Sinterit | Product Model:

ST0013

Flexa Soft Elastic Powder (2kg)

Regular price

¥92,500 JPY

Unit price

/

Unavailable

Subtotal

—

Flexa Soft Elastic Powder (2kg) is backordered and will ship as soon as it is back in stock.

Choose add-on

Couldn't load pickup availability

Flexa Soft Elastic Powder (2kg)

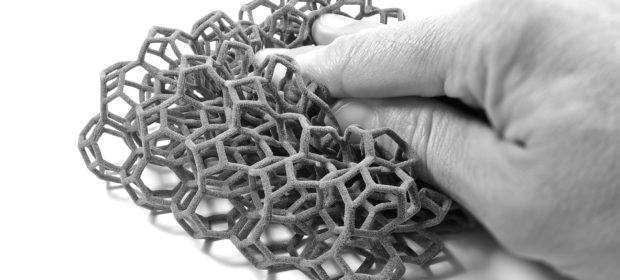

At Formnext 2018, Sinterit showcased Flexa Soft, the softest TPU powder designed specifically for SLS 3D printers . It boasts the lowest hardness (indicated by Shore A hardness) within its material range, offering unprecedented versatility.

Laminated manufacturing is typically used to produce rigid objects. Through various techniques, laser powder sintering ( SLS ) primarily uses fine, high-quality finished products made from PA powder (polyamide).

This type of TPU (thermoplastic polyurethane) material has excellent softness with a Shore A rating of 40-55. Flexa Soft has a very wide range of applications, from fashion to medicine; it provides near-perfect support when you need a soft material.

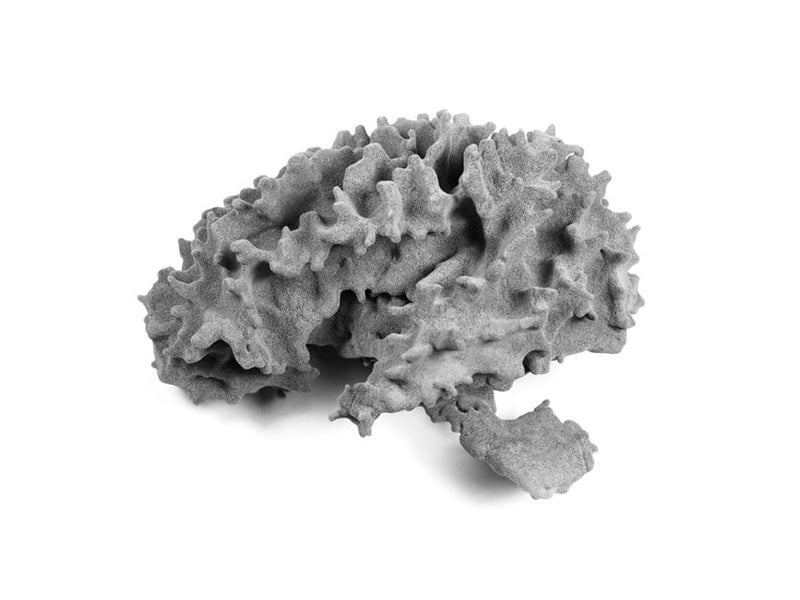

Used for experimental surgery

In recent years, with the advancement of medical imaging, 3D printing has also attracted attention from medical researchers, scholars, and related industries. For some surgeons, it has become routine to use 3D printed models to simulate the process before surgery: selecting appropriate surgical tools, planning the path, and even conducting surgical trials, such as actually cutting with a scalpel.

From the perspective of medical professionals, this material completely mimics the hardness of certain tissues. Finished products made from this powder not only have an excellent tactile feel, but their unique elasticity allows them to simulate the state and shape of being squeezed, and they retain their original appearance after being released.

