3Devo Filament Maker ONE Series

3Devo Filament Maker ONE Series - is backordered and will ship as soon as it is back in stock.

Choose add-on

Couldn't load pickup availability

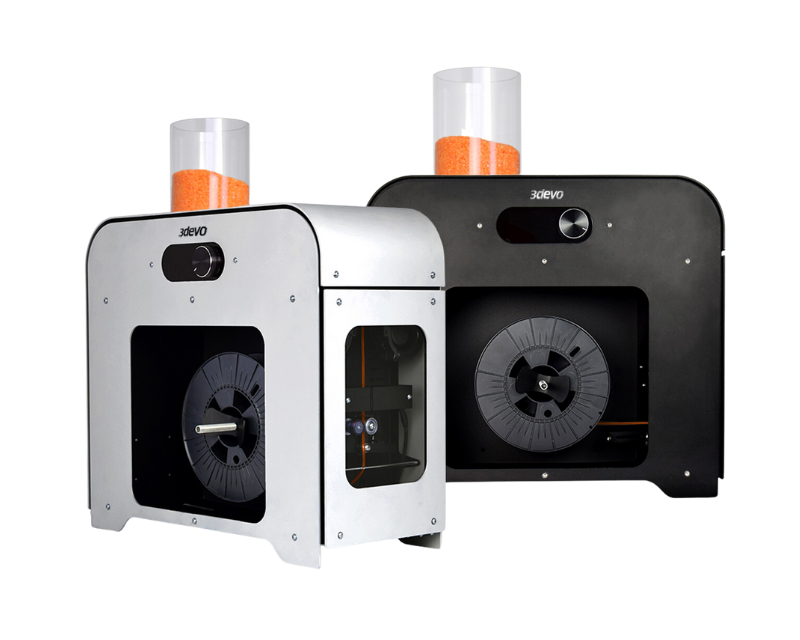

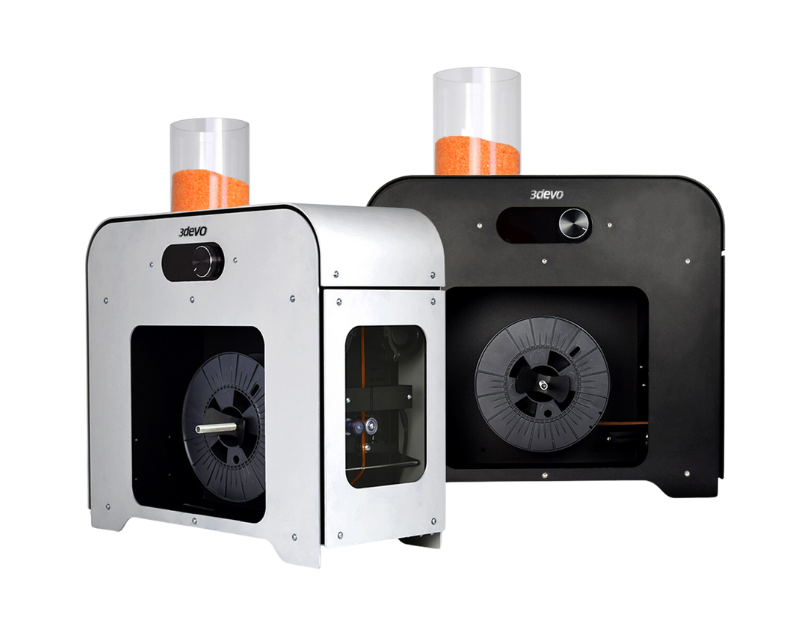

3Devo Filament Maker ONE Series - Precision / Composer

Early wire extruder models were pioneers in 3D printing, providing reliable extrusion and material versatility.

