[3D Printing Applications] 3D printing filaments can actually lift a 12-ton tank!? Ultimaker's amazing innovation!

"How strong are 3D-printed objects?" This is a question that everyone, including engineers, likely has. After all, understanding the applications of materials is crucial. Ultimaker , Covestro, and the Royal Dutch Navy gathered to brainstorm and find the answer!

The common way to test material strength is to use a tensile testing machine to print a small sample and apply a strong force until the sample breaks. The strength coefficient is the force applied at the point of fracture divided by the surface area at the center intersection. While this data is significant for engineers, sometimes "seeing is believing." To achieve the strength of 3D-printed samples that they envisioned, Ultimaker and Covestro embarked on an unprecedented collaboration with the Royal Netherlands Navy: lifting something incredibly heavy! Was it a super-heavy dumbbell, a motorcycle, a car, or a jeep?

The Royal Netherlands Navy suggested, "Why not try armored vehicles?"

This proposal has shocked everyone's imagination!

The Royal Netherlands Navy suggested, "Why not try armored vehicles?"

This proposal has shocked everyone's imagination!

Initial design creation

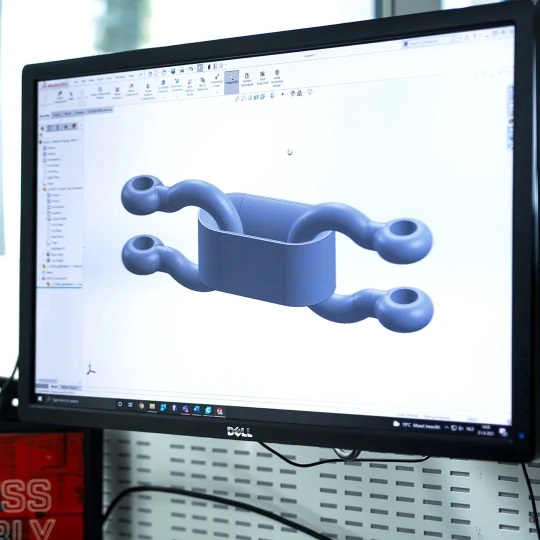

To use a 3D-printed sample to lift an extremely heavy vehicle, the first step is to analyze the available hardware. The Royal Netherlands Navy has a special lifting tank that can be used, connected by steel rings that can be opened on both sides. One side connects to a crane, and the other side connects to a cable for lifting the vehicle. The design is a slender O-ring that connects two metal rings and can lift extremely heavy vehicles.

After importing the geometry of the metal ring into the CAD software, Lars de Jongh, an application engineer at Ultimake , served as the initial designer.

First, he defined the design requirements:

• The object to be connected needs a flat surface for stable 3D printing. • The direction of the layer lines to be printed must be the same as the direction of the force applied to the sample. • The interaction surface between the printed sample and the metal ring should be as large as possible to evenly distribute the force.

Finding suitable materials

Hundreds of filaments are compatible with Ultimaker , each with a unique combination of properties that are likely to meet design requirements. Additionally, the filament itself must be very strong and able to absorb short-peak forces. Covestro's Addigy® F1030 CF10 perfectly meets these requirements. This nylon-based polymer contains carbon fibers, and the Ultimaker S5, when paired with a CC printhead, can be used for printing.

Using simulation to optimize design

Compared to traditional production methods, 3D printing a robust 2kg bond takes significantly less time. However, validating the printed samples requires repeated testing. Optimizing the print by simulating the real object using a computer before printing can effectively save time on repeated testing.

Covestro uses software based on the physical properties of carbon fiber and nylon to digitally apply forces to designs. Through simulations and calculations, the design can be precisely adjusted, eliminating unwanted wire sections. This optimizes the entire design, allowing for the lifting of greater weights with less wire, resulting in faster production times and lower costs.

Verification Simulation

Before being able to lift super-heavy vehicles, physical verification of the calculated strength of printed samples is required. Two sizes, two designs: the first weighs 1 kg and is estimated to withstand 12 tons; the second weighs approximately 2 kg and is estimated to withstand 38 tons. The Royal Netherlands Navy has an industrial tensile testing machine on site, capable of applying forces up to 343 kN to objects. Both the initial and optimized versions underwent testing for both large and small loads.

First, he defined the design requirements:

• The object to be connected needs a flat surface for stable 3D printing. • The direction of the layer lines to be printed must be the same as the direction of the force applied to the sample. • The interaction surface between the printed sample and the metal ring should be as large as possible to evenly distribute the force.

