Bambu Lab | Product Model:

BL0026_175mm_500g

Bambu Lab ABS Support Material

Regular price

¥2,500 JPY

Unit price

/

Unavailable

Subtotal

—

Bambu Lab ABS Support Material is backordered and will ship as soon as it is back in stock.

Choose add-on

Couldn't load pickup availability

Bambu Lab ABS support material

Enhance your ABS printing experience with our innovative support materials.

This material is designed for easy printing and easy removal, ensuring a perfect support interface every time.

It is fully compatible with the AMS system, simplifying your ABS printing process from start to finish.

Say goodbye to cumbersome deletion support and enjoy a smoother, more efficient workflow!

This material is designed for easy printing and easy removal, ensuring a perfect support interface every time.

It is fully compatible with the AMS system, simplifying your ABS printing process from start to finish.

Say goodbye to cumbersome deletion support and enjoy a smoother, more efficient workflow!

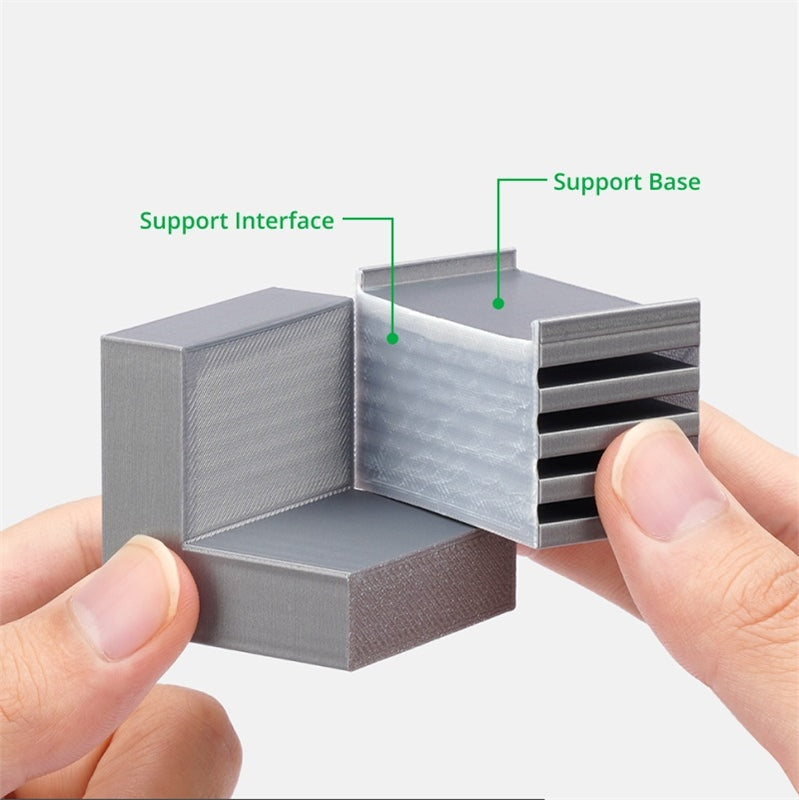

Easily remove support

Our support material is specially formulated for ABS, allowing it to adhere precisely to ABS surfaces and thus be easily removed.

This simplifies your post-production work and ensures a more efficient workflow.

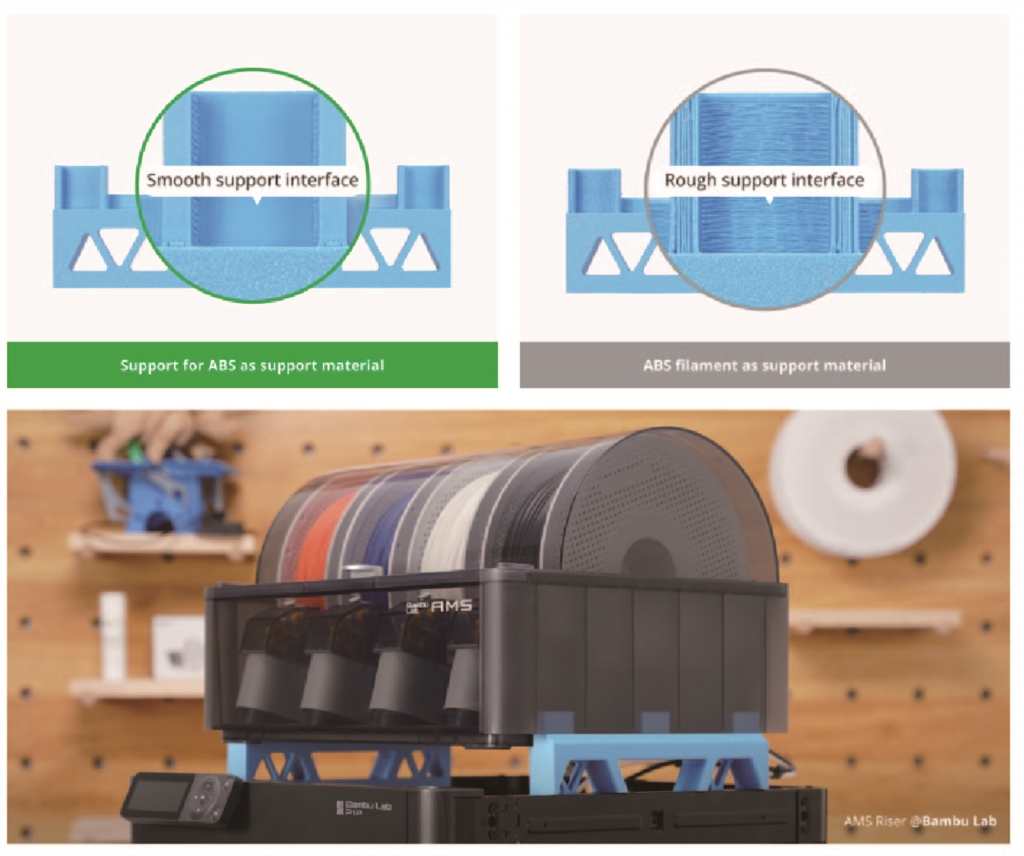

Excellent support interface quality

The support for ABS ensures that the Top Z distance and Top interface spacing are 0 during printing, guaranteeing that the support surface is free of scars.

This enhances the clarity of details and improves the overall look and integrity of the final print.

The support for ABS ensures that the Top Z distance and Top interface spacing are 0 during printing, guaranteeing that the support surface is free of scars.

This enhances the clarity of details and improves the overall look and integrity of the final print.

RFID Smart Printing

All printing parameters are embedded in RFID and can be read through our AMS (Automated Material System).

Load and print! No more tedious setup steps required.

Contact us for more information about Bambu Lab 3D printers !

Recommended print settings

| project | Setting value |

|---|---|

| Drying settings (forced air drying oven) | 80℃, 4 hours |

| Print and maintain container humidity | < 20% RH (sealed, with desiccant) |

| Nozzle temperature | 240 - 270 ℃ |

| Bed temperature (including adhesive) | 80 - 100 ℃ |

| Printing speed | < 100 mm/s |

Physical properties

| project | numerical values |

|---|---|

| density | 1.16 g/cm³ |

| Vicat softening temperature | not applicable |

| Heat distortion temperature | not applicable |

| melting temperature | 195 ℃ |

| Melt Flow Index | 11.6 ± 0.7 g/10 minutes |