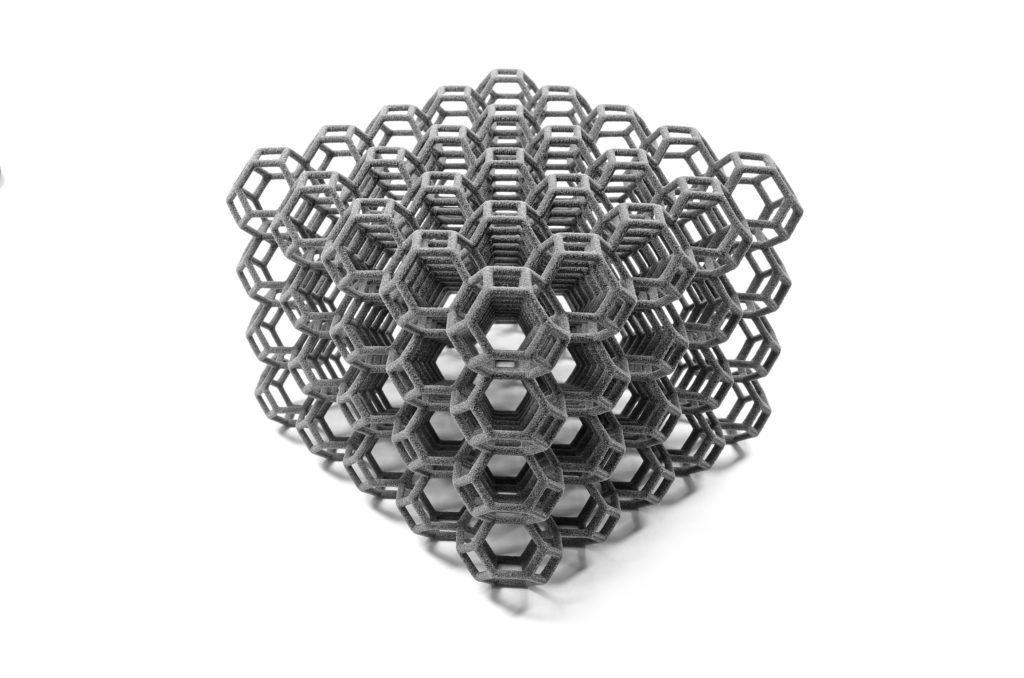

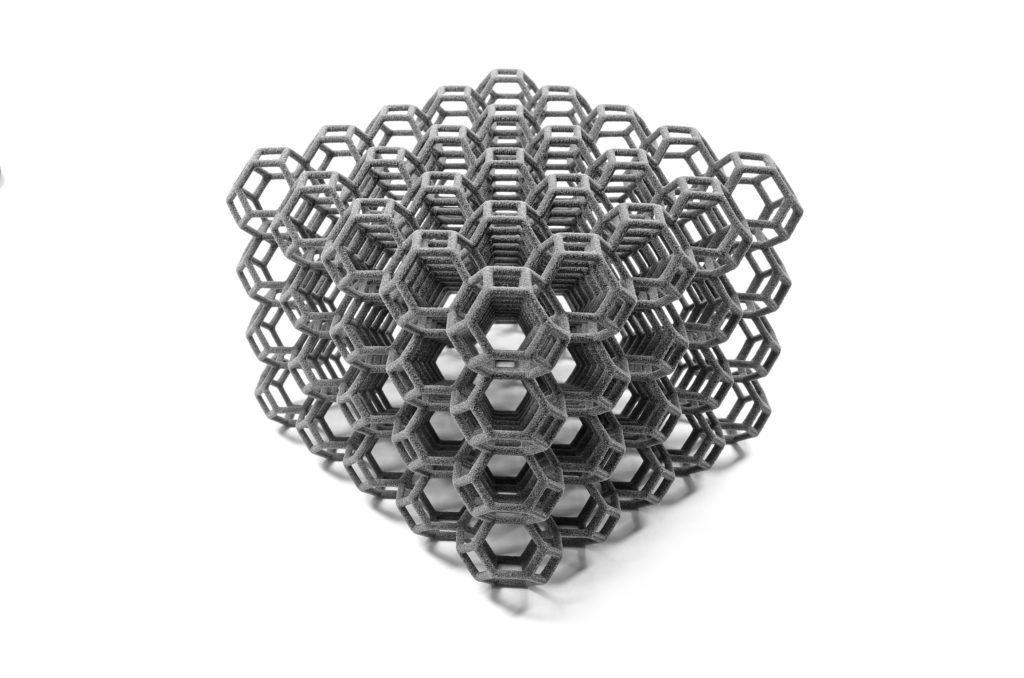

A New Direction in Fashion

For the fashion industry, it's a game-changer. We previously shared that fashion designers used another Sinterit fabric— Flexa Black —to create decorative accessories for swimwear (further reading: 3D Printing Fashion Adds a Touch of Splendor to Miss South Africa ).

The possibilities are now much wider because Flexa Soft can fit the wearer's body more closely, with almost no curvature limitations.

Developing new materials

In summary, the ultra-soft powder Flexa Soft will have 5 main features:

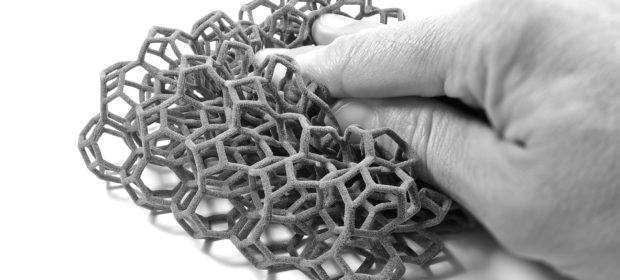

Super-elastic powder material, even more so than Flexa Black.

The data speaks for itself: Shore A softness rating 40-55.

• Simulates parts of human organs for surgical experiments. • A fashionable new option, fits snugly when worn. • Other general prototypes, rubber gaskets, or elastic applications.

“Our users are very enthusiastic about trying new powders and constantly asking us to develop new materials, which expands the manufacturing possibilities of the Sinterit Lisa printer,” said Konrad Glowacki, co-founder of Sinterit . “We welcome this feedback because we know there are many more possibilities for the use of SLS rapid prototyping,” he added.

With its superior elasticity, Flexa Soft is an excellent choice for general prototyping, making washers, or sensory toys. Discover more applications for Flexa Soft and purchase this new ultra-soft 3D printing material today!