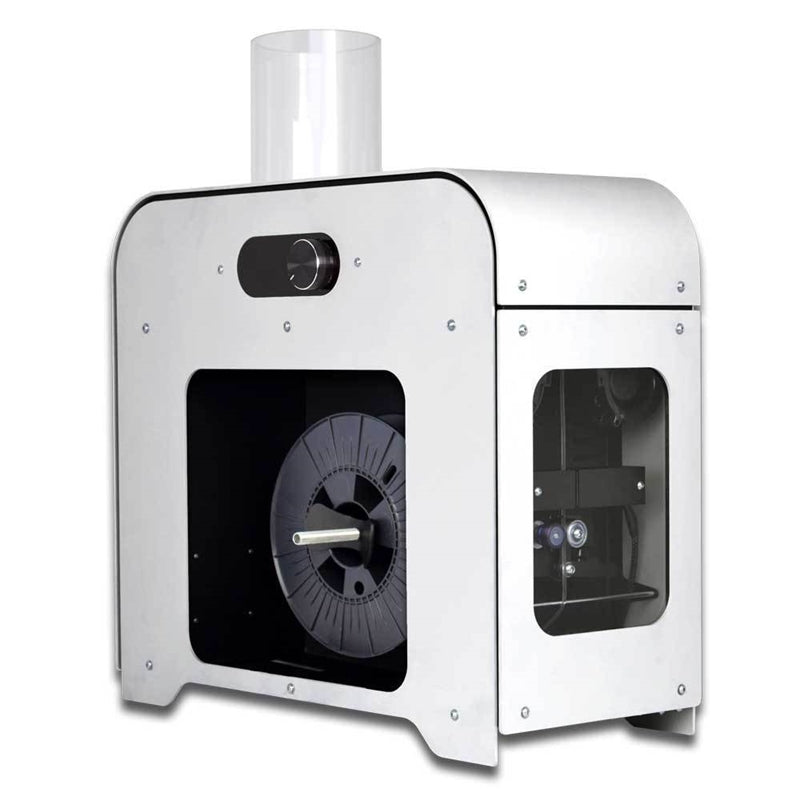

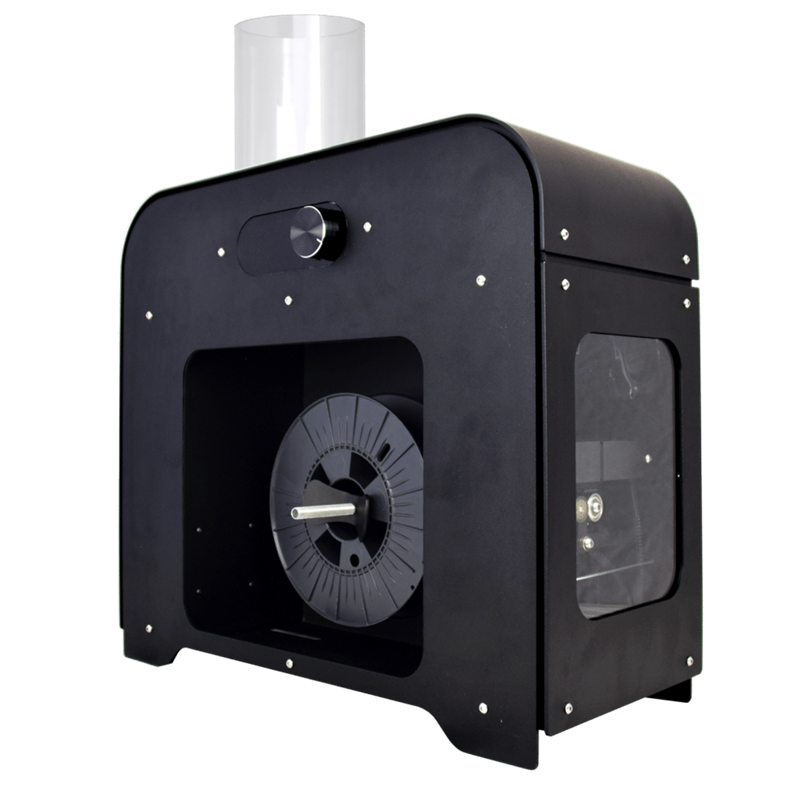

Unsatisfied with the finished product? Are you producing excess material from printed filaments? In this new era of environmental protection, here's a solution for you! 3Devo's Filament Maker ONE series of filament makers can mix various materials to create new filaments, achieving recycling and making the most of your filaments while saving costs! This series offers two models: Composer and Precision.

User-friendly control interface

• Streamlined interface: Easily navigate via an OLED display and a simple rotary button.

• Quick Setup Profiles: Start your project using standard preset materials (PLA, ABS, PA12, PC, PEEK, and PS), or create your own custom profiles for unparalleled results.

Comprehensive data monitoring

• Real-time process insights: Real-time monitoring of key parameters such as heater settings, wire thickness, and motor current to maintain precise system control.

• Detailed analysis: Track the speed of the wire drawing machine and the screw rotation speed. All data is displayed intuitively in the form of charts and graphs, and the data can be easily exported to Excel for further analysis.

• Optimize performance: Use this comprehensive data to fine-tune material settings to ensure consistently high-quality wire production.

• Industrial-grade extruder screw: Nitrided and hardened, durable, with mixing capabilities to mix wire evenly.

• Multi-functional extruder mixing zone: Try using various additives, plastics, fibers or powders to customize wires to your needs.

• Smart Material Handling: Includes an optical hopper sensor for monitoring material level.