Finding suitable materials

Hundreds of filaments are compatible with Ultimaker , each with a unique combination of properties that are likely to meet design requirements. Additionally, the filament itself must be very strong and able to absorb short-peak forces. Covestro's Addigy® F1030 CF10 perfectly meets these requirements. This nylon-based polymer contains carbon fibers, and the Ultimaker S5, when paired with a CC printhead, can be used for printing.

Using simulation to optimize design

Compared to traditional production methods, 3D printing a robust 2kg bond takes significantly less time. However, validating the printed samples requires repeated testing. Optimizing the print by simulating the real object using a computer before printing can effectively save time on repeated testing.

Covestro uses software based on the physical properties of carbon fiber and nylon to digitally apply forces to designs. Through simulations and calculations, the design can be precisely adjusted, eliminating unwanted wire sections. This optimizes the entire design, allowing for the lifting of greater weights with less wire, resulting in faster production times and lower costs.

Verification Simulation

Before being able to lift super-heavy vehicles, physical verification of the calculated strength of printed samples is required. Two sizes, two designs: the first weighs 1 kg and is estimated to withstand 12 tons; the second weighs approximately 2 kg and is estimated to withstand 38 tons. The Royal Netherlands Navy has an industrial tensile testing machine on site, capable of applying forces up to 343 kN to objects. Both the initial and optimized versions underwent testing for both large and small loads.

The Royal Netherlands Navy tested a 2-kilogram link, finding it capable of withstanding 38 tons under normal conditions.

The optimized version can withstand more force while being one-third lighter. The test results and simulated data are also very close, with an average error of 1%. This proves that this workflow is feasible, significantly benefiting both time-to-market and performance improvements.

Lift two cars

After months of design, printing, testing, and planning, it's time for the lifting and weightlifting test! Two linkages are about to lift a real military heavy vehicle. At an army base in the southern Netherlands, the Royal Netherlands Navy provided armored recovery vehicles from the 13th Light Rhino Brigade to assist in the testing. Test results showed that a 1kg linkage can lift a military version of a Mercedes-Benz Jeep weighing over 2 tons. Of course, the vehicle was easily lifted; even larger tests will follow!

A 2-kilogram carbon fiber reinforced nylon connector was placed between the M113 armored vehicle and the Buffalo crane. The metal ring was tightened to its maximum, and four cables were connected to the tank from hooks below. The crane slowly began to move upwards, bringing the cables and 3D-printed connector to maximum tension. The 12-ton tank slowly rose, suspended on the 3D-printed connector. The Buffalo moved back and forth, backwards, forwards, and even changed direction, yet the 3D-printed connector held up perfectly! This three-way collaboration was a great success.

A 2-kilogram 3D-printed sample can easily withstand the weight of a vehicle up to 6,000 times its own weight.

Experiences and key takeaways

The success of this project wasn't just due to changes in workflow; we also learned a great deal. CAD software simulations are no longer limited to just shapes; they now take into account wire material and fiber orientation to provide accurate predictions, making it an incredibly powerful tool for engineers!

Although all prints were done indoors with well-controlled temperature and humidity, and the filament was not exposed to moisture, there are significant differences between versions printed in a dry warehouse and those printed in a heated, dry printing room using specially dried spools. Nylon absorbs moisture, making the printed product brittle; therefore, understanding the properties of the filament and handling it accordingly is crucial.

Although technical specifications provide abstract numerical strengths, actual testing and firsthand experience can lead to a better understanding of the possibilities of additive manufacturing technology , and you might even gain unexpected inspiration from it!

Did you enjoy this sharing? 3D printers offer more than just 3D printing . Contact us now to learn more about our 3D printers and 3D scanners .

Follow our fan page to stay up-to-date with the latest news: https://www.facebook.com/3dmart.com.tw/

https://www.instagram.com/3dmart/

References

The success of this project wasn't just due to changes in workflow; we also learned a great deal. CAD software simulations are no longer limited to just shapes; they now take into account wire material and fiber orientation to provide accurate predictions, making it an incredibly powerful tool for engineers!

Although all prints were done indoors with well-controlled temperature and humidity, and the filament was not exposed to moisture, there are significant differences between versions printed in a dry warehouse and those printed in a heated, dry printing room using specially dried spools. Nylon absorbs moisture, making the printed product brittle; therefore, understanding the properties of the filament and handling it accordingly is crucial.

Although technical specifications provide abstract numerical strengths, actual testing and firsthand experience can lead to a better understanding of the possibilities of additive manufacturing technology , and you might even gain unexpected inspiration from it!

Did you enjoy this sharing? 3D printers offer more than just 3D printing . Contact us now to learn more about our 3D printers and 3D scanners .

Follow our fan page to stay up-to-date with the latest news: https://www.facebook.com/3dmart.com.tw/

https://www.instagram.com/3dmart/

References