[3D Printing Applications] 11 Carbon Fiber Composite Material Applications + Free 3D Model Resources!

Carbon fiber composites are a class of 3D printing materials with enormous potential advantages. They are high-strength, lightweight, and their graphite-black cross-woven pattern has a unique visual appeal. 3D printing can be used to create small batches of final parts in a time-saving manner. (See my full article: [3D Printing Knowledge] The Advantages of Using Carbon Fiber for 3D Printing! )

All the parts described in this article are available from Ultimaker Thingiverse's free 3D model resources, which have accumulated over 1.8 million free STL files, far exceeding many competitors. Every creator can upload and share models for free. Thingiverse also has a professional design team demonstrating how these parts can leverage the powerful advantages of carbon fiber.

To help you make the most of these materials, we've compiled 12 applications of carbon fiber composites, including clamps, fasteners, and automotive parts. Use these examples in your daily life or work projects.

Download UltiMaker Y-type connector 3D model

Designer: Jeremy Evers - UltiMaker Technical Sales Engineer Material: PET CF

Printing time: 16 hours 20 minutes

In UltiMaker's office, dozens of Y-connectors made of different materials are displayed. These parts are used as benchmark prints when testing new materials to help adjust the material profile. They have many useful functions, helping you judge dimensional accuracy and visual quality. They can also be used for the next part – Y-connector extenders.

Download UltiMaker Y-type connector extender 3D model

Designer: Jeremy Evers, Technical Sales Engineer at UltiMaker; Material: PET CF

Printing time: 10 hours 39 minutes

This part is a complementary product to the UltiMaker Y-connector and is used to test its dimensional accuracy. If the Y-connector slides easily into the extender and the threads tighten correctly, the dimensions and accuracy of the two prints can be verified. The textured pattern on the extender also helps adjust the visual quality of the print.

Erik Schwartz clutch intake 3D model download

Designer: Erik Schwartz

Material: PET CF

Printing time: 19 hours 46 minutes

The Erik Schwartz racing team collaborated with Ultimaker to test composite materials under demanding automotive operating conditions, and this part is a perfect example of the value they provide. The CVT clutch system on Schwartz racing vehicles generates a significant amount of heat. Belt temperatures can exceed 120°C. Keeping the belt temperature as low as possible is crucial for extending belt life. This bracket secures a large hose to the frame, acting as an air intake. The carbon fiber composite material has a high heat distortion temperature, allowing the print to withstand proximity to high-heat areas without deformation.

Download Erik Schwartz switch bracket 3D model

Designer Erik Schwartz

Material: PET CF

Printing time: 5 hours 33 minutes

Racing regulations require a power-off switch at the rear of the race car so that safety personnel can shut it down in an emergency. The Erik Schwartz racing team uses this bracket to simulate a metal mold. It is also used as a temporary part while waiting for the metal mold to arrive. Many manufacturing plants are already using 3D-printed metal jigs, fixtures, and replacement parts in their factories. Using plastic molds for design before creating expensive metal molds is an effective way to address the challenges. The material cost savings from switching from metal to plastic are substantial.

Download Erik Schwartz helmet blower stand 3D model

Designer: Erik Schwartz

Material: PET CF

Printing time: 9 hours 8 minutes

Keeping the driver cool is important during a race. This bracket, designed by Erik Schwartz, is used to secure the blower that delivers fresh air to the driver's helmet. The composite material is durable and strong, allowing for repeated installation and removal during a race.