• Vertical extrusion: Ensures precise wire roundness and direct roll formation, improving 3D printing quality.

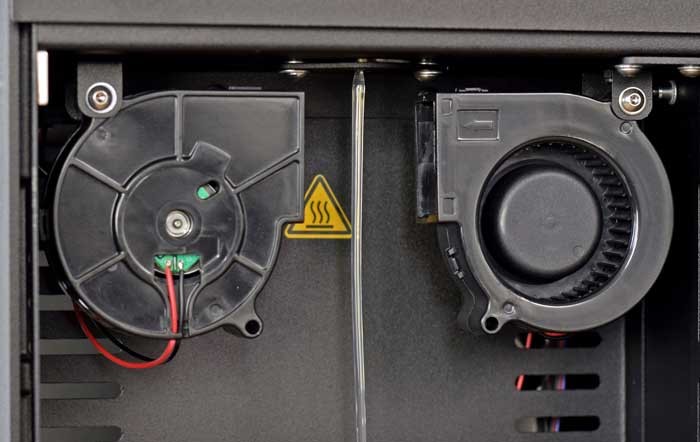

• Cutting-edge cooling and spools: A balanced dual-fan system provides uniform cooling, while precise spool settings with an adjustable positioner and automatic spool function enhance performance.

Apply advanced technology

High-efficiency spool mechanism

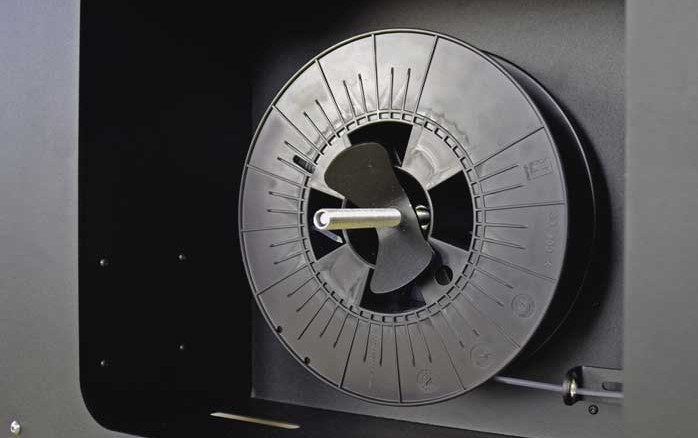

• Adaptable spool mounting: Supports spools of various sizes, allowing for flexible material production.

• Customizable spools: Set specific dimensions for perfect spool winding, while the built-in slip clutch adjusts tension for smooth operation.

• Precise take-up: Supports a maximum diameter of 240 mm and a width of 120 mm, ensuring neat and tangle-free spools.

Filament Maker One - Composer Highlights:

Suitable for mixing, preparation and experimentation

Fiber Maker - Product Specifications

Heating system

| highest temperature | The 450 series has a maximum temperature of 450 °C. |

| strip heater | ceramics |

| heating zone | 4 |

| Independent control | yes |

Output

| Speed range | 2 - 15 RPM |

| Wire diameter range | 0.5 - 3 mm (0.02 - 0.12 inches) |

| Optical sensor accuracy | 43 micrometers (1.69 mils) |

| Nozzle extruder | 4 mm (0.16 inch) diameter - replaceable |

Extruder system

| Screw/Barrel Alloy | High-chromium molybdenum alloy steel |

| Hardening treatment | Nitriding |

| compression | Level 3 |

| Extruder design | Replaceable |

| Material mixing zone | Composer series only |

Energy consumption

| Average consumption | 300 - 400 W |

| Maximum consumption | 1300 W |

| Voltage | 110 - 230 V |

| frequency | 50 - 60 Hz |

capacity

| Hopper volume | 2 liters |

| spool support | 1 |

| spool size | 240 mm (9.4 inches) in diameter 120 mm (4.7 inches) wide |

Size and weight

| size | 506 x 216 x 448 mm 19.2 x 8.5 x 17.6 inches |

| weight | Extruder (excluding packaging): 24.5 kg (54 lbs) Extruder + Box: 27 kg (59.5 lbs) |

connect

| Firmware update | Regular updates |

| Extrusion data analysis | DevoVision application |

| Connectivity | USB |

Filament Maker One Wire Making Machine - Model Comparison

| Composer Model | use | For mixing, preparation and experimentation |

| screw | Hybrid screw | |

| Precision b model | use | For high-quality mass production |

| screw | High flow screw | |

| model | Model 450 | The maximum temperature for engineered polymers and high-performance polymers is 450 °C. Polymers and high-performance polymers PEK, PC, PS, PEKK, PAEK, PEI, PSU, PES, PTFE, PVD+ |