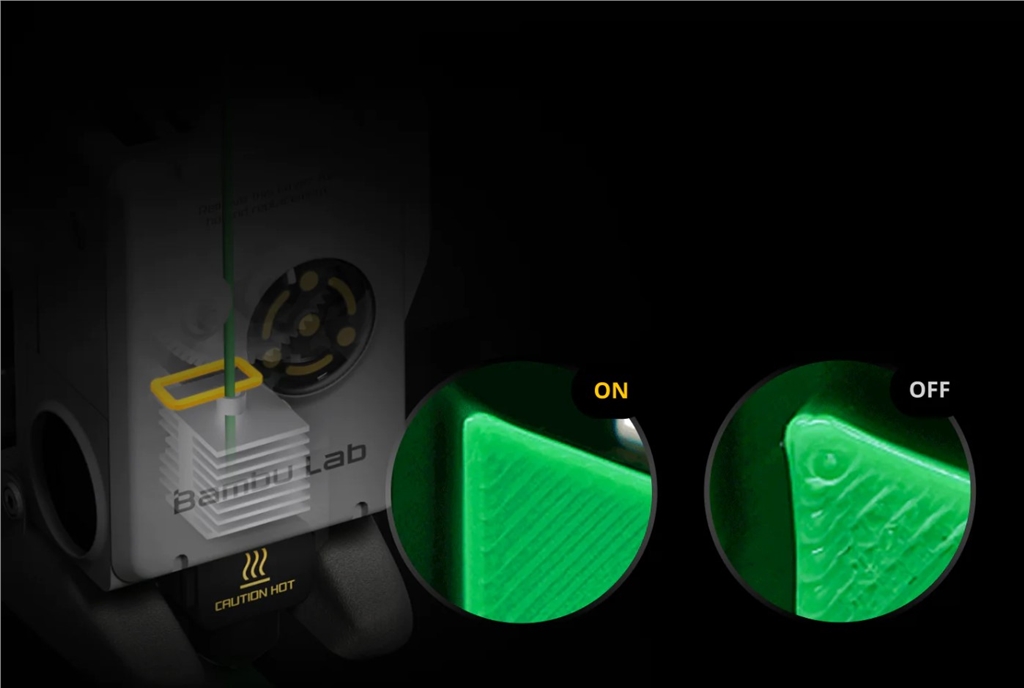

Active traffic compensation

The A1 mini revolutionizes flow control in 3D printing. It utilizes a high-resolution, high-frequency eddy current sensor to measure pressure in the nozzle. An algorithm actively compensates for the flow rate based on these readings, achieving precise extrusion and ensuring a smooth, seamless finish at every turn!