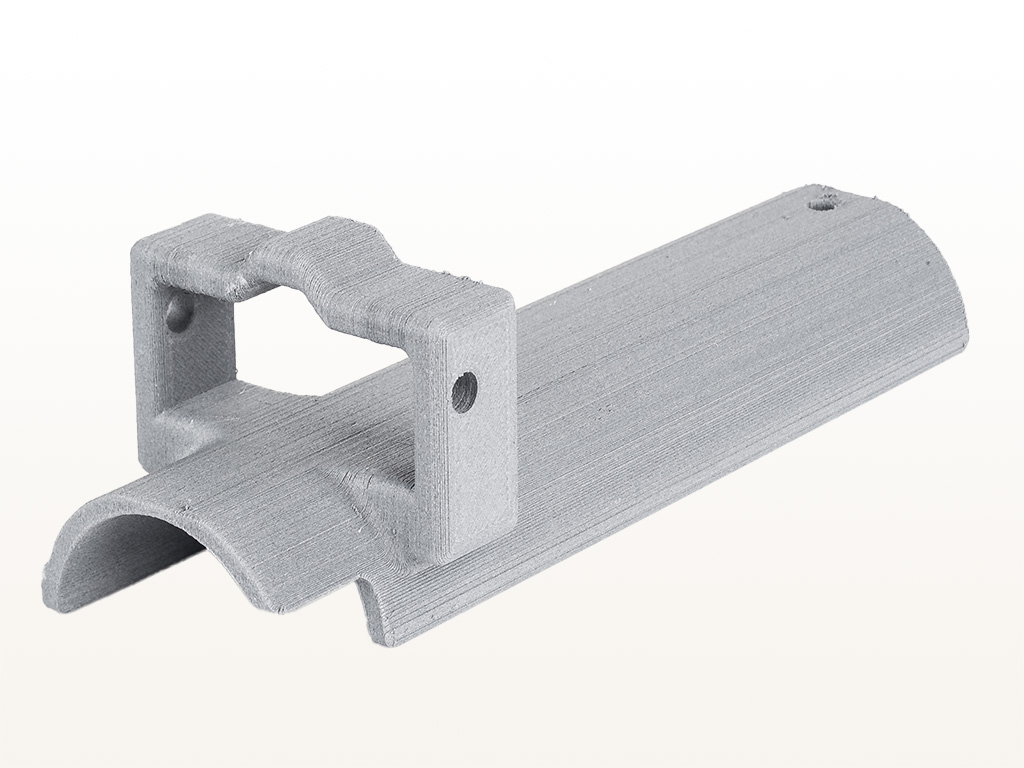

UltiMaker bicycle computer mount 3D model download

Designer: Felipe Castaneda - Creative and Content Director, UltiMaker Material: ABS Carbon Fiber

Printing time: 1 hour 17 minutes

Source: GRAN FONDO Cycling Magazine

For both amateur and professional cyclists, mounting a cycling computer is a common accessory. This simple, quick-to-print bracket, using the UltiMaker 3D printer combined with Thingiverse's free 3D model resources, provides ample inspiration for creating custom or bespoke parts and developing your own products. High-performance materials like carbon fiber can be directly transformed into finished products, converting them into potential business opportunities!

Download UltiMaker Textured Mechanical Grip 3D Model

Designer: Felipe Castaneda - Creative and Content Director at UltiMaker Material: ABS Carbon Fiber

Printing time: 19 hours 50 minutes

This textured gripper sample is part of a multi-part end-tool assembly that needs to be both lightweight and durable, and carbon fiber composite material perfectly meets both requirements.

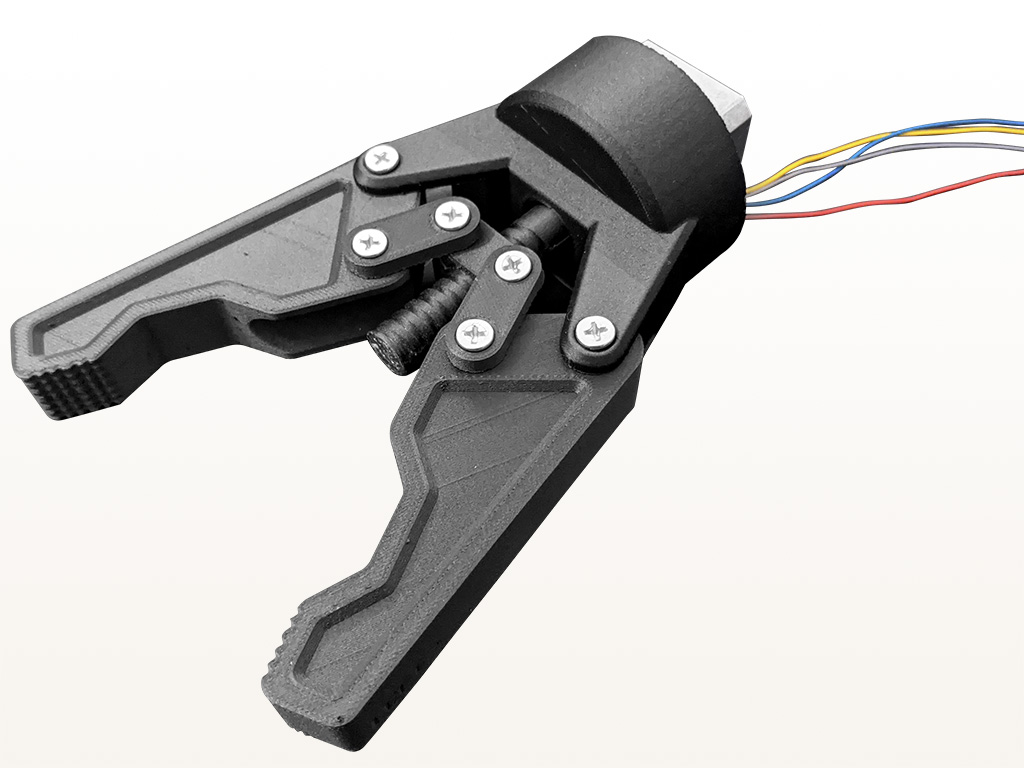

Download UltiMaker Robot Gripper Component 3D Model

Designer: Felipe Castaneda - Creative and Content Director at UltiMaker Materials: Nylon 12 Carbon Fiber

Printing time: 17 hours 23 minutes

For truly lightweight end-effectors, printing a single part isn't enough; the entire assembly must be printed simultaneously. This demonstrates that carbon fiber not only provides the necessary strength and durability but also the accuracy required to manufacture complex assemblies of moving parts, thereby enhancing the speed and maneuverability of robotic arms.