At Formnext 2018, Sinterit showcased Flexa Soft, the softest TPU powder designed specifically for SLS 3D printers . It boasts the lowest hardness (indicated by Shore A hardness) within its material range, offering unprecedented versatility.

Laminated manufacturing is typically used to produce rigid objects. Through various techniques, laser powder sintering ( SLS ) primarily uses fine, high-quality finished products made from PA powder (polyamide).

This type of TPU (thermoplastic polyurethane) material has excellent softness with a Shore A rating of 40-55. Flexa Soft has a very wide range of applications, from fashion to medicine; it provides near-perfect support when you need a soft material.

Used for experimental surgery

In recent years, with the advancement of medical imaging, 3D printing has also attracted attention from medical researchers, scholars, and related industries. For some surgeons, it has become routine to use 3D printed models to simulate the process before surgery: selecting appropriate surgical tools, planning the path, and even conducting surgical trials, such as actually cutting with a scalpel.

From the perspective of medical professionals, this material completely mimics the hardness of certain tissues. Finished products made from this powder not only have an excellent tactile feel, but their unique elasticity allows them to simulate the state and shape of being squeezed, and they retain their original appearance after being released.

A New Direction in Fashion

For the fashion industry, it's a game-changer. We previously shared that fashion designers used another Sinterit fabric— Flexa Black —to create decorative accessories for swimwear (further reading: 3D Printing Fashion Adds a Touch of Splendor to Miss South Africa ).

The possibilities are now much wider because Flexa Soft can fit the wearer's body more closely, with almost no curvature limitations.

Developing new materials

In summary, the ultra-soft powder Flexa Soft will have 5 main features:

Super-elastic powder material, even more so than Flexa Black.

The data speaks for itself: Shore A softness rating 40-55.

• Simulates parts of human organs for surgical experiments. • A fashionable new option, fits snugly when worn. • Other general prototypes, rubber gaskets, or elastic applications.

“Our users are very enthusiastic about trying new powders and constantly asking us to develop new materials, which expands the manufacturing possibilities of the Sinterit Lisa printer,” said Konrad Glowacki, co-founder of Sinterit . “We welcome this feedback because we know there are many more possibilities for the use of SLS rapid prototyping,” he added.

With its superior elasticity, Flexa Soft is an excellent choice for general prototyping, making washers, or sensory toys. Discover more applications for Flexa Soft and purchase this new ultra-soft 3D printing material today!

Flexa Soft Elastic Powder

Material type: TPU

Shore A hardness: 45/56 (depending on print settings)

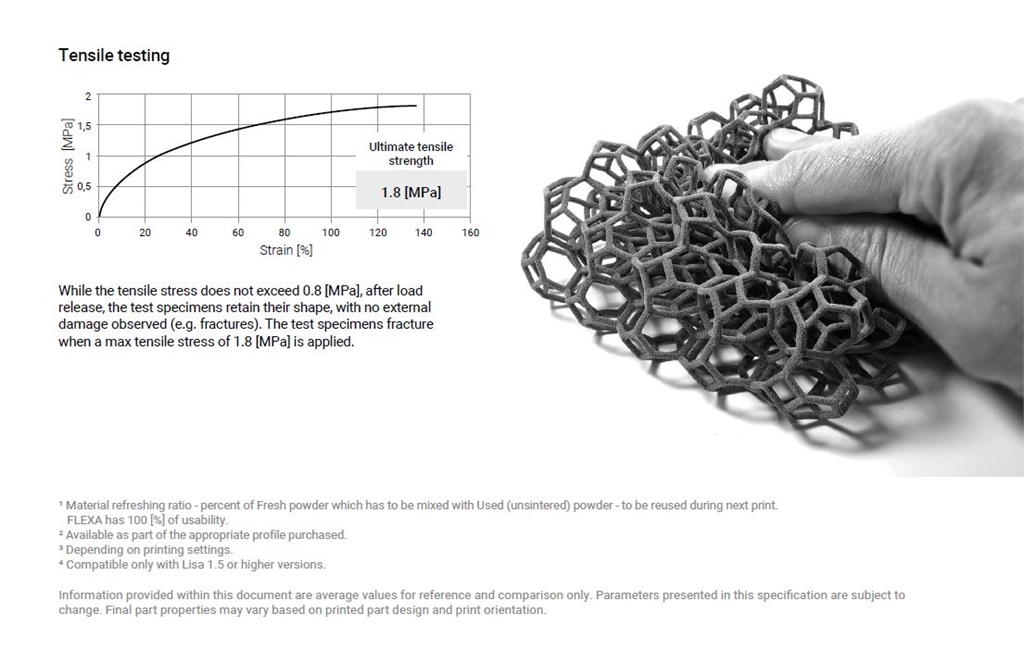

Tensile strength: 1.8 MPa

Elongation: 137%

Melting point: 150℃

Parameter table

Material type: TPU

Shore A hardness: 45/56 (depending on print settings)

Tensile strength: 1.8 MPa

Elongation: 137%

Melting point: 150℃

Parameter table