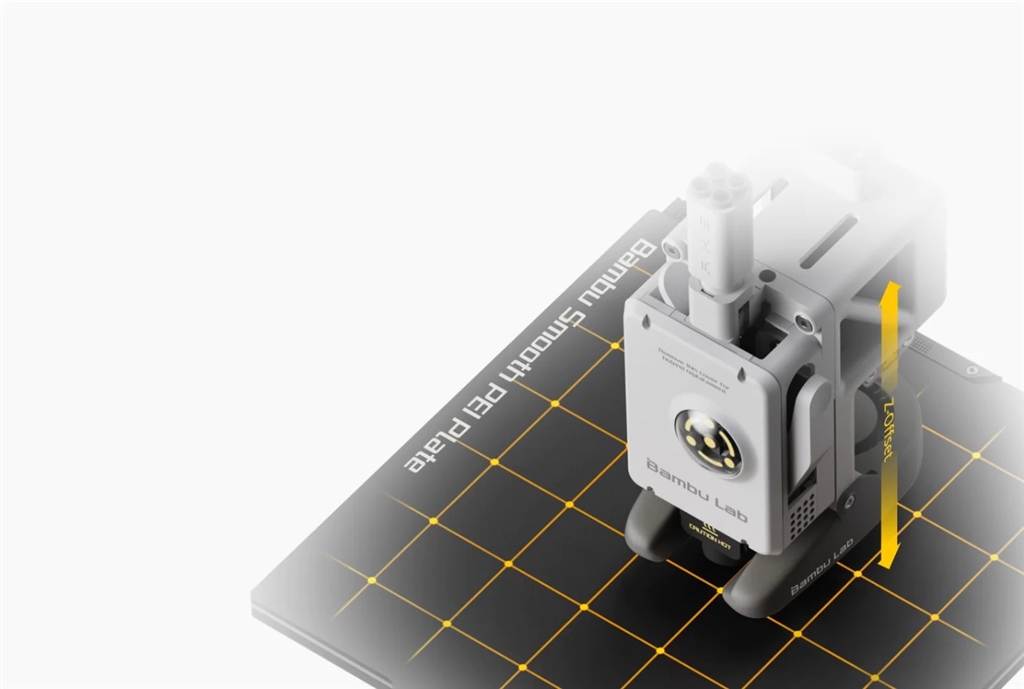

Fully automatic calibration

The A1 mini can handle various calibrations automatically. It can automatically and meticulously calibrate Z-offset, bed level, vibration resonance, and nozzle pressure for each print job. No more tedious manual calibration and adjustments!

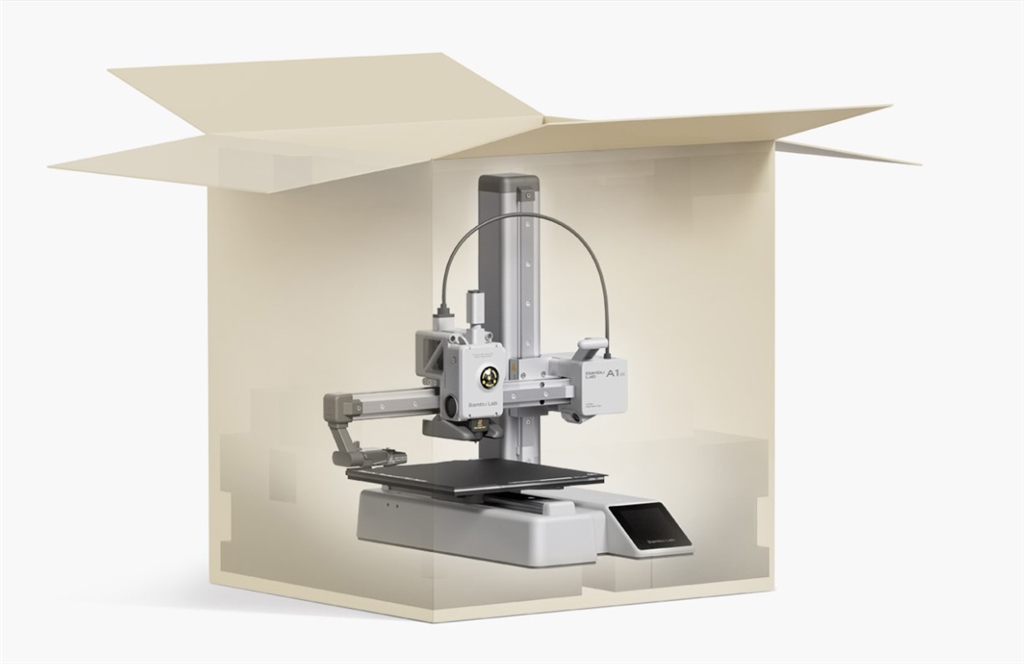

Plug and play

The A1 mini comes pre-assembled and precisely pre-calibrated and pre-leveled at the factory. Once you receive it, you're ready to print your first print in just 20 minutes, without any manual adjustments. Getting started has never been easier!

Motor active noise reduction technology

The A1 mini can calibrate parameters to match the subtle individual differences between each drive motor. This compensates for unwanted motor noise. Active noise cancellation and silent mode keep the printer's operating noise level below 48 dB, allowing you to take a break in the printer 's workspace without being disturbed!

High speed and precision

The A1 mini features an all-metal rail and frame, a nozzle pressure sensor, an accelerometer, and a powerful MCU. With precise control from its advanced motion control system, the A1 mini can fire a perfect 14-minute boat without the need for a special PLA.