Download UltiMaker 3D model of pipe welding fixture

Designer: Felipe Castaneda - Creative and Content Director at UltiMaker Materials: Nylon 12 Carbon Fiber Printing Time: 8 hours 40 minutes

Source : Enhancing your jigs and fixtures with carbon fiber composites

This part, made by UltiMaker, demonstrates a simple pipe welding fixture. Fixtures are used daily in assembly shops, testing labs, and machining workshops. Using carbon fiber composites can greatly benefit them because they can be easily customized to the job at hand, while also possessing sufficient strength to hold your product in place.

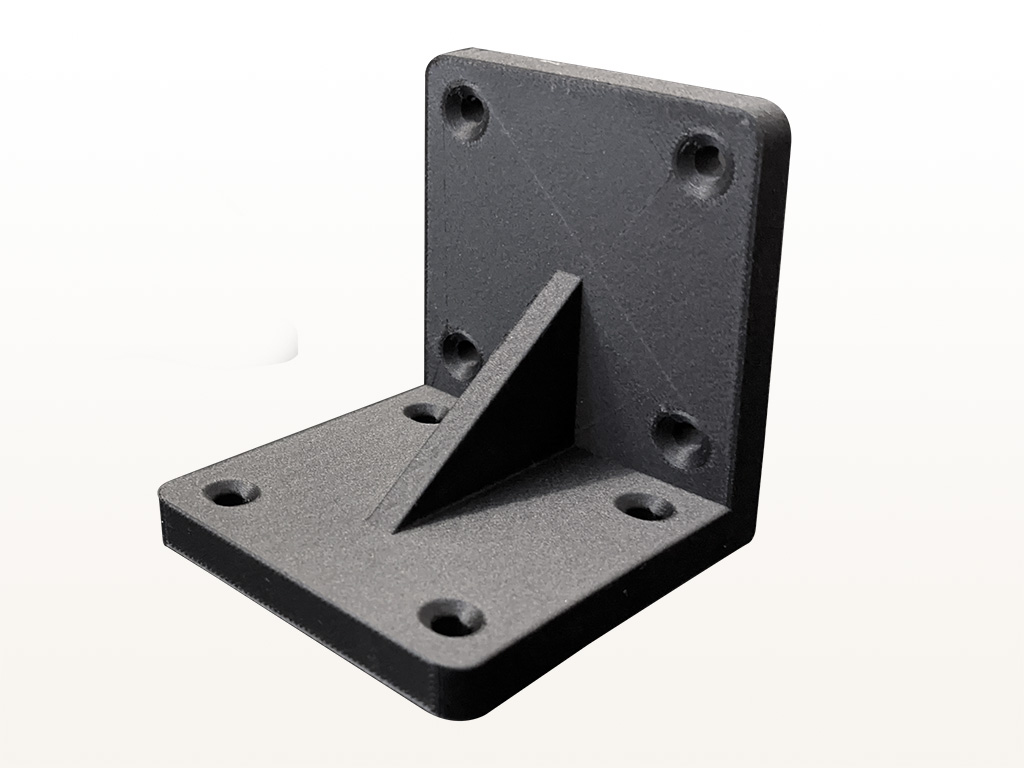

UltiMaker Rectangular Bracket 3D model download

Designer: Felipe Castaneda - Creative and Content Director, UltiMaker Materials: Nylon 12 Carbon Fiber

Printing time: 5 hours 7 minutes

This simple bracket benefits from the customization capabilities and fast printing time of 3D printing, as well as the strength and stiffness provided by the carbon fiber composite material.

Download UltiMaker positioning fixture 3D model

Designer Felipe Castaneda - Creative and Content Director at UltiMaker. Materials: Nylon carbon fiber (Nylon 6/66 blend).

Printing time: 7 hours 51 minutes

Positioning fixtures like these require a high degree of customization and may need to be repeatedly replicated as production processes are improved. 3D printing can significantly reduce the costs of continuous iteration. It also avoids the need to maintain a large inventory of replacement fixtures. Some factories even create a fixture database, printing them out as needed.

See more information about printing with various materials in Ultimaker: [3D Printing Materials] How to use various materials in Ultimaker for printing.

Check out the Ultimaker 3D printer and the Ultimaker value-for-money 3D printer demo unit.

-Contact Us-

Find more information on filaments and 3D printers ! Make an informed choice to meet your needs!

SanDiMa offers more than just 3D printing ; we provide three major OEM services: " 3D Printing Manufacturing ," " 3D Scanning Services ," and " Spatial 3D Scanning Services "!

Follow our fan page and stay up-to-date with the latest news:

Facebook: https://www.facebook.com/3dmart.com.tw/

Instagram: https://www.instagram.com/3dmart

LinkedIn: https://www.linkedin.com/company/3dmart/

References