Synchronize with Bambu Studio and Bambu Handy

Remotely control and monitor your printer using Bambu Studio or Bambu Handy. You can also record time-lapse videos using the built-in camera.

Contact us for more information about Bambu Lab 3D printers !

| body | A1 Mini | |

| technology | Fused deposition modeling | |

| Print size (length × width × height) | 180 x 180 x 180 mm | |

| hot end | All Metal | |

| Extruder teeth | steel | |

| nozzle | Stainless steel | |

| Maximum temperature at the hot end | 300℃ | |

| Nozzle diameter (default setting) | 0.4mm | |

| Nozzle diameter (optional) | 0.2mm, 0.6mm, 0.8mm | |

| Tool head cutter | built-in | |

| wire diameter | 1.75 mm | |

| Compatible print plate surface | Bambu textured PEI panel, Bambu smooth PEI panel | |

| Maximum temperature of printing plate | 80℃ | |

| Maximum speed of tool head | 500 mm/s | |

| Maximum acceleration of tool head | 10 m/ s² | |

| Maximum hot end flow | 28 mm/s @ABS (Model: 150 × 150 mm Single-wall material: Bambu ABS; Temperature: 280°C) | |

| Component cooling fan | Closed-loop control | |

| Hot end fan | Closed-loop control | |

| MC board cooling fan | Closed-loop control | |

| PLA, PETG, TPU, PVA | ideal | |

| ABS, ASA, PC, PA, PET, Carbon/ Glass Fiber Reinforced Polymer | Not recommended | |

| Surveillance cameras | Low-speed cameras (up to 1080p) support time-lapse photography. | |

| Material breakage detection | support | |

| Fineness measurement | support | |

| Power outage resume printing | support | |

| Wire winding sensor | support | |

| External dimensions | 347 x 315 x 365 mm | |

| net weight | 5.5 kg | |

| Voltage | 100-240VAC, 50/60Hz | |

| Maximum power | 150W | |

| Display screen | 2.4-inch 320 x 240 IPS touchscreen | |

| capacity | Micro SD Card | |

| User interface | Touchscreen, mobile app, desktop application | |

| motion controller | Dual-core Cortex-M4 processor | |

| Slicing software | It supports other vendor slicers that can export standard G-code, such as Superslicer, Prusaslicer, and Cura, but some smart features may not be supported. | |

| The slicing software supports operating systems. | MacOS, Windows | |

| program | IEEE 802.11 b/g/n | |

| Product contents | Topzhu Bambu Lab A1 Mini 3D Printer Bambu Lab AMS Lite chassis (cable not included, for display only) Bambu AMS Lite Stand AMS Lite Rotary Spool Holder x5 cleaning wipers Bambu Texture PEI Panel PTEF pipe x5 Accessory box 20g Bambu cable x1 (color/type random) |

|

For any Bambu Lab equipment purchases, SanDima provides a one-year warranty and maintenance service . For any operational questions, please contact SanDima via email .

• If the machine malfunctions, please fill out the technical support form first. If the engineer assesses that the damage is not caused by human error, the following two methods can be used:

🔧【 Customer DIY Parts Repair】

We will ship the parts to the designated location free of charge → Customers will assemble the parts themselves.

👨💻【Sandyma Engineer Repair Service】

1. Original packaging available → Pay shipping + repair fee $2000 → Sandima dispatches a vehicle to pick up the machine → Sandima engineer performs maintenance → Sandima dispatches a vehicle to return the machine after completion

2. No original packaging → You are responsible for arranging your own shipping or retrieval costs → Send to Sandima Co., Ltd. → Sandima engineers will repair the machine → After completion, retrieve the machine from Sandima Co., Ltd.

• The engineer assessed the damage as caused by human error or unauthorized modification . For non-human-caused damage, original manufacturer repair and warranty services are available. Consumables (such as spray nozzles) and spare parts are not covered by the warranty.

• All operation training is quoted separately by a Sandima specialist. You can fill out the contact form to inquire.